Bypass afterburning composite regenerative turbo supercharging system of boiler

A turbocharging system and boiler technology, applied in lighting and heating equipment, steam generating devices, engine components, etc., can solve the problems of low working condition performance, poor start-up performance, etc., and achieve improved stability, heat balance and steam balance stability , Improve the effect of transient response characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

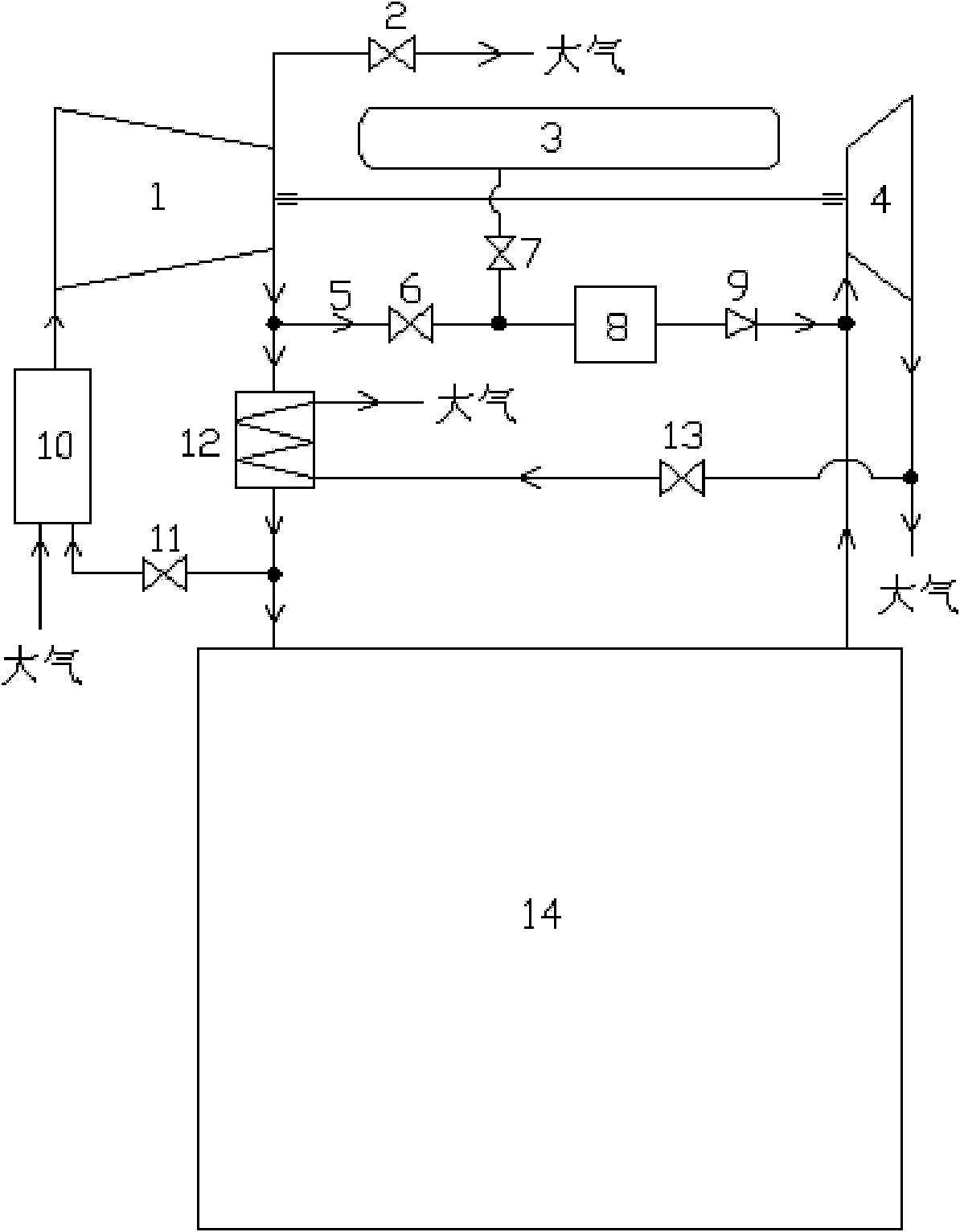

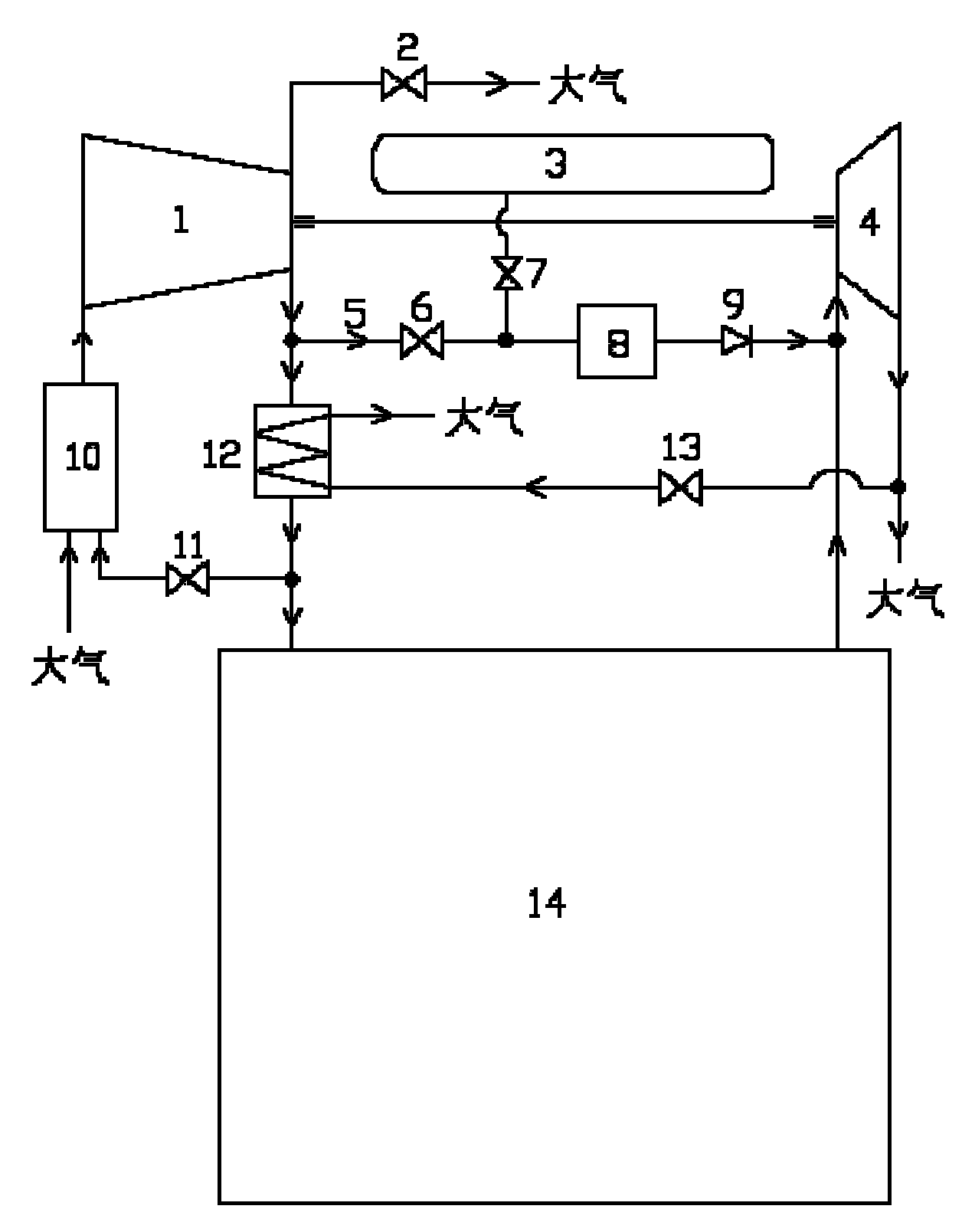

[0012] combine figure 1 , the boiler bypass supplementary combustion combined heat recovery turbocharged system includes a boiler 14, a compressor 1, a turbine 4, a valve, a bypass pipe 5, a supplementary combustion chamber 8, a gas storage tank 3, a regenerator 12 and a blending pipe 10 The inlet of the compressor 1 is installed with a mixing pipe 10, the outlet of the compressor 1 is connected to the boiler 14 through a heat recovery pipe 12, a regulating valve 11 is installed between the mixing pipe 10 and the heat regenerator 12, and the first branch of the outlet of the turbine 4 is connected to into the atmosphere, the second branch of the turbine 4 is connected to the regenerator 12 through the regulating valve 13, and a bypass pipe 5, a bypass valve 6, a supplementary combustion chamber 8 and a check valve 9 are installed between the compressor 1 and the turbine 4, The gas storage tank 3 is connected with the supplementary combustion chamber 8 through the air release v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com