Patents

Literature

99results about How to "Improve operational performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

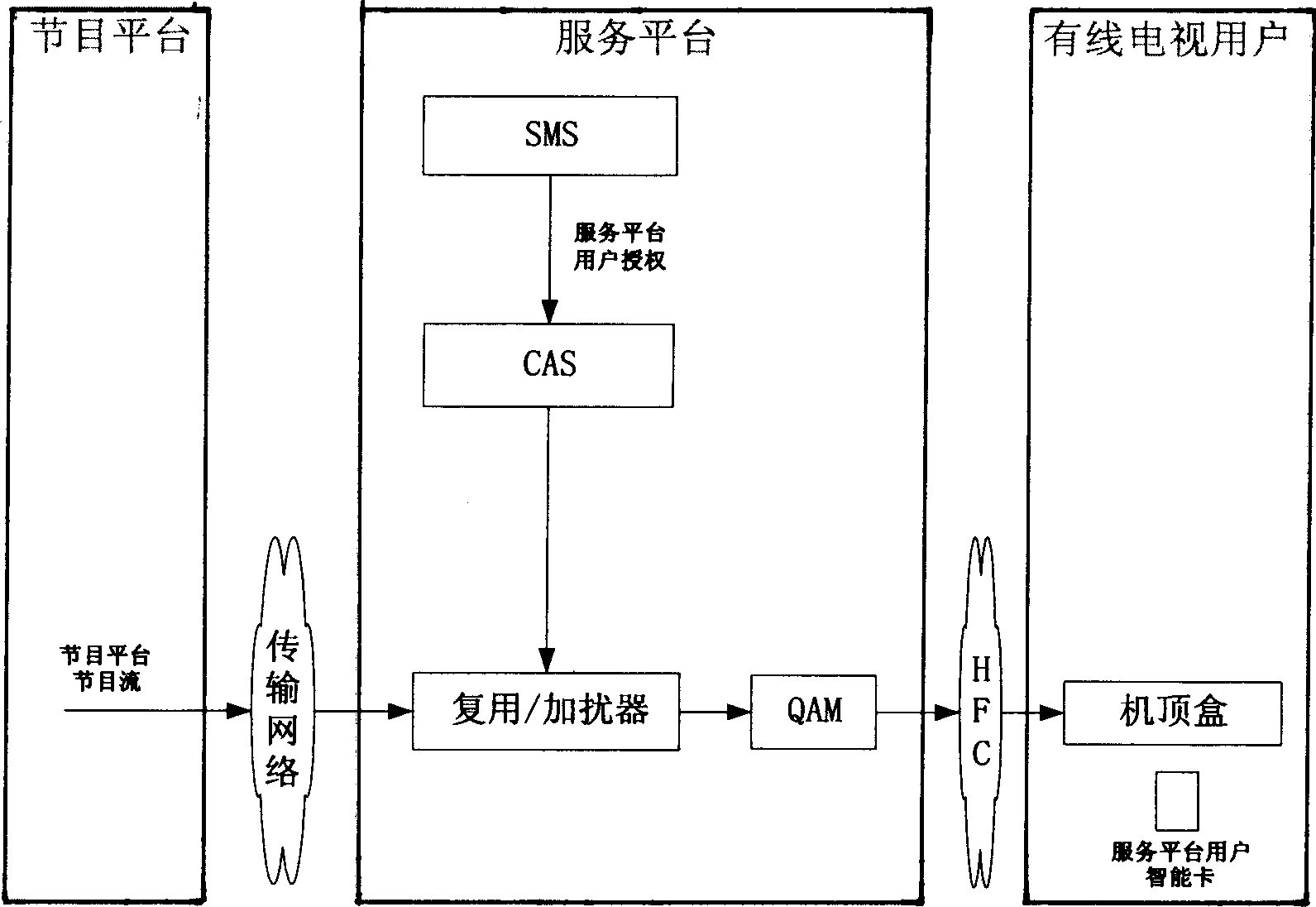

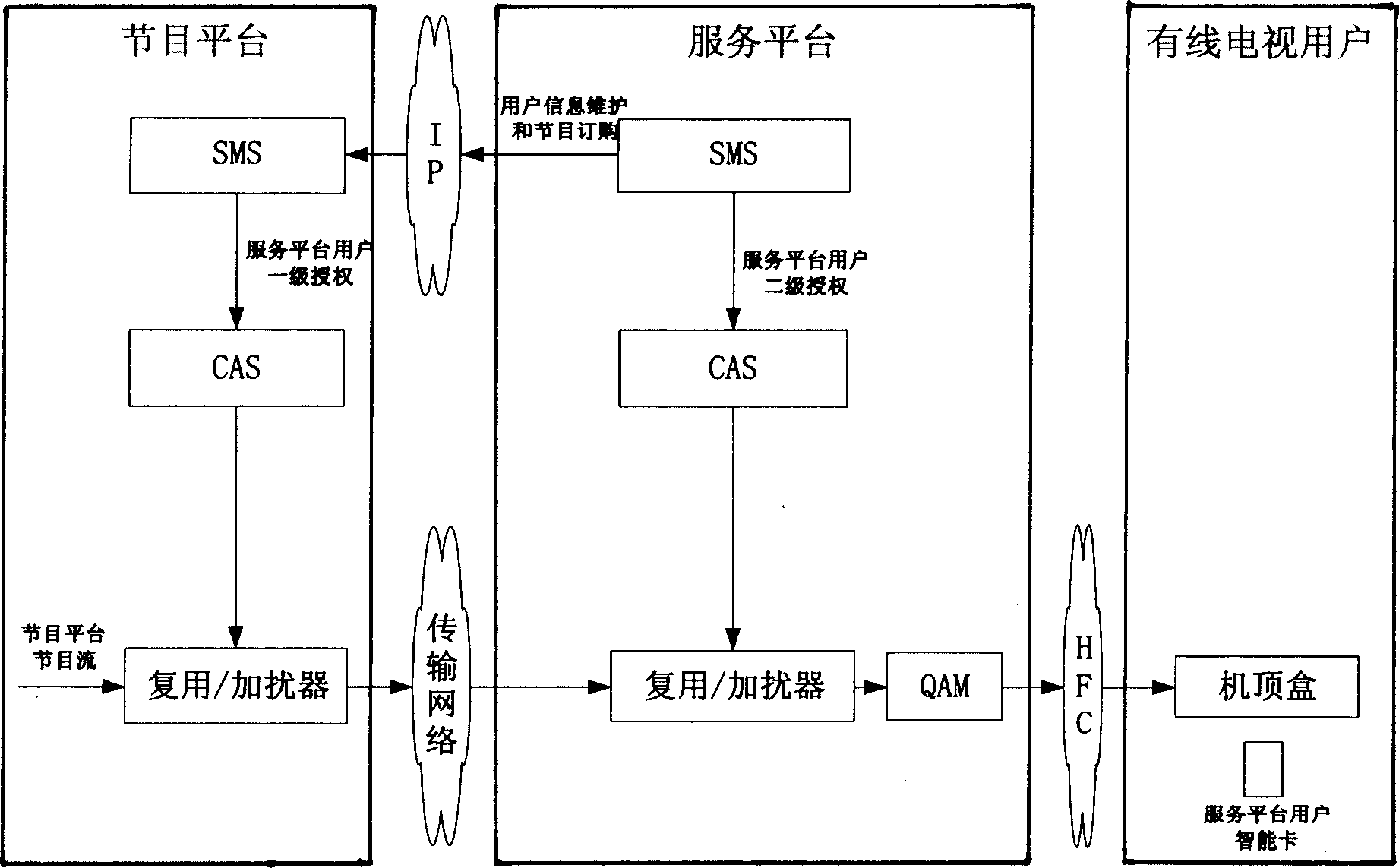

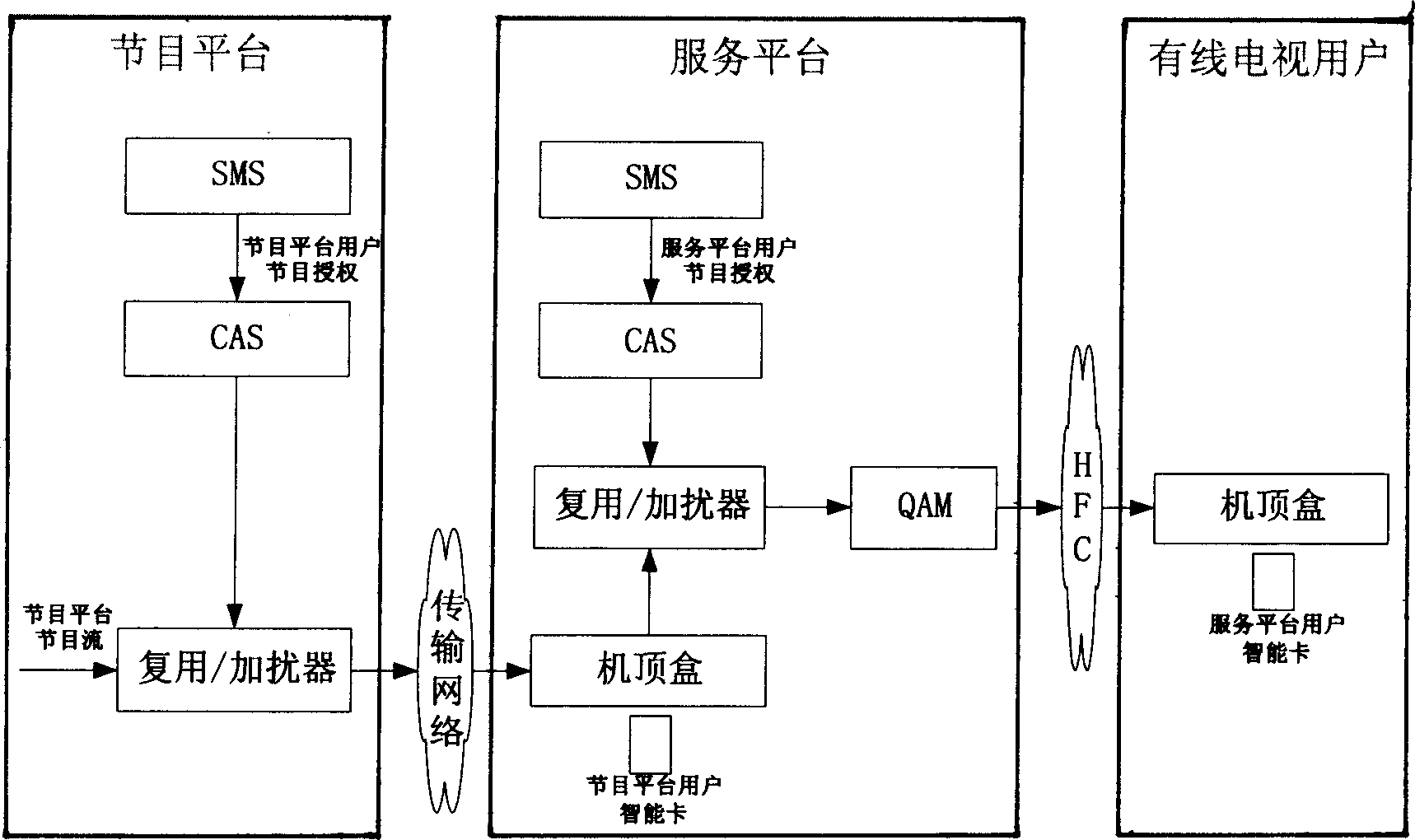

Program exchanging system

InactiveCN1878160AEnsure safetyImprove securityPulse modulation television signal transmissionTransmissionUsabilityComputer science

The invention discloses a program switching system, which is characterized by the following: the service platform transmits the stored user viewing information to monitor platform and program platform with program switching function separately; the program platform transmits the user viewing information to monitor platform, which monitors the program. The invention guarantees the accuracy and fairness of shared settlement for program and service platforms, which improves usability of program switching system.

Owner:HUAWEI TECH CO LTD

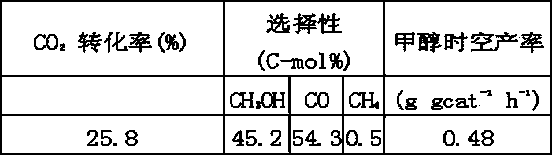

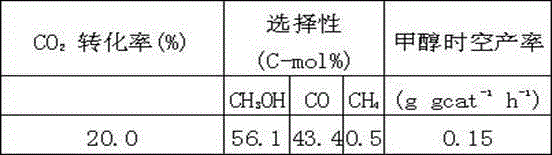

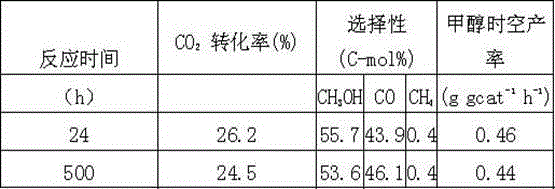

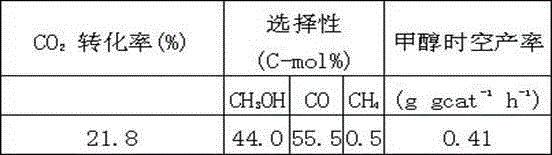

Catalyst for synthesizing methanol through CO2 hydrogenation as well as preparation method and application

ActiveCN103721719ALarge specific surface areaGood dispersionOrganic compound preparationHydroxy compound preparationPtru catalystHalogen

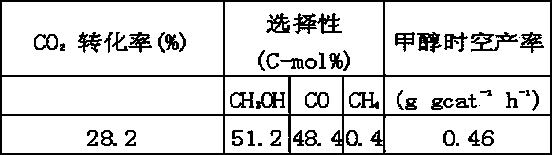

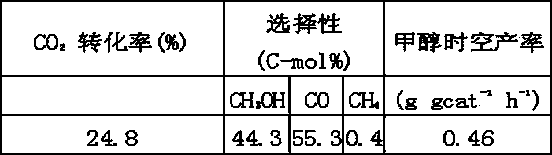

The invention discloses a catalyst for synthesizing methanol through CO2 hydrogenation, comprising Cu, Zn, Al, X, halogen and oxygen elements, oxides and halides, wherein the molar ratio of [Cu+Zn+MA] to [Al+Mb] is 2-18; the molar ratio of Cu to Zn is 0.5-5; the molar ratio of MA to [Cu+Zn] is 0-5; the molar ratio of MB to Al is 0-9; the molar ratio of halogen to Al is 0.05-5; MA and MB cannot be 0 at the same time; MA represents a mono-valent or divalent metal ion in X; MB represents a trivalent and / or tetravalent metal ion in X; X is one or a combination of more elements of Li, K, Mg, B, Ga, In, transition metal elements and rare-earth metal elements. The catalyst has the advantages of high carbon dioxide conversion rate, good methanol selectivity and high methanol yield.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Intelligent wireless fire detection alarm system

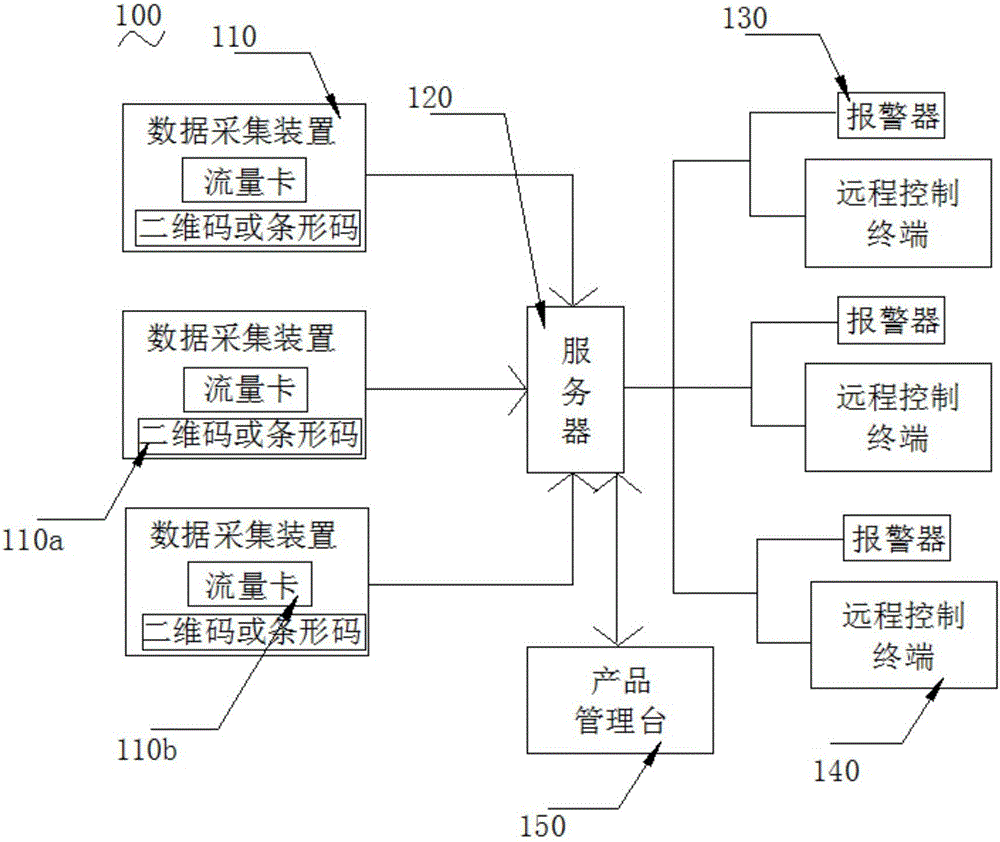

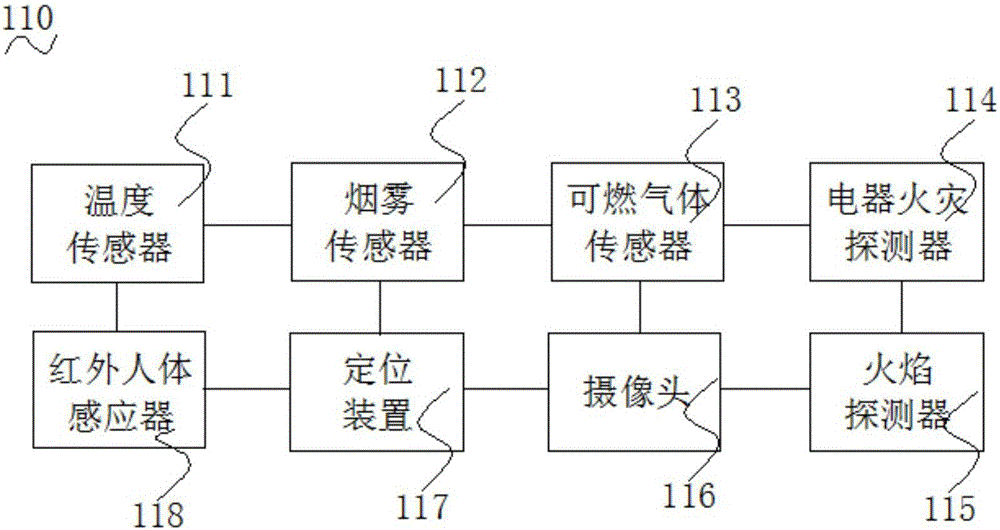

PendingCN105825616ARealize remote controlReduce security risksAlarmsProduct stewardshipFire protection

The invention relates to the field of fire protection, and specifically relates to an intelligent wireless fire detection alarm system. The system comprises data acquisition devices used for acquiring the environment parameters of an installation site, a server used for storing, analyzing and processing data, an alarm used for sounding an alarm at the installation site, remote control terminals used for remote control, and a production management platform used for background management. The data acquisition devices and the alarm are installed on the site. Each data acquisition device comprises a temperature sensor used for detecting temperature, a smoke sensor used for detecting the concentration of smoke, and a combustible gas sensor used for detecting the concentration of combustible gas, wherein the temperature sensor, the smoke sensor and the combustible gas sensor are integrated as a whole. Each integrated data acquisition device is equipped with a bar code or a two-dimensional code. The data acquisition devices, the server, the alarm, the remote control terminals and the production management platform are connected wirelessly. With the intelligent wireless fire detection alarm system, remote control is realized, and measures can be taken to prevent fire accidents. The system has a high degree of intelligence.

Owner:刘浩

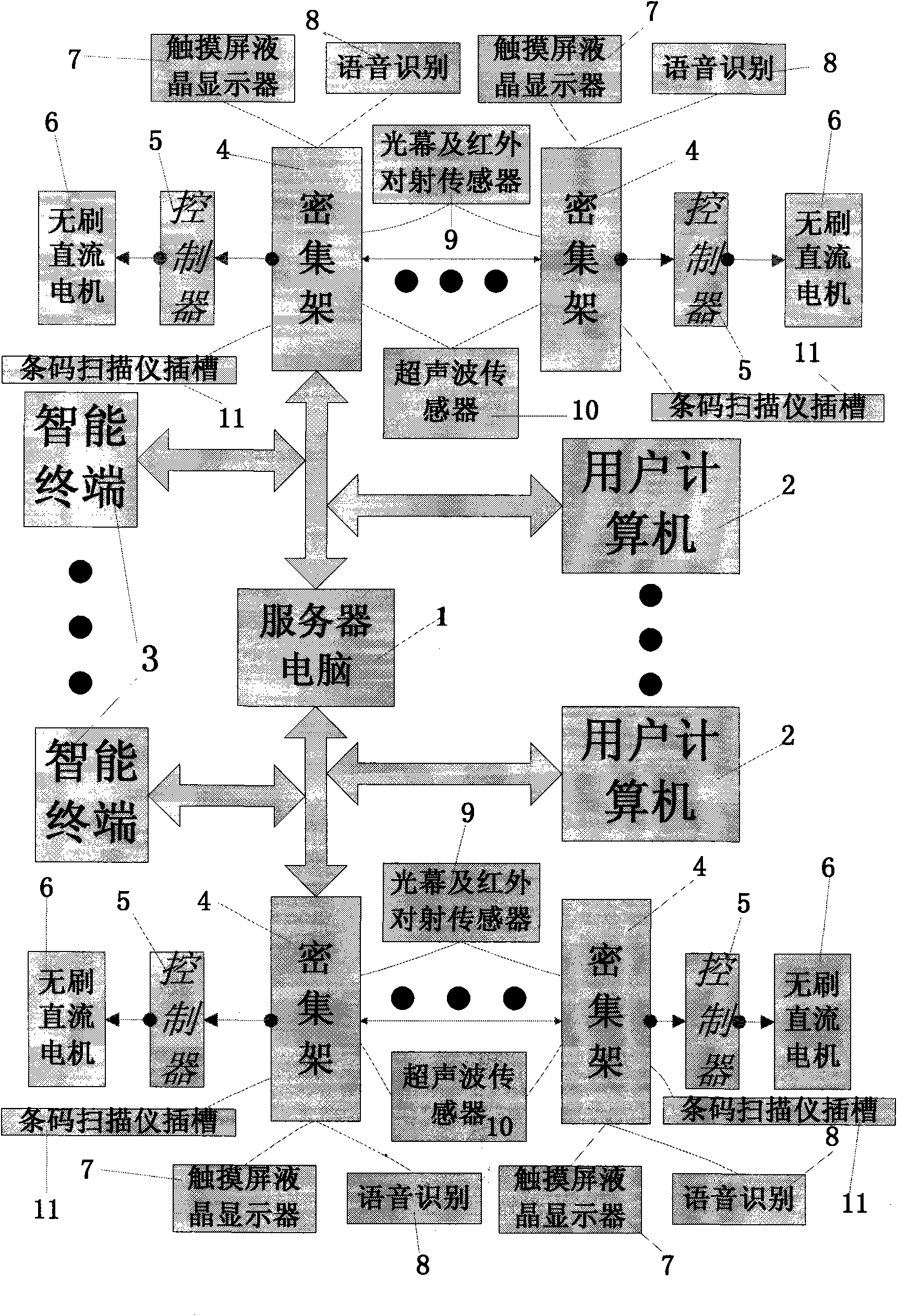

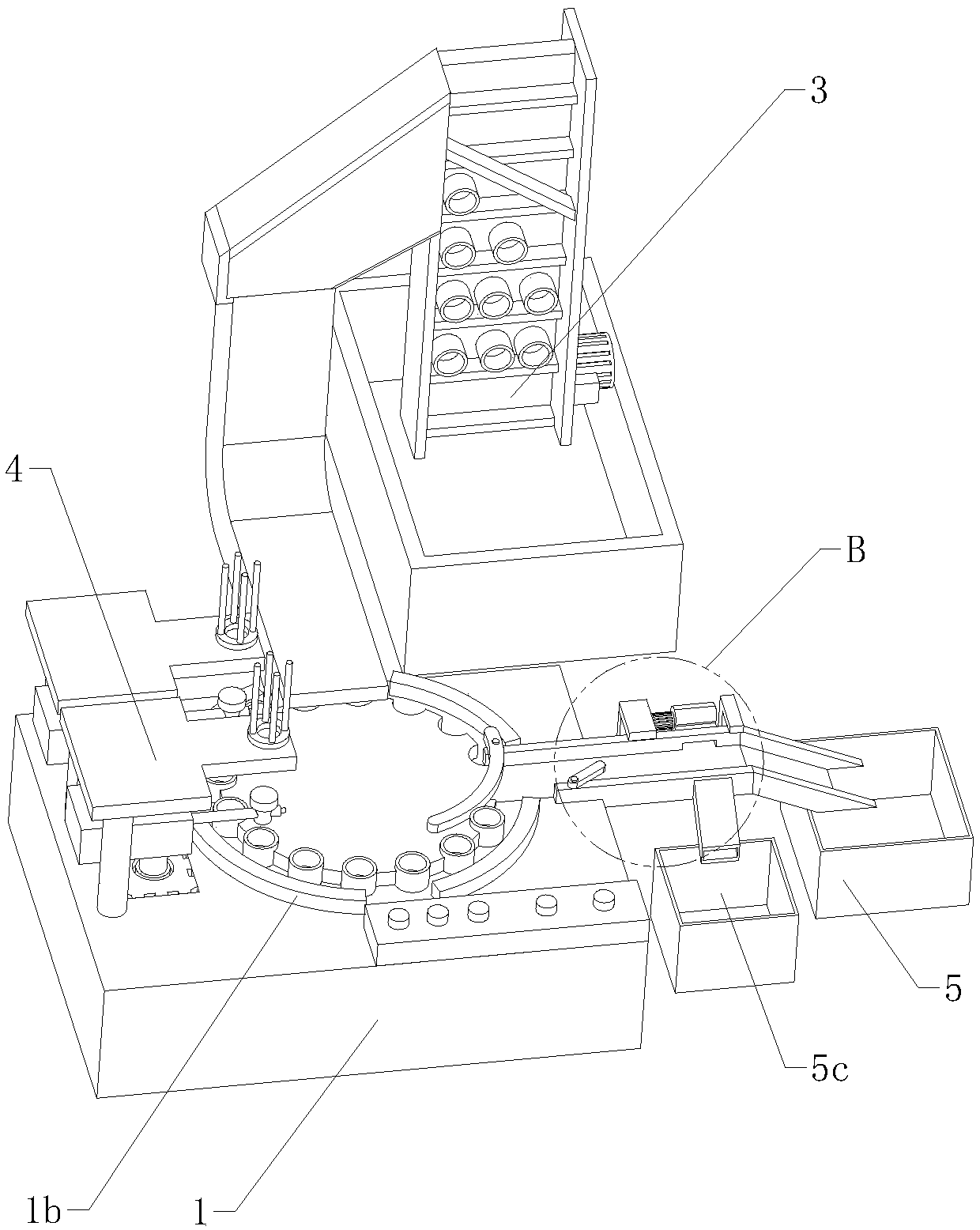

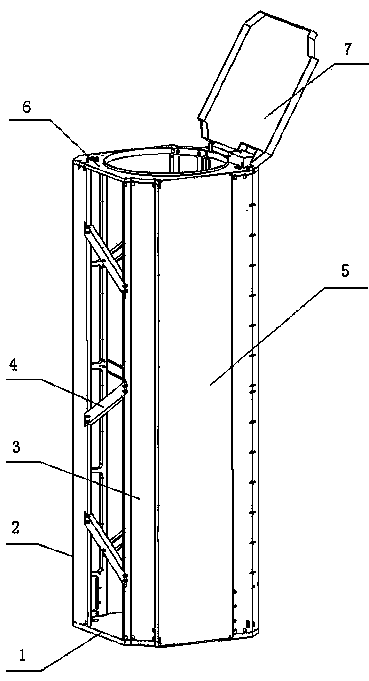

Intelligent operation and control system of compact rack

InactiveCN101592952AImprove operational performanceSmooth startTotal factory controlProgramme total factory controlIntelligent user interfaceMovement control

The invention discloses an intelligent operation and control system of a compact rack, which can greatly improve the efficiency of user file management and the using convenience, fully considers the safety of human body and equipment, provides a humanized friendly operation interface of a user, and is adaptive to the file management and sharing demand of an information-based society. The intelligent operation and control system of the compact rack comprises a motion control module and a device for providing stabilization and curve control during the running of the compact rack, a temperature-humidity management module and a device for conveniently monitoring and controlling a file room environment, a B / S structural enquiry and remote control module for improving the file management efficiency of the compact rack, an intelligent user interface module and a device for greatly improving user operation performance, a safety guarantee module and a device for guaranteeing the safety of the human body of the user and the equipment, and a bar code management module and a device for providing file storage convenience.

