Aluminum alloy door and window multi-face frame film tearing equipment for architectural decoration

A technology for aluminum alloy doors, windows and frames, applied in the field of building decoration, can solve the problems of sore hands, cumbersome ways of tearing off the protective film and removing residual glue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

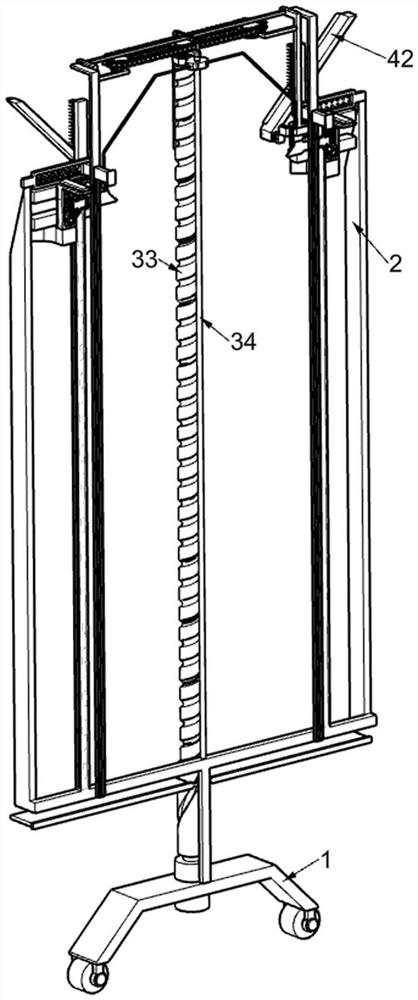

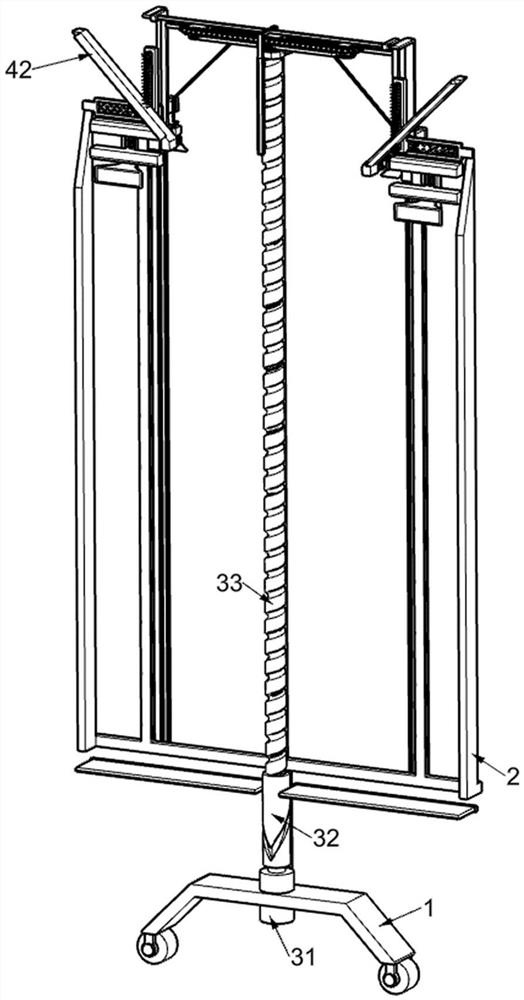

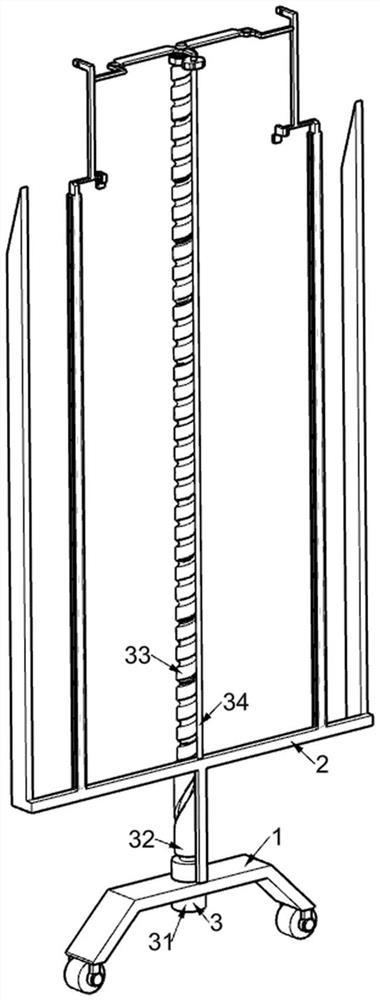

[0035] A kind of equipment for building decoration to tear the multi-faceted frame of aluminum alloy doors and windows, such as Figure 1-7 As shown, it includes a roller frame 1, a special-shaped wedge-shaped slotted bracket 2, a driving mechanism 3, a film scraping mechanism 4, and a clamping and tearing film mechanism 5. A driving mechanism 3 is arranged on it, a film scraping mechanism 4 is set on the special-shaped wedge-shaped slotted bracket 2, and a clamping tear-off mechanism 5 for tearing off the protective film is slidably connected to the special-shaped wedge-shaped slotted bracket 2.

[0036] The driving mechanism 3 includes a servo motor 31, a sheave 32, a screw mandrel 33, a limit round rod 34, a special-shaped opening frame 35 and a nut cover 36, and the roller frame 1 is fixedly equipped with a servo motor 31, and one end of the output shaft of the servo motor 31 A grooved wheel 32 is welded, and a threaded rod 33 is welded on the top of the grooved wheel 32 a...

Embodiment 2

[0043] On the basis of Example 1, such as Figure 8-10 As shown, a scraping mechanism 6 is also included, and the special-shaped opening frame 35 is provided with a scraping mechanism 6. The scraping mechanism 6 includes a gear one 61, a chain body 62, a gear two 63, a chain cover 64, and a slotted mobile frame. 65. Scraper plate 2 66 and L-shaped slotting frame 67, two gears 1 61 are connected in rotation on the special-shaped opening frame 35, and a chain body 62 is connected in transmission between the two gears 1 61, away from the wire of sheave 32. One end of the bar 33 is welded with a gear 2 63, the chain body 62 is meshed with the gear 2 63, the chain body 62 is provided with a chain cover 64, and the special-shaped wedge-shaped slotted support 2 is slidably connected with a slotted mobile frame 65, and the slotted mobile frame 65 is slidingly connected with the chain cover 64, and the slotted mobile frame 65 is welded with a scraper plate 2 66, which is used to scrape...

Embodiment 3

[0049] On the basis of Example 2, such as Figure 7 As shown, a preheating lamp 9 is also included, and the bottom end of the special-shaped slotted sliding frame 51 is fixedly installed with a preheating lamp 9, and the preheating lamp 9 is used for heating the protective film on the aluminum alloy doors and windows.

[0050] When the upper device on the special-shaped slotted sliding frame 51 moves downward, the special-shaped slotted sliding frame 51 will drive the preheating lamp 9 to move downward, and the preheating lamp 9 will heat the protective film on the aluminum alloy doors and windows, so as to facilitate the subsequent removal of the protective film. Tear off from aluminum door and window frames.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com