U-shaped steel and anchor cable collaborated support structure for laneway with large-deformation deep part

A support structure and large deformation technology, applied in tunnels, tunnel linings, shaft linings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

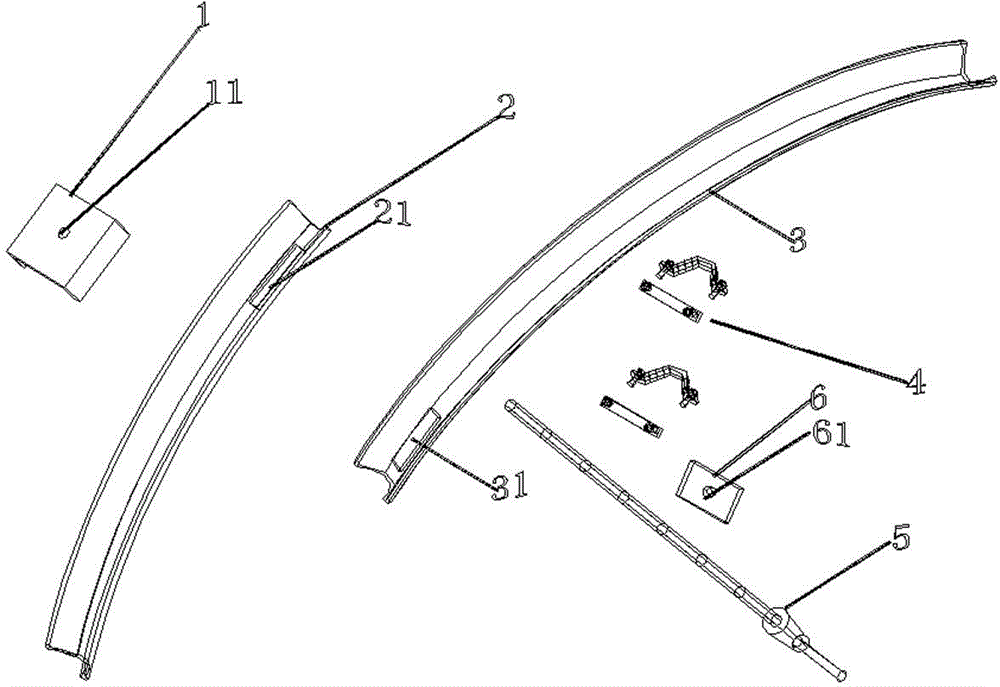

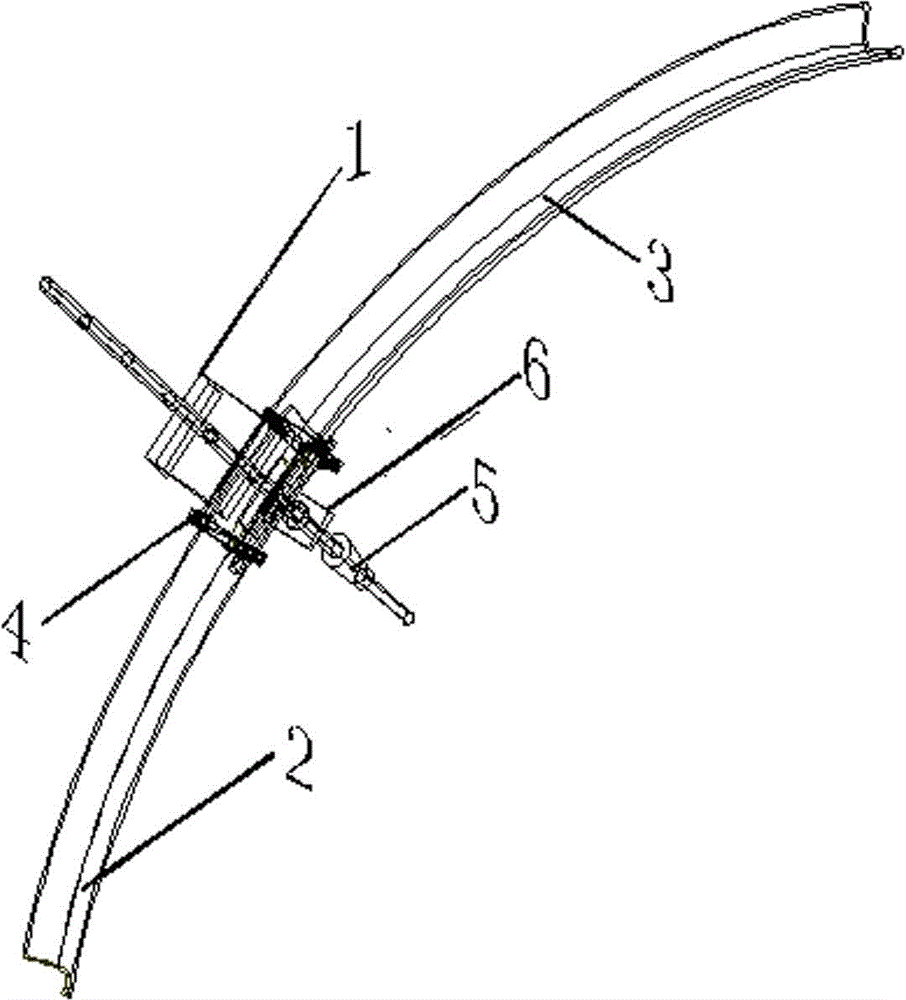

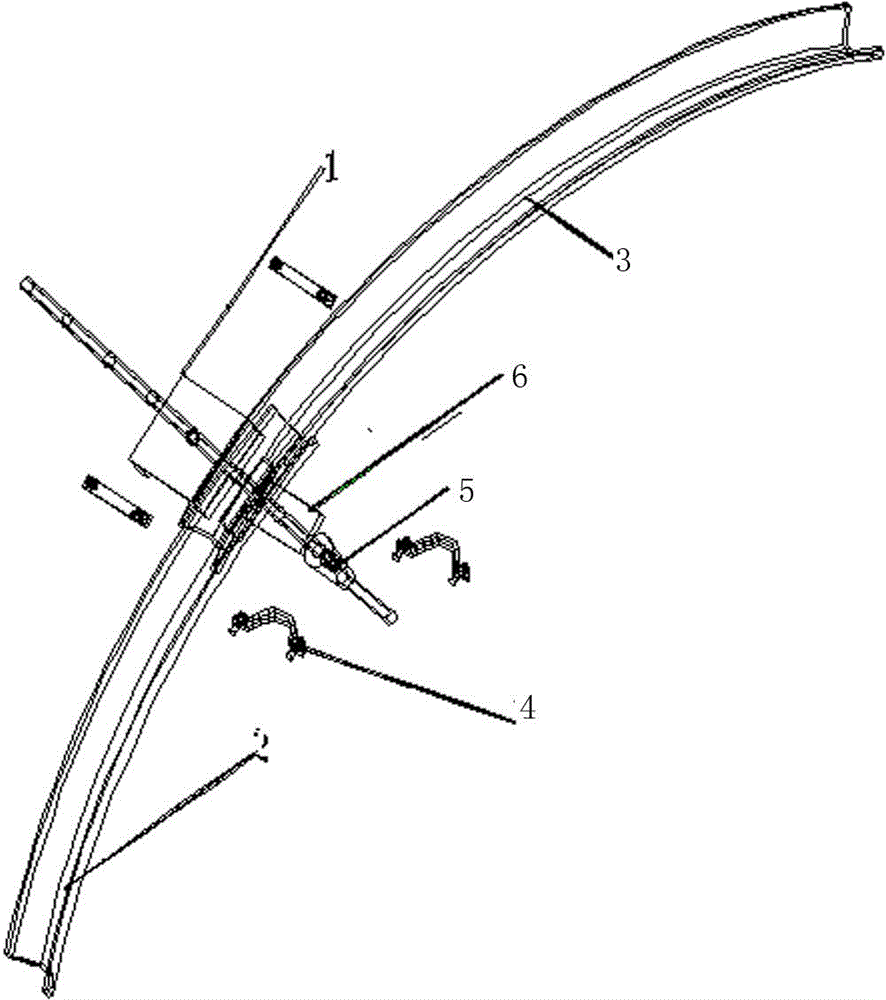

[0017] Such as figure 1 As shown, the present invention includes a channel steel block 1 , a first U-shaped steel segment 2 , a second U-shaped steel segment 3 , a card cable 4 , an anchor cable 5 , and a backing plate 6 . The corresponding positions on the first U-shaped steel section 2 and the second U-shaped steel section 3 are provided with rectangular holes 21, 31 for the passage of the anchor cable 5, and the first U-shaped steel section 1 and the second U-shaped steel section 1 and the second U-shaped steel section are connected by the clamp cable 6. The section 2 is fixed firmly, the channel steel block 1 is placed behind the rectangular hole, and the backing plate 6 is located at the contact position between the U-shaped steel and the anchor cable 5 lockset.

[0018] Such as image 3 As shown, the middle part of the channel steel block 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com