Owner:NANCHANG HANGKONG UNIVERSITY +1

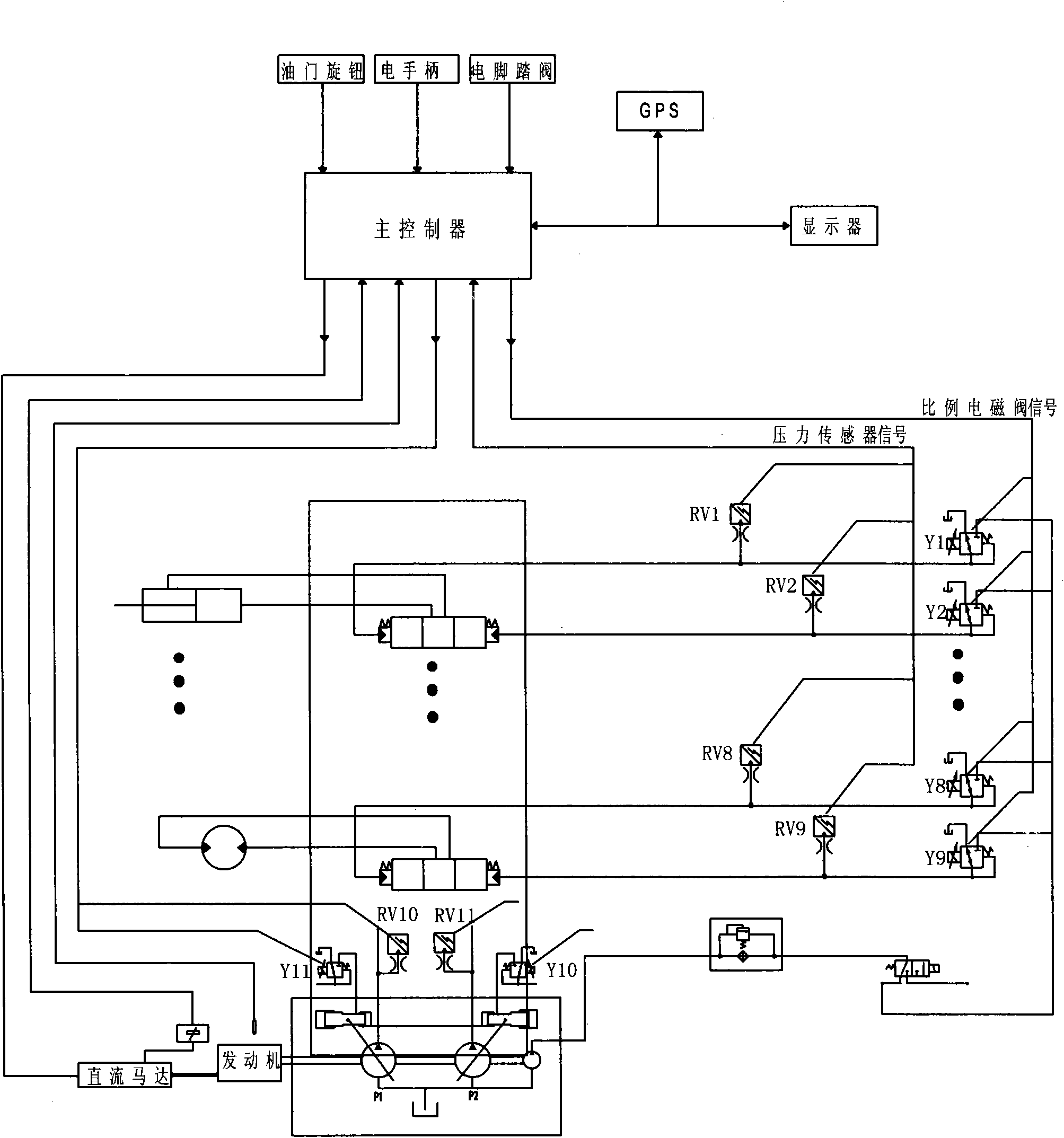

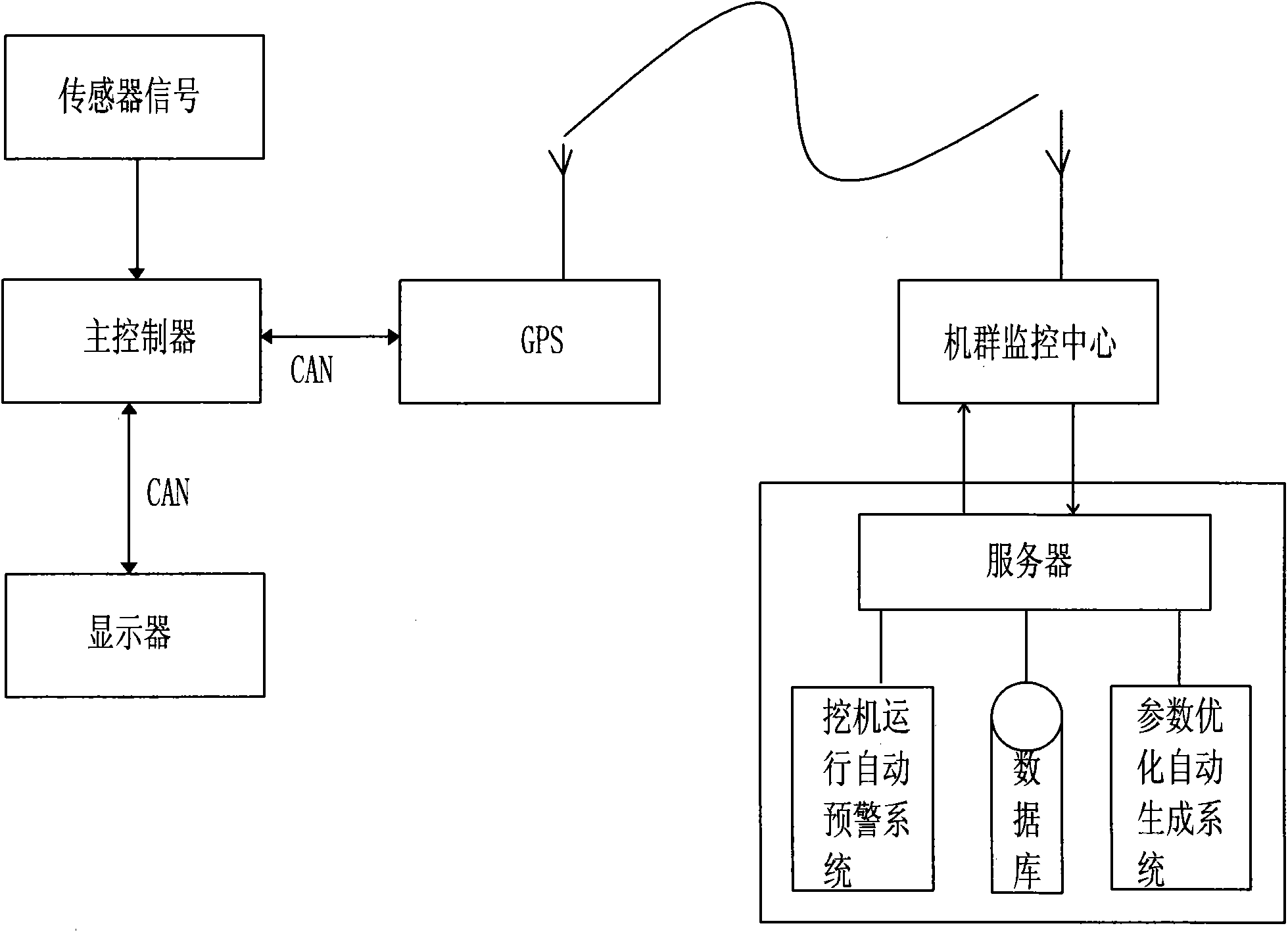

Intelligent control method for hydraulic excavator

InactiveCN101864780AImprove handlingImprove workabilityProgramme controlMechanical machines/dredgersLogical operationsEngineering

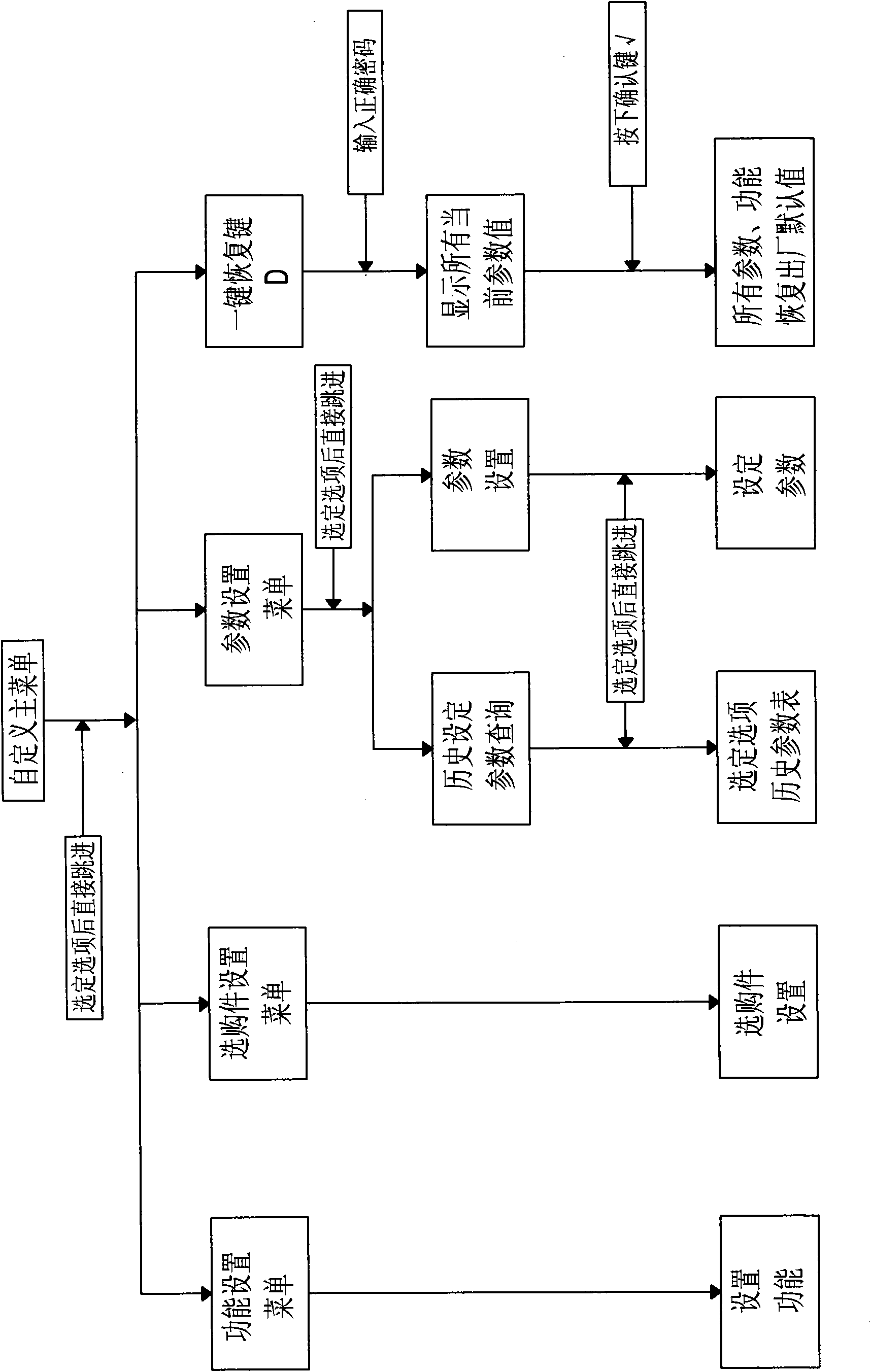

The invention discloses an intelligent control method for a hydraulic excavator. The method is characterized in that: a database set in a main controller is divided into a setting area and a recovery area; and the main controller is connected with a display modification interface through a CAN bus, wherein the operation method of the main controller comprises the following steps of: a. data modification, namely (1) the main controller detects data and obtains regulating ranges of excavator control parameters and engine output power by a logical operation; (2) an operator sets the excavator control parameters and the engine output power in the regulating ranges; and (3) modified self-defining data is stored in the setting area through a CAN bus and an excavator operates according to the data; and b. data recovery, namely the main controller calls the data in a recovery area and covers the self-defining data in the setting area. In the intelligent control method for the hydraulic excavator, data regulating ranges are given according to detected data; and the operator can modify according to implementing working conditions and habits so as to meet the requirements on site environment and user control and contribute to improving the operating performance of the excavator.

Owner:SANY HEAVY MACHINERY

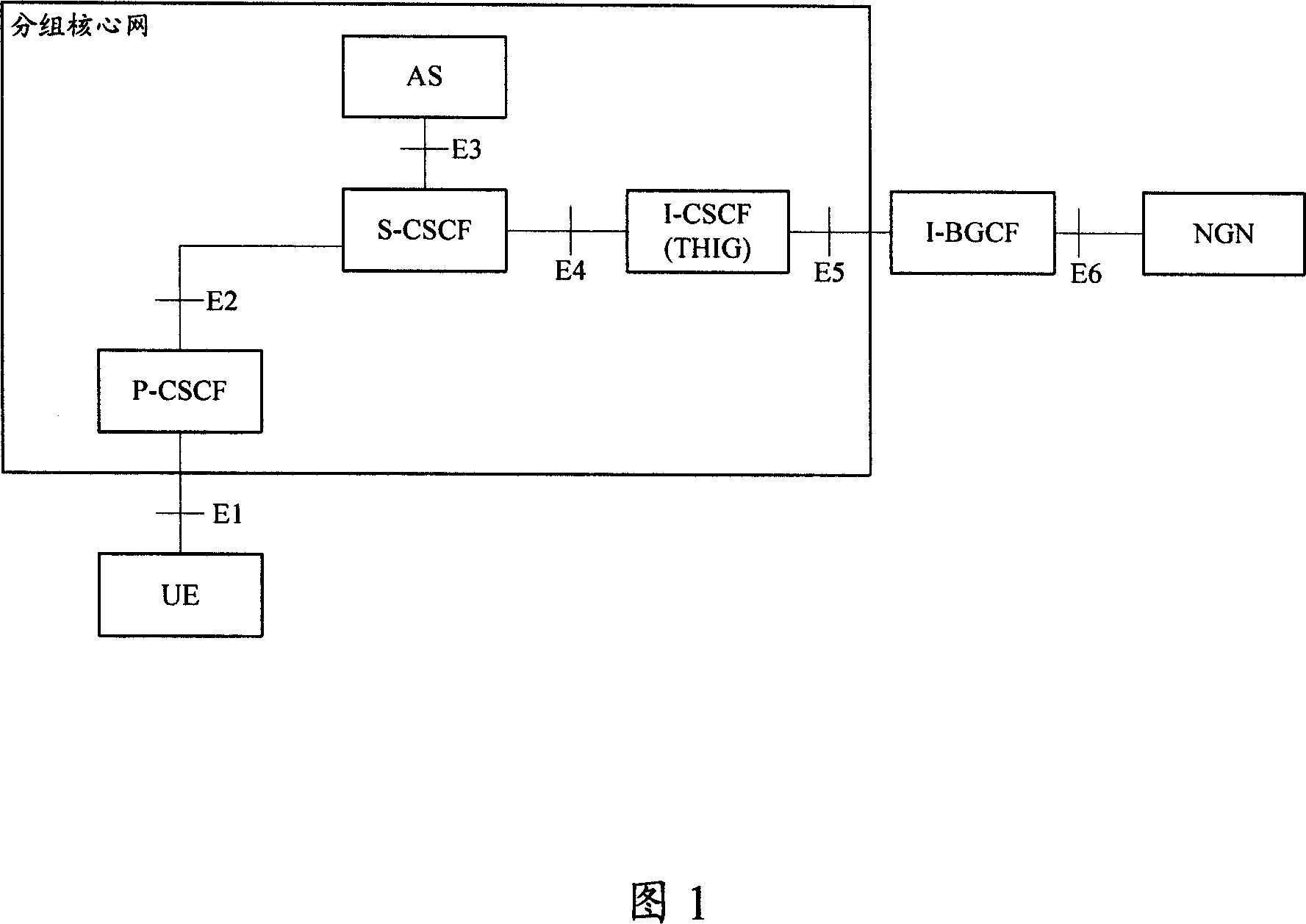

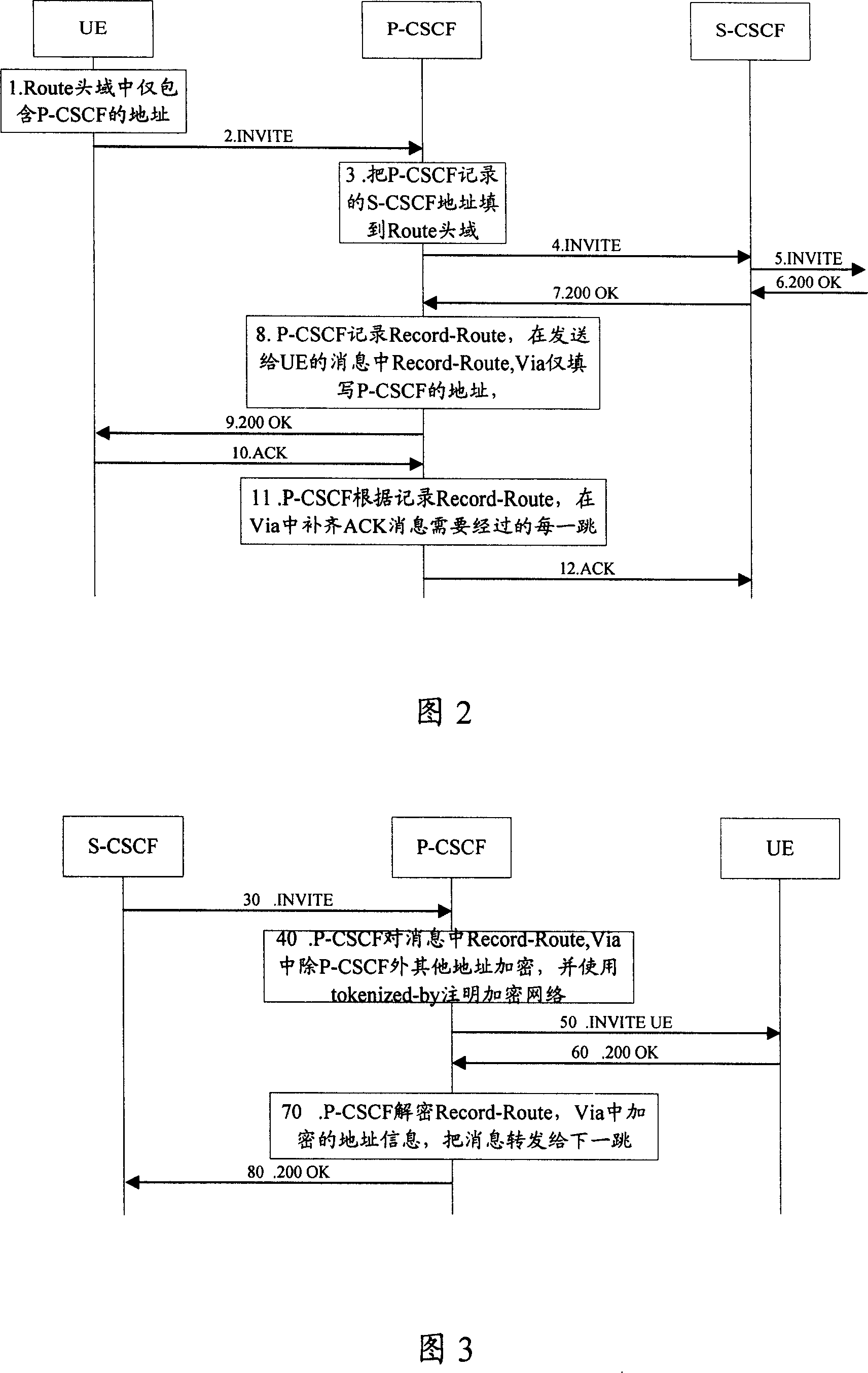

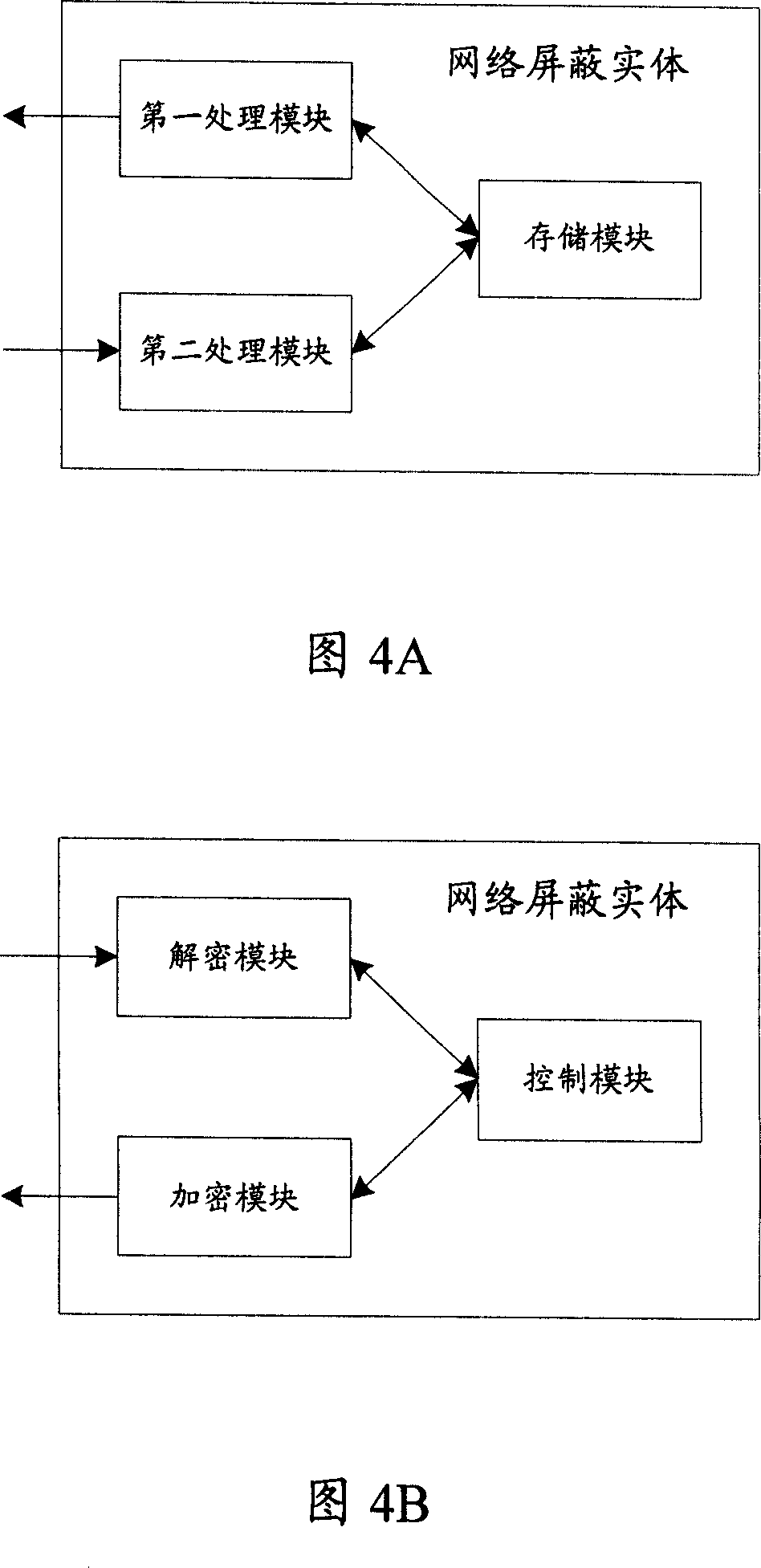

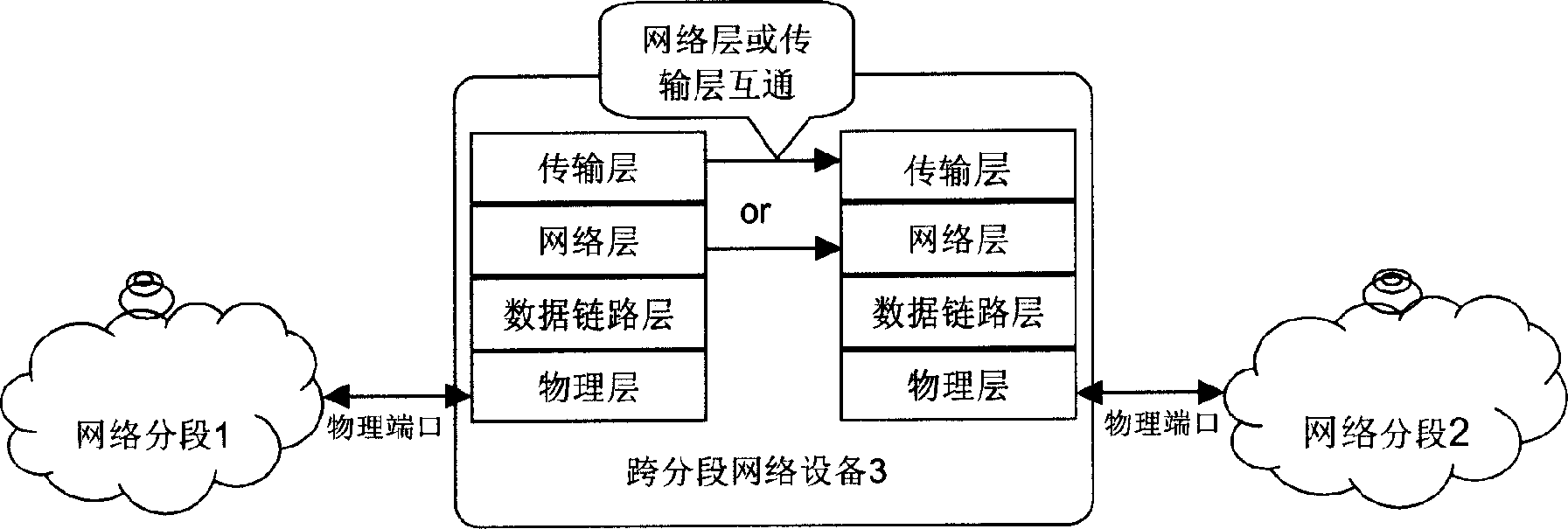

A method and system to realize network shield in packet network

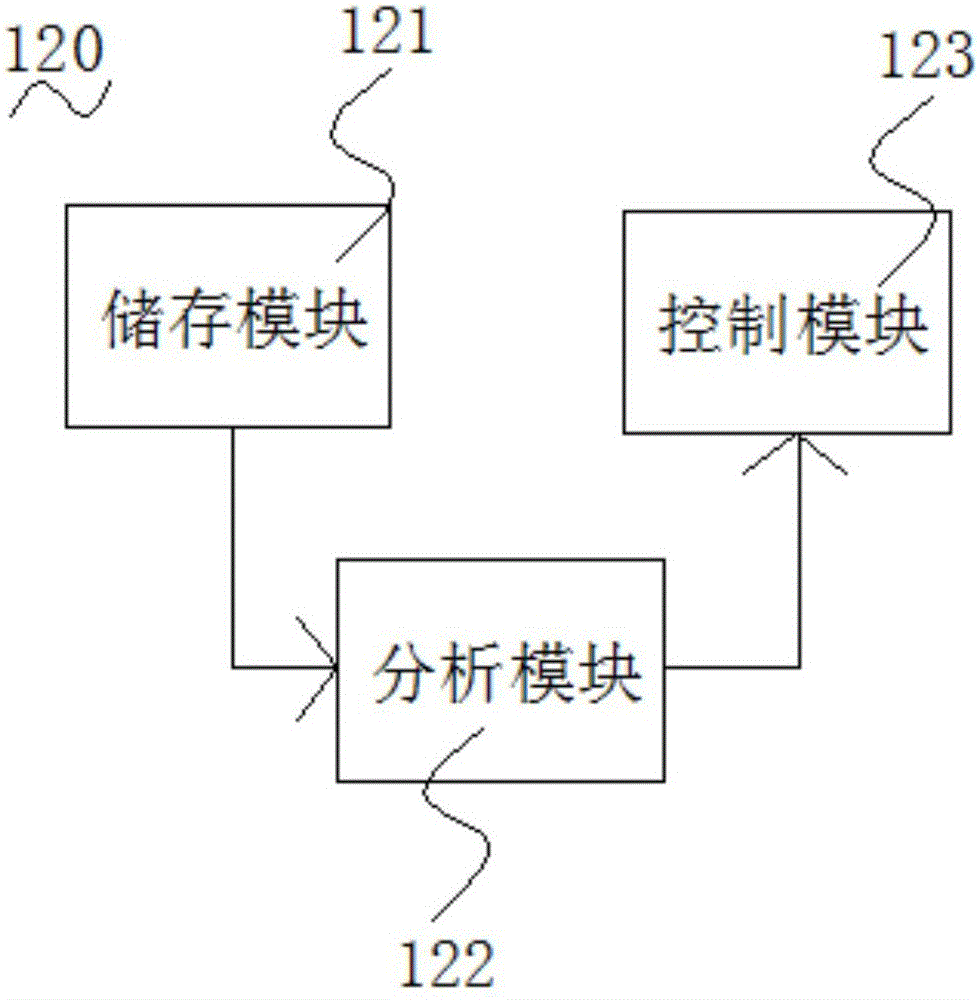

InactiveCN1964316AImprove securityImprove operational performanceData switching networksRelevant informationProcess module

The disclosed method for shielding network in packet network comprises: sending the SIP information to be outside to the network shielding point in this network; using the said network shielding point to store the relative information to be shielded in SIP information, and hiding the relative information in SIP information to send it out of the network. It also discloses a shielding device for packet network, which includes: a storage module for the information required to shield, a first process module to store the relative information into last module and shield the relative information in SIP information, and a second process module to recover the shielded information according to stored relative information.

