Method for preparing new protective film without incohesion

A non-adhesive protective film, a new type of technology, applied in the field of polymers, can solve the problems of difficult adjustment of bonding strength, strong temperature sensitivity, and easy residue generation, and achieve low manufacturing cost, good product quality, and easy lamination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

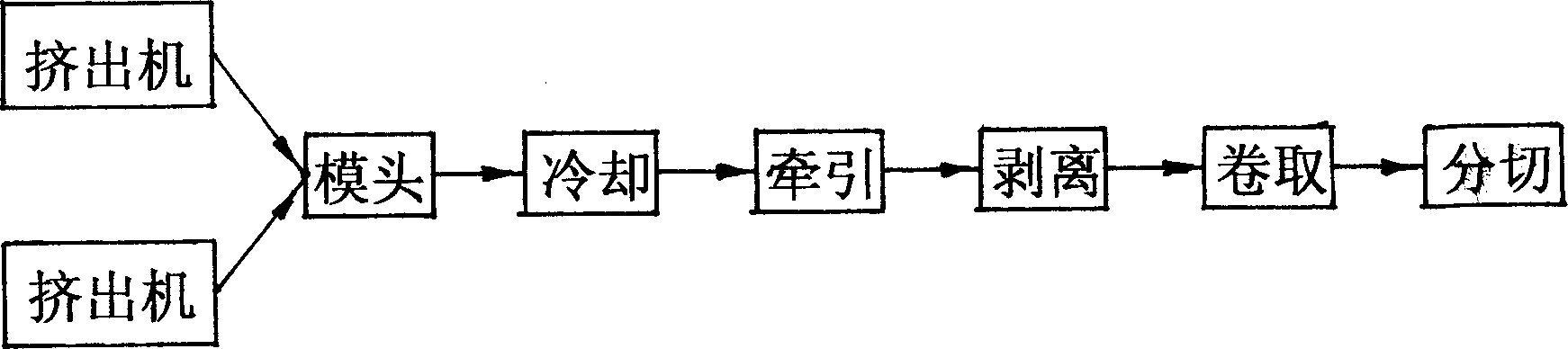

Image

Examples

Embodiment example 1

[0012] A layer formula (weight), LDPE: 25, LLDPE: 75, the melt index is 2, the processing temperature (plasticizing temperature) of LDPE is 10 ℃ lower than that of LLDPE, and the extruder is controlled by low temperature Between 155-185°C, the temperature of the die head is controlled between 150-165°C. If you want to improve the transparency of the new adhesive-free protective film, you can add an inner cooling air ring device at the die head.

[0013] Layer B formula (weight), LDPE: 30, LLDPE: 70, PIB: 15, LDPE, LLDPE and PIB do not contain any additives and slip agents, the melt index is 2, and the processing temperature is close to (+ / -10℃ ), the temperature of the extruder is controlled between 155-185°C. When using a multi-layer extruder with more than three layers, the B layer is set on the outer layer, not the middle layer. The bonding strength of the new adhesive-free protective film can be adjusted by changing the amount of polyisobutylene (PIB).

[0014] After the...

Embodiment example 2

[0016] A layer formula (weight), LDPE: 25, LLDPE: 75, melt index is 2, the processing temperature (plasticizing temperature) LDPE is 10 ℃ lower than LLDPE, the temperature of the extruder is controlled between 155-185 ℃, the mold The temperature of the head is controlled between 150-165°C. If you want to improve the transparency of the new adhesive-free protective film, you can add an inner cooling air ring device at the die.

[0017] B layer formula (weight), LDPE: 30, LLDPE: 70, MLLDPE: 25, LDPE, LLDPE and MLLDPE do not contain any additives and slip agents, the melt index is 2, and the processing temperature is close to (+ / -10℃ ), the temperature of the extruder is controlled between 155-180°C. When using a multi-layer extruder with more than three layers, the B layer is set on the outer layer, not the middle layer. The bonding strength of the new adhesive-free protective film can be adjusted by changing the amount of metallocene linear high-pressure polyethylene (MLLDPE) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com