Backwashing device of shellfish catcher

A trap and backwash technology, applied in the field of shellfish traps, can solve the problems of reducing the service life of the shellfish traps, the connection method is easy to fail, the connecting pipe is easy to break, etc., and achieves a simple structure, convenient discharge and Collect, avoid the effect of short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

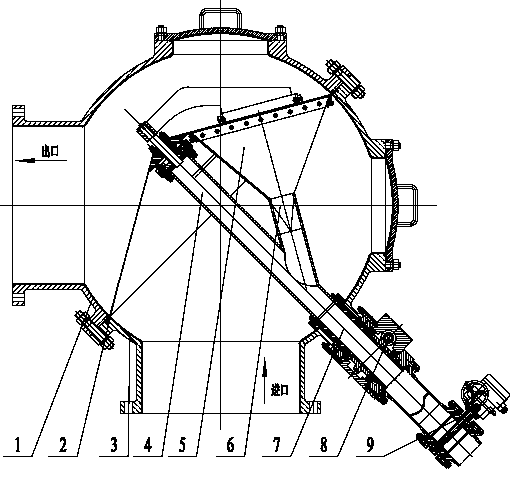

[0010] Such as figure 1 As shown, a backwashing device of a shellfish trap includes a central axis 4 installed on the axis of the shellfish trap filter screen 2 and a blowdown pipe 7 installed on the shellfish trap shell. The trap shell is composed of the left shell 1 and the right shell 3, the shellfish trap filter screen 2 is installed between the left shell 1 and the right shell 3, the left shell 1 and the right shell 3 are connected by bolts Fixed connection, the sewage pipe 7 is installed on the right housing 3, the driving device 8 is connected to the sewage pipe 7, and the catch pipe 6 is installed at the bottom of the shellfish trap filter screen 2, and the catch pipe 6 A trapping cavity 5 is formed between the filter screen 2 of the shellfish trap, the central shaft 4 and the trapping pipe 6 are integrated, and the two are connected to each other, and the end of the central shaft 4 is fixedly connected with the sewage pipe 7 by bolts , a blowdown valve 9 can also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com