Owner:HUAWEI TECH CO LTD

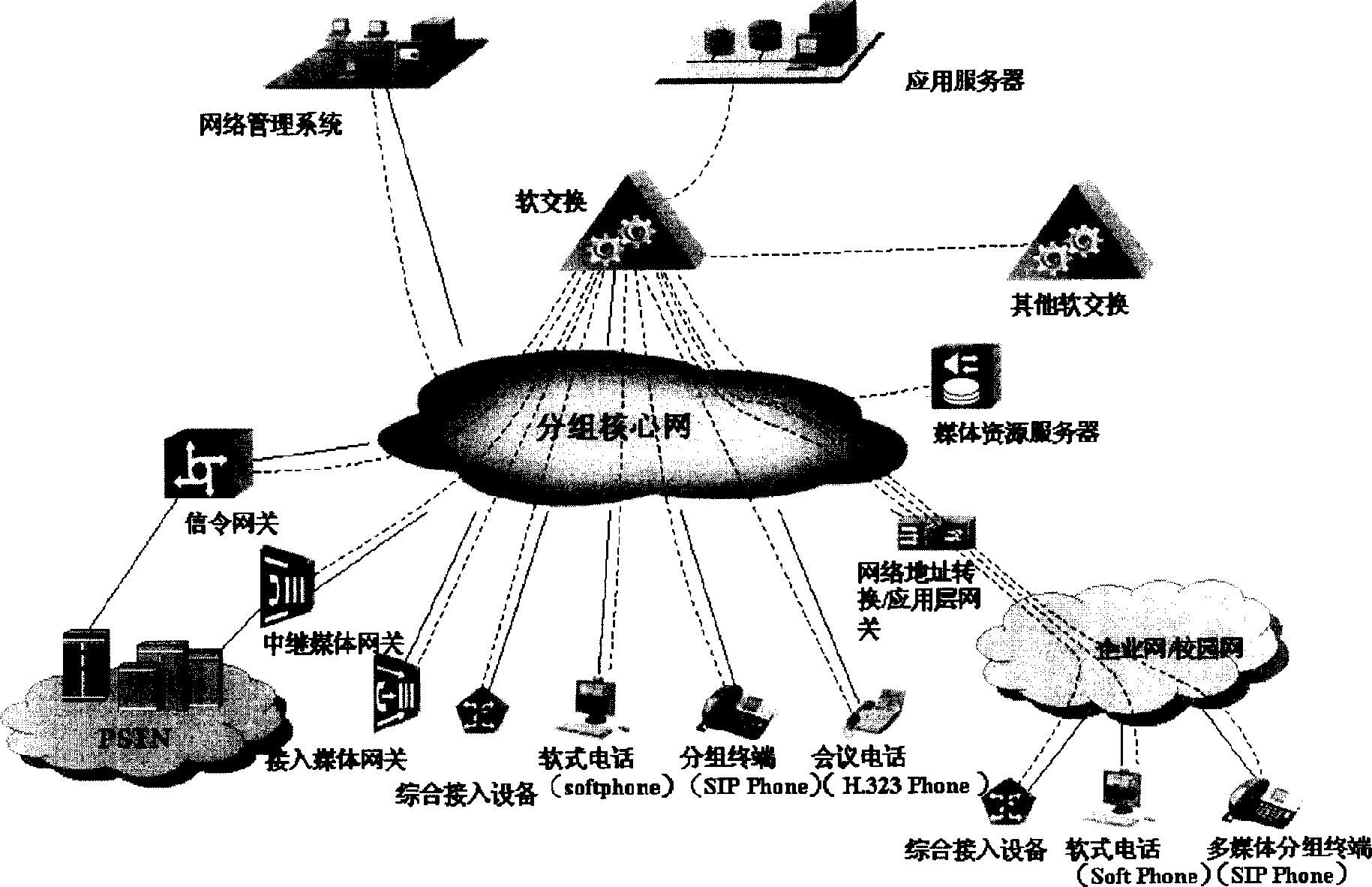

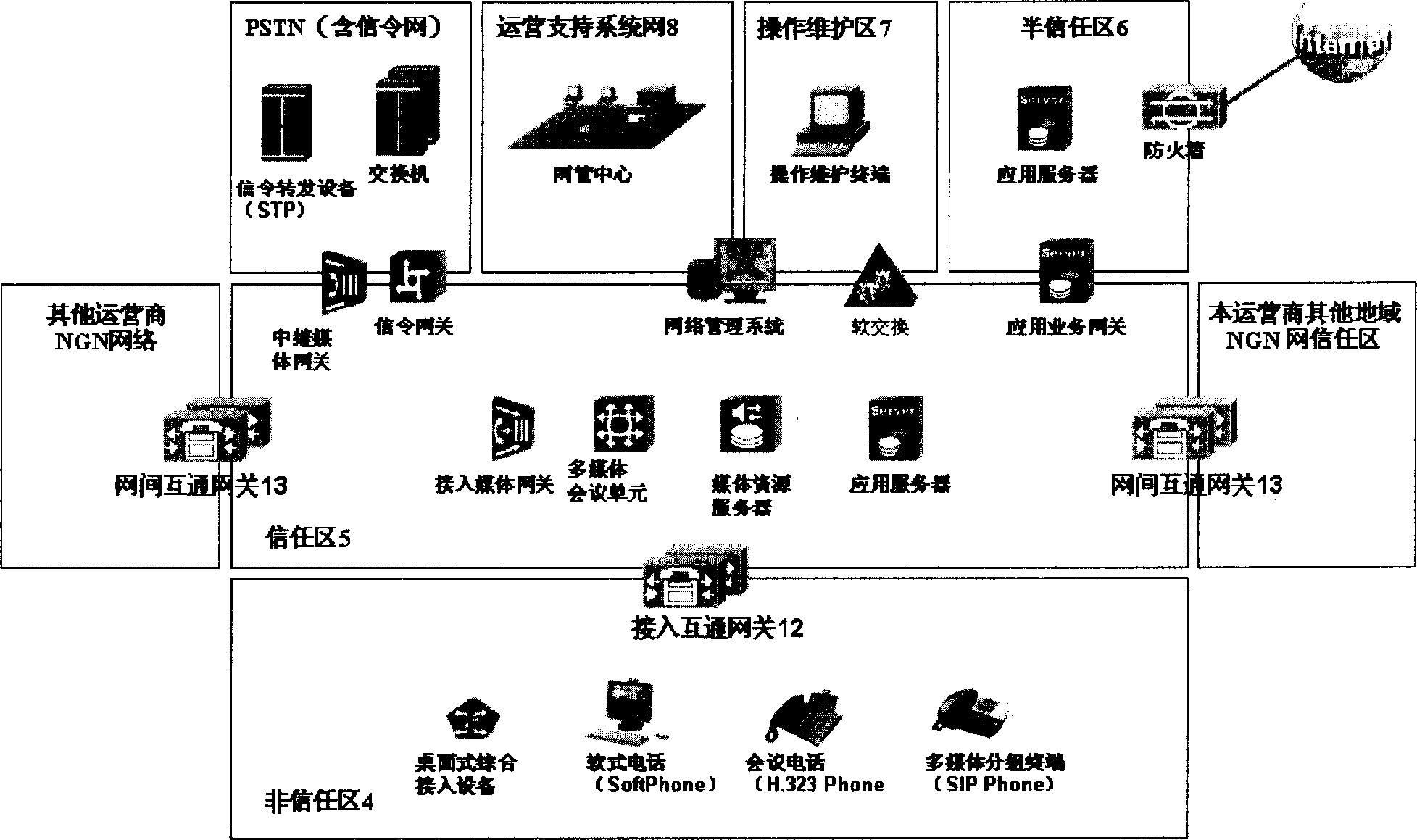

Networking system for next generation network

InactiveCN1665238AImprove securityAchieve securityTransmissionOperational maintenanceApplication server

The invention discloses a networking system for next-generation network, comprising several network subregions, all connected by transregional network components, where these components only implement intercommunication between the application layers of all the network subregions and then implement their service intercommunication. The networking system comprises the below network subrgions: non-trust region, meaning the network the users can directly access to as well as the network with undetermined safety; trust region, meaning the service special network for the next-generation network; semi-trust region, the IP network region connected with the external data network by the firewall; operation maintaining region, an independent IP network, one side connected with the equipment at the operation maintaining server end and the other side connected with client ends; operation supporting network, a special network, managing the whole network equipment of the operator. The networking system has feasibility and implements the safety of access network and application server, implementing the intercommunication of all the network subregions.

Owner:HUAWEI TECH CO LTD

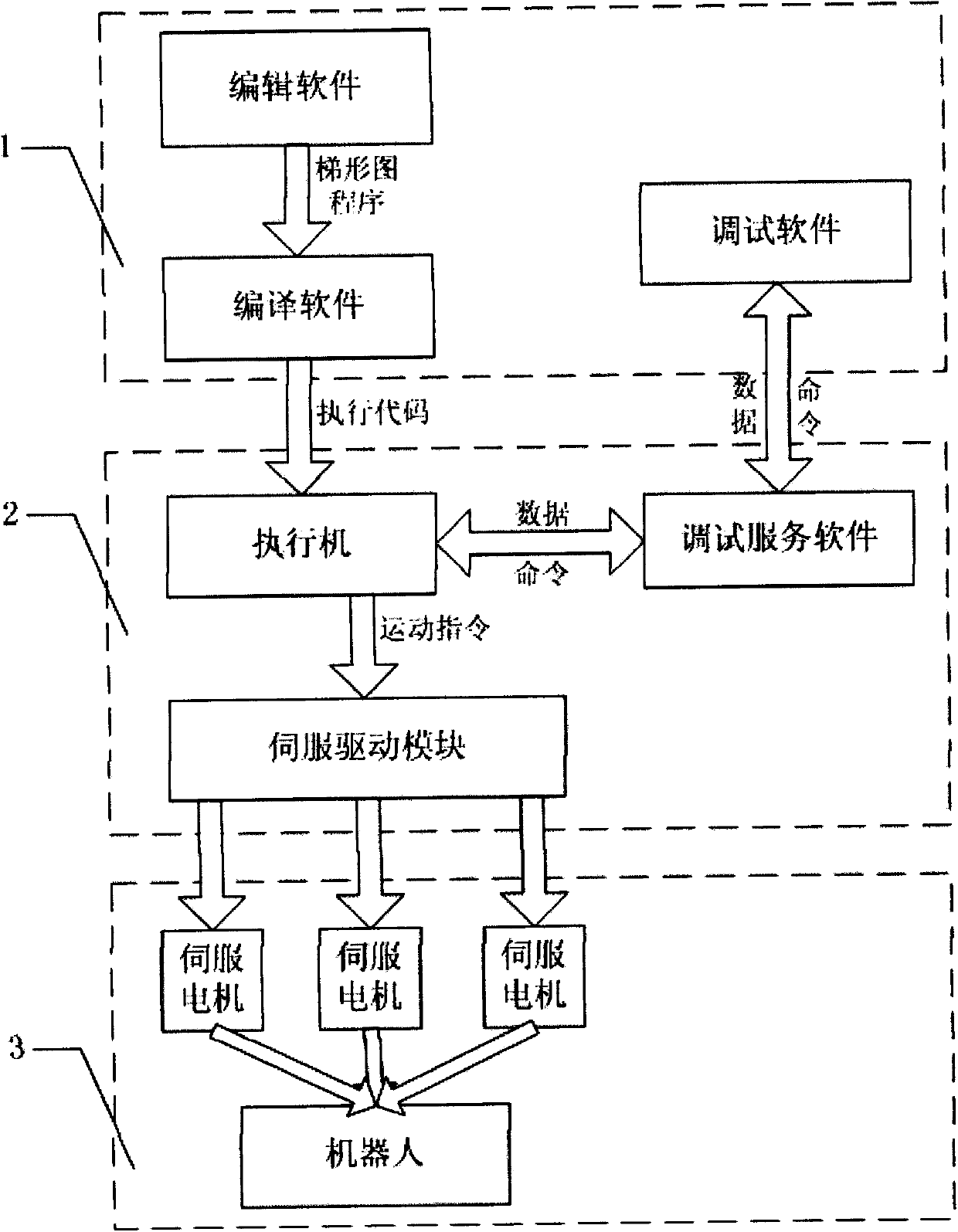

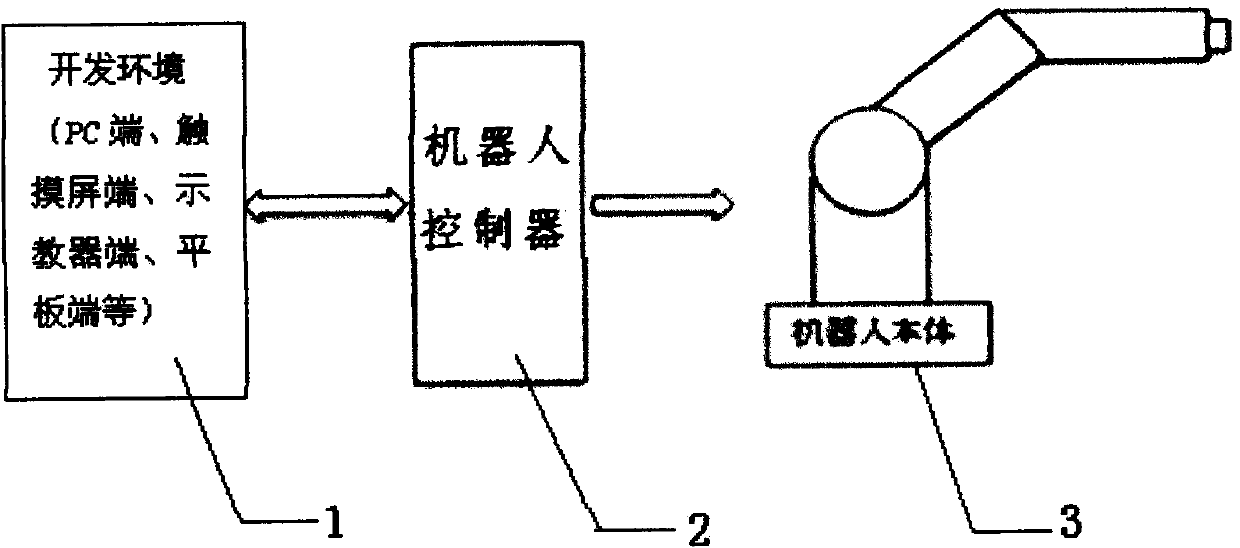

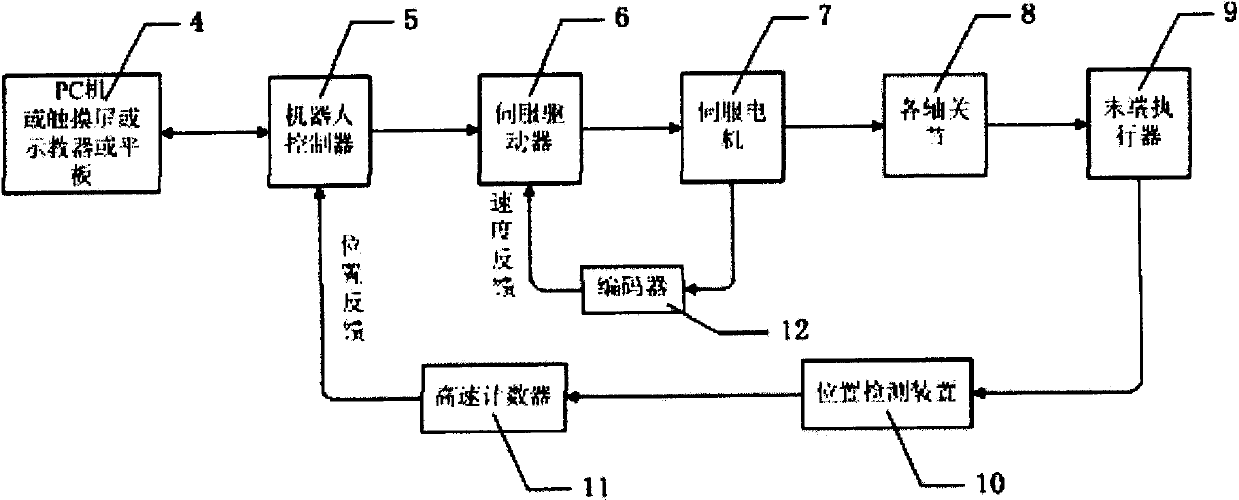

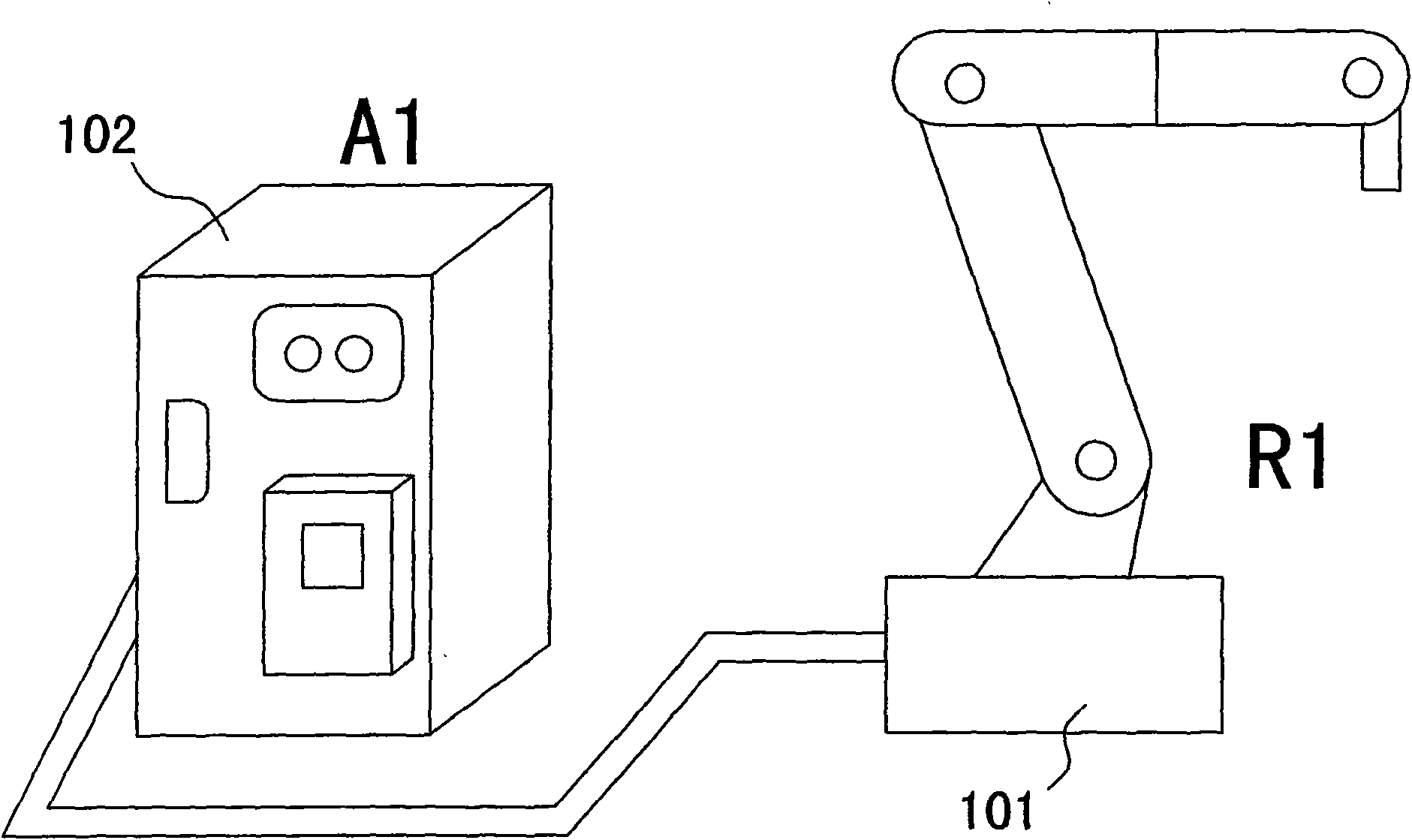

Robot programming control method

ActiveCN103386685AImprove operational performanceImprove versatilityProgramme-controlled manipulatorComputer moduleComputer science

The invention discloses a robot programming control method comprising the following steps of (1), programming all operation commands of a robot by a ladder diagram programming mode in a program editor at an development interface, wherein the operation commands are used for controlling the moving process and posture of the robot; (2), generating the operation commands designed by the ladder diagram programming mode into command codes capable of being executed by a robot controller by a compiling module; and (3), sending the command codes to a servo driving module in the robot controller, thus driving a servo motor to drive the robot to finish all actions in space. The robot programming language in the ladder diagram mode is easily understood, and a work method of scanning round and sequential scanning is adopted to replace the special, complex and time-consuming robot programming language, so better universality and standardization are realized, and the operation use performances of the robot are obviously improved.

Owner:WUXI XINJIE ELECTRICAL

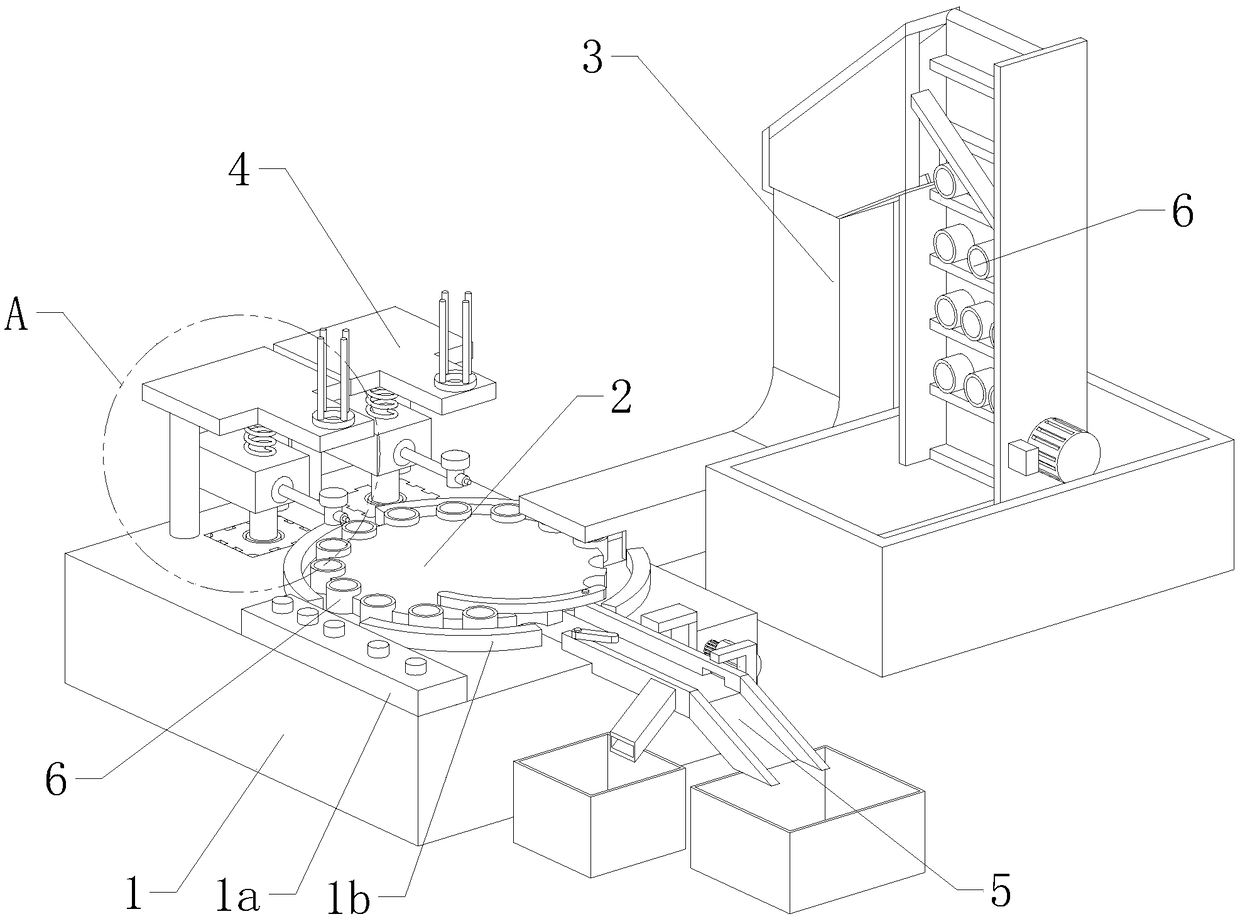

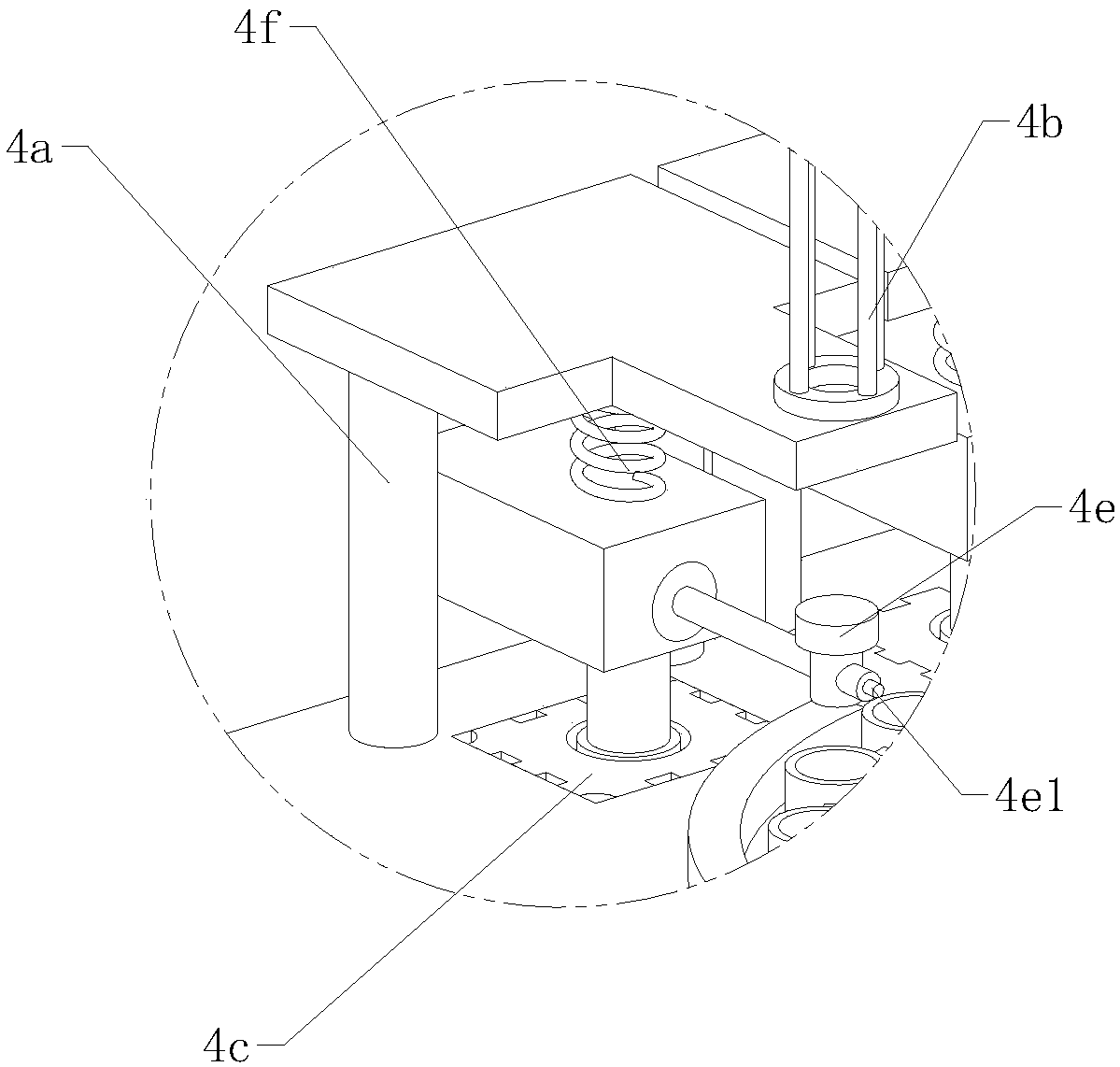

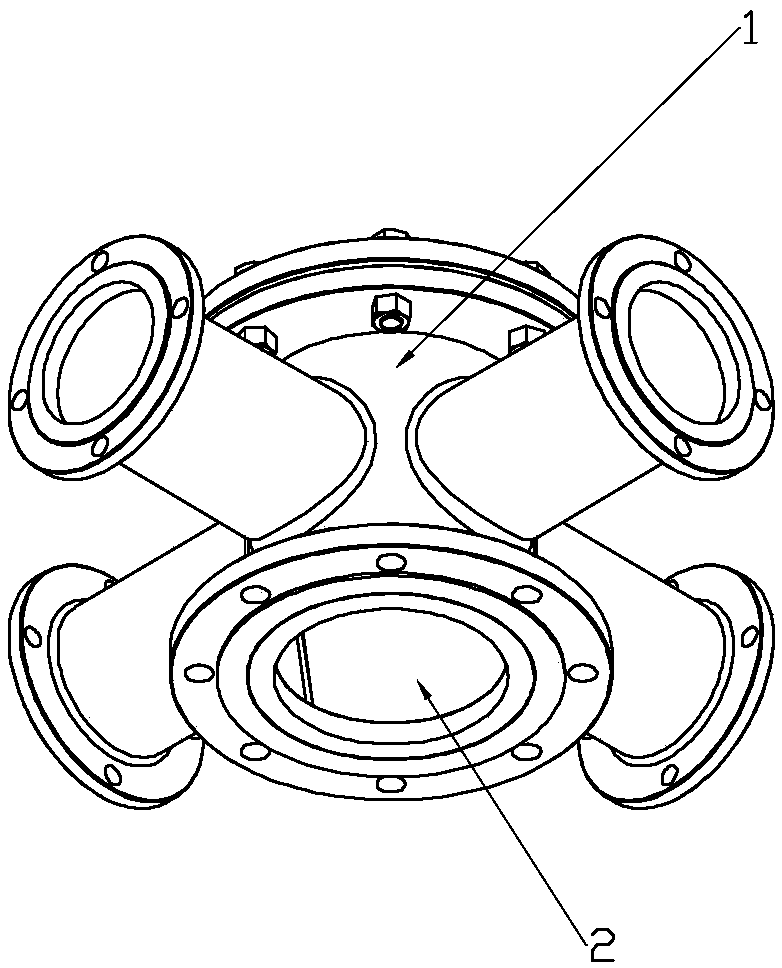

Full-automatic bottle cap gasket machine

The invention relates to the field of gasket entrance into caps, in particular to a full-automatic bottle cap gasket machine. The full-automatic bottle cap gasket machine comprises a machine tool, a multi-station rotary disc, a cap arranging and loading mechanism, a gasket mechanism and an unloading mechanism; bottle caps are firstly placed in a material box, gaskets are placed in a gasket cylinder, a waterfall lifting belt arranges the bottle caps and transports the bottle caps upwards, then the bottle caps enter a transferring bin to fall into a bottle cap conveying way, the bottle caps aresent to a bottle cap jig on the multi-station rotary disc, the multi-station rotary disc is driven by a rotating motor to rotate, the bottle caps are brought to the gasket mechanism, a lifting cylinder pushes an overturning motor and a suction cup upwards, the suction cup sucks the gaskets from the gasket cylinder, then the overturning motor drives the suction cup to overturn, a lifting motor is simultaneously lowered to the position above the bottle caps on the bottle cap jig, the gaskets enter the bottle caps, and then finished products enter an unloading conveyor belt, a detecting device detects whether a defective product exists or not, the defective product is removed with a removing device if the defective product exists, and the finished products enter a finished product box. The full-automatic bottle cap gasket machine is easy to operate and stable in performance and improves the production capacity.

