Full-automatic bottle cap gasket machine

A fully automatic, bottle cap technology, applied in hand-held tools, manufacturing tools, etc., can solve problems such as lack of multiple functions, slow gasket processing, and unrecognizable bottle caps, so as to speed up processing, improve efficiency, and save time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

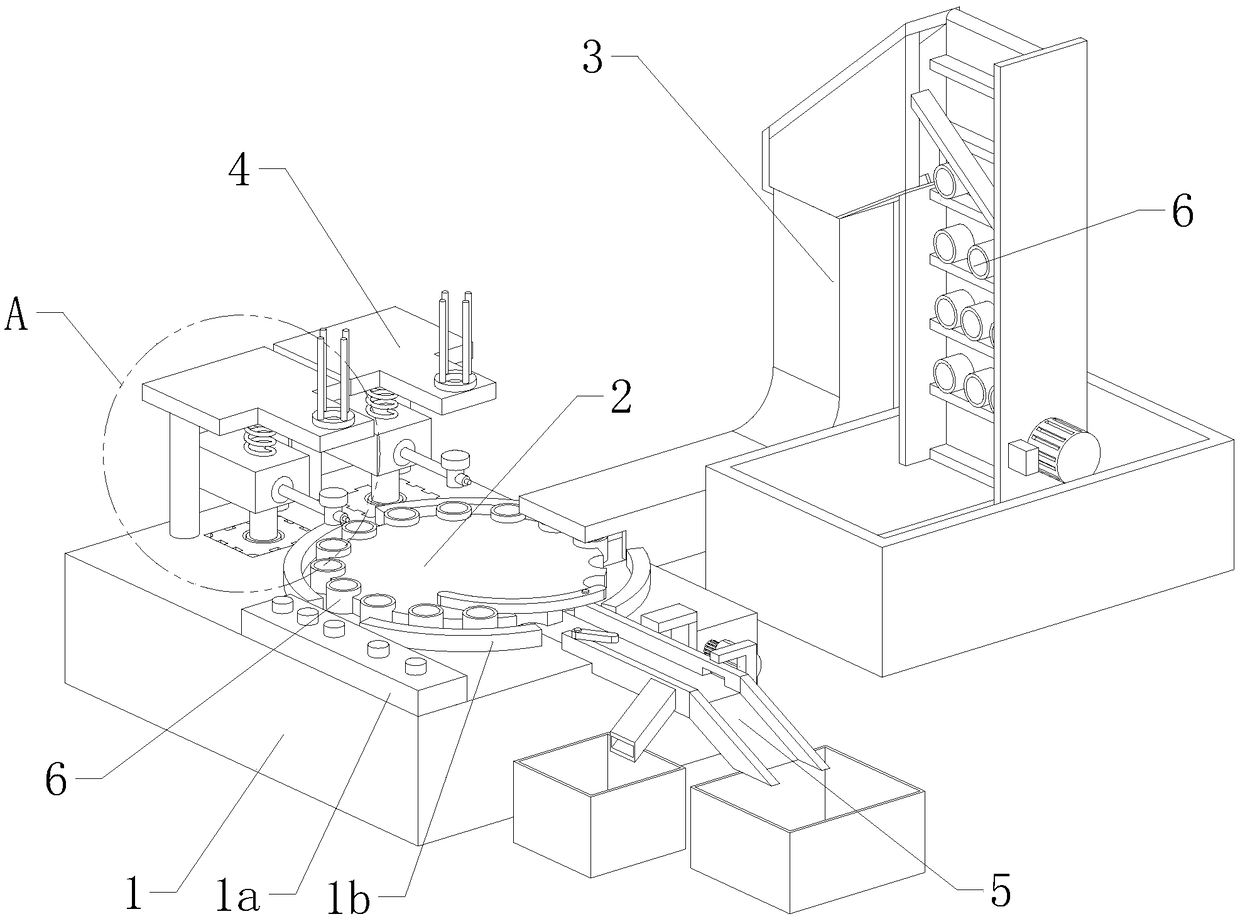

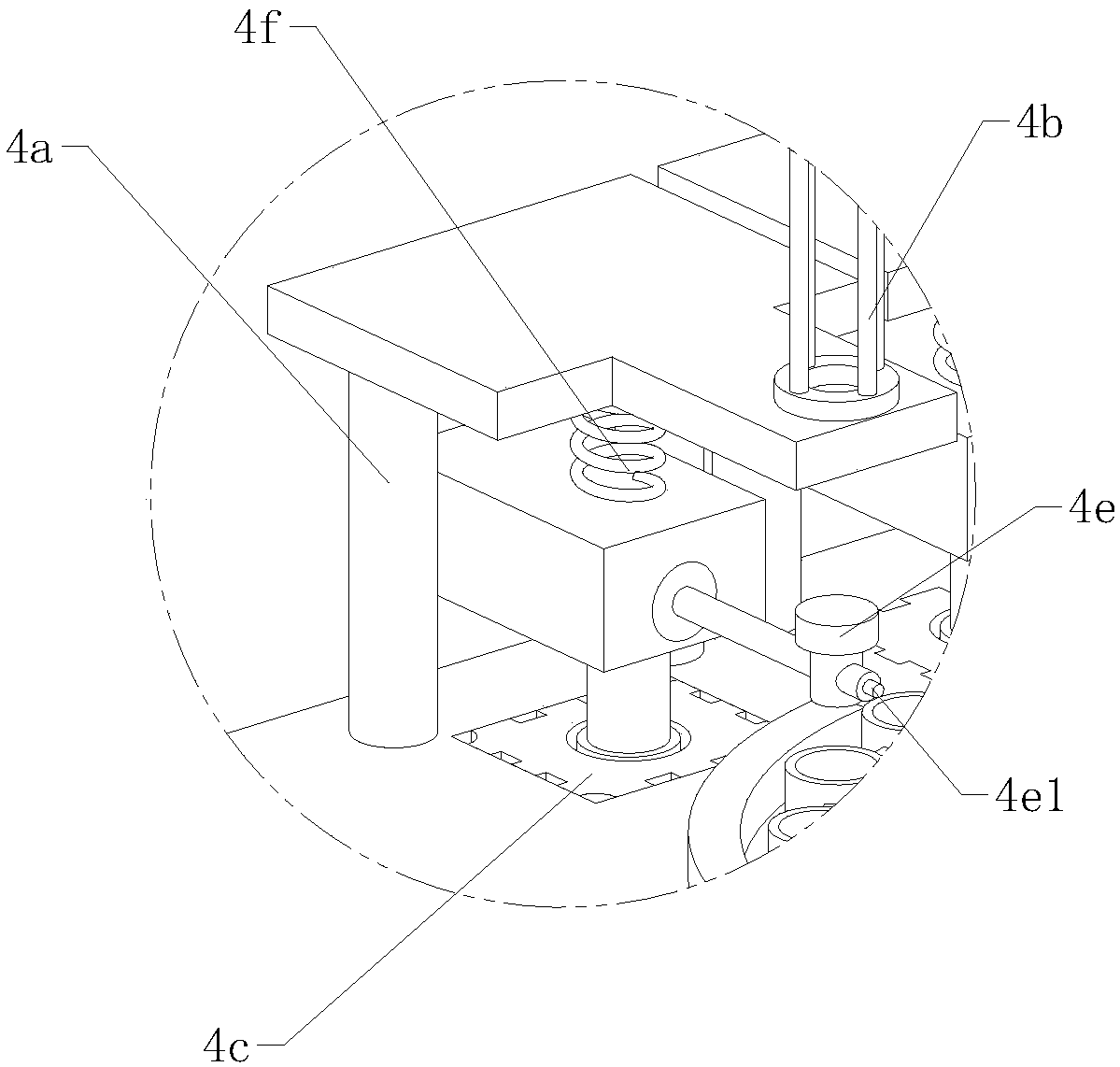

