Operation method of logistics transport vehicle suitable for automatic production line

A technology of automatic production line and operation method, applied in the direction of motor vehicles, transportation and packaging, trolleys, etc., can solve problems such as insufficient friction, inability to carry on shelves, pollute the workshop environment, etc., and achieve the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

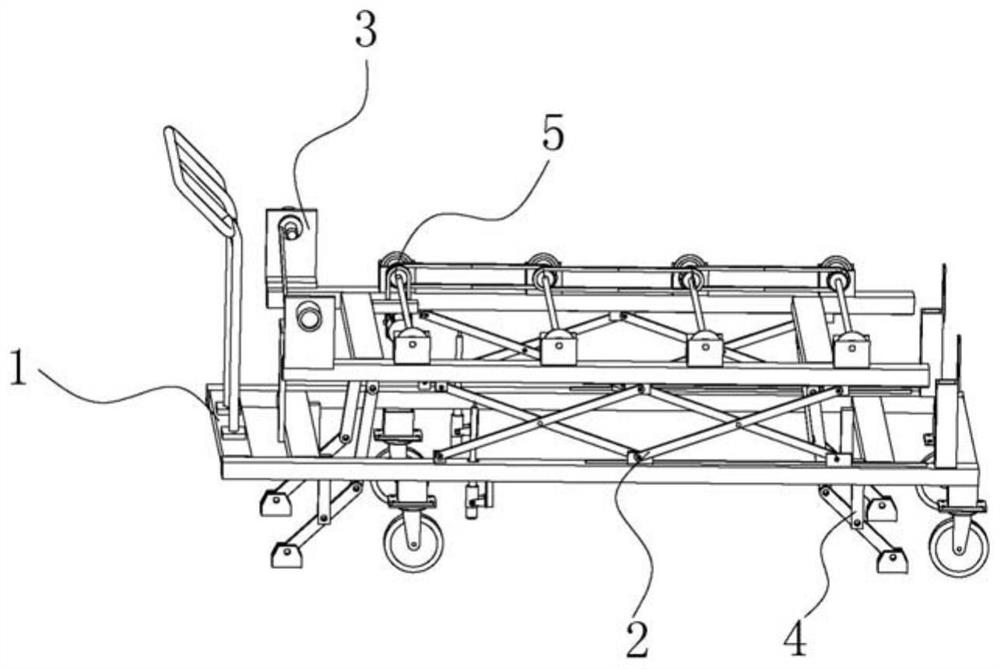

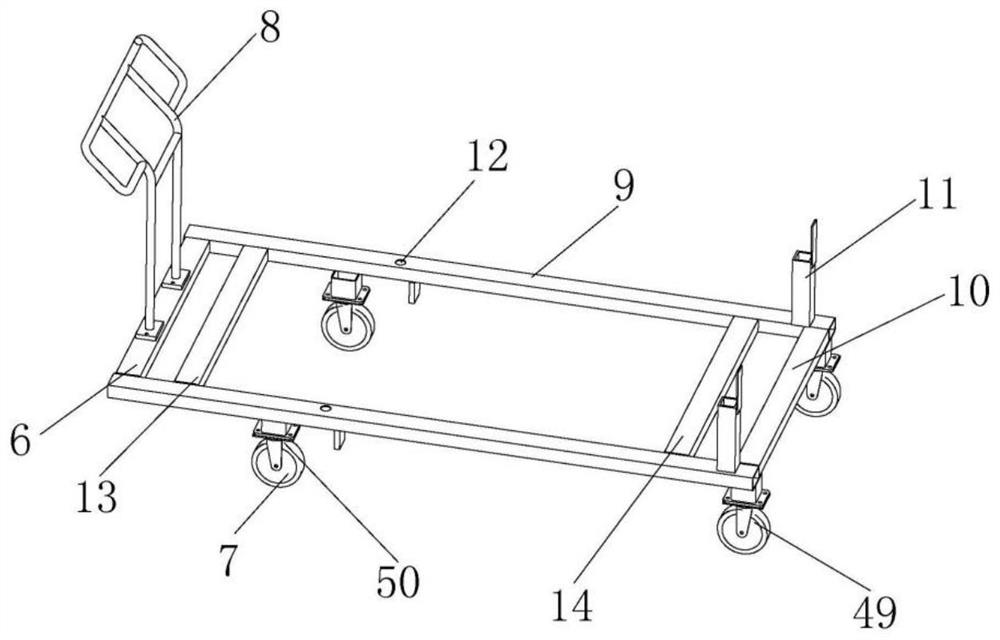

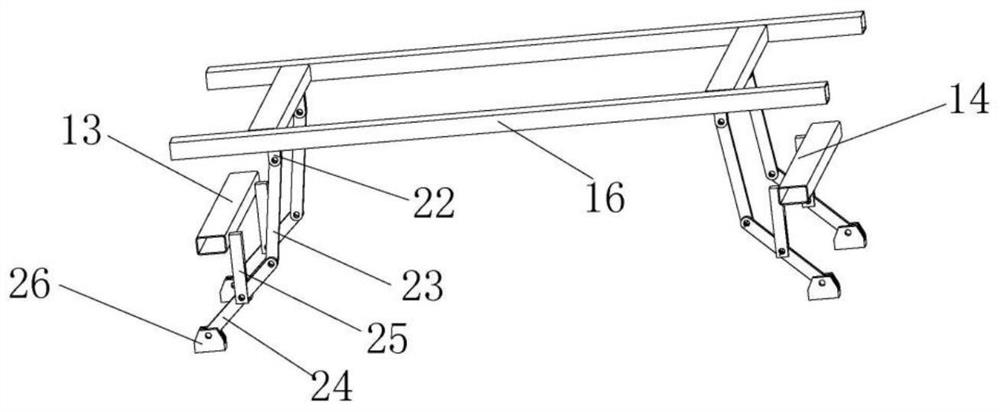

[0036] Such as Figure 1 to Figure 11 As shown, a logistics transport vehicle adapted to an automated production line includes a vehicle frame 1, a lifting assembly 2, a limit assembly 3, a support assembly 4 and a conveying assembly 5, and the vehicle frame 1 includes a bottom plate 6, wheels 7 and push rods 8. The bottom plate 6 is welded by two long cross bars 9 and two short cross bars 10, and the right sides of the two long cross bars 9 are provided with a positioning piece 11, and the left side of the long cross bar 9 is provided with a round Shaped hole 12, between the two long crossbars 9, one side near the short crossbar 10 is respectively provided with support rod one 13 and support rod two 14;

[0037]The lifting assembly 2 is installed on two long cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com