Owner:宁波数缘软件有限公司

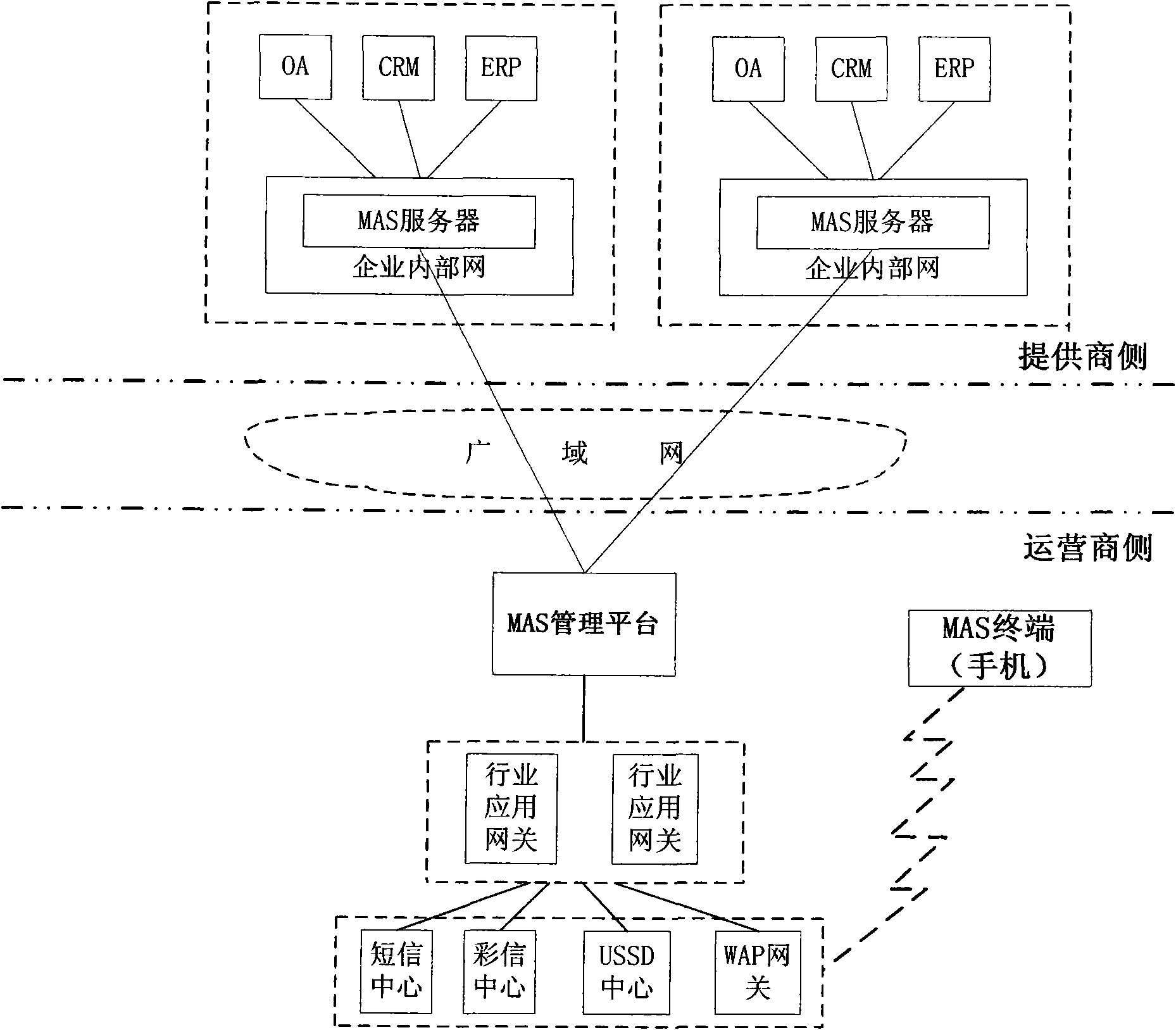

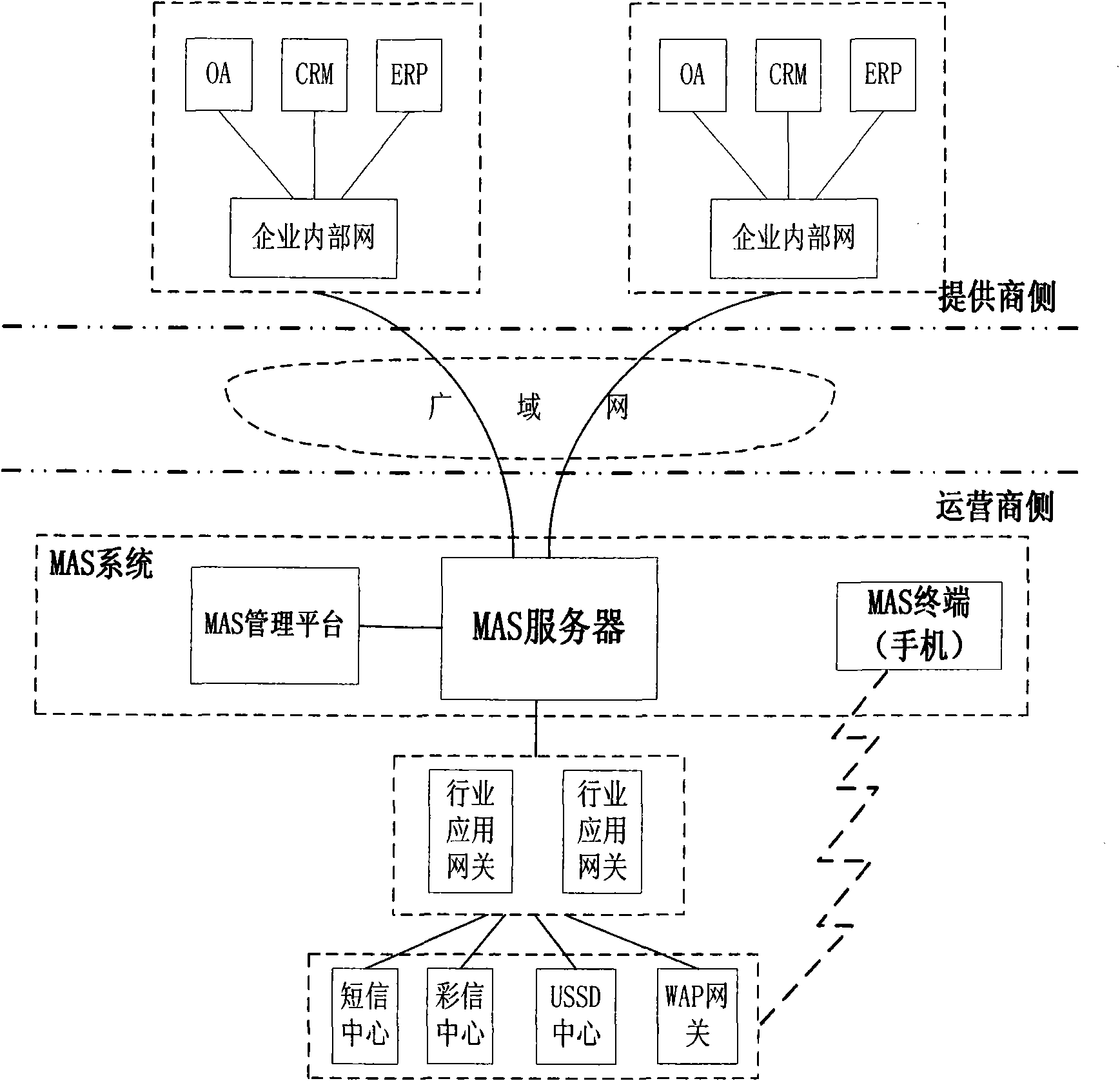

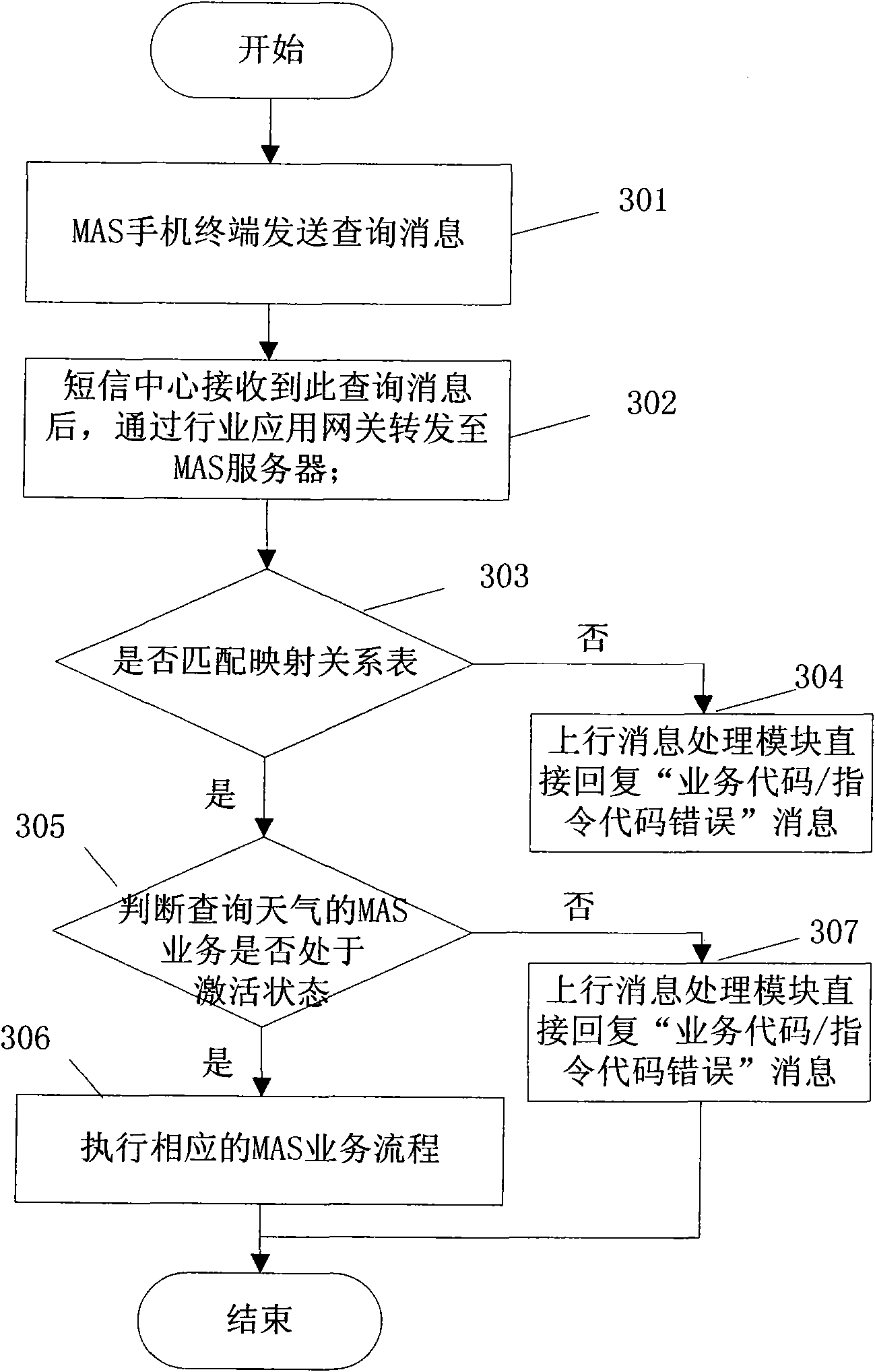

Management method and management system of centralized mobile agent server

InactiveCN101959220ALower acquisition costsEasy to manageNetwork traffic/resource managementNetwork architectureStructure of Management Information

The invention provides a management method and a management system of a centralized mobile agent server. The system comprises a mobile agent server and a mobile agent server management platform, wherein the mobile agent server is positioned on the side of an operator, directly connected with the mobile agent server management platform and connected with one or more enterprise application systems on the side of the operator through a wide area network; the mobile agent server is used for finishing the transmission of service data between the enterprise application server and the mobile terminal and performing controlling; and the mobile agent server management platform is used for performing unified management on the service data of the mobile agent server. By arranging an MAS server on the side of the operator in a centralized way, the method and the system ensure simple network architecture, contribute to management and maintenance of the operator, reduce the operation maintenance cost, and effectively reduce the data transmission redundancy of network element equipment, such as the MAS server, industry application gateways and the like, thereby reducing the communication cost and improving the system response speed.

Owner:ZTE CORP

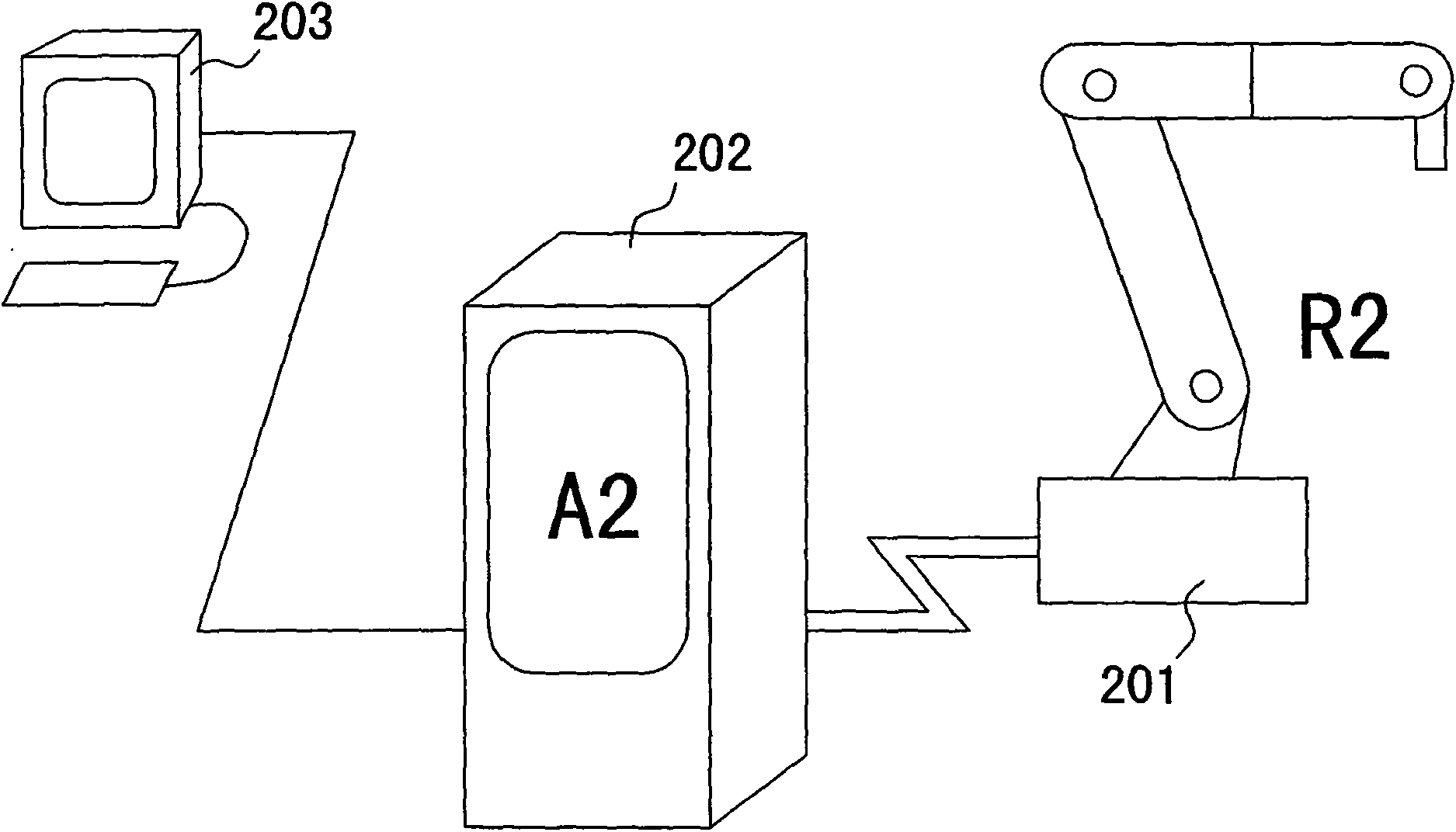

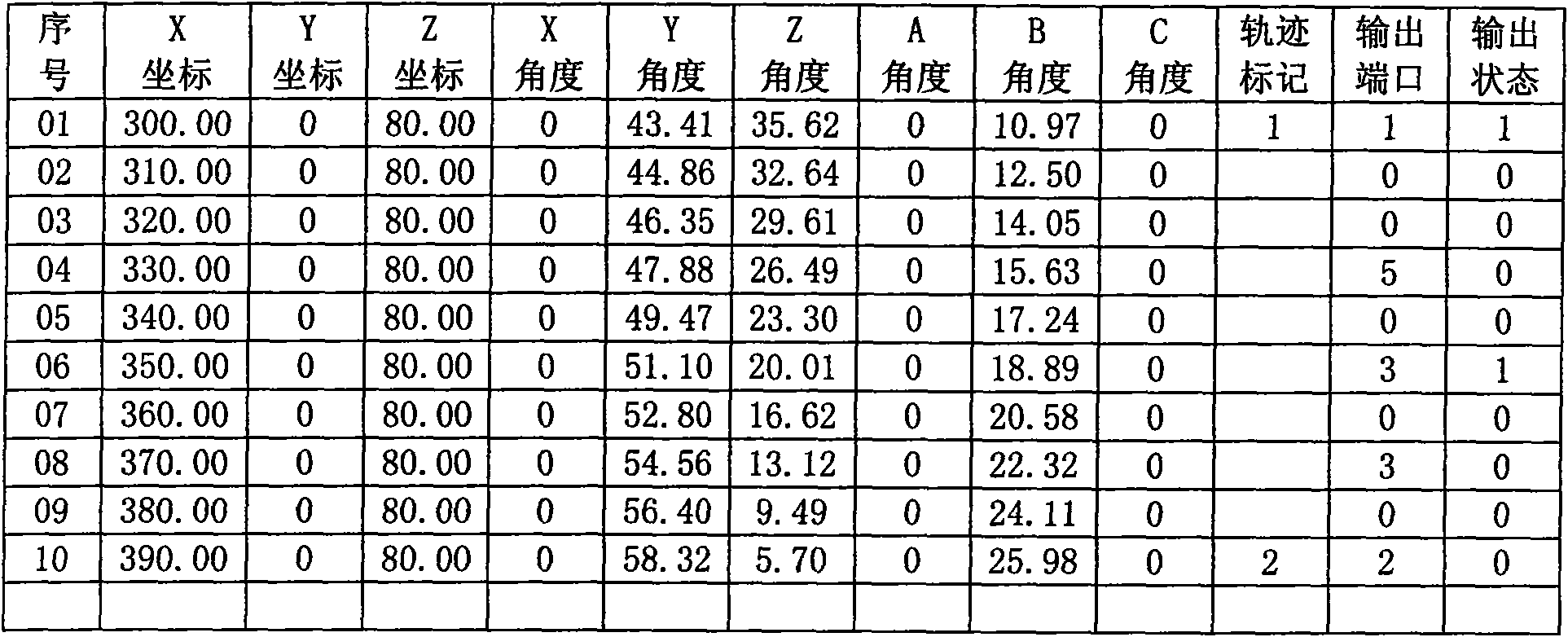

Opened obot control method based on table prgraming and its system

InactiveCN101551654AAchieve operational controlSimplify the control problemComputer controlSimulator controlMotion parameterSimulation

The invention discloses an opened robot control method based on table prgraming and its system, the method including the following steps: working out a table procedure in the control interface, to depict the movement gesture of the robot, and records the movement path of the robot; converting table procedure data, checking the process of the robot movement, at the same time setting the movement parameter of the robot; based on the table procedure data, the robot reading and performing the setup robot movement parameter. As a means of table procedureis adopted, and the check to the movement path of the robot is completed by data conversion function of the table procedure, and simultaneously movement parameter is added in the prgraming, to realize the operation control of opened robot based on table prgraming; and complex and time-consuming prgraming process of special robot speech is replaced by a prgraming mode of filling data in the table, so that the control and prgraming of the opened robot is directly simplified, and the operation service performance of the opened robot is significantly increased.

Owner:ADTECH SHENZHEN TECH

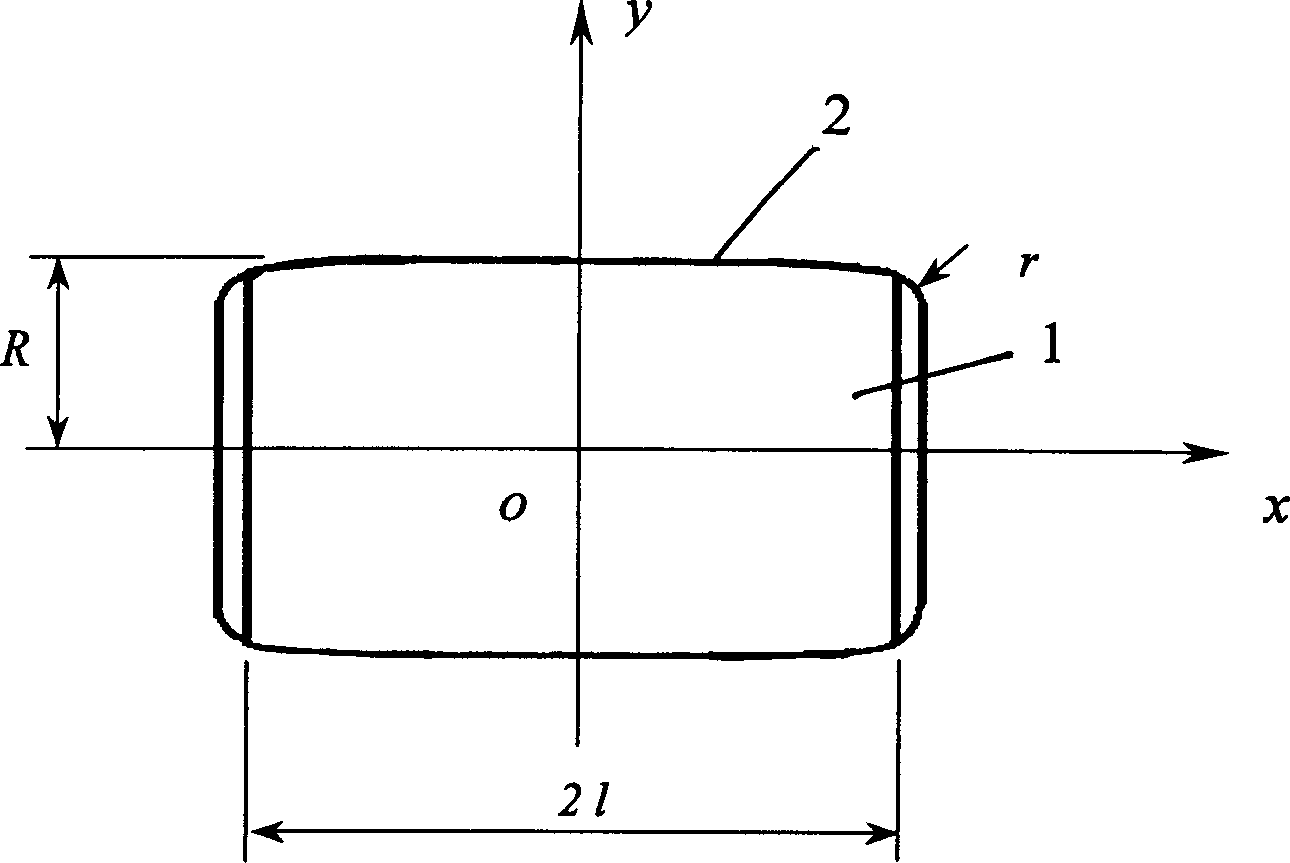

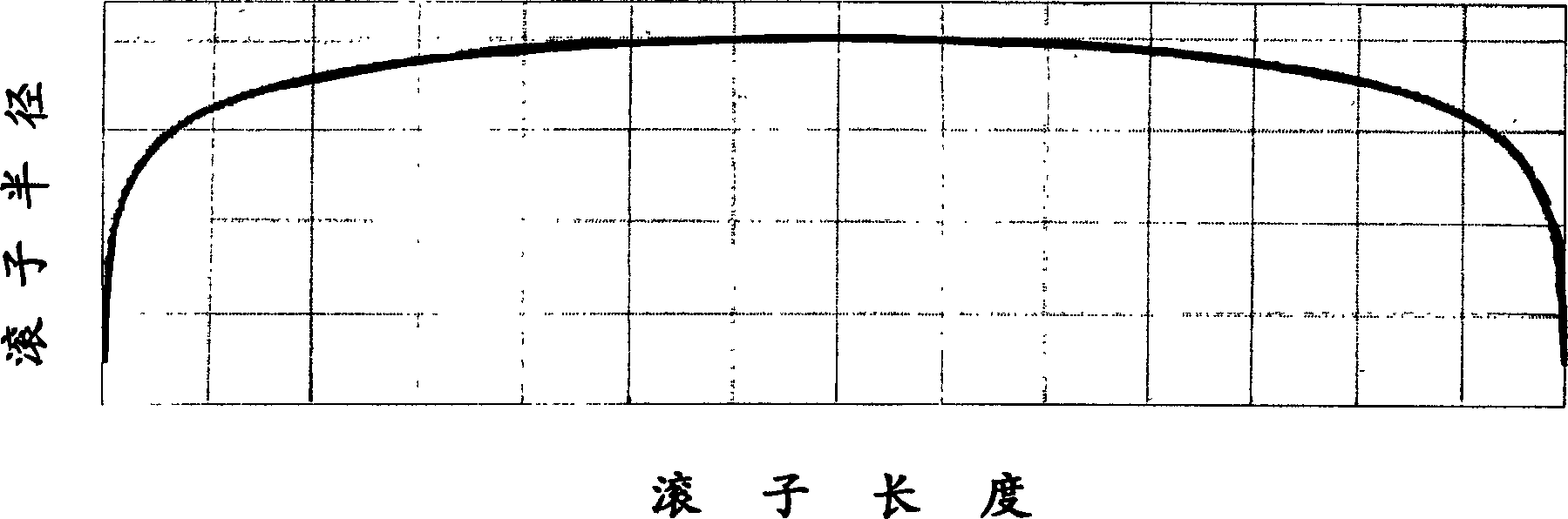

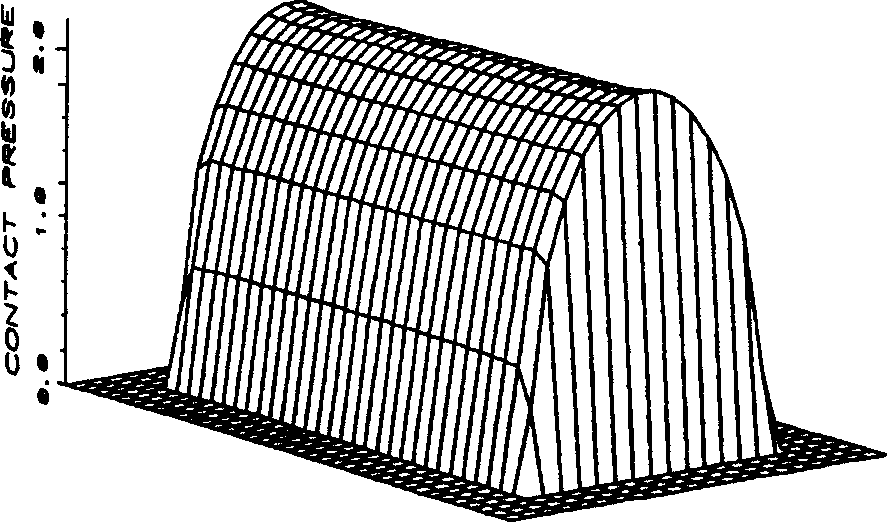

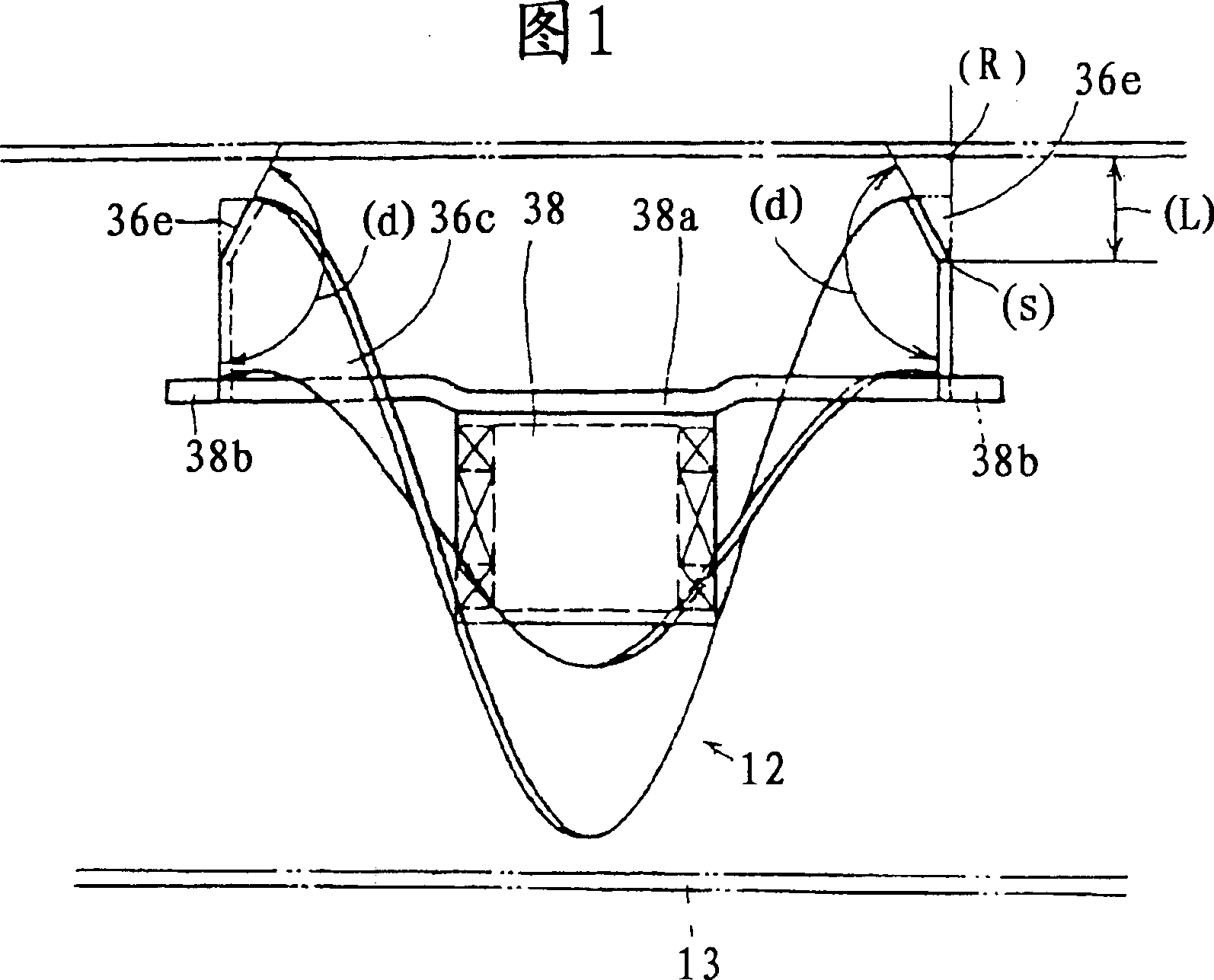

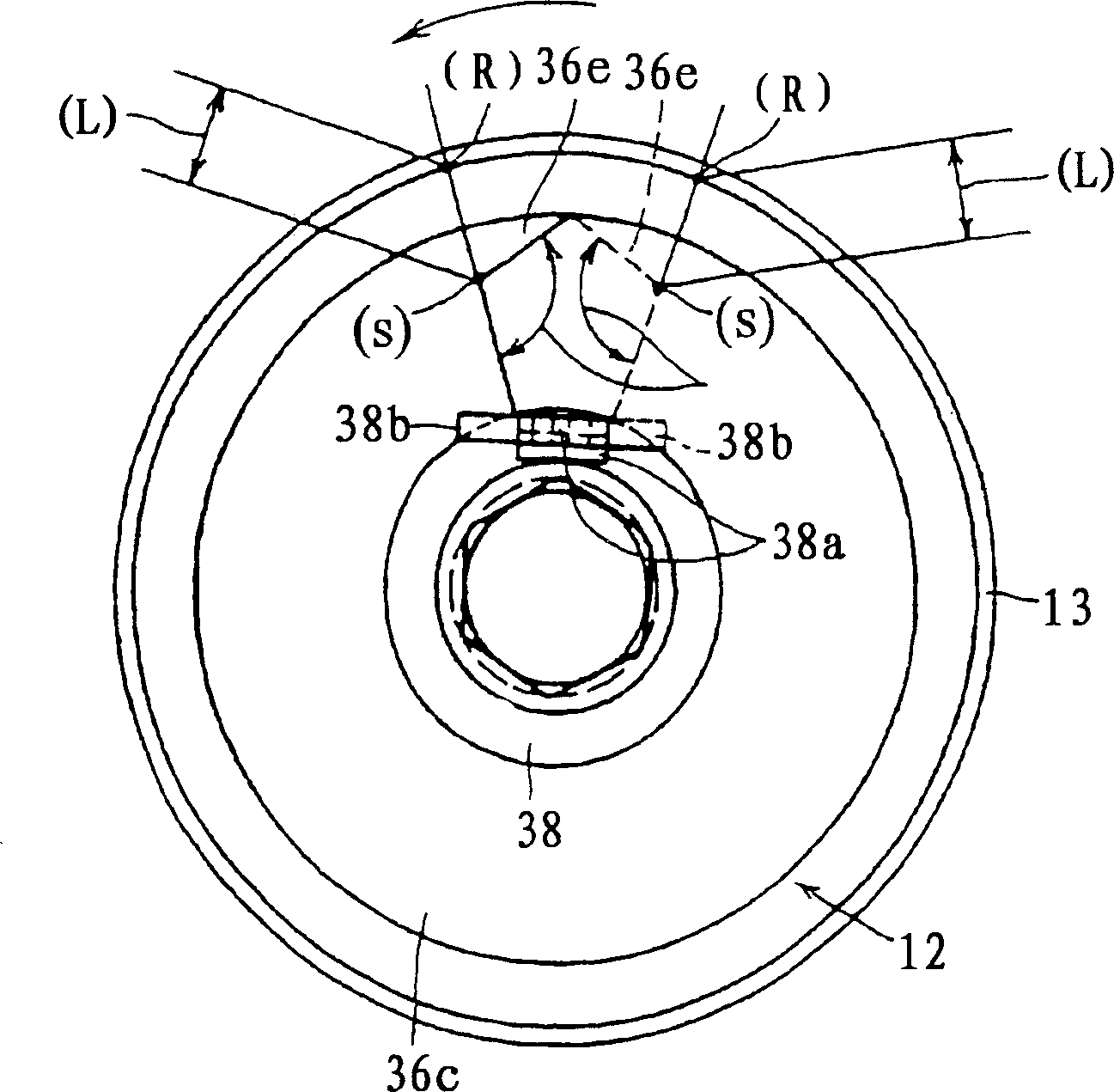

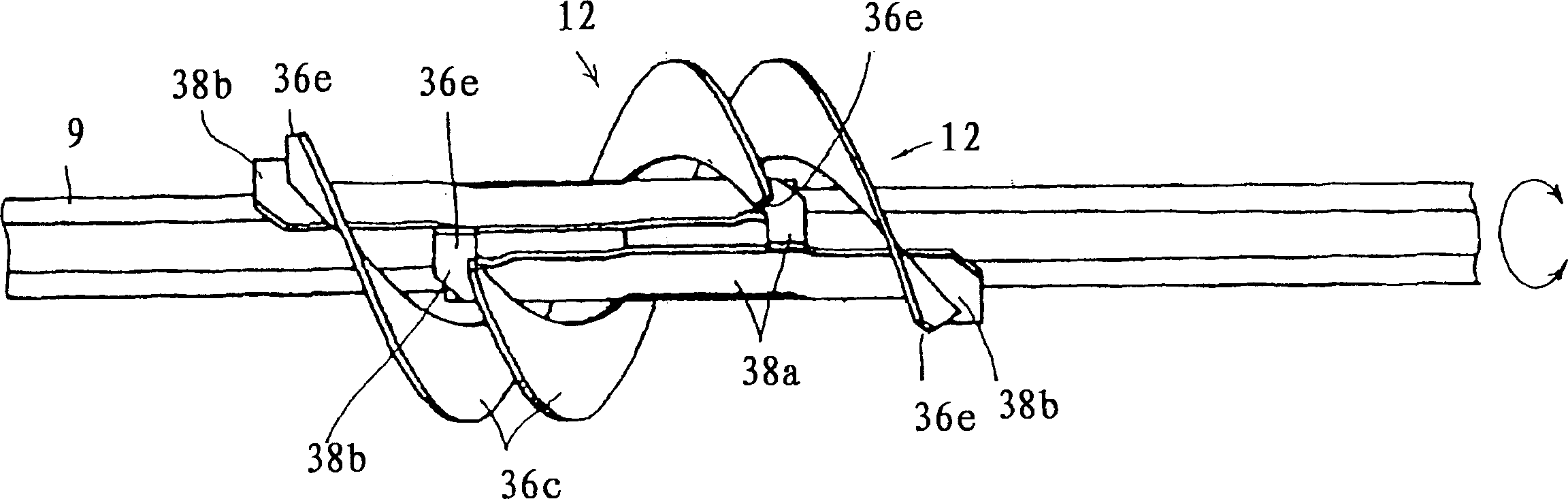

Cylindrical roller with logarithmic curve

ActiveCN1807910AEliminate edge effectsImprove rigidity and load carrying capacityBearing componentsEdge effectsContact mechanics

The invention relates to a logarithmic cylinder roller, whose generatrix of support surface is a logarithmic curve. The middle of said generatrix is protruded and two ends of generatrix are connected to two chamfering arc. The invention can eliminate the edge effect in the contact of cylinder roller to uniform distribute the contact pressure along the axes and improve the bearing ability and rigidity of roller contact couple, and the end part of cylinder roller can form a lubricate film to reduce the friction and abrasion in rolling. The better lubricate property can reduce the vibration and noise, improve the stability, improve the bearing ability and the application for worse working condition. The invention can apply the rolling needle too and other linear contact mechanics elements.