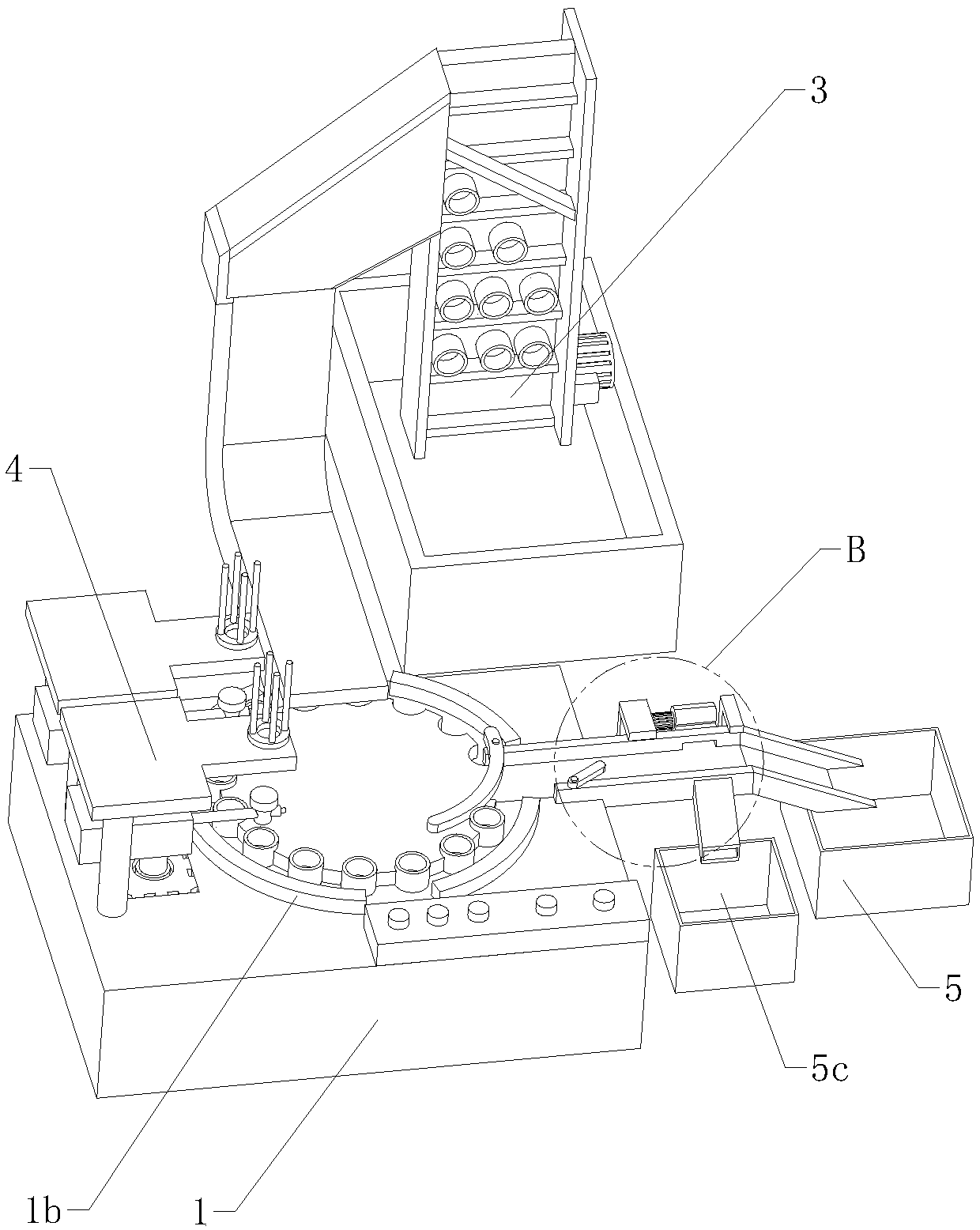

[0031] refer to Figure 1 to Figure 14A fully automatic bottle cap gasket machine shown includes a machine tool 1, a multi-station turntable 2, a cap sorting and feeding mechanism 3, a gasket mechanism 4 and a blanking mechanism 5, and the multi-station turntable 2 is set on the machine tool 1 upper middle position, several bottle cap fixtures 2a are arranged around the multi-station turntable 2, and a rotating motor 2b is arranged below the multi-station turntable 2, and the output end of the rotation motor 2b is in phase with the middle of the multi-station turntable 2. connected, the cap sorting and feeding mechanism 3 is arranged on the side of the multi-station turntable 2, and the cap sorting and feeding mechanism 3 includes a material box 3a, a waterfall lifting belt 3b, a bottle cap conveying path 3c and a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com