Encircling type vibration generating device

A vibrating power generation, surround-type technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problem of low utilization rate of magnetic circuit, and achieve the effect of improving power generation efficiency, utilization rate and coil utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

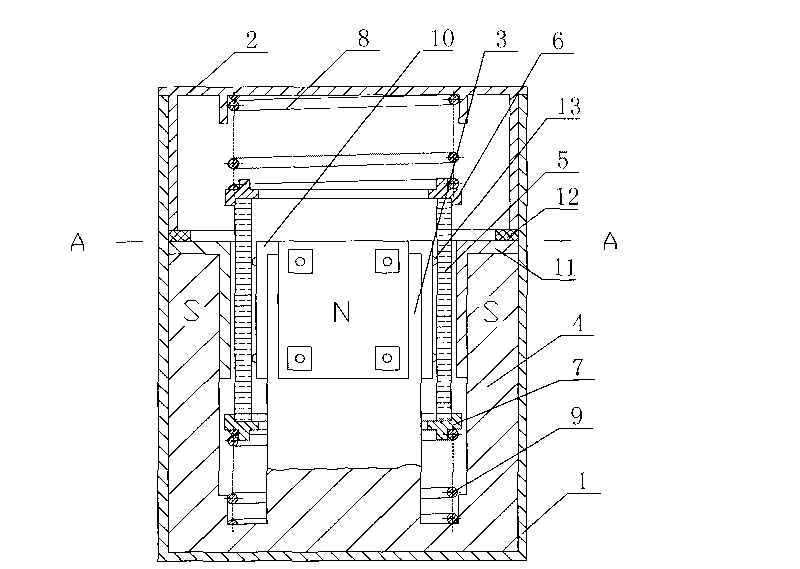

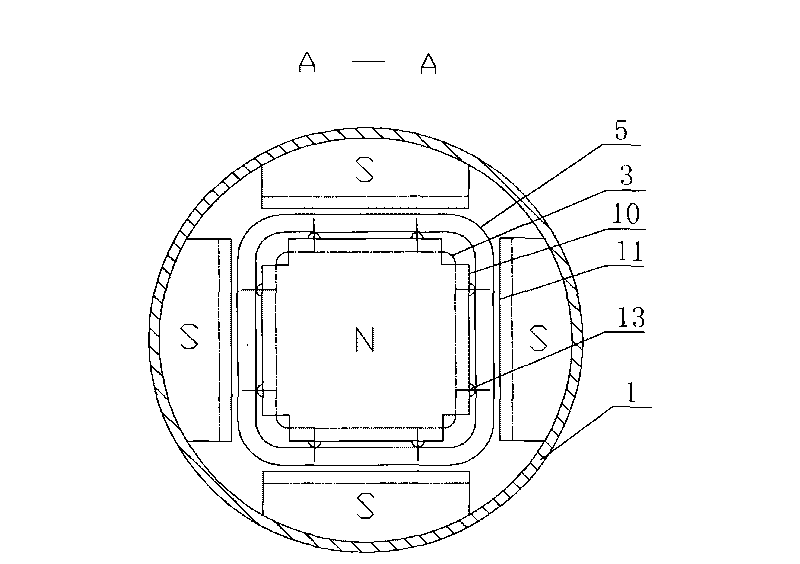

[0022] refer to figure 1 , figure 2 , Surrounding vibration power generation device, comprising a casing 1, the casing 1 is provided with a cover 2, the casing 1 is provided with a flower-shaped bonded permanent magnet, and the middle of the bonded permanent magnet is a square N pole 3, The N pole 3 is surrounded by four S poles 4, and the S poles 4 are symmetrically distributed in a cross, and their bottoms are connected together and connected to the N pole 3; between the N pole 3 and the S pole 4, a Coil 5, the upper and lower ends of the coil 5 are provided with square deck frames 6, 7, the upper deck frame 6 and the lower deck frame 7 are respectively connected with springs 8, 9, the lower deck frame 7 Set on the N pole 3, the lower end of the lower spring 9 is connected to the bottom of the S pole 4, and the upper end of the upper spring 8 is fixed on the cover 2.

[0023] The housing 1 is a cylindrical structure.

[0024] The bonded permanent magnet is formed by mixi...

Embodiment 2

[0033] The difference between this embodiment and the first embodiment is that the ball 13 is made of duralumin. The duralumin material will not have a suction effect, and the friction force will be low when rolling, but it will not have the benefit of reducing the local air gap. Other structures and functions are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com