Meat stuffing chopping device for food processing

A technology for food processing and meat stuffing, which is applied to the field of mincing devices for meat stuffing in food processing, can solve the problems of ineffective scraping effect of minced meat, insufficient mincing of minced meat, etc. The effect of smooth movement and enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

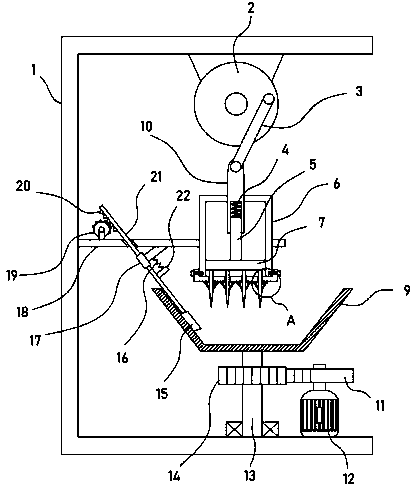

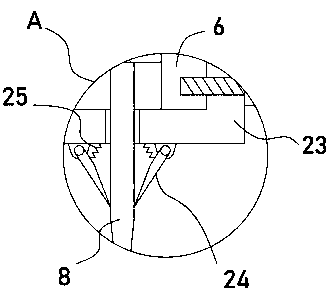

[0022] see Figure 1-4 , a food processing meat mincing device, comprising an operating frame 1, the rotating type in the operating frame 1 is provided with a minced meat tank 9, the minced meat tank 9 is provided with a mincing mechanism, and the mincing mechanism includes a knife seat 7 that is evenly fixed at the bottom There are several crushing knives 8, a bottom plate 23 for the crushing knives 8 to slide through is provided under the knife seat 7, a scraper 24 abutting against the crushing knives 8 is hinged at the bottom of the bottom plate 23, and a connecting spring 25 is fixed between the scraper 24 and the bottom plate 23 , the bottom of the operating frame 1 is provided with a stepping mechanism that is in transmission connection with the minced meat tank 9, and the crushing knife 8 is eccentrically installed in the minced meat tank 9.

[0023] The meat to be chopped is placed in the minced meat groove 9, and the crushing knife 8 in the chopping mechanism is drive...

Embodiment 2

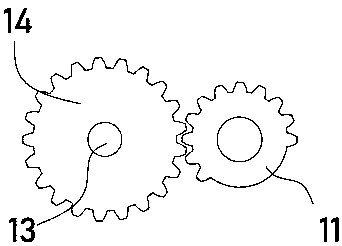

[0027] In order to further ensure the degree of refinement of the meat in the minced meat tank 9, on the basis of Embodiment 1, in addition, the stepping mechanism includes a servo motor 12, and the servo motor 12 is driven and connected with an incomplete gear I11, and the minced meat tank 9 The bottom is fixed with a driven shaft 13 pivotally connected with the operating frame 1, and the driven shaft 13 is coaxially fixed with a transmission gear 14 meshing with the incomplete gear I11.

[0028] The servo motor 12 is used for power output to the incomplete gear I11, and the incomplete gear I11 is intermittently meshed with the transmission gear 14, so that the transmission gear 14 drives the driven shaft 13 and the minced meat groove 9 to rotate intermittently, realizing 8 pairs of crushing knives The meat at different positions in the meat tank 9 is minced, and the minced meat is more comprehensive and sufficient.

[0029] Because in the process of chopping meat, there will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com