Electric stapler

A stapler and electric technology, which is applied in the direction of manufacturing tools, nailing tools, nailing tools, etc., can solve the problems of inconvenient use of manual staplers, non-adjustable distance between paper edges, and insufficient stability of functions, etc., to achieve Low noise, simple mechanism, and stable nailing action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

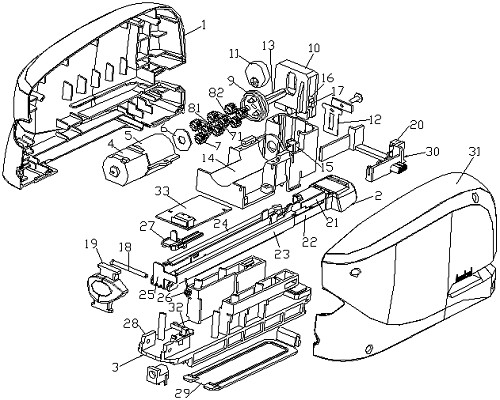

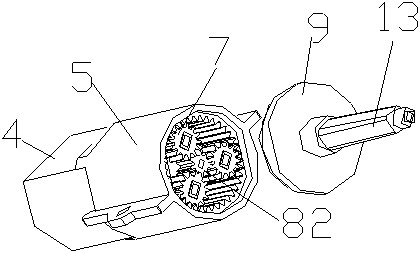

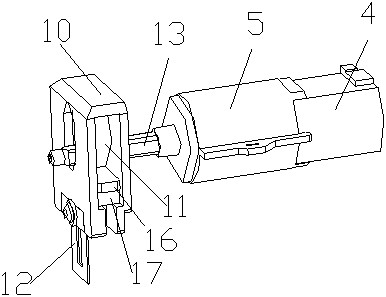

[0035] Such as Figure 1-6 As shown, this embodiment provides an electric stapler, including a left cover 1 and a right cover 31, the left cover 1 and the right cover 31 are fastened together to form an accommodating space, and also includes:

[0036] A stapling mechanism, the stapling mechanism includes a base 3 and a binding frame 2, and the tail end of the base 3 and the binding frame 2 are rotatably connected through a rotating shaft 18;

[0037] A nail pressing mechanism, the said nail pressing mechanism is arranged above the front end of the binding frame 2, and is used to drive the staple mechanism to complete the binding work;

[0038] A driving mechanism, the driving mechanism is arranged above the staple mechanism, the driving mechanism is connected with the nail pressing mechanism through a transmission shaft 13, and the driving mechanism is used to drive the up and down movement of the nail pressing mechanism;

[0039] The distance adjustment block 30, the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com