High-temperature-resistant and high-pressure-resistant rubber material as well as preparation method and application thereof

A technology of rubber material and high pressure resistance, applied in the fields of high pressure resistance rubber material and high temperature resistance, can solve the problems of increasing the technical difficulty and cost of domestic deep well and ultra-deep well mining, undisclosed technical measures, and high cost of packers, etc. The effect of improving H2S resistance, improving operation performance and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

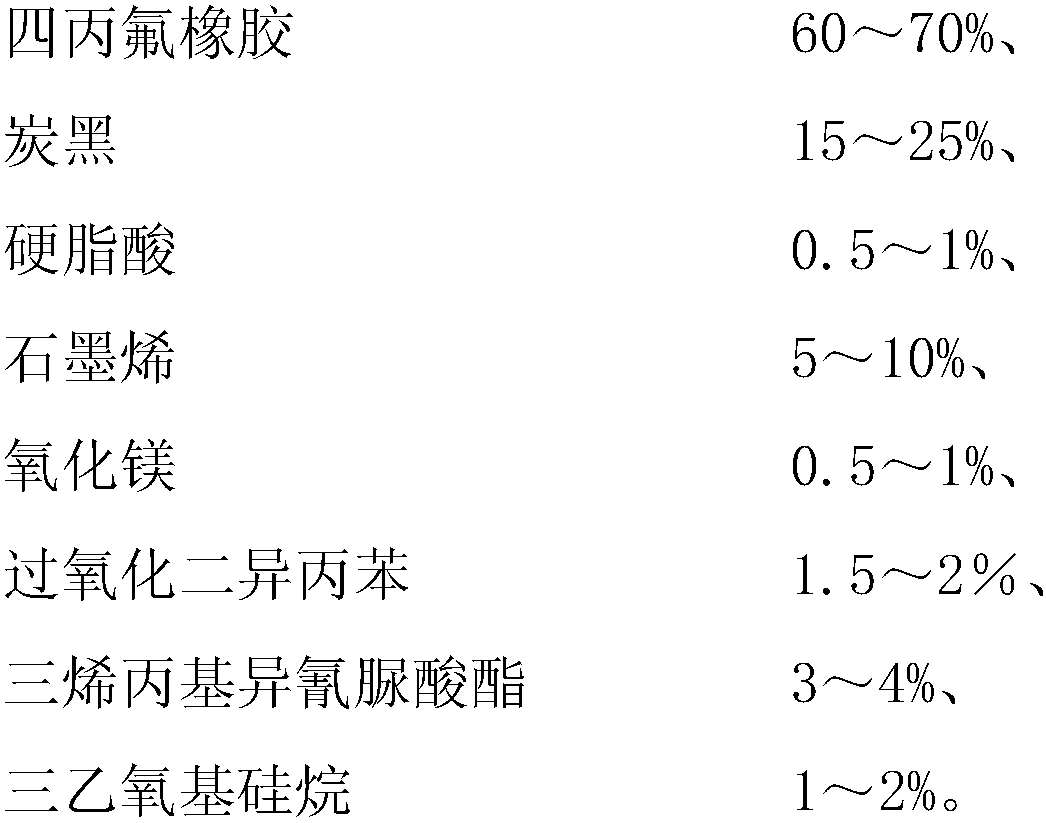

Method used

Image

Examples

Embodiment 1

[0026] The present invention is composed of the following raw materials in mass percentage: 62% of tetrapropyl fluoro rubber, 22.9% of carbon black, 0.8% of stearic acid, 7% of graphene, 0.8% of magnesium oxide, 1.5% of dicumyl peroxide, triene Propyl isocyanurate 4%, triethoxysilane 1%.

[0027] In the above formulation, tetrapropanefluoro rubber is tetrapropanefluoro raw rubber, the dynamic shear storage modulus of tetrapropanefluoro rubber is 340KPa, and the Mooney viscosity value is 160 at a temperature of 100°C.

[0028] In the above formula, graphene is graphene oxide, and the sheet diameter of graphene is 3 μm.

[0029] In the above formula, triethoxysilane is a mixture of methyltriethoxysilane and vinyltriethoxysilane, and the mixing ratio is 1:1.

[0030] The preparation method of the present invention is:

[0031] Each component in the formula raw material is according to tetrapropyl fluorine rubber, carbon black, stearic acid, graphene, magnesium oxide, dicumyl pe...