Owner:HANGZHOU LOGROLE BEARING & ROLLER

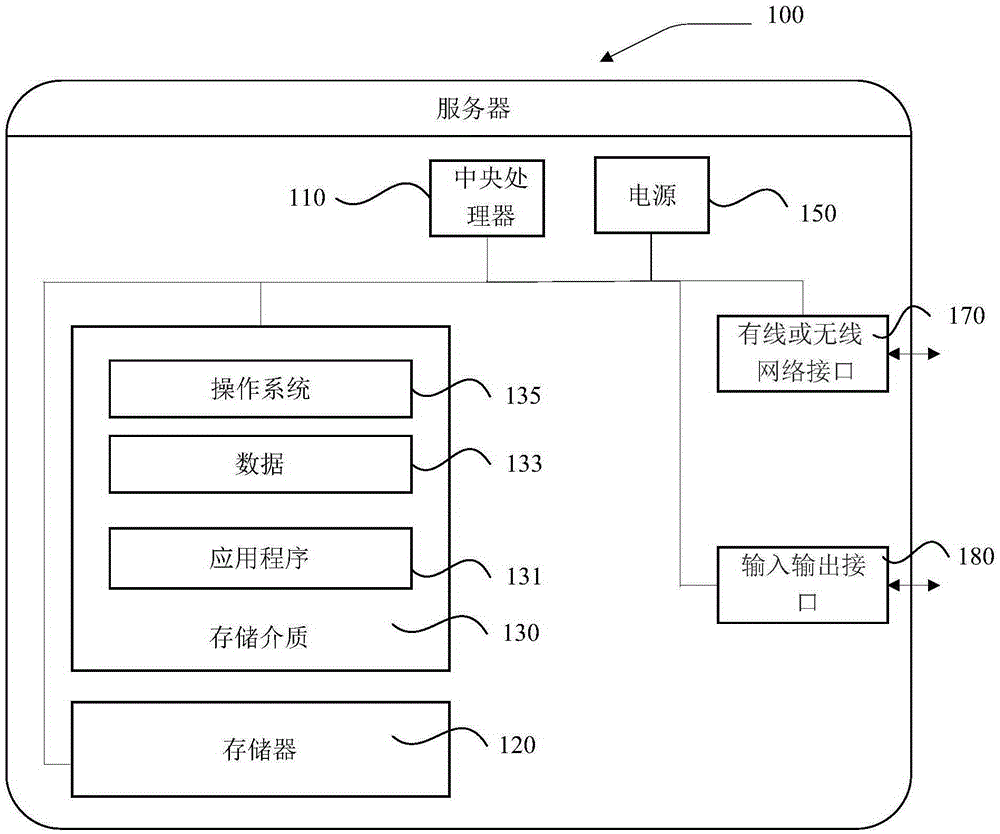

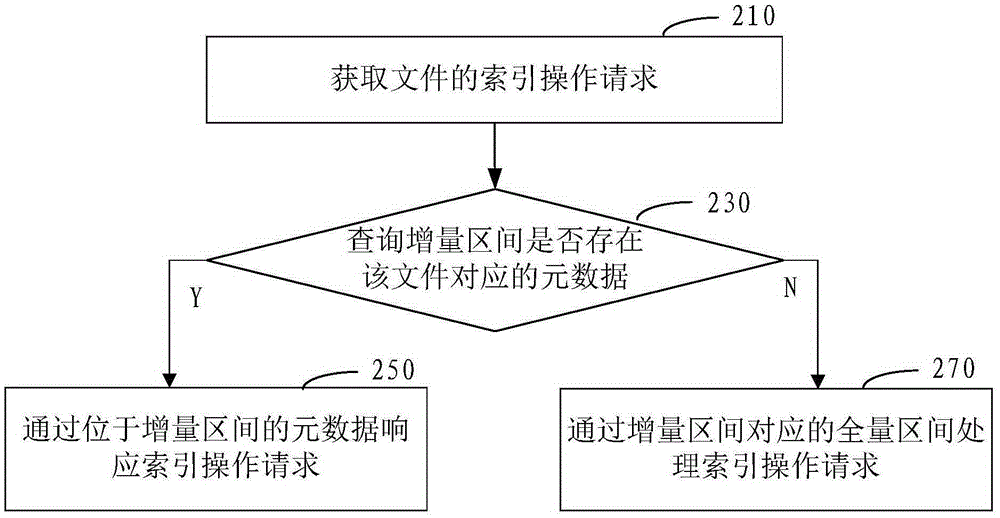

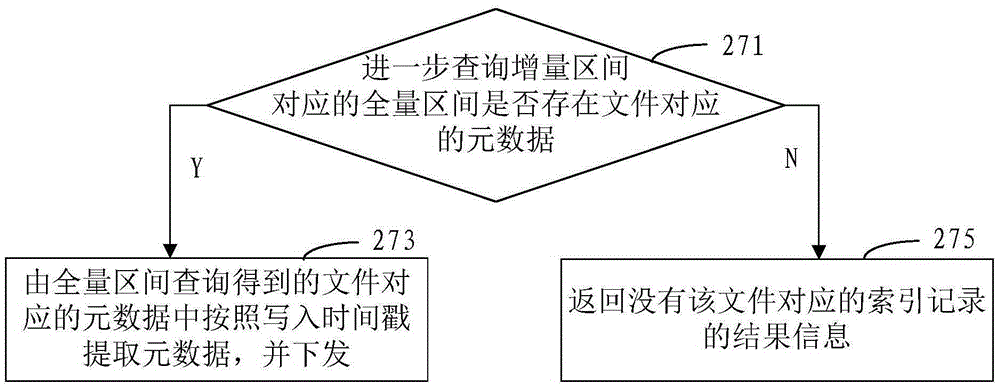

Method and system for implementing index in file storage

ActiveCN106649403AImprove read and write performanceImprove operational performanceFile access structuresSpecial data processing applicationsMetadataDatabase

The invention provides a method and system for implementing an index in a file storage. The method comprises the steps of obtaining a file index operation request, querying whether the metadata corresponding to the file exists in the increment interval, if the answer is yes, responding to the index operation request through the metadata located in the increment interval, if the answer is no, processing the index operation request through the full range corresponding to the increment interval, wherein the metadata comprises an index corresponding to the file. Moreover, an index implementation system in the file storage that matches with the method is also provided. The method and system for implementing index in file storage cab meet the needs of mass memory, and substantially enhance the operation performance of the index.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

Mechanical device for immediately adjusting installing angle of guide vane

InactiveCN104847704AImprove static pressure efficiencyImprove work efficiencyPump componentsPumpsEngineeringAxial thrust

The invention relates to a mechanical device for immediately adjusting an installing angle of a guide vane. The mechanical device can immediately play optimum performance under the different working conditions and has the advantages of being capable of saving effort in adjustment and convenient to user. According to the technical scheme, the mechanical device for immediately adjusting the installing angle of the guide vane comprises a guide vane hub located at the upstream position of a box, coaxial with the box and arranged in a fan housing and a plurality of guide vane blades evenly distributed on the outer circumferential face of the guide vane hub along the circumference and is characterized in that the guide vane blades are respectively and rotatably hinged to the outer circumferential face of the guide vane hub, an adjusting mechanism drives and controls rotating angles of the guide vane blades and comprises prism adjusting shafts capable of moving along the axis of the fan housing and provided with side prisms identical to the guide vane blades in number, groove block matching structures converting movements of the prism adjusting shafts into rotation of the guide vane blades around the hinge axis and an adjusting motor exerting axial thrust on the prism adjusting shafts.

Owner:ZHEJIANG SCI-TECH UNIV

Grain discharging device

The present invention relates to a grain discharge equipment. It is characterized by that in the fixed conveying tube connected with grain longitudinal conveying tube in the storage container of grains to be discharged a mobile conveying tube which can be freely extended along the length direction is mounted so as to form an extensible grain conveying device. Besides, said grain discharge equipment also equipped with a upward, downward, leftward and rightward switching capable of making the grain discharge hole be moved upward, downward, leftward and rightward.

Owner:ISEKI & CO LTD

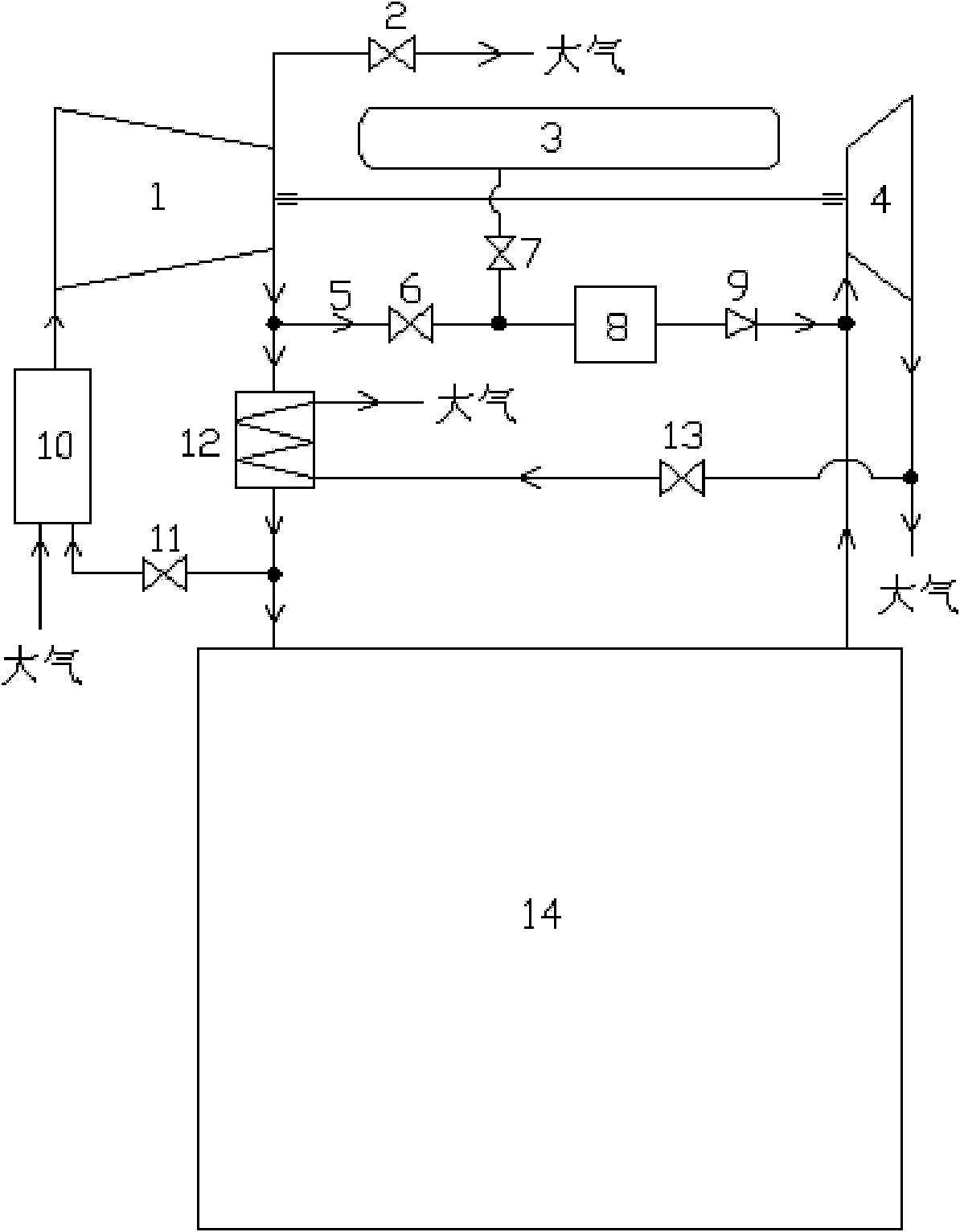

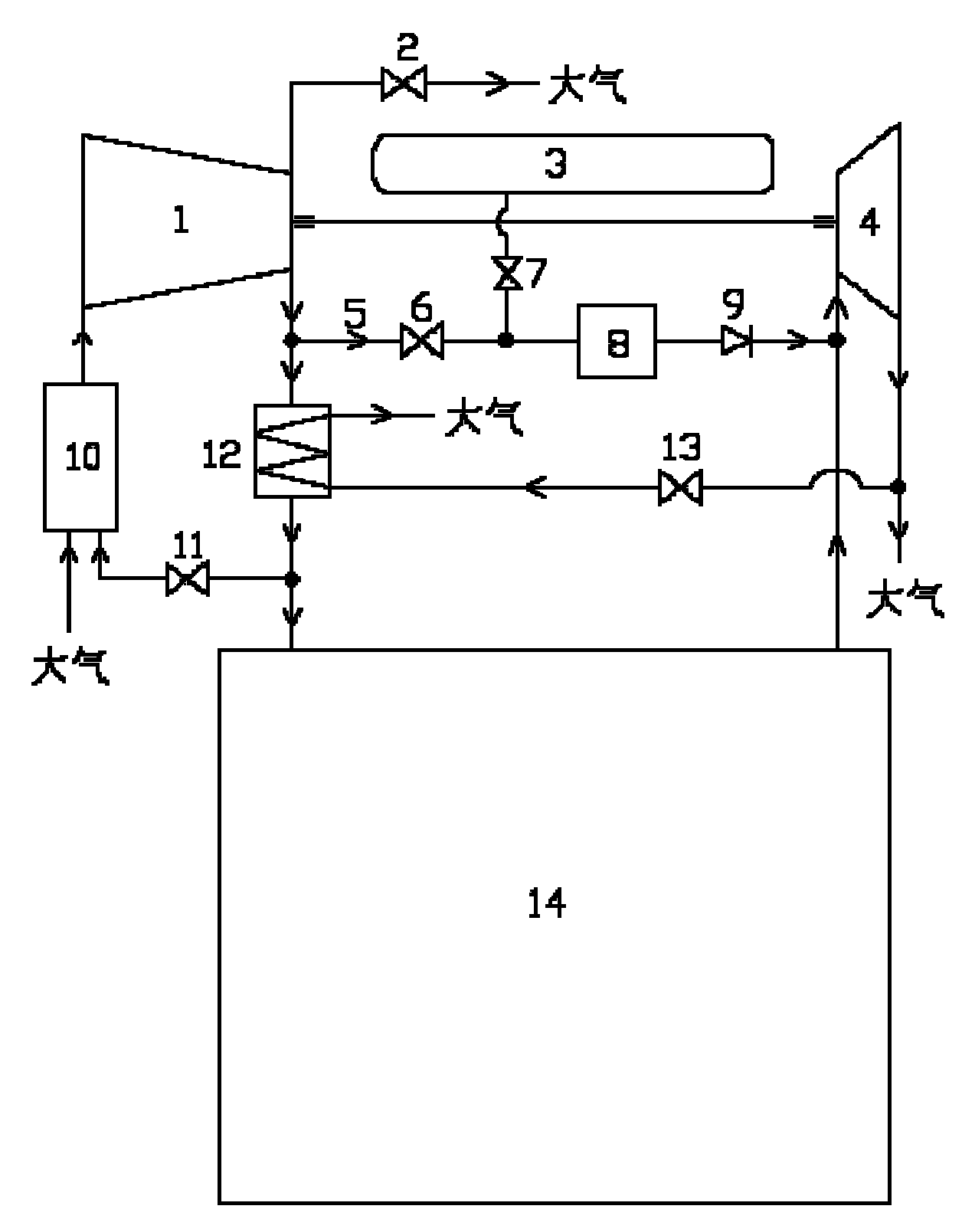

Bypass afterburning composite regenerative turbo supercharging system of boiler

InactiveCN102183003AImprove transient response characteristicsIncrease vitalitySteam generation plantsMachines/enginesAtmospheric airGas compressor

The invention aims to provide a bypass afterburning composite regenerative turbo supercharging system of a boiler. The system comprises a boiler, a gas compressor, a turbine, valves, a bypass pipe, an afterburning chamber, a gas storage tank, a regenerator and a mixing pipe, wherein an inlet of the gas compressor is provided with the mixing pipe, and an outlet of the gas compressor is connected with the boiler through a regenerative pipe; a first adjusting valve is arranged between the mixing pipe and the regenerator; a first branch of an outlet of the turbine is connected with atmosphere; a second branch of the turbine is connected with the regenerator through a second adjusting valve; the bypass pipe, a bypass valve, the afterburning chamber and a check valve are arranged between the gas compressor and the turbine; and the gas storage tank is connected with the afterburning chamber through a gas escape valve. Through the system, the running of a supercharging set is free from limitation of a flue gas and air system and a steam system of the boiler, transient response characteristic of a supercharged boiler is improved, low working condition performance and starting performance of the supercharged boiler are improved, thermal balance and steam balance of a ship power device are more stable, and viability of a ship is improved.

Owner:HARBIN ENG UNIV

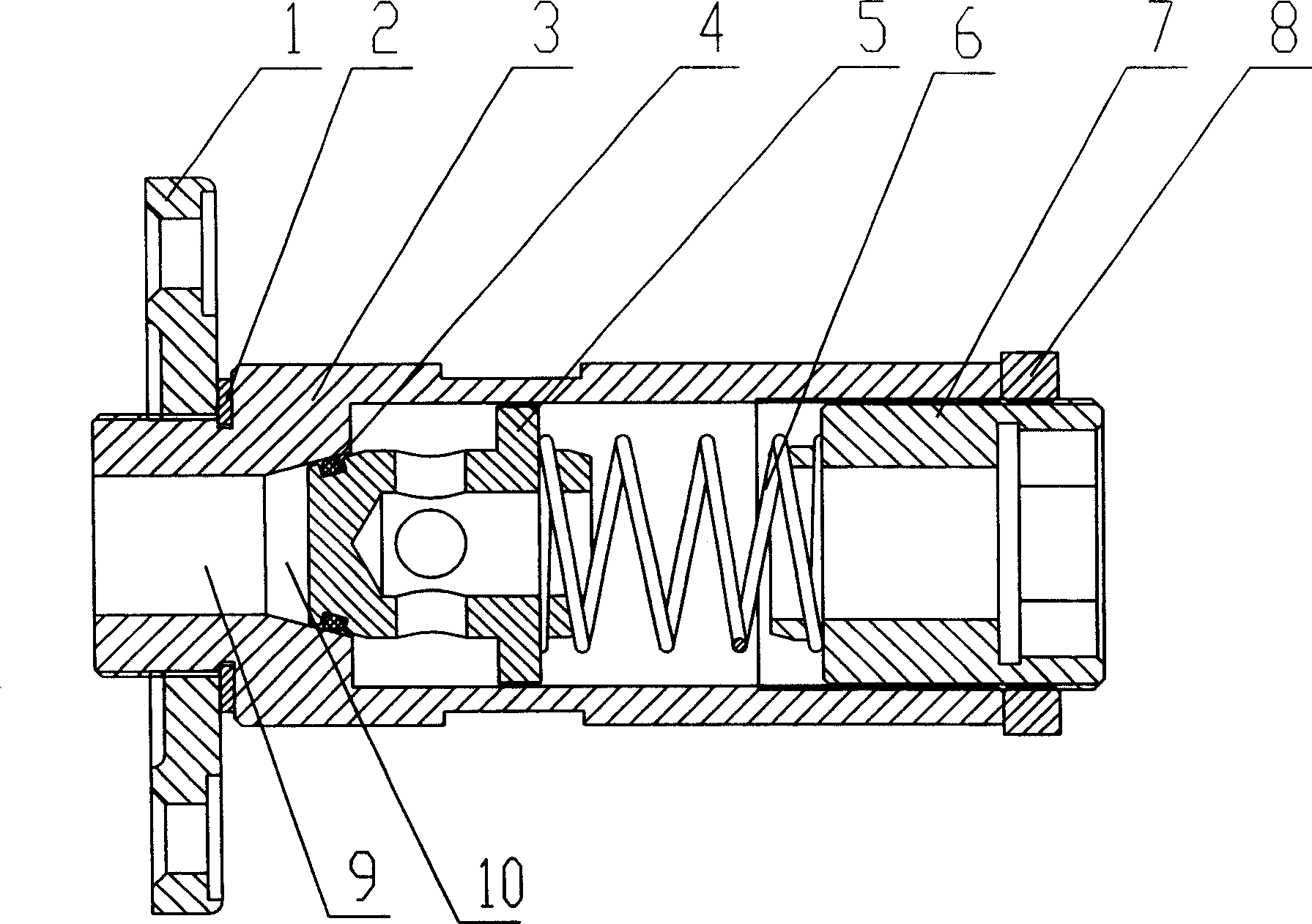

Automatic deflation equipment of turbo-charging system of medium speed diesel engine

InactiveCN101008343AImprove low-speed high-torque performanceImprove operational performanceInternal combustion piston enginesEngine componentsLow speedEngineering

The invention discloses an automatic discharge device of middle-speed diesel boosting system, comprising a discharge valve with hollow chamber and an air inlet through to the air inlet tube of diesel engine, a discharge valve in the chamber of discharge valve and near one side of air inlet to sliding along the chamber, a hollow limiting valve screw plug at another end, and a limiting spring between the discharge valve and the limiting valve screw plug. The discharge valve at the outer end of the limiting valve screw plug is arranged with a limiting valve locking cap; the air inlet of the discharge vale is connected to the sealing end cover fixed with the air inlet tube of diesel engine; the axial interface between the sealing end cover and the discharge valve is arranged with a sealing ring. The invention has simple production, small volume, and low cost, while it can improve the low-speed large-torsion property.

Owner:WEICHAI POWER CO LTD

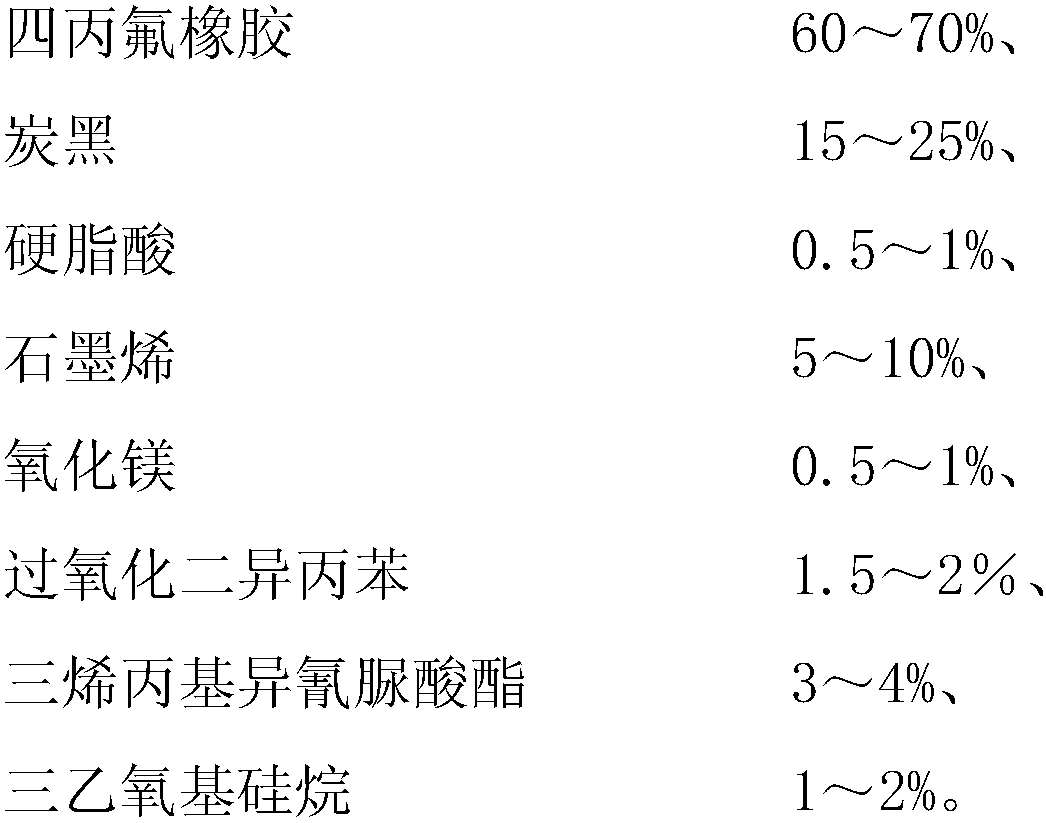

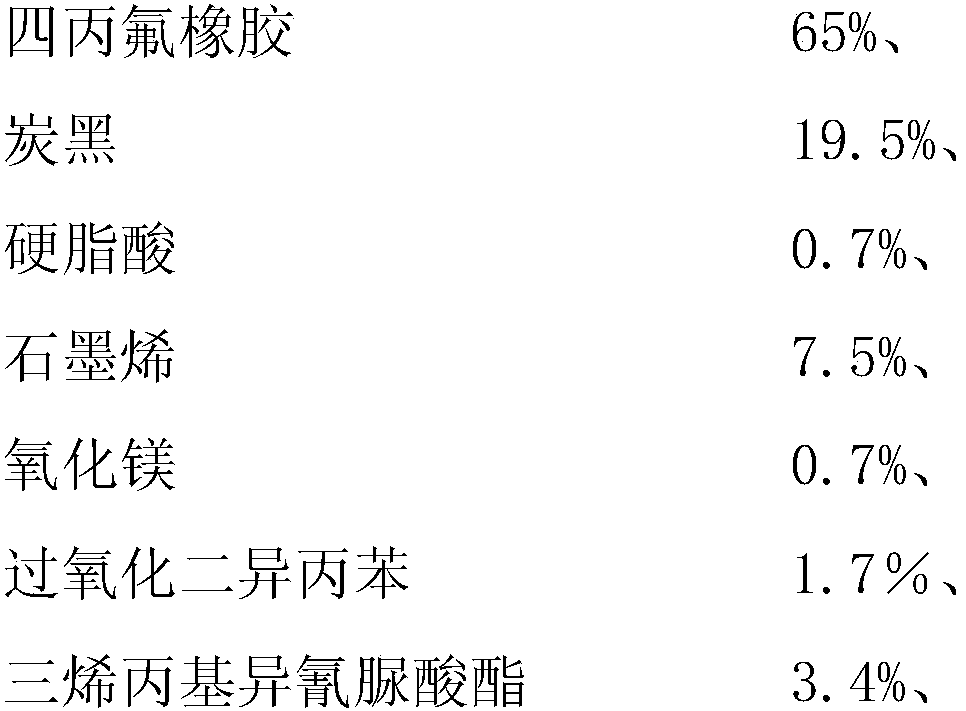

High-temperature-resistant and high-pressure-resistant rubber material as well as preparation method and application thereof

InactiveCN109401139AImprove operational performanceImprove processing operabilityCarbon blackDicumyl peroxide

The invention discloses a high-temperature-resistant and high-pressure-resistant rubber material as well as a preparation method and application thereof. The rubber material is prepared from the following raw materials in percentage by mass: 60-70% of tetrafluoroethylenepr-opylene copolymer, 15-25% of carbon black, 0.5-1% of stearic acid, 5-10% of graphene, 0.5-1% of magnesium oxide, 1.5-2% of dicumyl peroxide, 3-4% of triallyl isocyanurate and 1-2% of triethoxysilane. According to the high-temperature-resistant and high-pressure-resistant rubber material as well as the preparation method andthe application thereof, the components are synergistic and compatible, the prepared rubber material can bear a high temperature of 205 DEG C and a high pressure difference of 105 MPa at the same time, the high-temperature-resistant performance and the high-pressure-resistant performance are excellent, the resistance to a high hydrogen sulfide environment with 20% H2S is achieved, the economic benefits are remarkable, and the application prospect is good.

