Carding machine for textile processing

A carding machine and textile technology, applied in textiles and papermaking, mechanical cleaning, thin material processing, etc., can solve the problems of high labor intensity, general carding effect, and low efficiency, and achieve the effect of reducing labor intensity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

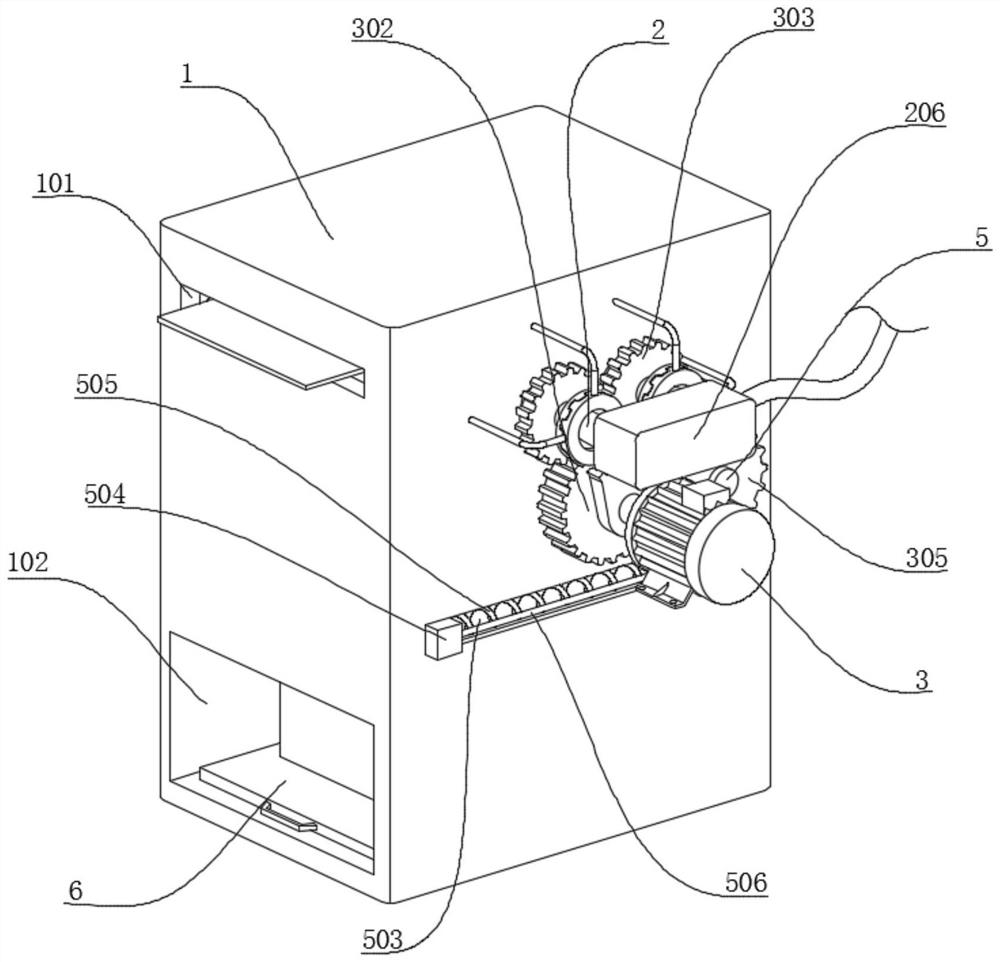

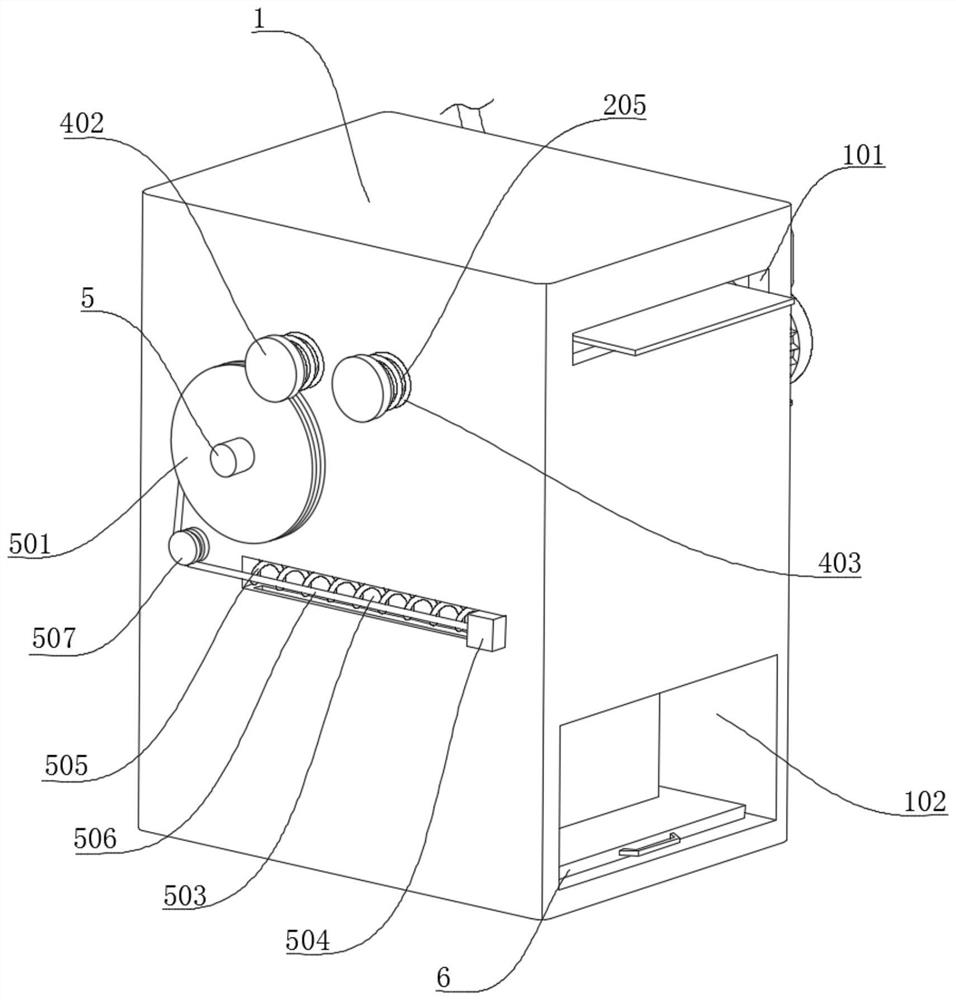

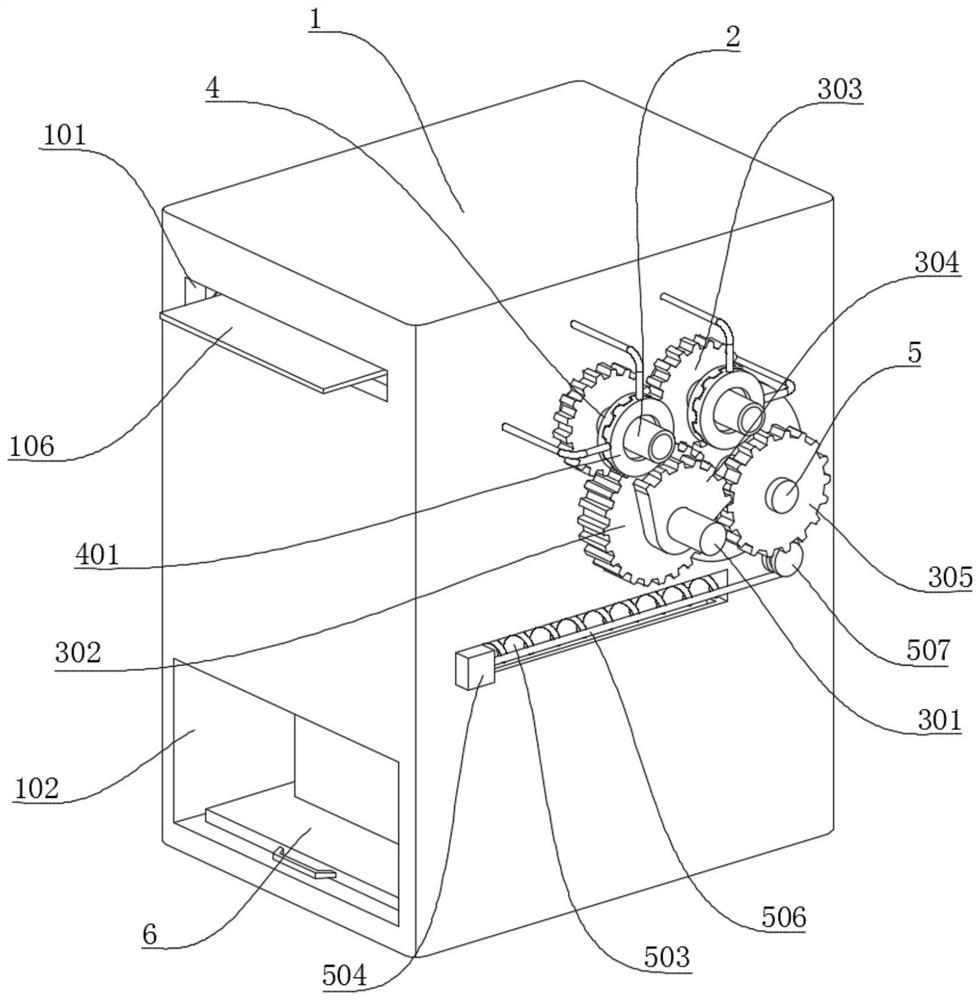

[0031] refer to Figure 1-10 , a carding machine for textile processing, comprising a hollow case 1, the side wall of the case 1 is provided with a cloth inlet 101 and a cloth outlet 102, and the inner side wall of the case 1 is rotatably connected with a guide roller 104, a turning roller 105 and Two cloth feeding rollers 103, the two cloth feeding rollers 103 are connected with a motor (not shown in the figure), which can make the two cloth feeding rollers 103 rotate in the opposite direction to transport the fleece 106, which is the prior art, and is not described here. to repeat, such as Figure 4 As shown, the diameter of the turning roller 105 is larger than the diameter of the guide roller 104, the turning roller 105 makes the fleece 106 turn, and the fleece 106 is fed into the case 1 through the cloth inlet 101 with the fleece side facing down, and the side wall of the case 1 runs through the sliding connection There are two air intake pipes 2, the air intake pipe 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com