Jet oiling mechanism and double-sided para-aramid fiber oiling device

A para-aramid fiber, double-sided technology, which is applied in the field of para-aramid fiber oiling devices, can solve the problems of affecting the alignment of nozzles and fiber bundles, increase worker workload, reduce production efficiency, etc. The effect of wetting effect, improving oiling efficiency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0044] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of structure, change of proportional relationship or adjustment of size shall fall within the range covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. within range.

[0045] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

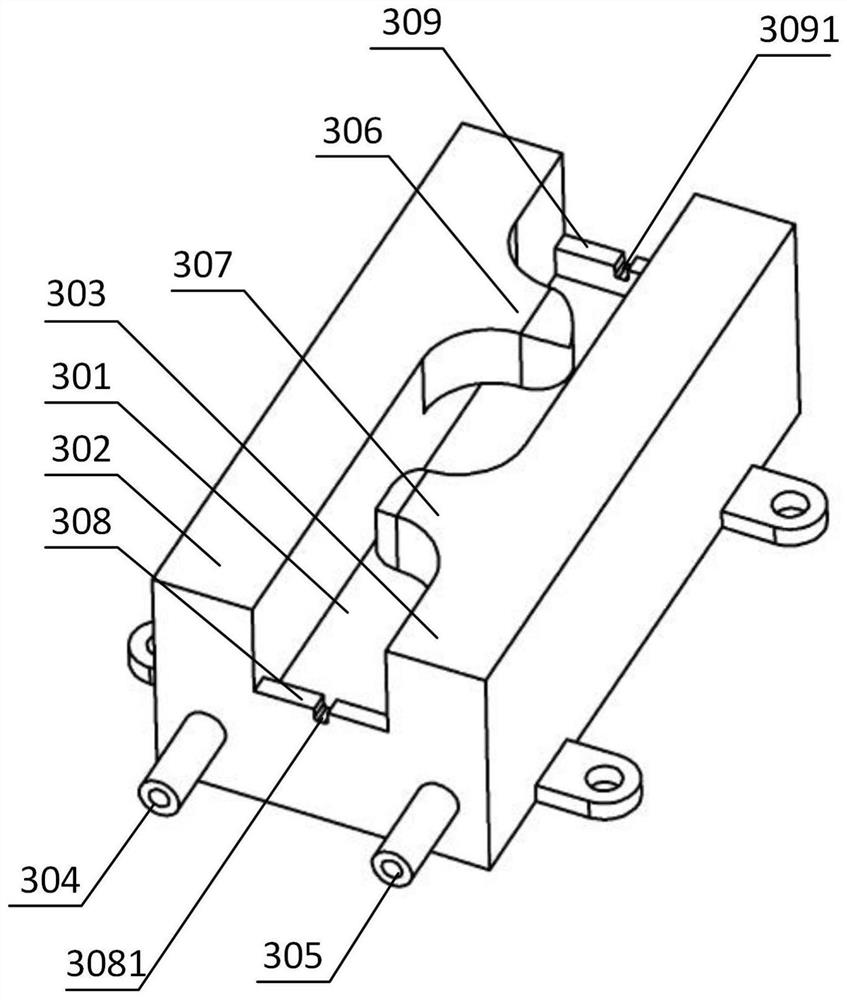

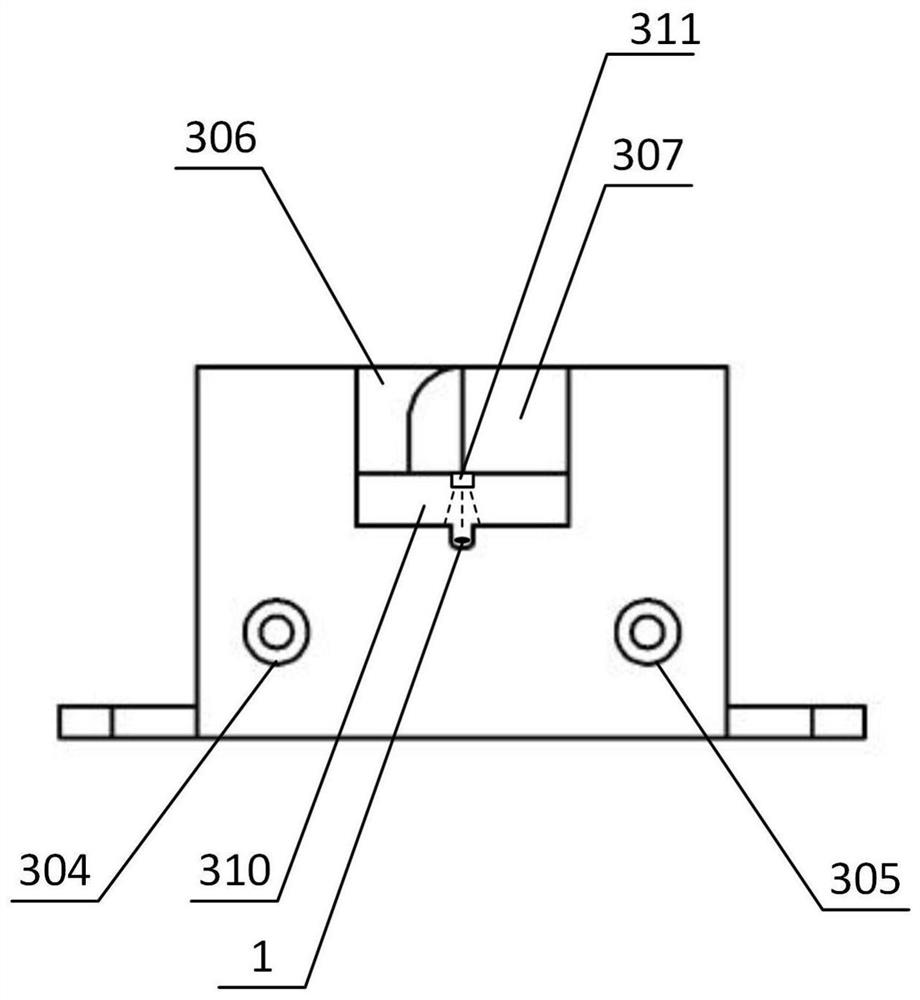

[0047] combined with Figure 1-3 , a spray oiling mechanism, including a wire groove 310 formed by a bottom plate 301, a first side plate 302 and a second side plate 303, the two ends of the wire groove 310 are respectively provided with a first positioning plate 308 and a second positioning plate Two positioning plates 309, the first positioning plate 308 is provided with a first positioning groove 3081, and the second positioning plate 309 is provided with a second positioning groove 3091,