Owner:CHINA PETROCHEMICAL CORP +2

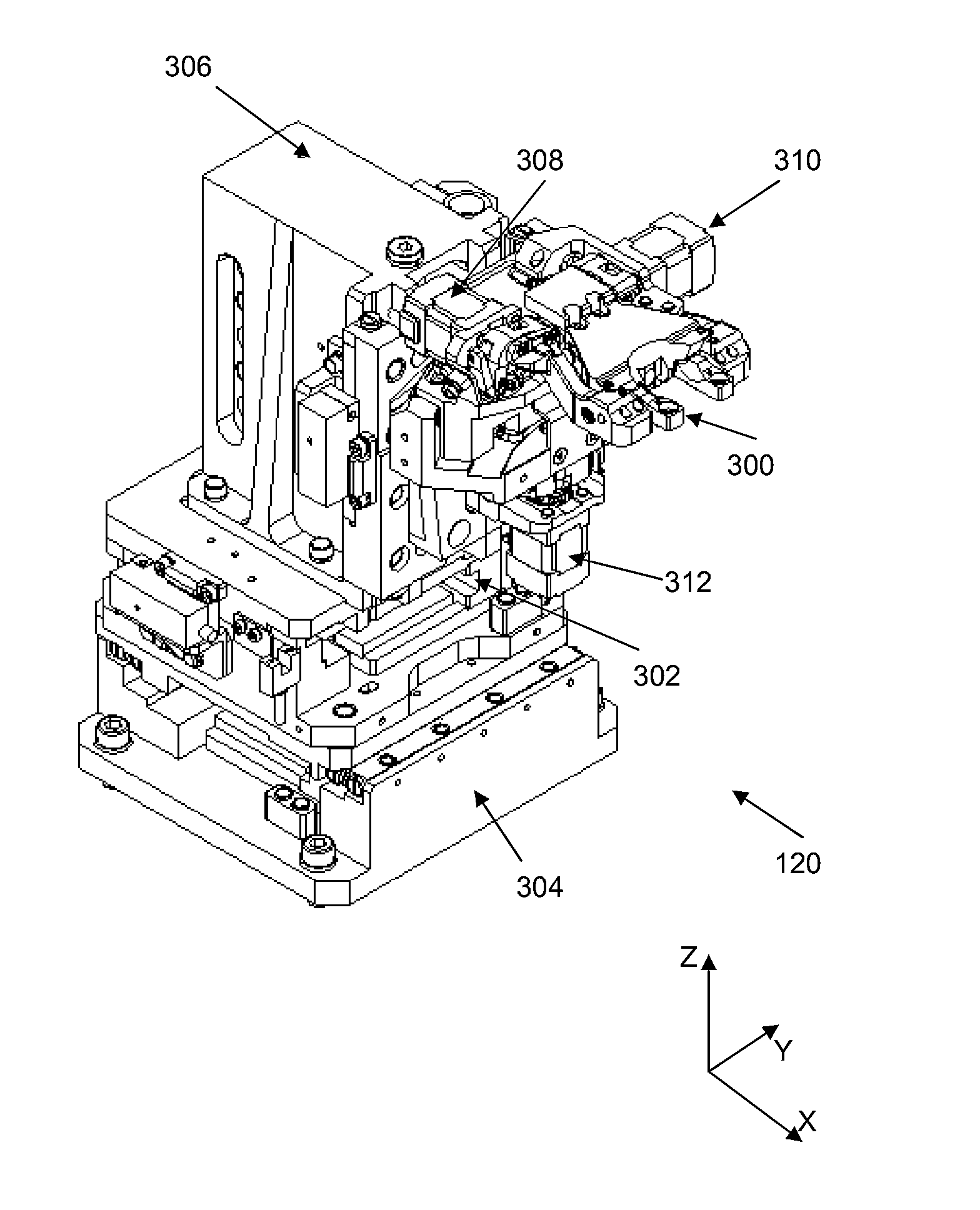

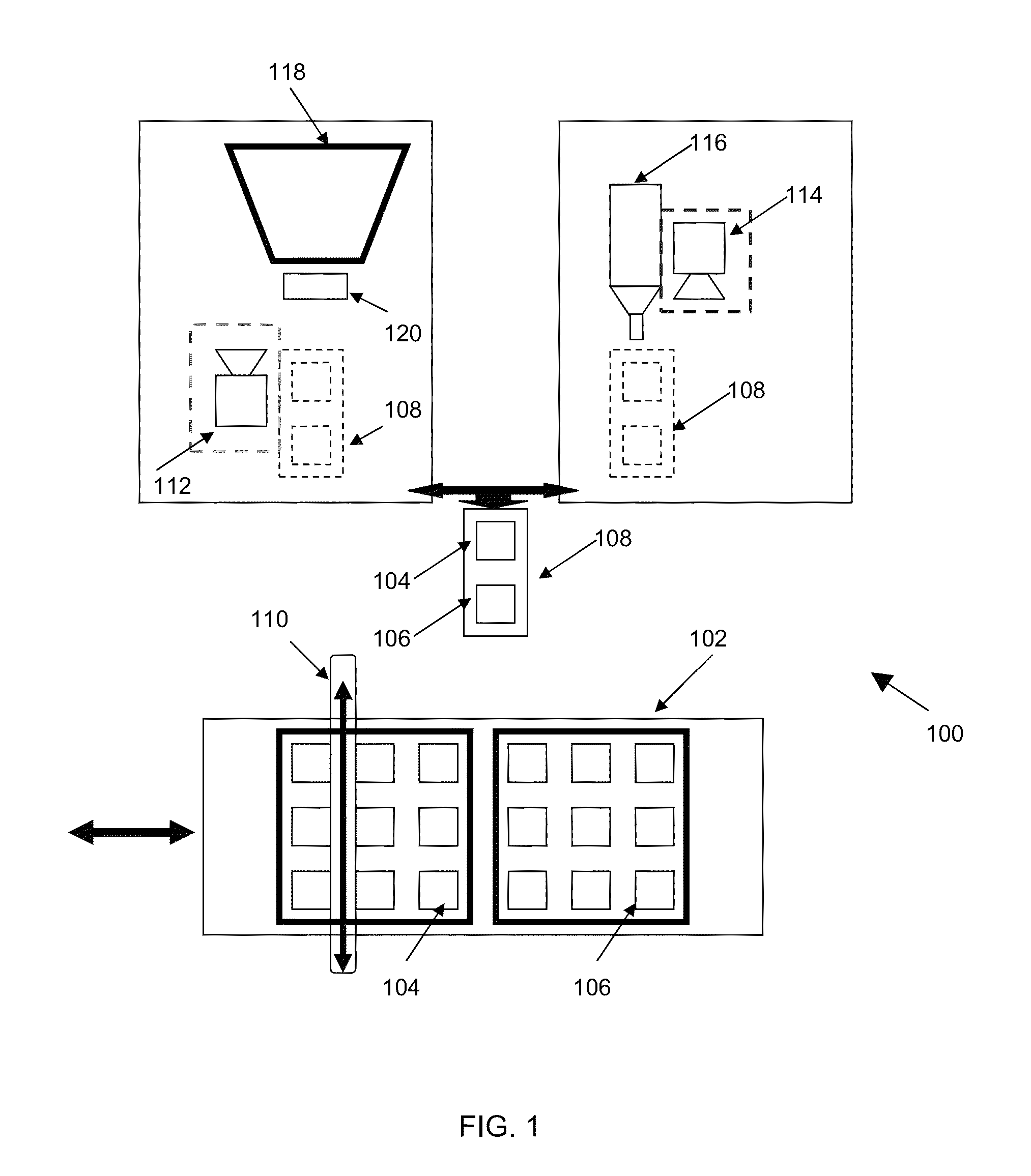

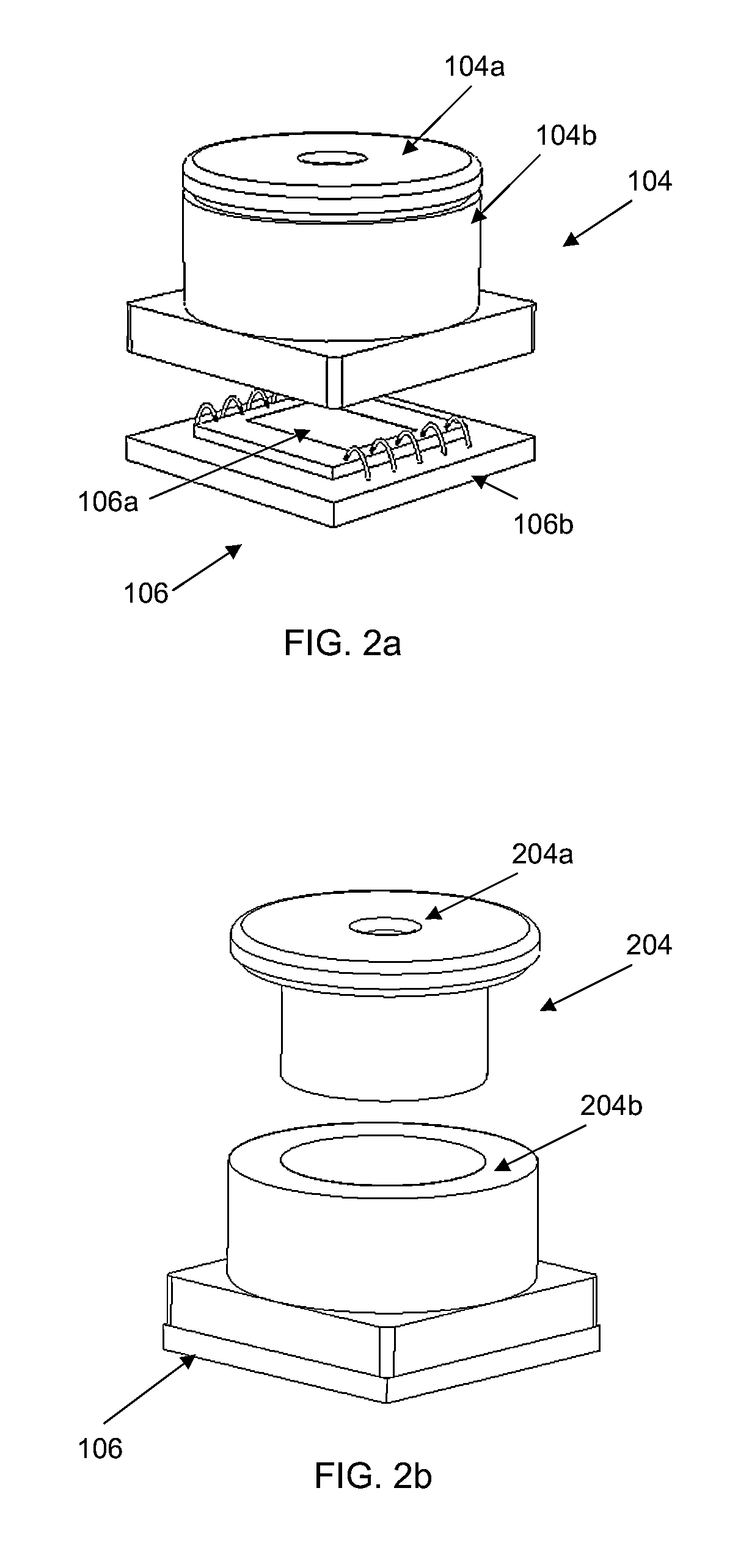

Apparatus for assembling a lens module and an image sensor to form a camera module, and a method of assembling the same

ActiveUS9009952B2Improve operational performancePrecise alignmentAutomatic control devicesAssembly machinesCamera lensComputer module

An apparatus for assembling a lens module and an image sensor to form a camera module. The apparatus comprises i) a positioning system for adjusting a relative arrangement between the lens module and the image sensor; and ii) an inspection system operative to view fiducials of the lens modules and the image sensor. In particular, the positioning system is configured to align the lens module and the image sensor based on a relative alignment of the respective fiducials of the lens module and the image sensor as viewed by the inspection system. A method of assembling a lens module and an image sensor to form a camera module is also disclosed.

Owner:ASMPT SINGAPORE PTE LTD

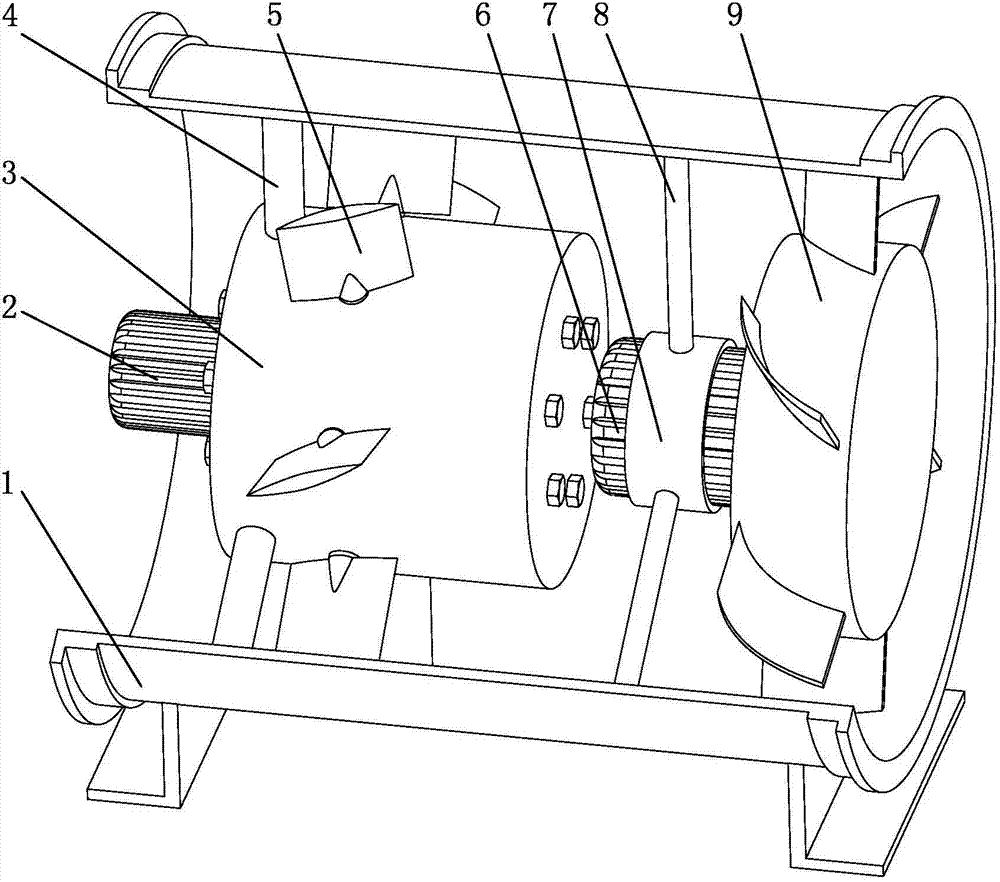

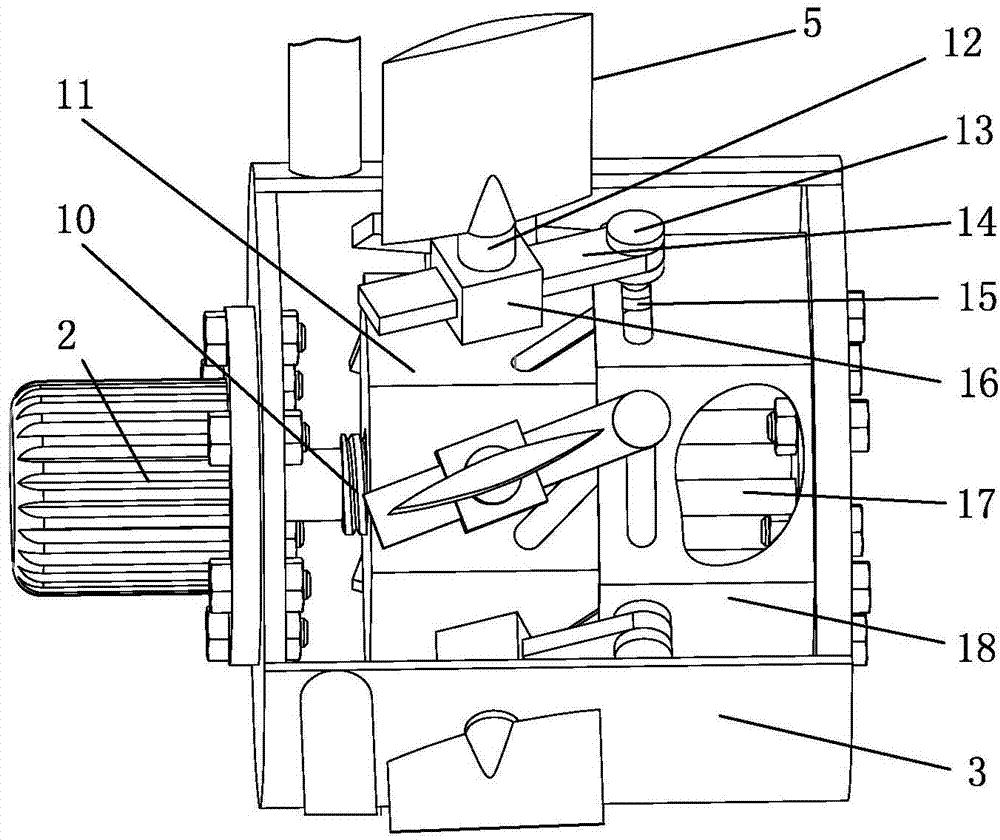

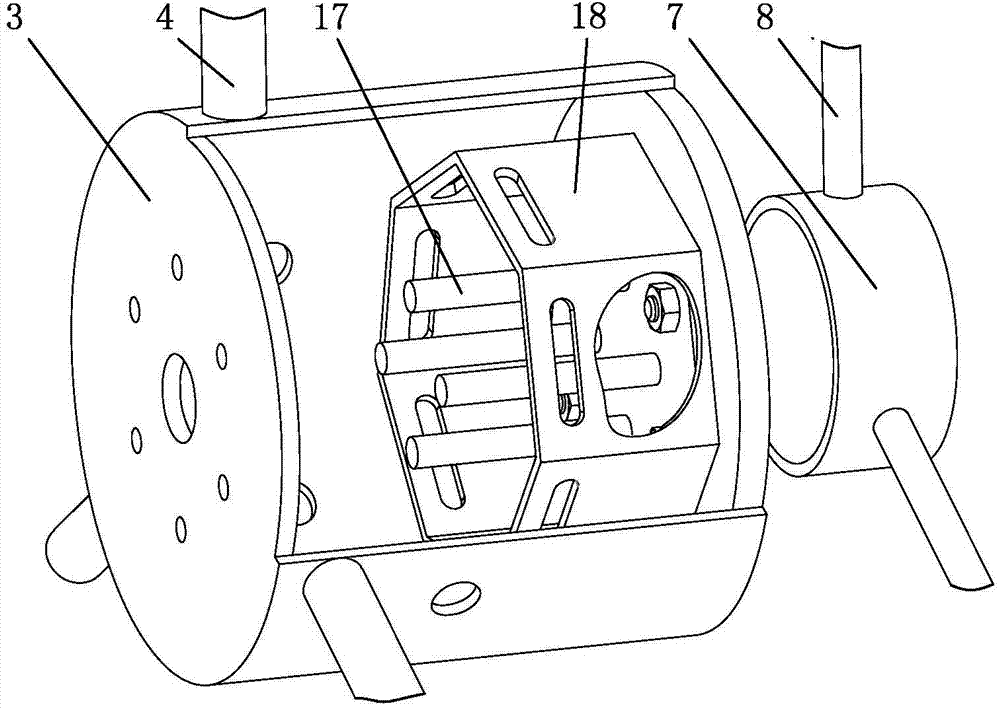

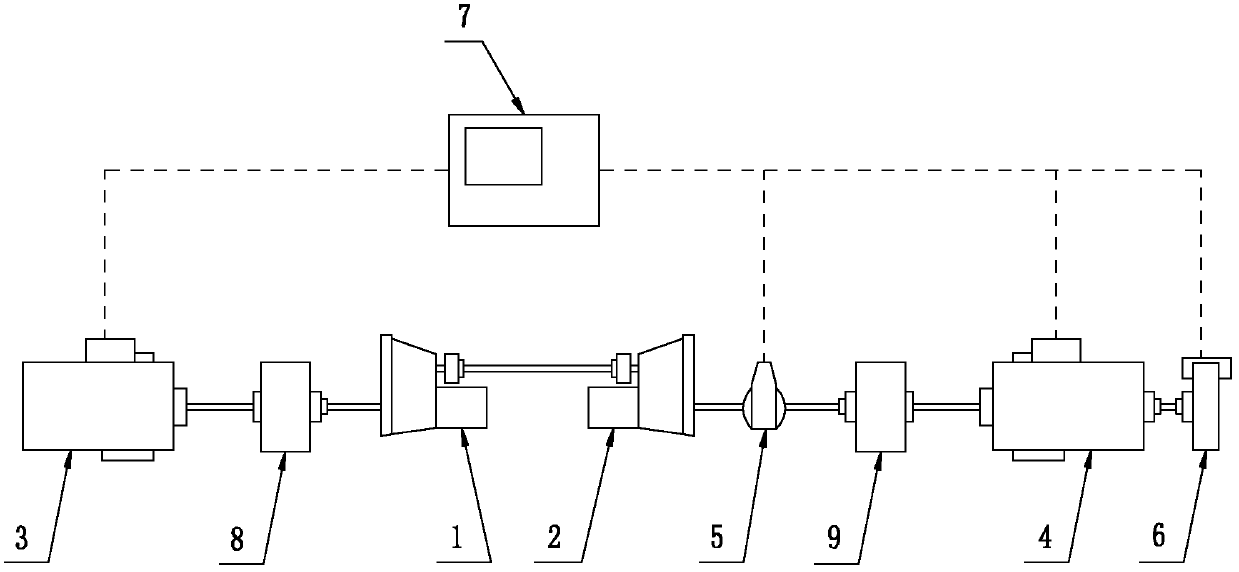

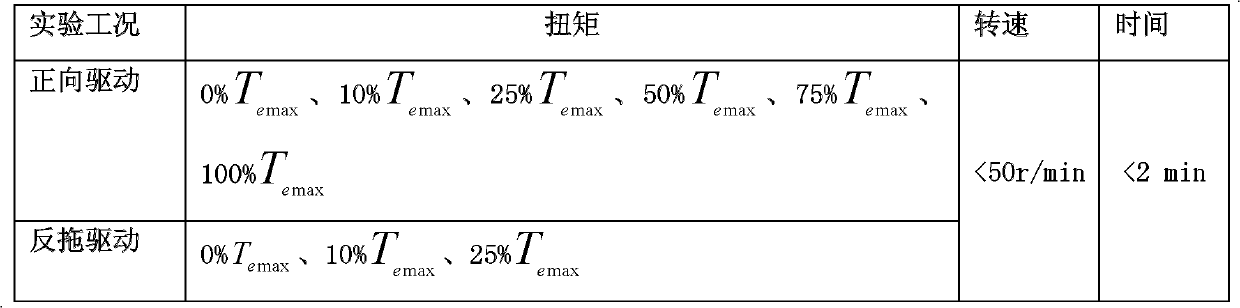

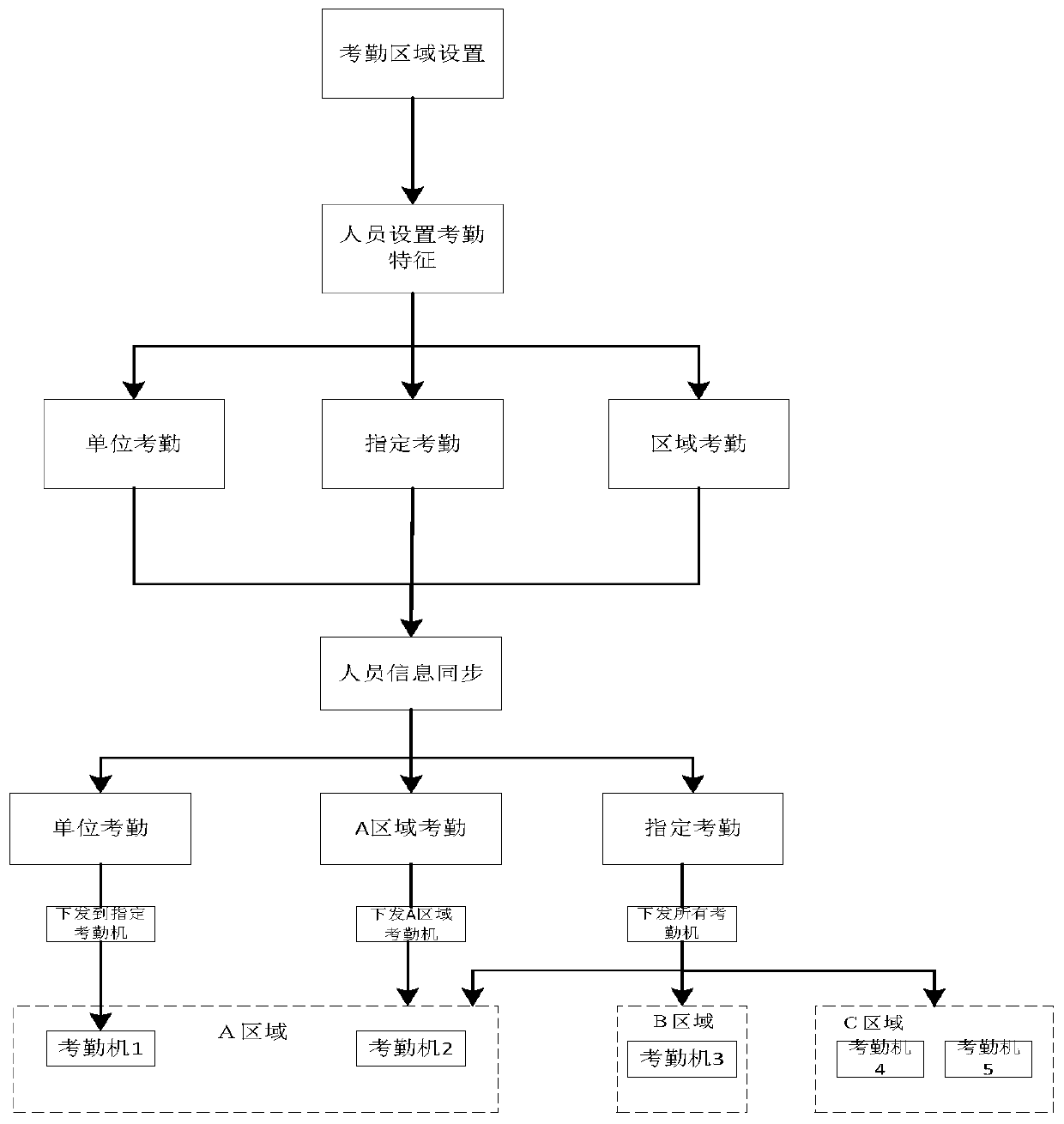

Transmission gear contact pattern experimental facility

ActiveCN102519721AImprove efficiencyQuality improvementMachine gearing/transmission testingElectric machineDrive shaft

The invention discloses a transmission gear contact pattern experimental facility, which comprises two test transmissions of which the output ends are connected through a transmission shaft, and is characterized by further comprising a driving motor, a dragging motor, a torsion sensor, a motor brake and a PC (Personal Computer) controller, wherein the output shaft of the driving motor is connected with the input end of the first test transmission; the output shaft of the dragging motor is connected with one end of the torsion sensor, the other end of the torsion sensor is connected with the input end of the second test transmission through the transmission shaft, and the tail end of the dragging motor is connected with the motor brake; and the driving motor, the dragging motor, the torsion sensor and the motor brake are all electrically connected with the PC controller. The transmission gear contact pattern experimental facility disclosed by the invention has the advantages of high automation degree, stabile performance, good detection precision, and capability of greatly increasing the efficiency and quality of a transmission gear contact pattern experiment.

