A sewage processor for industrial wastewater treatment

A technology for sewage treatment and industrial wastewater, which is applied in flotation water/sewage treatment, water/sludge/sewage treatment, water/sewage multi-stage treatment, etc. It can solve false alarms, foam uncertainty, and inaccuracy of the automatic control system and other issues to achieve the effect of avoiding false positives and scraping errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

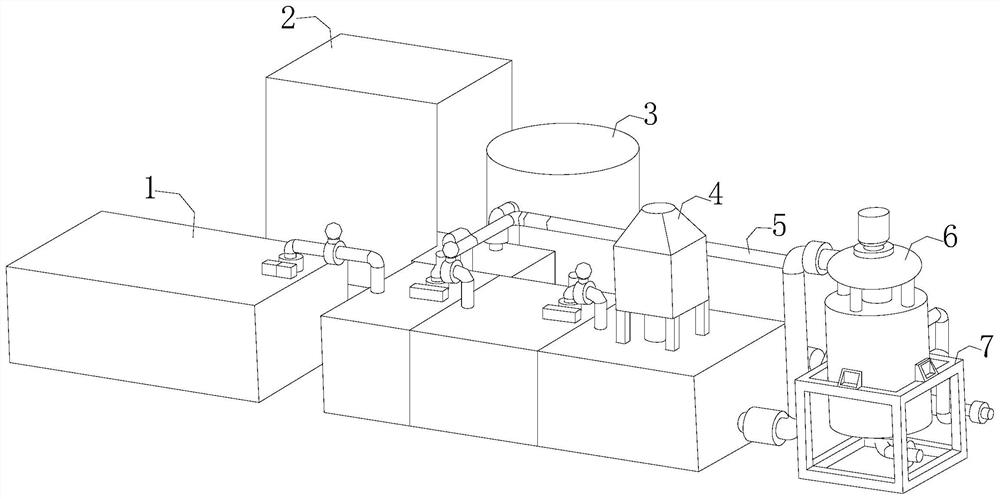

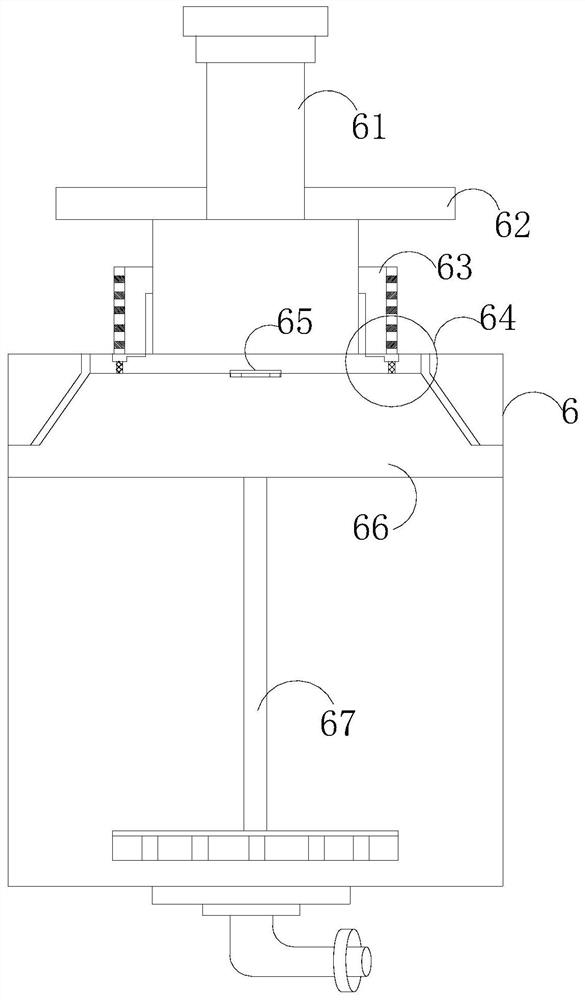

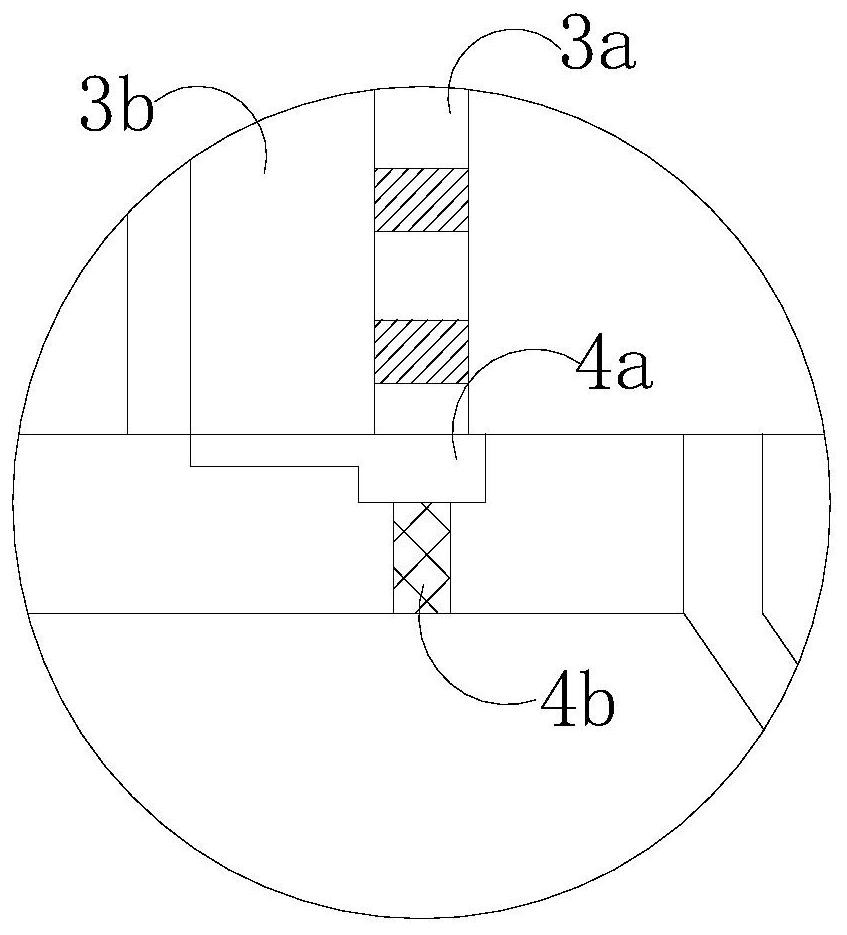

[0029] Such as Figure 1-Figure 3 As shown, the present invention provides a kind of sewage treatment device for industrial waste water treatment, and its structure comprises adjusting tank 1, grid 2, sedimentation tank 3, clear water disinfection tank 4, pipeline 5, air flotation machine 6, protection frame 7, The grid 2 is connected with the regulating tank 1, the sedimentation tank 3, the clear water disinfection tank 4, and the air flotation machine 6 with a pipeline 5. The pipeline 5 is equipped with a pump body, and the bottom of the air flotation machine 6 is protected by a protective frame. 7 is fixed, the inside of the air flotation machine 6 is provided with a motor 61, a partition 62, a cooling system 63, a telescopic mechanism 64, a rotating assembly 65, a dense cavity 66, and an agitator 67, and the motor 61 is connected with the telescopic system 63 through the cooling system 63. mechanism 64, the dense chamber 66 and the agitator 67 are both located inside the s...

Embodiment 2

[0031] Such as Figure 4-Figure 6 As shown, the rotating assembly 65 is composed of a middle screw 651, an air cylinder 652, a shell 653, a thread groove 654, and a hinge 655. The middle screw 651 and the thread groove 654 are threaded, and the air cylinder 652 is provided with four and Evenly distributed in the protective shell 653, located around the thread groove 654, the length of the middle screw 651 and the air cylinder 652 are consistent with the length of the protective shell 653, the surface of the air cylinder 652 and the thread groove 654 are hingedly connected by a hinge 655, the The angle between the gas cylinder 652 and the middle screw 651 is gradually increased, and the maximum angle between the gas cylinder 652 and the middle screw 651 is 60°, so as to control the effect of the gas and avoid blowing directly on the inner wall of the dense cavity 66 to cause foaming. When the air cylinder 652 is located inside the protective shell 653, the gas acts on the foam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com