Reinforced concrete stirrer

A mixer and concrete technology, applied in the direction of the unloading device, etc., can solve the problems of clogged pipes, affecting discharge, narrow discharge port and conveying pipeline, etc., to achieve the effect of avoiding clogging, slowing down solidification, and solid unloading structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

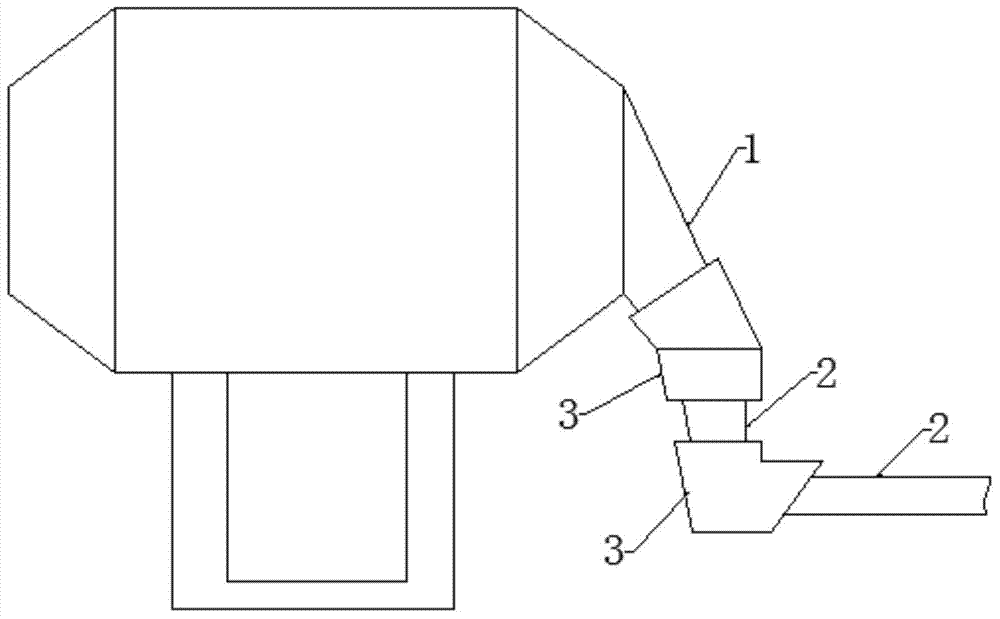

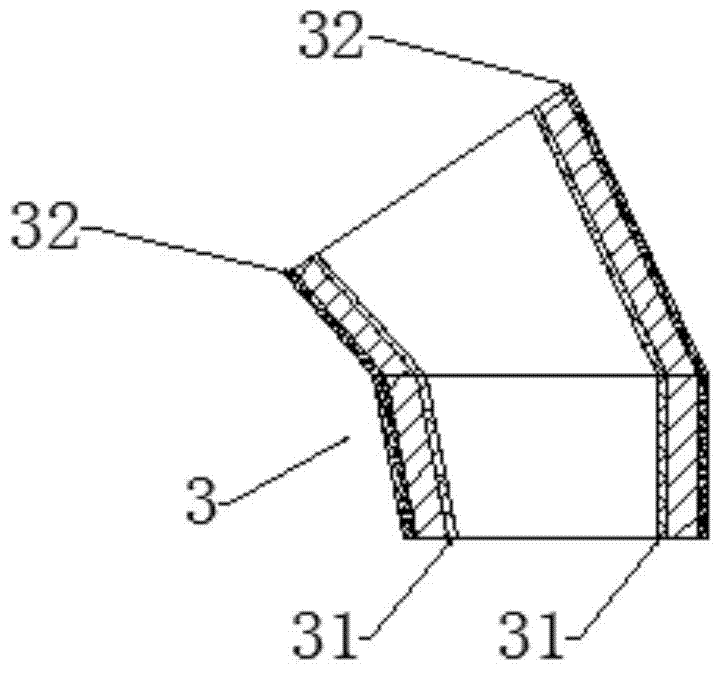

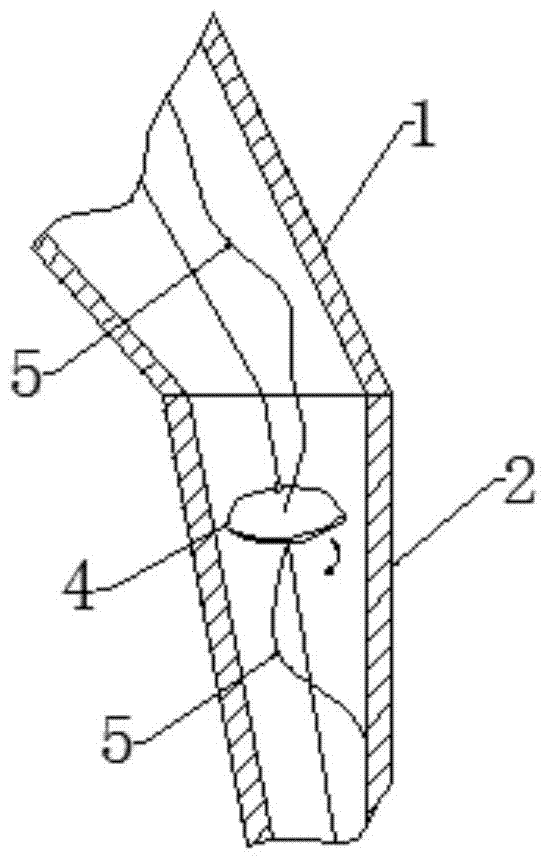

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings, as shown in the figure: a reinforced concrete mixer, comprising a discharge port 1 and a feed pipeline 2 connected to the discharge port 1, the discharge port 1 and the feed pipe 2 Reinforcement sleeves 3 are sheathed on the outside of the material pipeline 2; the reinforcement sleeves 3 are annular sleeves, the inner peripheral surface of the reinforcement sleeve 3 is provided with a buffer layer 31, and the outer peripheral surface is provided with a thermal insulation layer 32; 2 is provided with a scraper 4 that can move in the pipeline.

[0017] As a further improvement of the above-mentioned technical solution, the inner wall of the conveying pipeline 2 is provided with a longitudinal track; The active area faces the downstream direction of the conveying pipeline 2; traction ropes 5 are arranged on the front and back surfaces of the scraper 4, and the traction ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com