Owner:GIF RES CENT CHINA

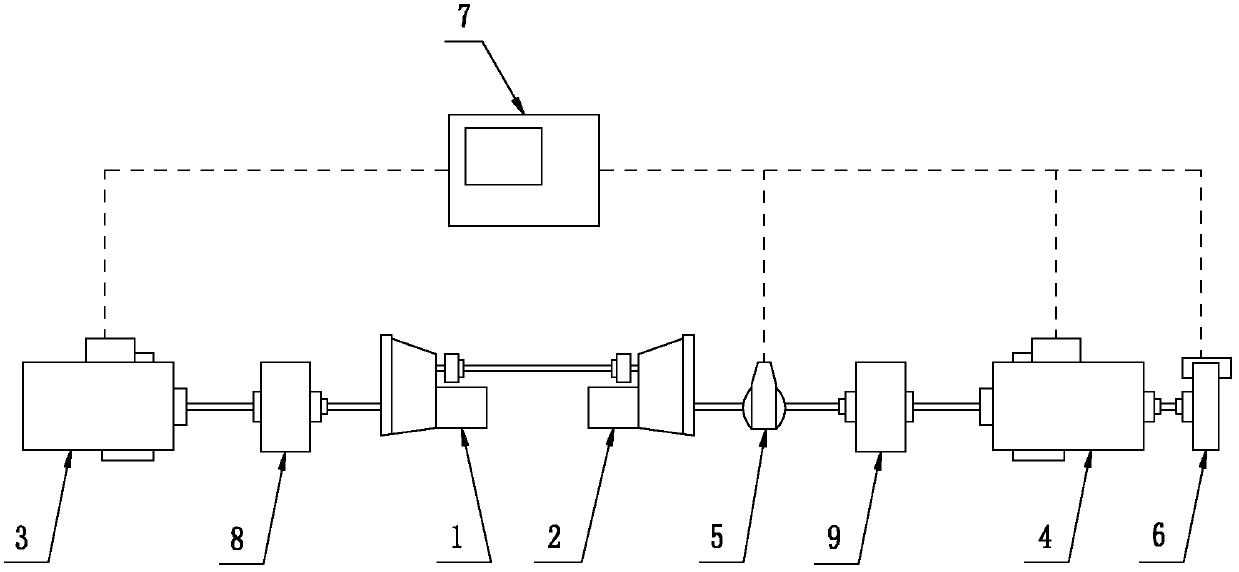

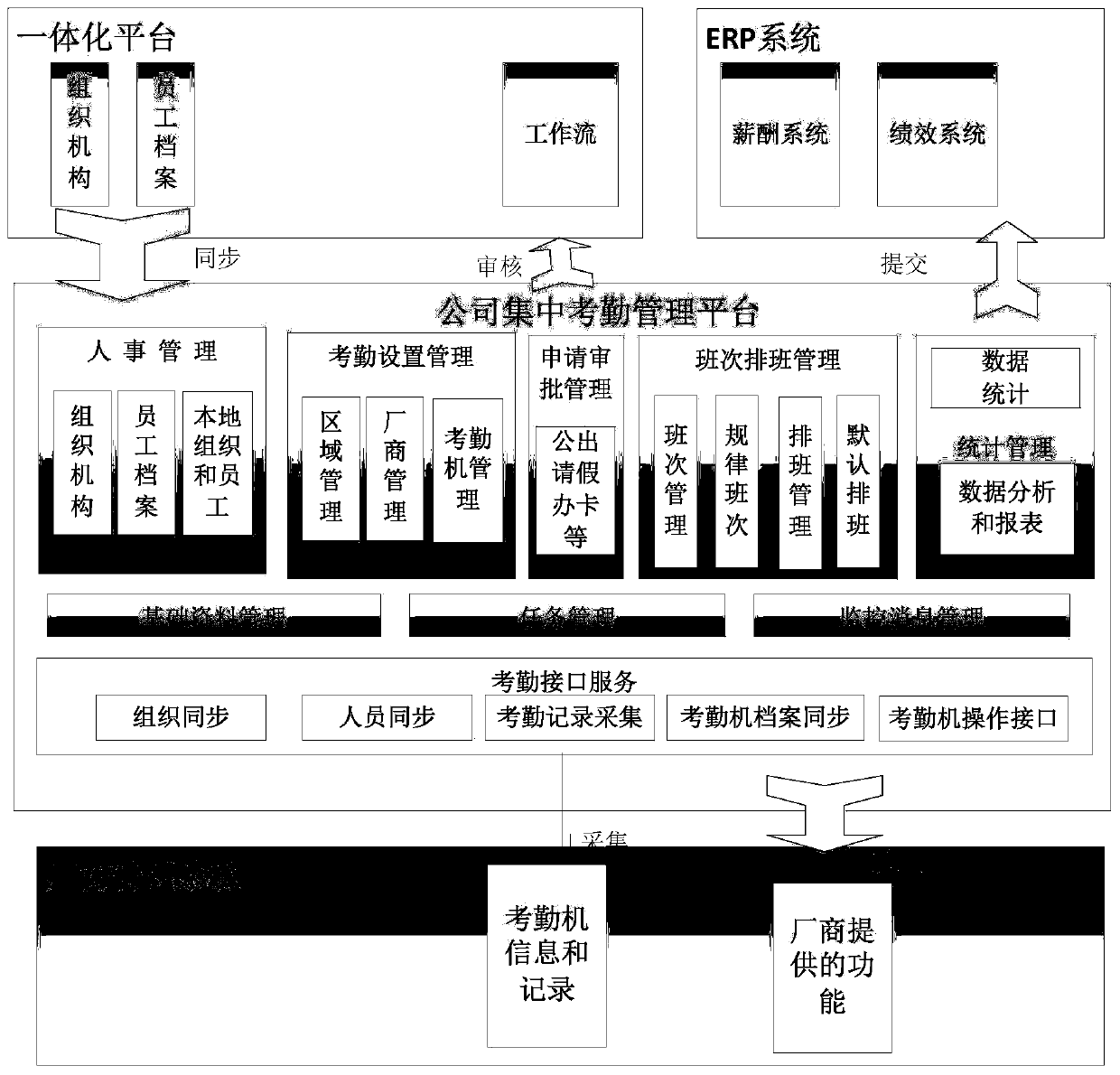

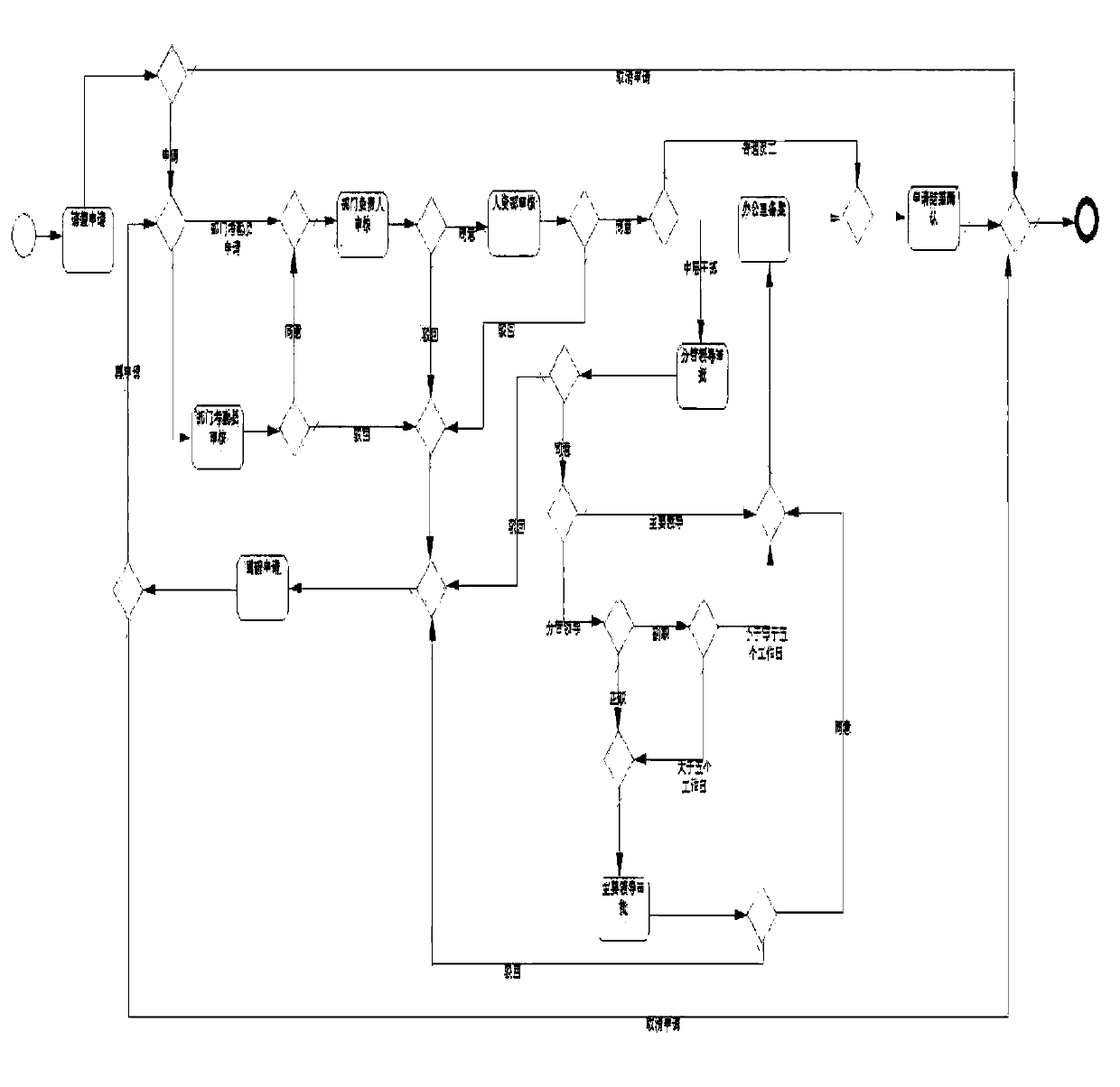

Centralized attendance intelligent management system for cross-regional large-scale enterprises

InactiveCN110288313ARealize the full coverage mode of attendanceSolve the problem of swiping card attendanceRegistering/indicating time of eventsOffice automationButt jointIntelligent management

The invention discloses a centralized attendance intelligent management system for cross-regional large-scale enterprises. The centralized attendance intelligent management system comprises a personnel management module, an attendance setting module, an application approval management module, a scheduling management module and a statistical management module, wherein the personnel management module is used for synchronizing all personnel information of an enterprise according to an ERP system of a head office; the attendance setting module is used for dividing attendance areas and classifying and setting the attendance modes; the application approval management module is used for carrying out on-line multi-level leader approval of overtime work, leave asking and business trips; the scheduling management module is used for setting a scheduling form and a scheduling form of the to-be-checked personnel; and the statistical management module is used for generating an attendance report and calculating an attendance index. According to the invention, a centralized management mode of the cross-regional large-scale enterprises is realized, the standard interfaces are standardized, so that each sub-point can easily realize butt joint with a main system, the system construction investment and operation and maintenance cost are greatly reduced, and the hardware resource intensification level is improved.

Owner:JIANGSU FRONTIER ELECTRIC TECH +1

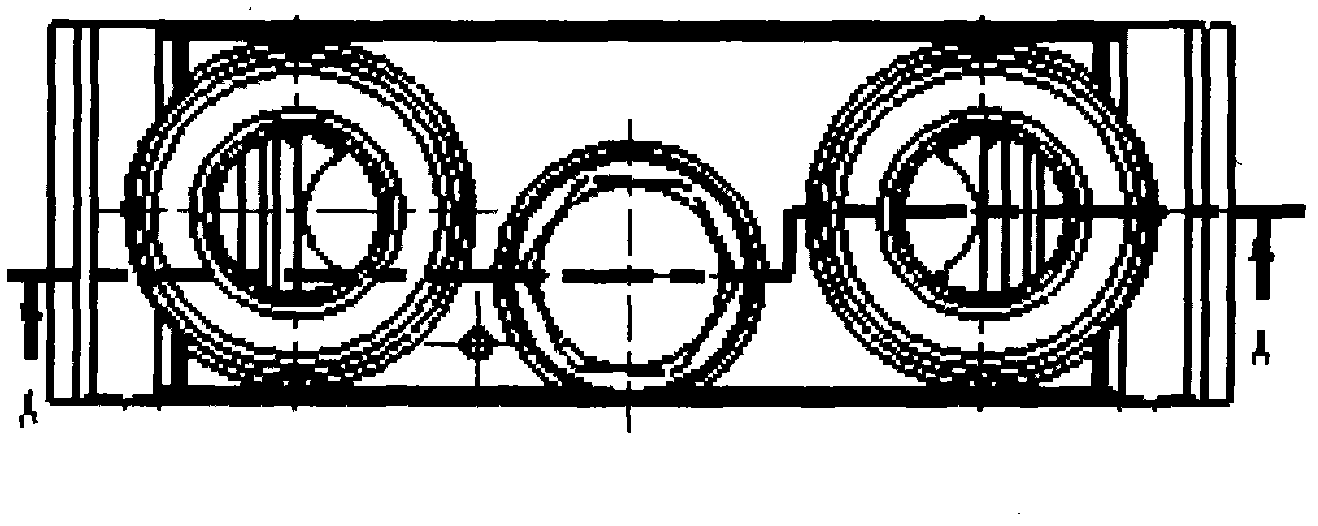

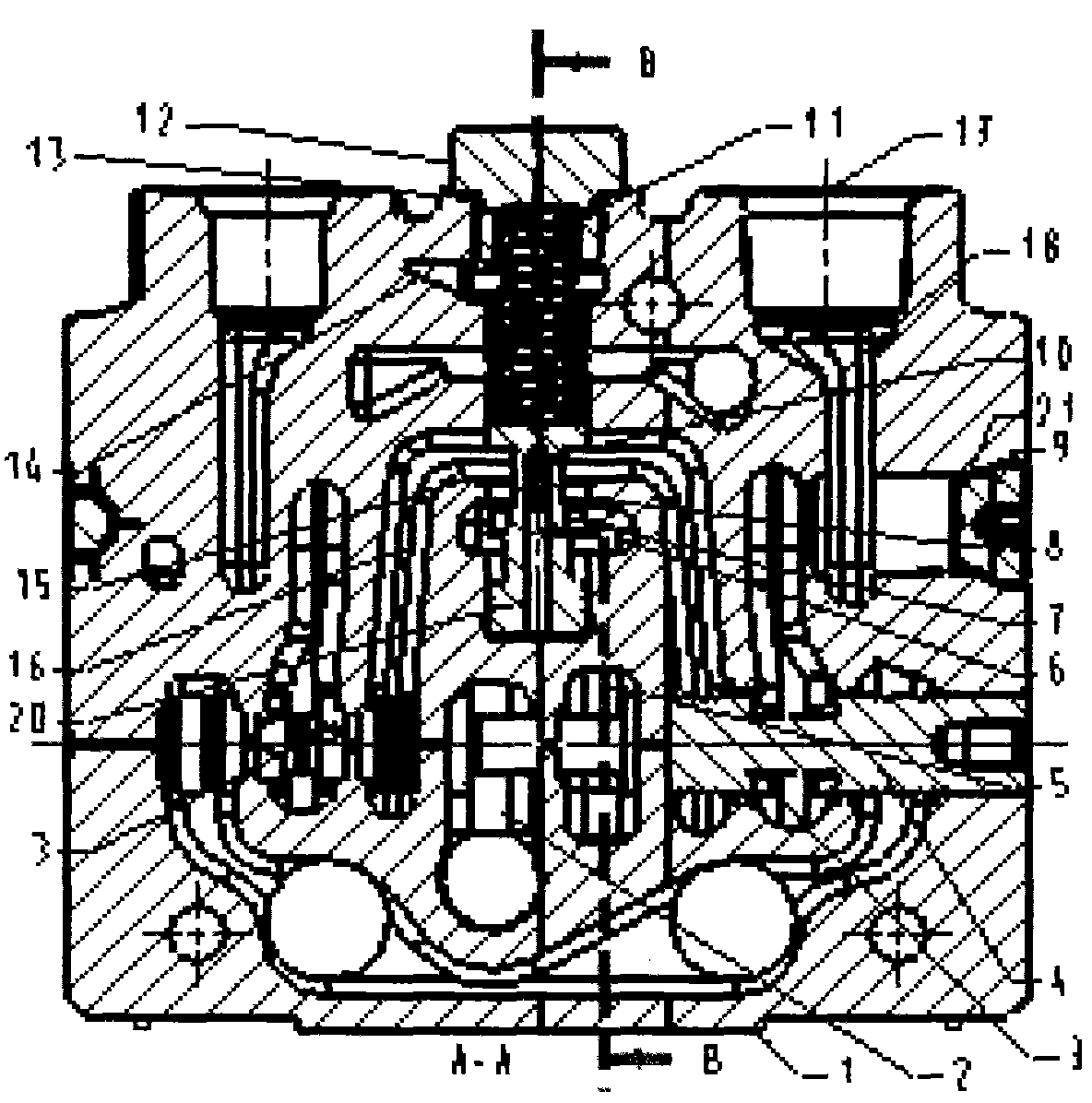

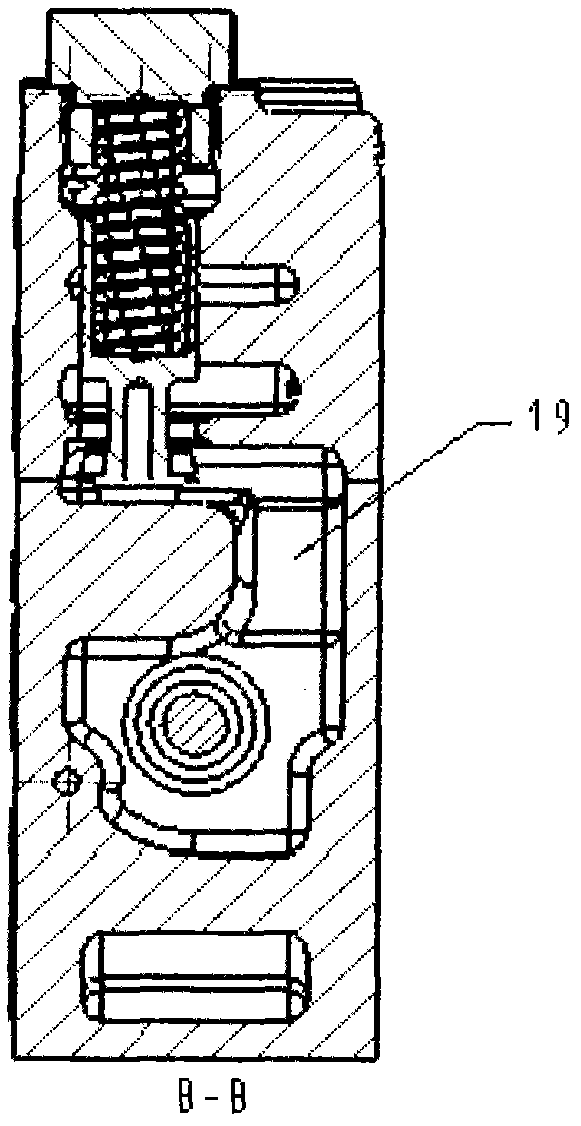

Electrohydraulic ratio multi-channel control valve with convertible pressure compensation mode

ActiveCN102094863AImprove operational performanceReduce machining and tooling costsServomotor componentsEngineeringHydraulic control

The invention relates to an electrohydraulic ratio multi-channel control valve with a convertible pressure compensation mode, wherein the electrohydraulic ratio multi-channel control valve provided by the invention is especially suitable for a multi-channel liquid control valve capable of converting the pressure compensation modes in the same valve body, belonging to the technical field of hydraulic control. The technical scheme adopted by the invention is as follows: in the electrohydraulic ratio multi-channel control valve with the convertible pressure compensation mode, a valve body is provided with a valve hole of a main valve and a compensator valve hole which are shared by two pressure compensation modes; through an offset oil channel, the oil inlet of a compensator is connected with oil channels which are communicated through the main valve; and a matched valve plug of the main valve can be placed in the same valve hole of the main valve, and a matched front compensator and a rear compensator can be placed in the same compensator valve hole. The electrohydraulic ratio multi-channel control valve with the convertible pressure compensation mode has the advantages of good pressure compensation effect, low pressure drop, and the like.

Owner:江苏国瑞液压机械有限公司

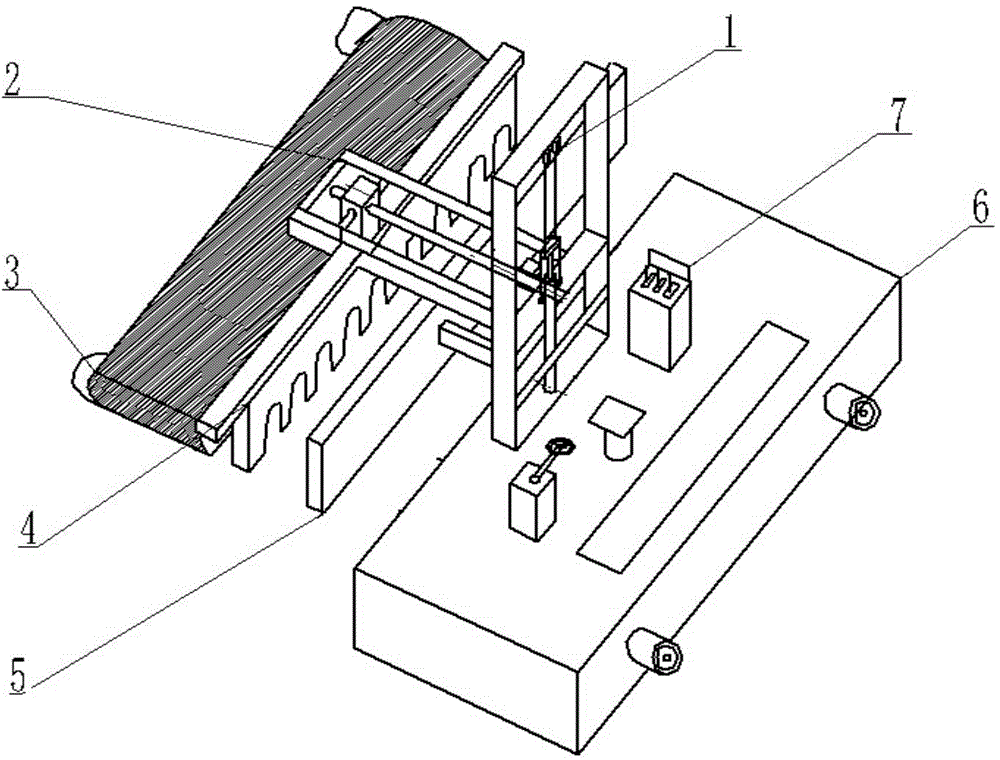

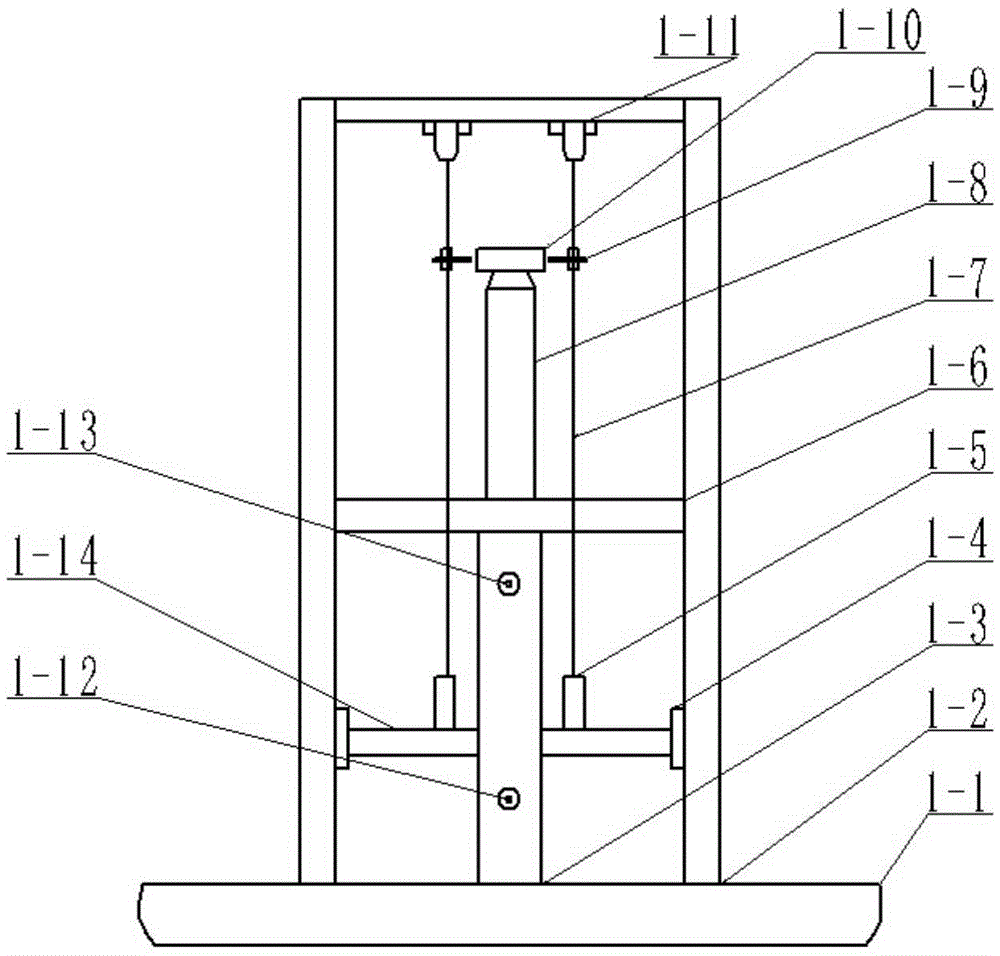

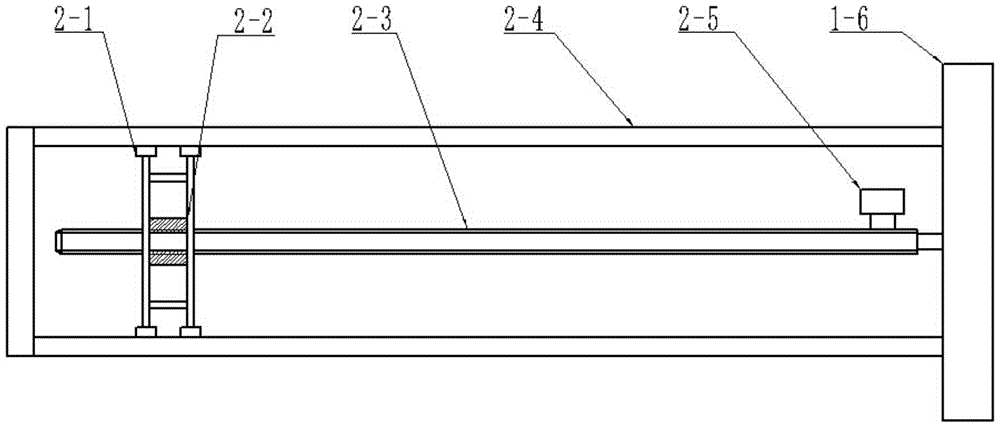

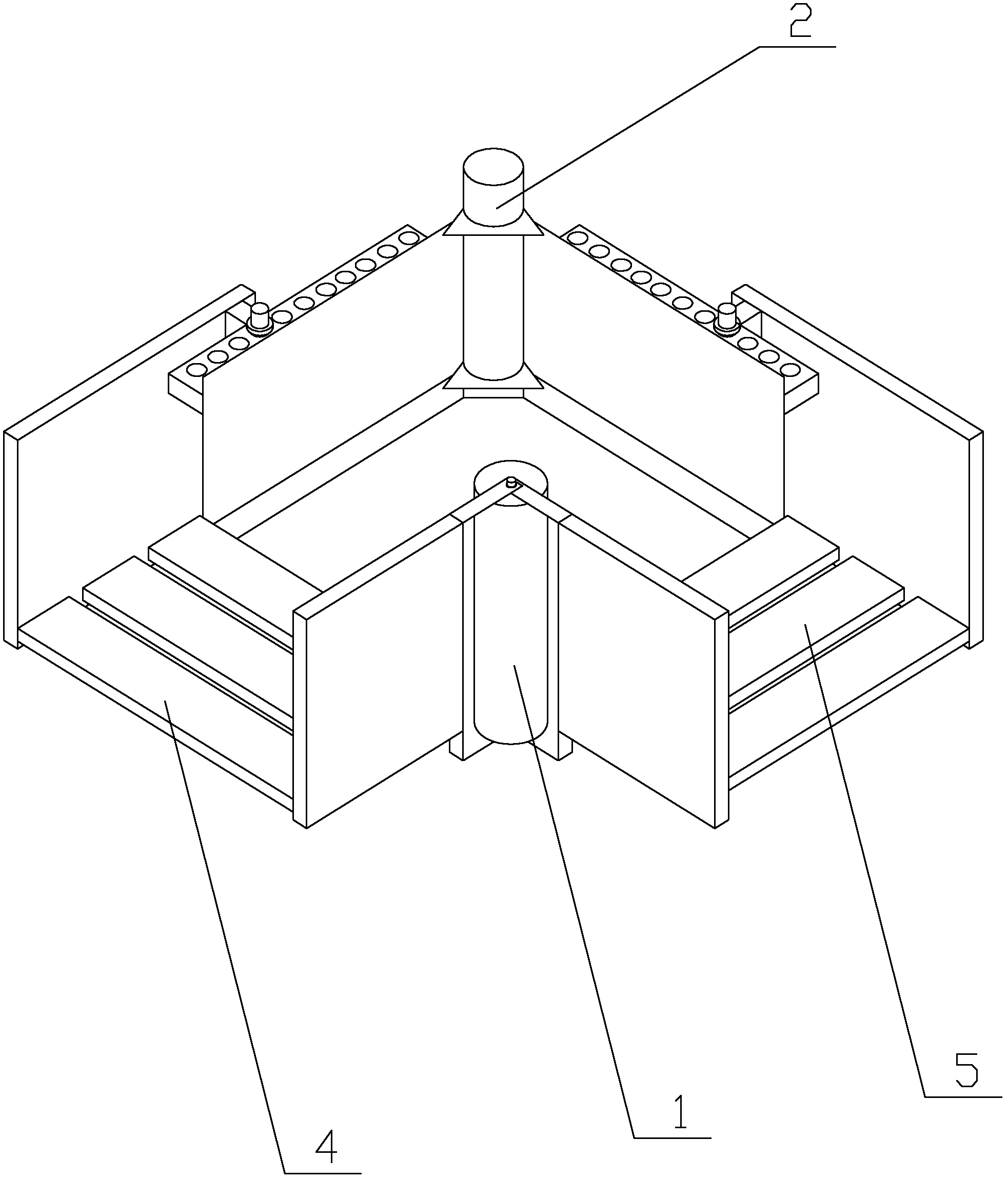

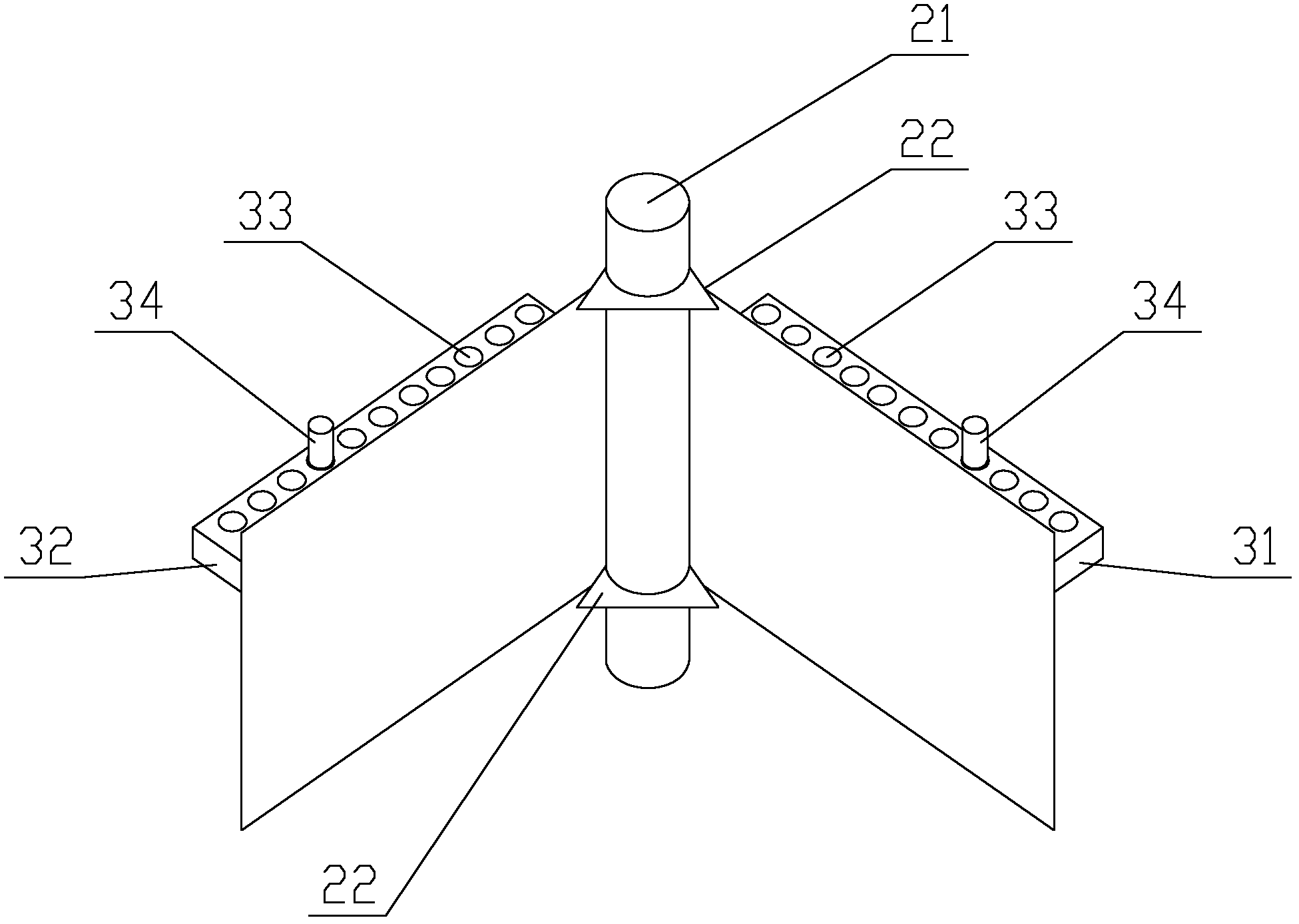

Mechanized oil pipe discharging machine used for oil field

InactiveCN105625960AReduce labor intensityStable operation performanceDrilling rodsDrilling casingsHydraulic cylinderVehicle frame

The invention discloses a mechanized oil pipe discharging machine used for an oil field. The mechanized oil pipe discharging machine comprises a pipe discharging lifting mechanism, a pipe discharging telescopic mechanism, a pipe-discharging pipe-poking mechanism, a pipe discharging scraper blade mechanism, a pipe discharging baffle mechanism, an electric walking mechanism and an electrically controlled operation mechanism. A hydraulic cylinder is designed and installed on the pipe discharging lifting mechanism so as to achieve lifting of a pipe discharging mechanism, and the pipe discharging lifting mechanism is welded to a vehicle frame of the electric walking mechanism. A rolling wheel, a slideway, a turbine and a worm are designed for achieving stretching out and drawing back of the pipe discharging telescopic mechanism. The pipe discharging telescopic mechanism is installed on a sliding lifting plate of the pipe discharging lifting mechanism. A rolling belt-shaped structure is adopted for connecting the pipe-discharging pipe-poking mechanism to the pipe discharging scraper blade mechanism. Oil pipe segment hoop clamping grooves are designed for fixedly connecting the pipe discharging scraper blade mechanism to a pulley of the pipe discharging telescopic mechanism. The pipe discharging baffle mechanism is welded to a support cross brace of the pipe discharging lifting mechanism. The electrically controlled operation mechanism is installed on and connected to the electric walking mechanism. The electric walking mechanism, the vehicle frame and the pipe discharging mechanism are connected integrally. Mechanized oil pipe discharging is achieved, the pipe discharging work efficiency is improved, and the manual pipe discharging labor intensity of staff is relieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Variable angle working platform

InactiveCN102587629AImprove operational performanceImprove usabilityBuilding support scaffoldsEngineeringOperability

The invention relates to a variable angle working platform, which comprises a first working platform frame, a second working platform frame, a first mounting frame and a second mounting frame. A front baffle of the first working platform frame and a front baffle of the second working platform frame are rotationally connected through the first mounting frame; and a rear baffle of the first working platform frame and a rear baffle of the second working platform frame are connected by the second mounting frame. The variable angle working platform provided by the invention has the following advantages: the first working platform frame and the second working platform frame are connected through the first mounting frame and the second mounting frame, the working platform frames can change the angle within 0-90 degrees; in this way, the working platform is applied for various types of building construction with arcs, and the operability, the applicability, the safety and the construction effect are improved.