[0048] The first positioning groove 3081 and the second positioning groove 3091 are located on the same straight line, and coincide with the conveying path of the para-aramid fiber bundle 1, and the para-aramid fiber bundle 1 enters the wire feeding groove 310 through the first positioning groove 3081, Leave the wire feeding slot 310 through the second positioning slot 3091 .

[0049] A plurality of nozzles 311 connected to an oil pump (not shown in the figure) are provided above the wi...

Embodiment 2

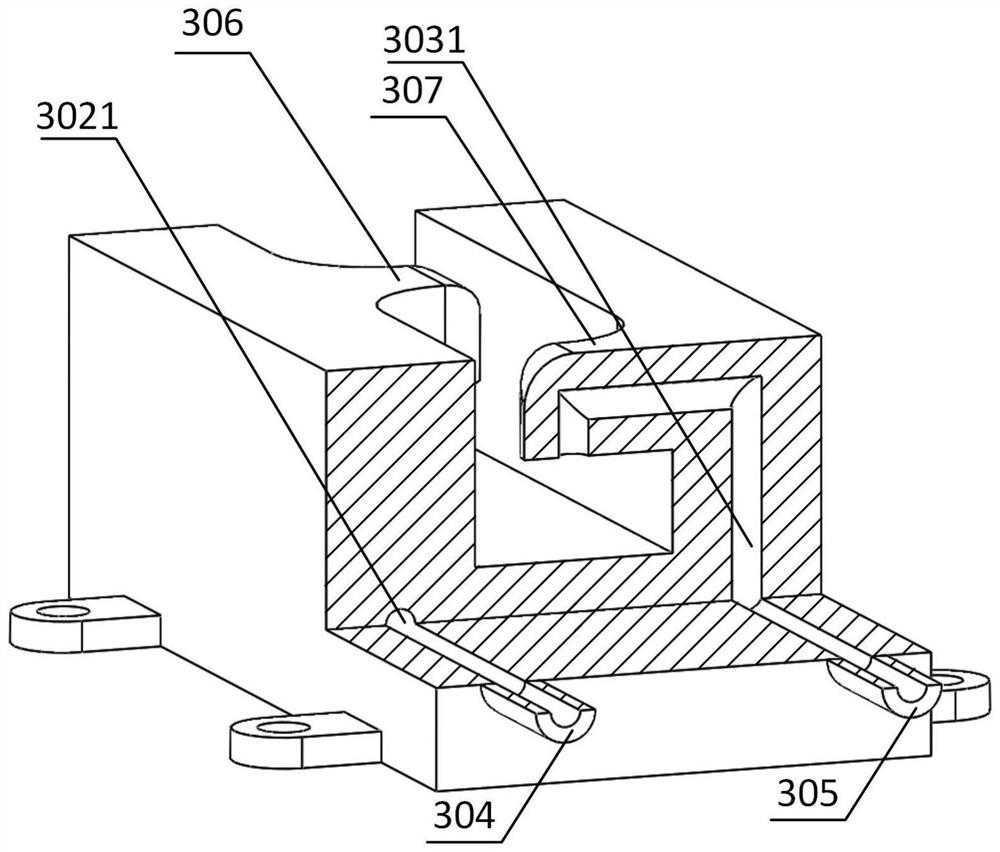

[0058] combined with Figure 4 , the injection oiling mechanism in this embodiment optimizes the nozzle 311 in Embodiment 1 to a double-headed atomizing nozzle, and the rest of the structure is the same as in Embodiment 1. The double-head atomizing nozzle includes a hollow shell 3111 and a first spray head 3112 and a second spray head 3113 connected to the shell 3111, one end of the shell 3111 is connected to the first protrusion 306 or the The second protrusion 307 is connected, the other end of the housing 3111 is provided with an inverted V-shaped groove, the inverted V-shaped groove opens along the length direction of the wire groove 310, the first nozzle 3112 and The second nozzles 3113 are respectively symmetrically disposed on two inclined surfaces of the inverted V-shaped groove. The included angle of the inverted V shape is preferably 90-145°.

[0059] The housing 3111 also includes a threaded connection portion 3114, the threaded connection portion 3114 is provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com