Air compressor for vehicle

A technology for air compressors and vehicles, which is applied in mechanical equipment, engine components, engine seals, etc. It can solve the problems of small transmission torque, short service life of the belt, and unstable operation, and achieve large transmission torque and long service life. , running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

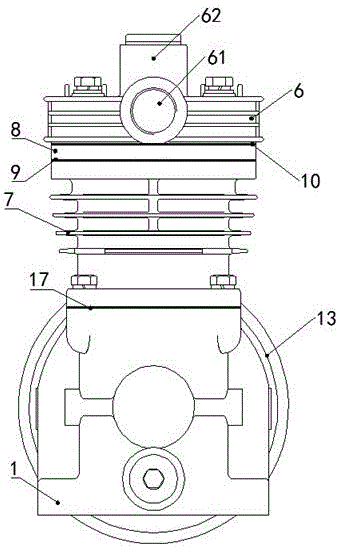

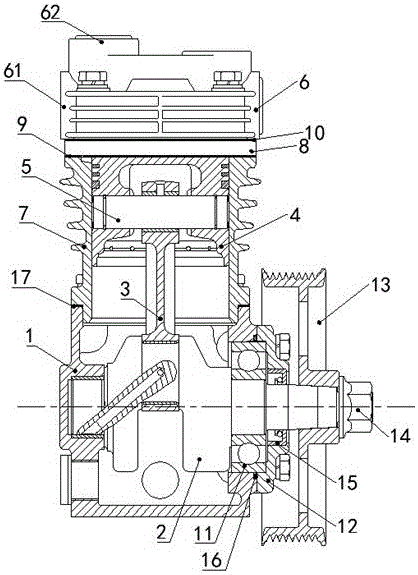

[0014] Depend on figure 1 , figure 2 Known, a kind of vehicle air compressor comprises crankcase 1, crankshaft 2, connecting rod 3, piston 4, piston pin 5, cylinder head 6 and cylinder block 7, described crankcase 1 is connected with cylinder block 7, connects A cylinder block gasket 17 is provided at the cylinder block 7; a piston 4 is provided in the cylinder block 7, and a piston pin 5 is connected to the piston 4, and the piston pin 5 is connected to the connecting rod 3, and a piston ring is provided at the connection, and the crankshaft 2 is connected to the connecting rod 3 A valve plate 8 is fixedly installed on the top of the cylinder block 7, a valve plate gasket 9 is arranged between the valve plate 8 and the cylinder block 7, the valve plate 8 is connected with the cylinder head 6, and a cylinder head gasket 10 is provided at the joint; The cylinder head 6 is provided with an air inlet 61 and an exhaust port 62; a bearing 11 is installed on one side of the crankc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com