Embodiment 2

[0036] The present invention is composed of the following raw materials in mass percentage: 67.8% of tetrapropyl fluoro rubber, 18% of carbon black, 0.7% of stearic acid, 6% of graphene, 0.5% of magnesium oxide, 2% of dicumyl peroxide, triene Propyl isocyanurate 3%, triethoxysilane 2%.

[0037] In the above formulation, tetrapropanefluoro rubber is tetrapropanefluoro raw rubber, the dynamic shear storage modulus of tetrapropanefluoro rubber is 340KPa, and the Mooney viscosity value is 160 at a temperature of 100°C.

[0038] In the above formula, graphene is graphene oxide, and the sheet diameter of graphene is 4 μm.

[0039] In the above formula, triethoxysilane is a mixture of methyltriethoxysilane and vinyltriethoxysilane, and the mixing ratio is 1:1.

[0040] The preparation method of the present invention is:

[0041] Each component in the formula raw material is according to tetrapropyl fluorine rubber, carbon black, stearic acid, graphene, magnesium oxide, dicumyl pero...

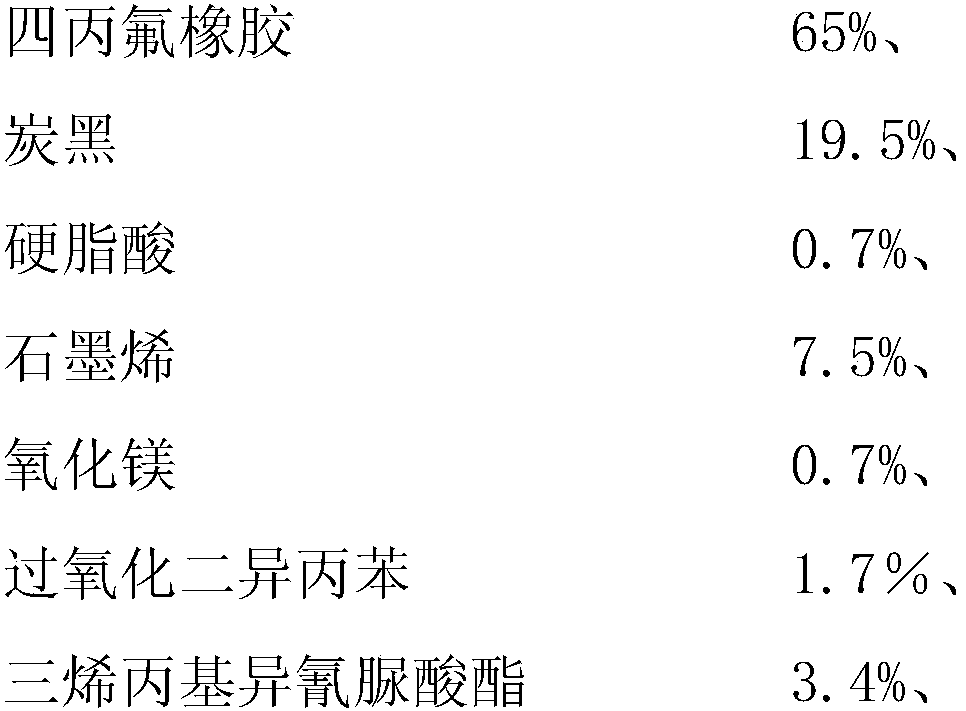

Embodiment 3

[0046] The present invention is composed of the following raw materials in mass percentage: 65% of tetrapropyl fluoro rubber, 19.5% of carbon black, 0.7% of stearic acid, 7.5% of graphene, 0.7% of magnesium oxide, 1.7% of dicumyl peroxide, triene Propyl isocyanurate 3.4%, triethoxysilane 1.5%.

[0047] In the above formulation, tetrapropanefluoro rubber is tetrapropanefluoro raw rubber, the dynamic shear storage modulus of tetrapropanefluoro rubber is 340KPa, and the Mooney viscosity value is 160 at a temperature of 100°C.

[0048] In the above formula, graphene is graphene oxide, and the sheet diameter of graphene is 5 μm.

[0049] In the above formula, triethoxysilane is a mixture of methyltriethoxysilane and vinyltriethoxysilane, and the mixing ratio is 1:1.

[0050] The preparation method of the present invention is:

[0051] Each component in the formula raw material is according to tetrapropyl fluorine rubber, carbon black, stearic acid, graphene, magnesium oxide, dicu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com