Mechanical liquid continuous reversing device

A reversing device, a mechanical technology, used in mechanical equipment, parts of pumping devices for elastic fluids, liquid fuel engines, etc. High commutation frequency problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

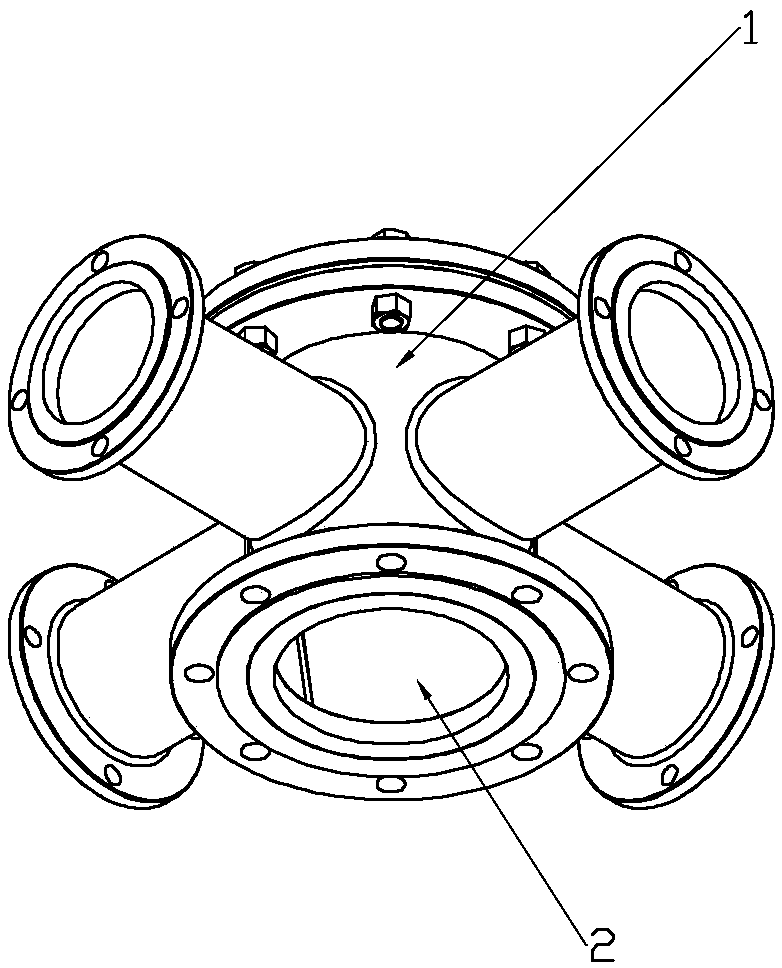

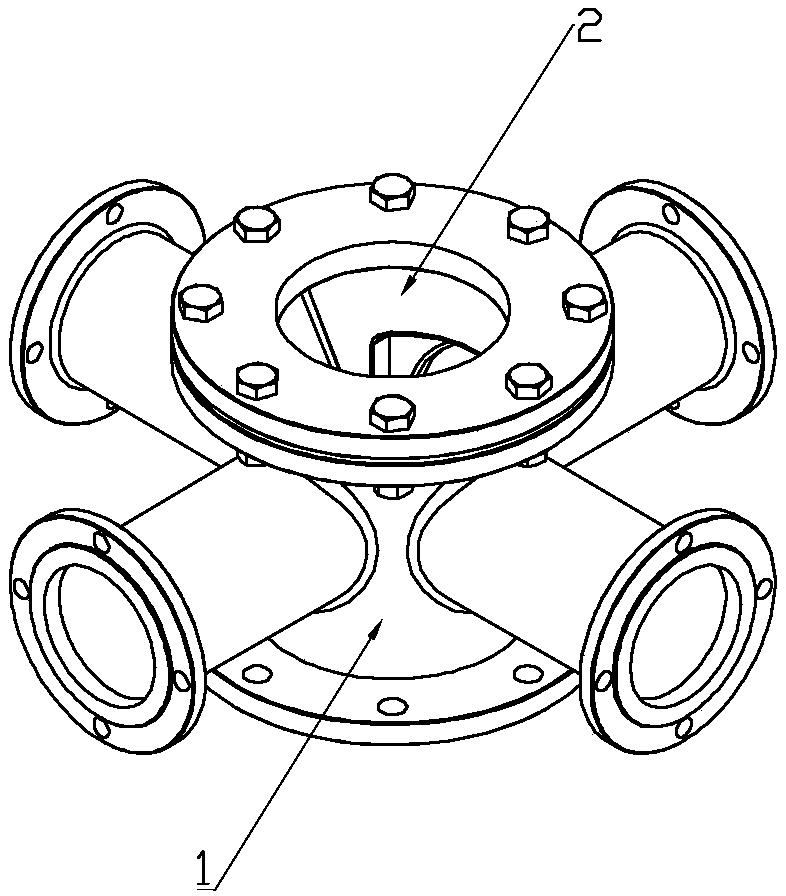

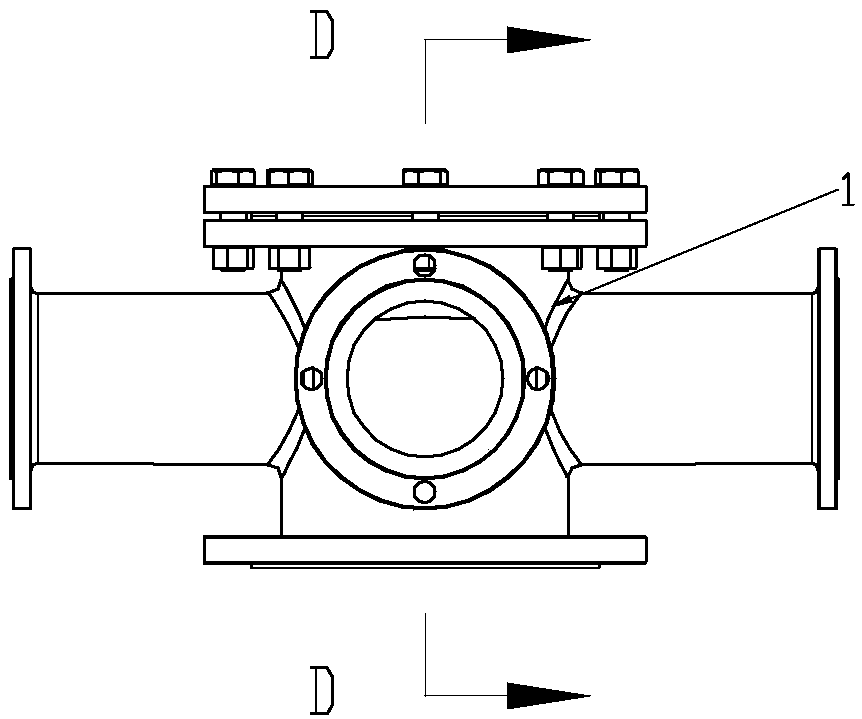

[0029] The structure of the rotor of the present invention is as Figure 5-Figure 8 , Figure 9-Figure 12 and Figure 13-Figure 16 These structures are shown as different embodiments of the rotor 2 . The basic structure of rotor 2 is as follows Figure 13-Figure 16 As shown, the rotor is a cylinder. There are three implementations of the rotor, and the present invention is not limited to these three implementations. Embodiment 1: a chamber is provided on the inner wall of the rotor 2, two through holes are provided on the peripheral wall of the rotor 2, a partition 3 is arranged in the chamber of the rotor, and the partition 3 divides the chamber of the rotor 2 into two independent small chambers, namely : the first independent small chamber 34 , the second independent small chamber 35 . Usually, the volumes of the two independent small chambers are equal, and in special cases, different volumes of the independent small chambers can be set according to actual needs. Each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com