A kind of industrial rubber cracking device

A cracking device and rubber technology, applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of affecting rubber cracking, small tangential force of rubber, and low cleaning speed, etc., to improve production efficiency, increase output, heat uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

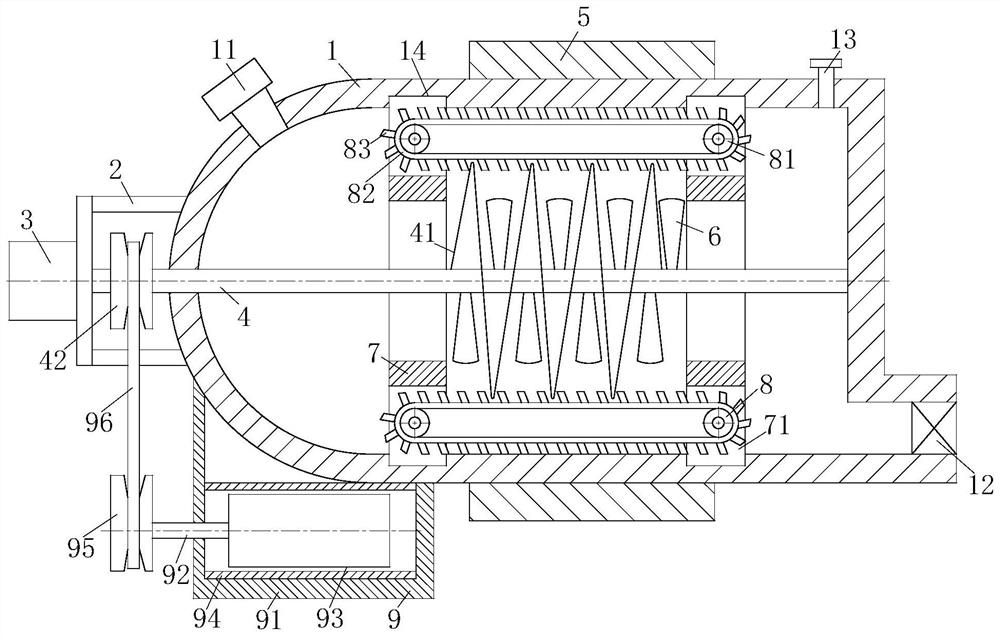

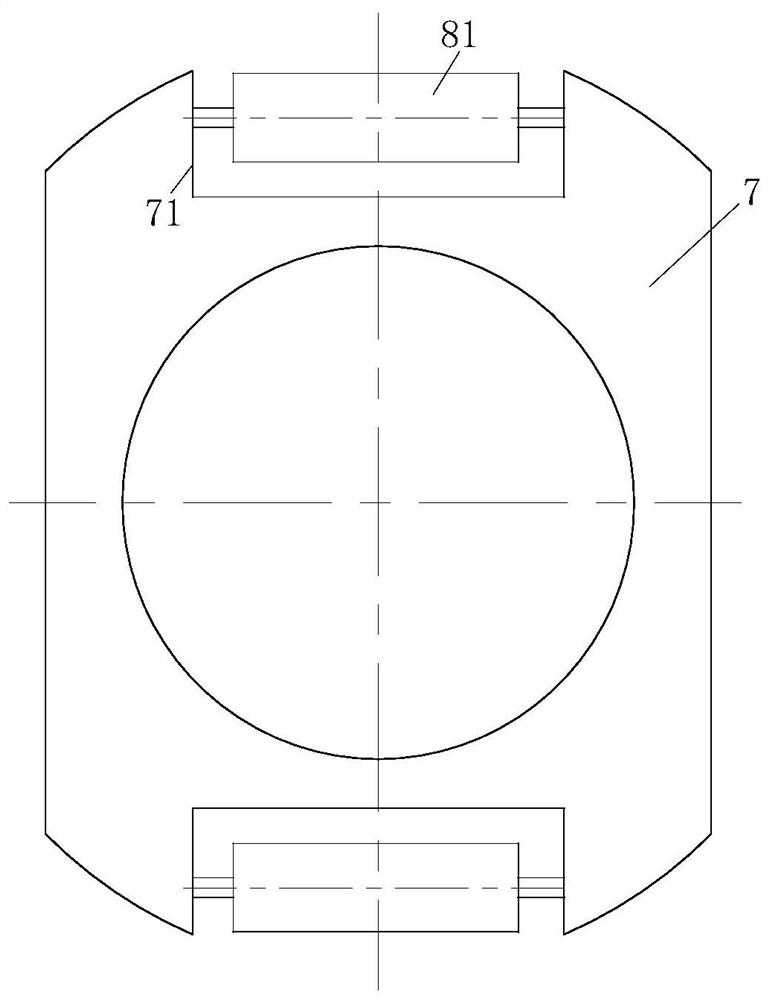

[0019] use Figure 1-Figure 2 The structure of an industrial rubber cracking device according to one embodiment of the present invention will be described below.

[0020] Such as figure 1 and figure 2As shown, a kind of industrial rubber cracking device of the present invention comprises cracking furnace 1, mounting frame 2, motor 3, rotating shaft 4, heating block 5, stirring rod 6, mounting block 7, cleaning module 8 and controller; The cracking furnace 1 is provided with a feed inlet 11, a feed outlet 12 and an exhaust port 13, the feed inlet 11 is positioned at the top left of the cracking furnace 1, the discharge port 12 is positioned at the bottom right of the cracking furnace 1, and the exhaust port 13 Located on the upper right side of the cracking furnace 1; the mounting frame 2 is installed on the left wall of the cracking furnace 1; the motor 3 is mounted on the mounting frame 2; the rotating shaft 4 is located in the cracking furnace 1, and one end of the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com