Owner:毛坤龙

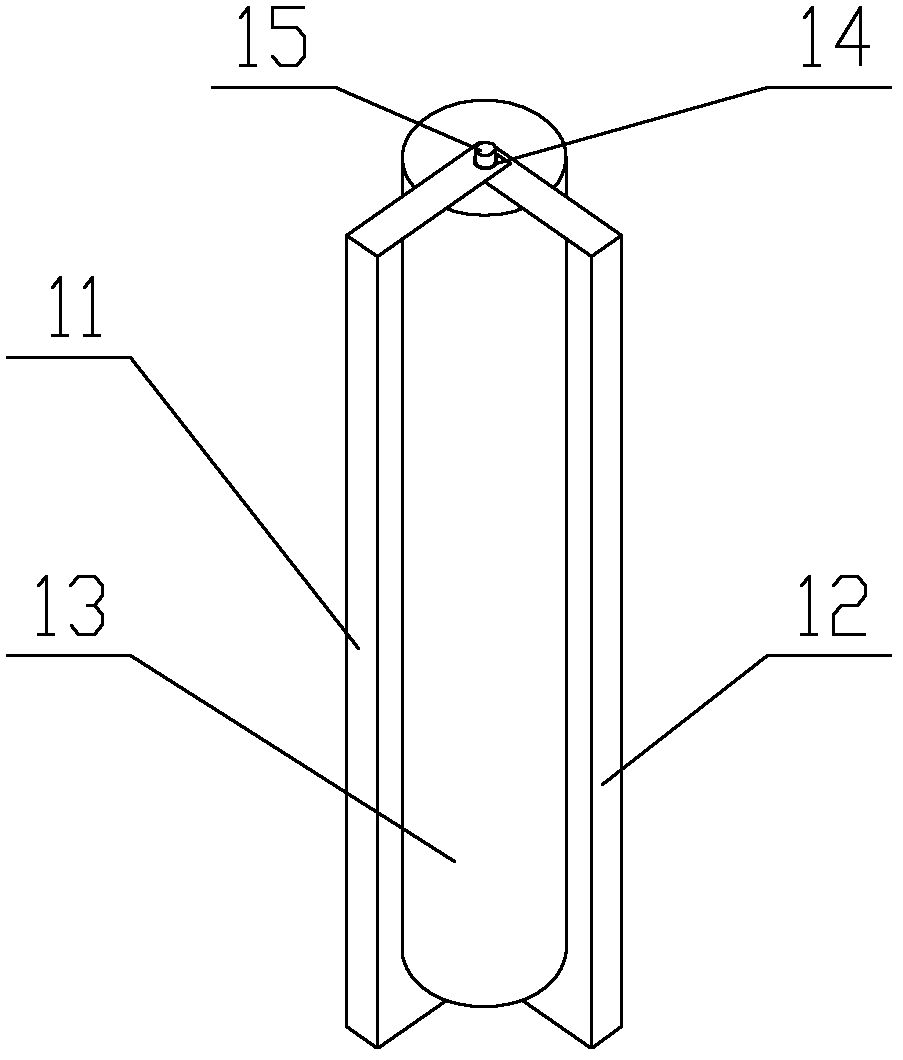

Light high-strength launch barrel

InactiveCN103808207AImprove cylinder strengthReduce weightLaunching weaponsStructural engineeringMechanical engineering

The invention relates to a launch barrel. In order to reduce occupied space of a launch platform and improve quality, the light high-strength launch barrel is provided. The light high-strength launch barrel comprises a barrel body, a top cover and a base plate. The barrel body comprises a square frame, a plurality of trusses and thin skin, the trusses are fixedly connected to the square frame according to set angles, the square frame is surrounded by the thin skin, and the thin skin is connected with the square frame. Compared with the prior art, the barrel body strength of the launch barrel is strengthened, the weight of the launch barrel is reduced, the occupied space of the launch platform is reduced, the quality is improved, the machine conveying fighting performance of a launch system is improved, and the light high-strength launch barrel is easy to machine, low in cost, high in installation adaptability, safe and reliable.

Owner:SHANGHAI XINYUE METER FACTORY

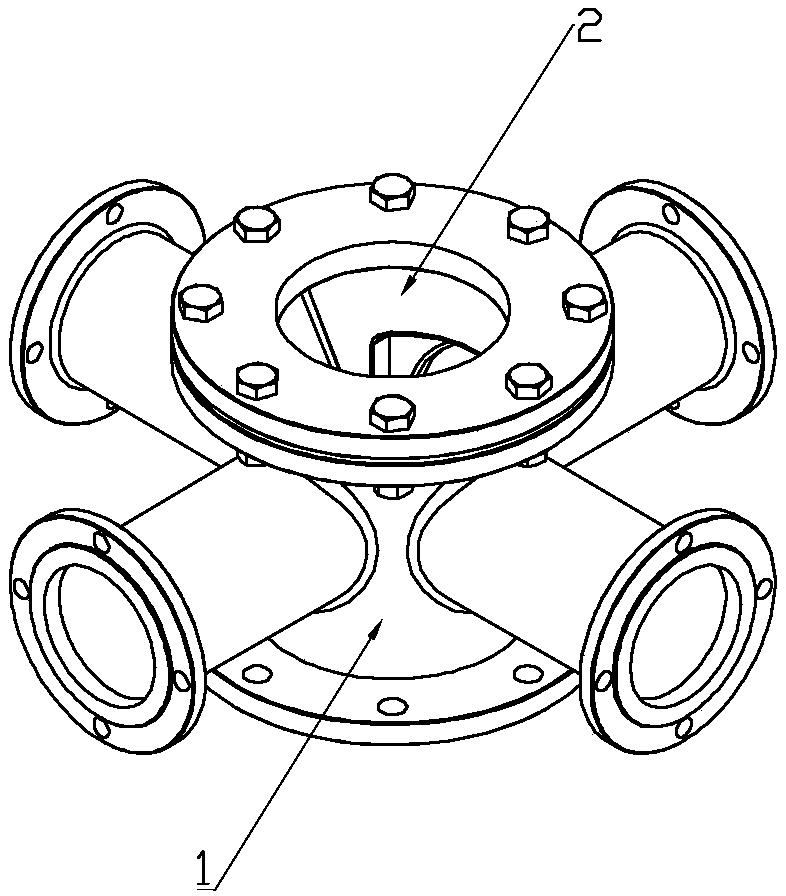

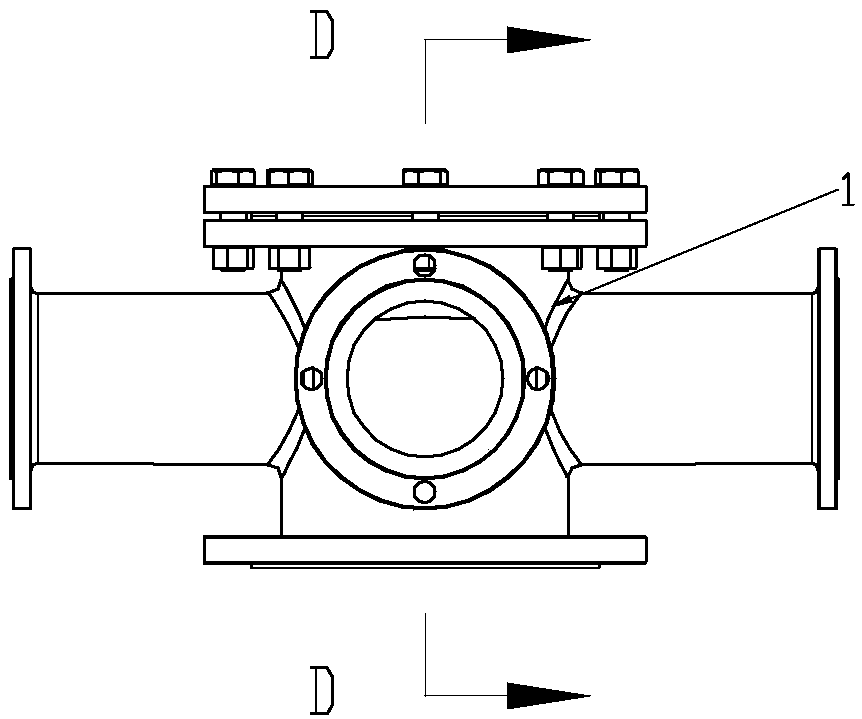

Mechanical liquid continuous reversing device

ActiveCN109209825ABig spaceFew partsPositive displacement pump componentsPistonsReciprocating motionMechanical energy

The invention relates to a mechanical liquid continuous reversing device, which comprises a stator, wherein the circumferential wall of the stator is provided with a through hole, the inner wall of the stator is matched with a rotor, the circumferential wall of the rotor is provided with two through holes, the rotor is provided with a chamber, the chamber of the rotor is internally provided with an isolation component, the isolation component divides the rotor chamber into two independent small chambers and enables one end of each independent small chamber to be open and the other end of eachindependent small chamber to be closed, the closed ends of the two independent small chambers are respectively located at two ends of the rotor in the height direction, each independent small chambercorresponds to the corresponding through hole on the wall of the rotor, the isolation component is connected with a component driving the rotor to rotate into a whole. The mechanical liquid continuousreversing device can enable a liquid circulating in a pipeline to realize continuous reversing in the case of high-speed motion, thereby enabling the liquid to perform reciprocating motion continuously; or the mechanical liquid continuous reversing device enables a liquid moving in a reciprocating manner continuously in the pipeline to perform circulating motion continuously, thereby converting kinetic energy of the liquid into mechanical energy for external work through a mechanical structure.

Owner:SHANDONG QINGGENG ELECTRIC CO LTD

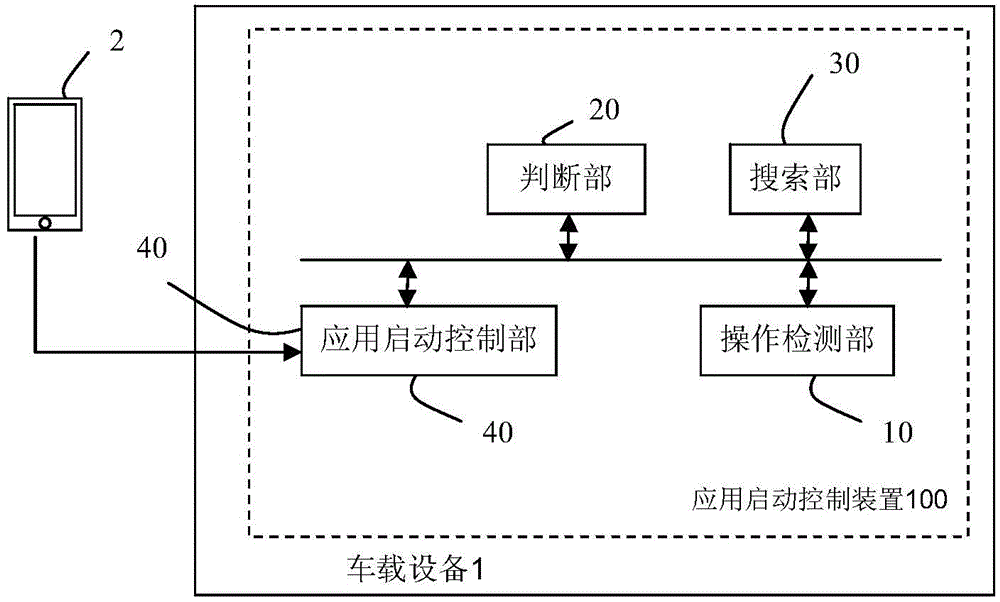

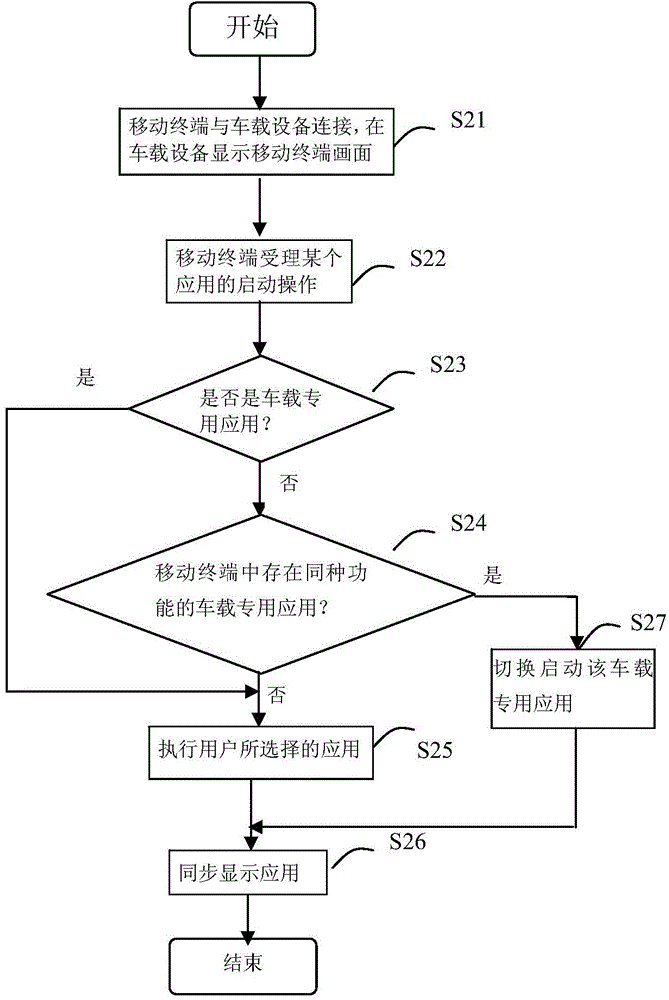

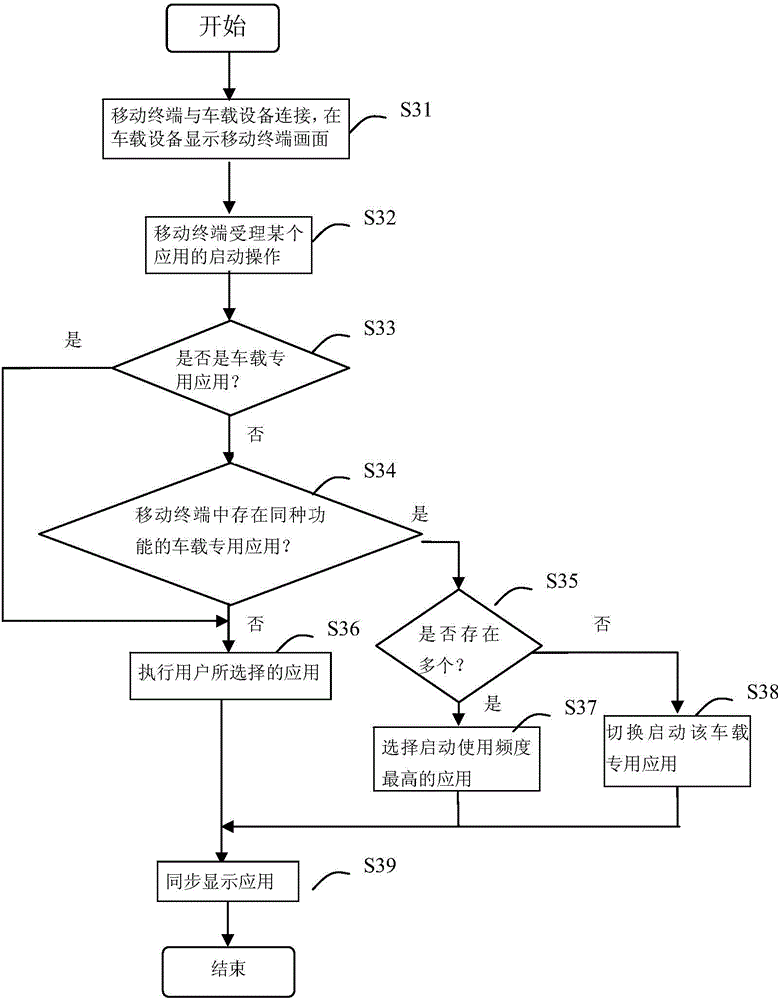

Start control device for applications and start control method for applications

ActiveCN105094856AReduce misuseImprove operational performanceProgram loading/initiatingElectric/fluid circuitComputer science

Owner:ALPINE ELECTRONICS INC

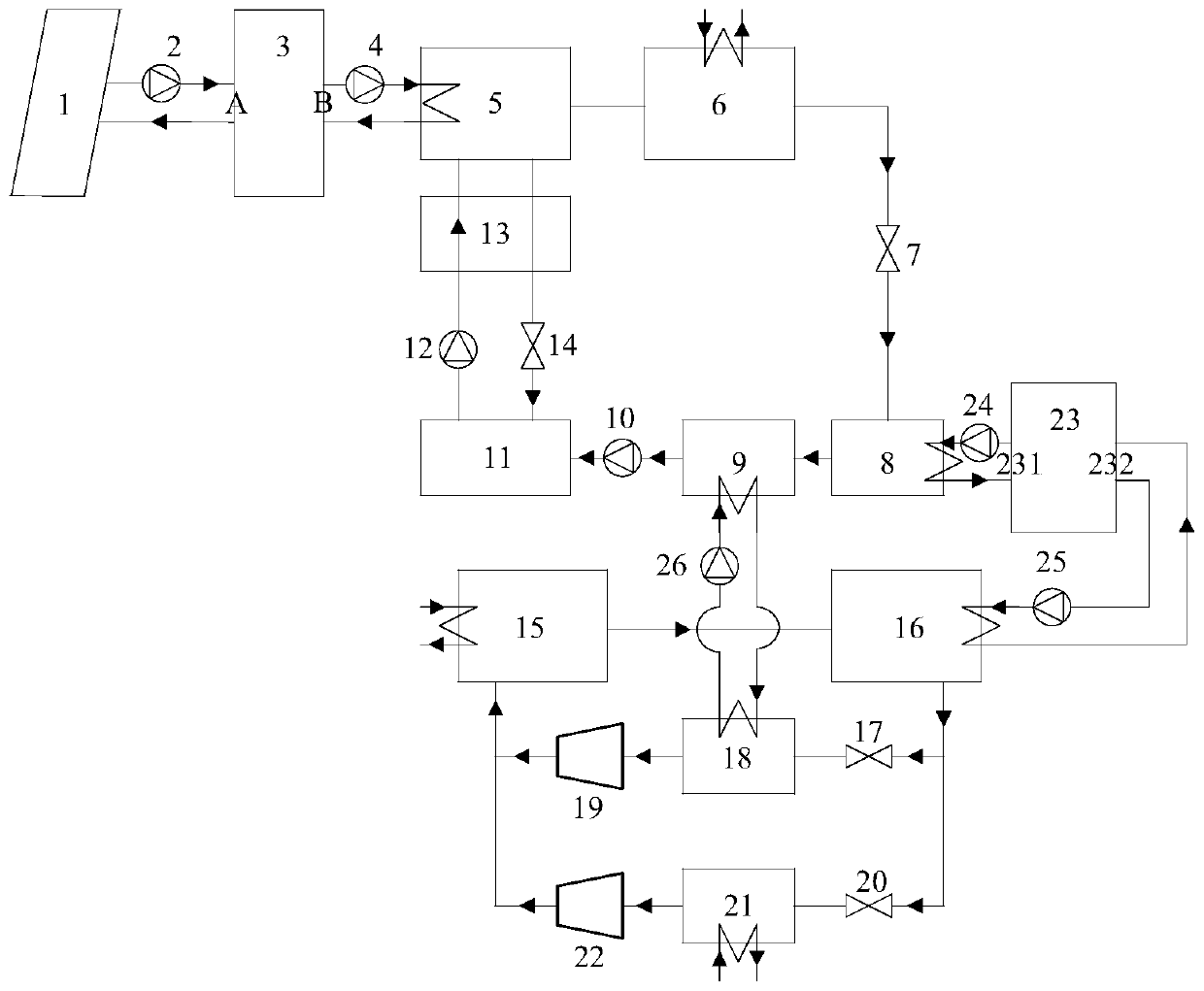

Refrigerating system and method based on secondary condensation pressurization absorption and supercooling compression

ActiveCN110906582AImprove the performance of low-temperature heat source conditionsReduce economic costsMechanical apparatusBoiler absorbersPhysicsCollector device

The invention discloses a refrigerating system and method based on secondary condensation pressurization absorption and supercooling compression. A heat collector is sequentially connected with a first hot water pump and a heat storage tank; the heat storage tank is sequentially connected with a second hot water pump and a generator; the generator is sequentially connected with an absorption circulating condenser, an absorption circulating throttle valve, an absorption circulating evaporator, a secondary condenser, a booster pump, an absorber, a solution pump, a solution heat exchanger and a solution throttle valve; a main-stage circulating compressor is sequentially connected with a condenser, a subcooler, a main-stage throttle valve and a main-stage evaporator; a secondary circulating compressor is sequentially connected with the condenser, the subcooler, a secondary throttle valve and a secondary evaporator; a cold storage tank is sequentially connected with an absorption circulating chilled water pump and an absorption circulating evaporator; and the cold storage tank is sequentially connected with a supercooling pump and the subcooler. According to the system, secondary condensation and the booster pump are combined to replace a large water vapor compressor to achieve pressurization absorption, and therefore, a heat source working condition range is widened, and the low-temperature heat source working condition performance of the system is remarkably improved.

Owner:SOUTH CHINA UNIV OF TECH

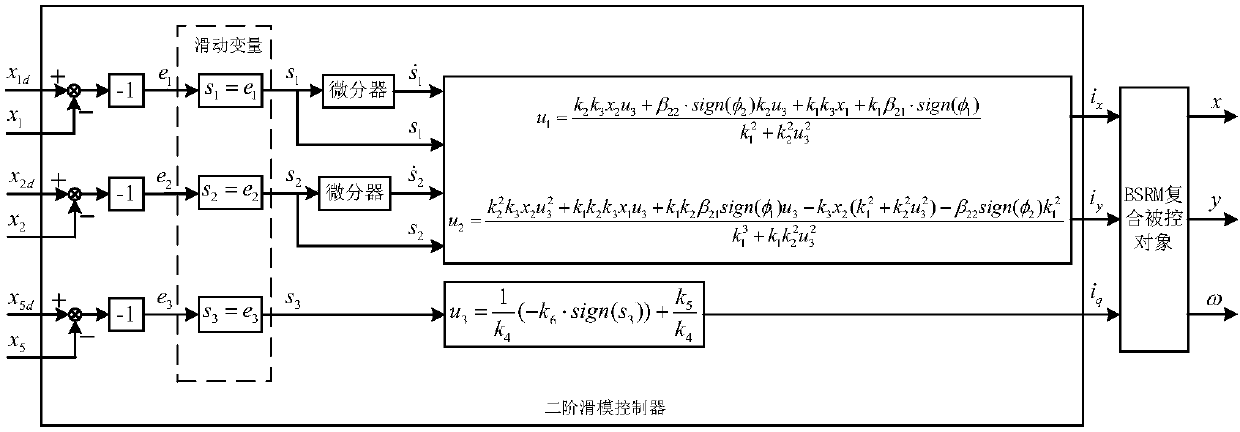

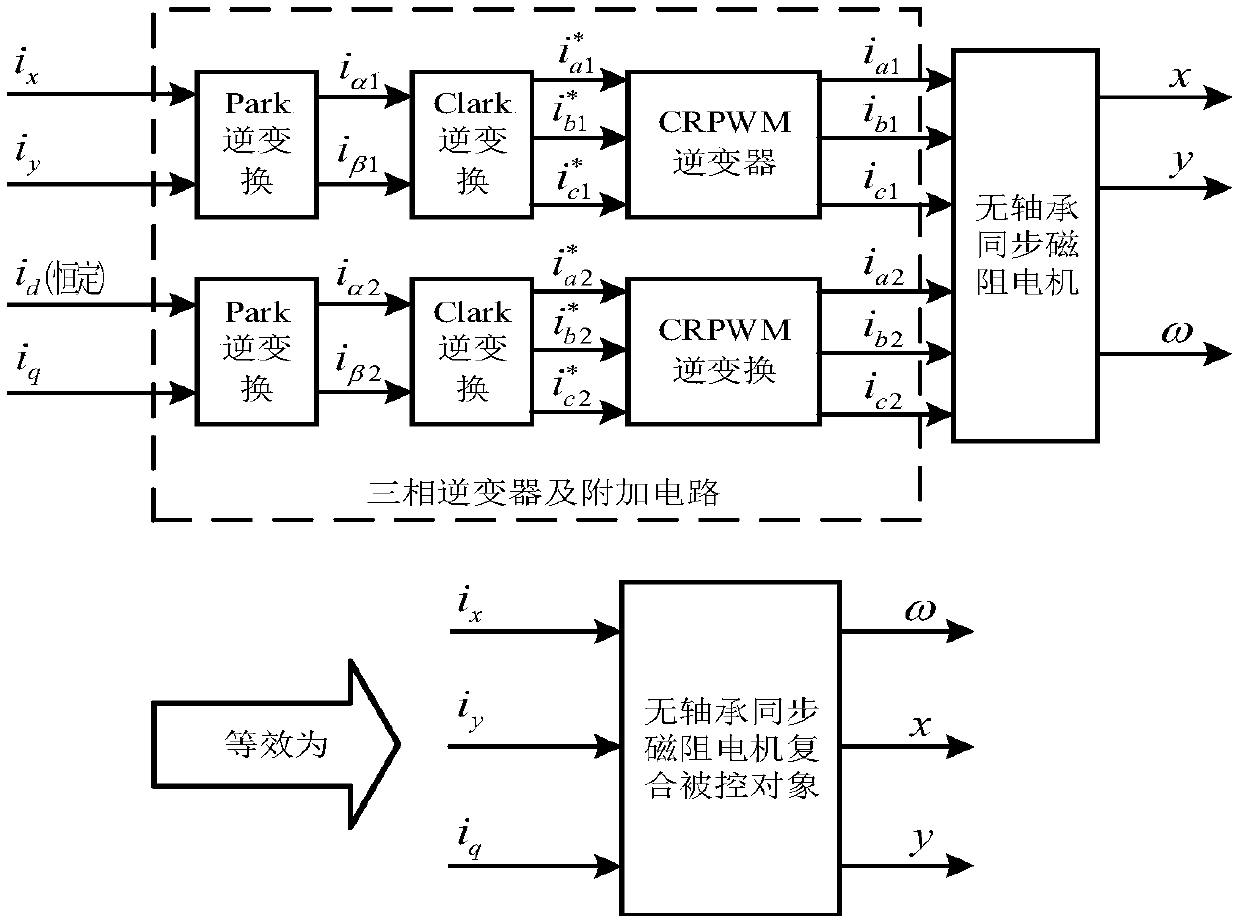

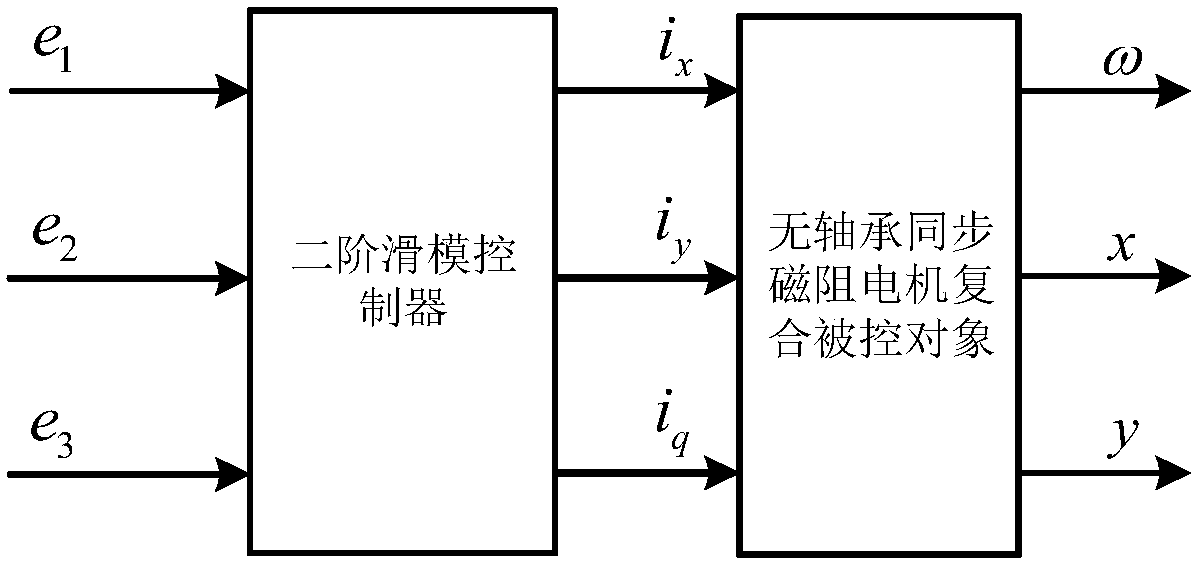

Method for controlling second order sliding mode of bearingless synchronous reluctance motor

InactiveCN107800342ASolve the coupling problemIncrease speedElectronic commutation motor controlAC motor controlSynchronous reluctance motorMathematical model

The invention discloses a method for controlling the second order sliding mode of a bearingless synchronous reluctance motor. According to a mathematic model of the bearingless synchronous reluctancemotor, a traditional sliding mode control method is applied to rotational speed control, the rotational speed of the bearingless synchronous reluctance motor reaches a preset rotational speed in finite time and the bearingless synchronous reluctance motor operates stably, the method for controlling the second order sliding mode is applied to radial displacement control of x axis and y axis, and the radial displacement of x axis and the radial displacement of y axis are stabilized to be zero in finite time respectively. The sliding mode controller is formed by rotational speed control based onfirst order sliding mode and displacement control based on second order sliding mode together, and a non-linear system of the bearingless synchronous reluctance motor is directly controlled, so that the dynamic characteristics and operation quality of the bearingless synchronous reluctance motor are effectively improved, the robustness of the system is enhanced, the chattering phenomena of the system is weakened, and the method is beneficial for engineering realization.

Owner:JIANGSU UNIV

A kind of carbon dioxide hydrogenation synthesis methanol catalyst and preparation method and application

ActiveCN103721719BLarge specific surface areaGood dispersionOrganic compound preparationHydroxy compound preparationPtru catalystHalogen

The invention discloses a catalyst for synthesizing methanol through CO2 hydrogenation, comprising Cu, Zn, Al, X, halogen and oxygen elements, oxides and halides, wherein the molar ratio of [Cu+Zn+MA] to [Al+Mb] is 2-18; the molar ratio of Cu to Zn is 0.5-5; the molar ratio of MA to [Cu+Zn] is 0-5; the molar ratio of MB to Al is 0-9; the molar ratio of halogen to Al is 0.05-5; MA and MB cannot be 0 at the same time; MA represents a mono-valent or divalent metal ion in X; MB represents a trivalent and / or tetravalent metal ion in X; X is one or a combination of more elements of Li, K, Mg, B, Ga, In, transition metal elements and rare-earth metal elements. The catalyst has the advantages of high carbon dioxide conversion rate, good methanol selectivity and high methanol yield.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com