Cylindrical roller with logarithmic curve

A cylindrical roller, logarithmic technology, applied in the field of rolling bearing parts, can solve problems such as local stress concentration, limited bearing performance improvement, and inability to use materials on both sides in a balanced manner, so as to reduce interference, pollution, contact, etc. Effects of increased fatigue life and reliability, reduced friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

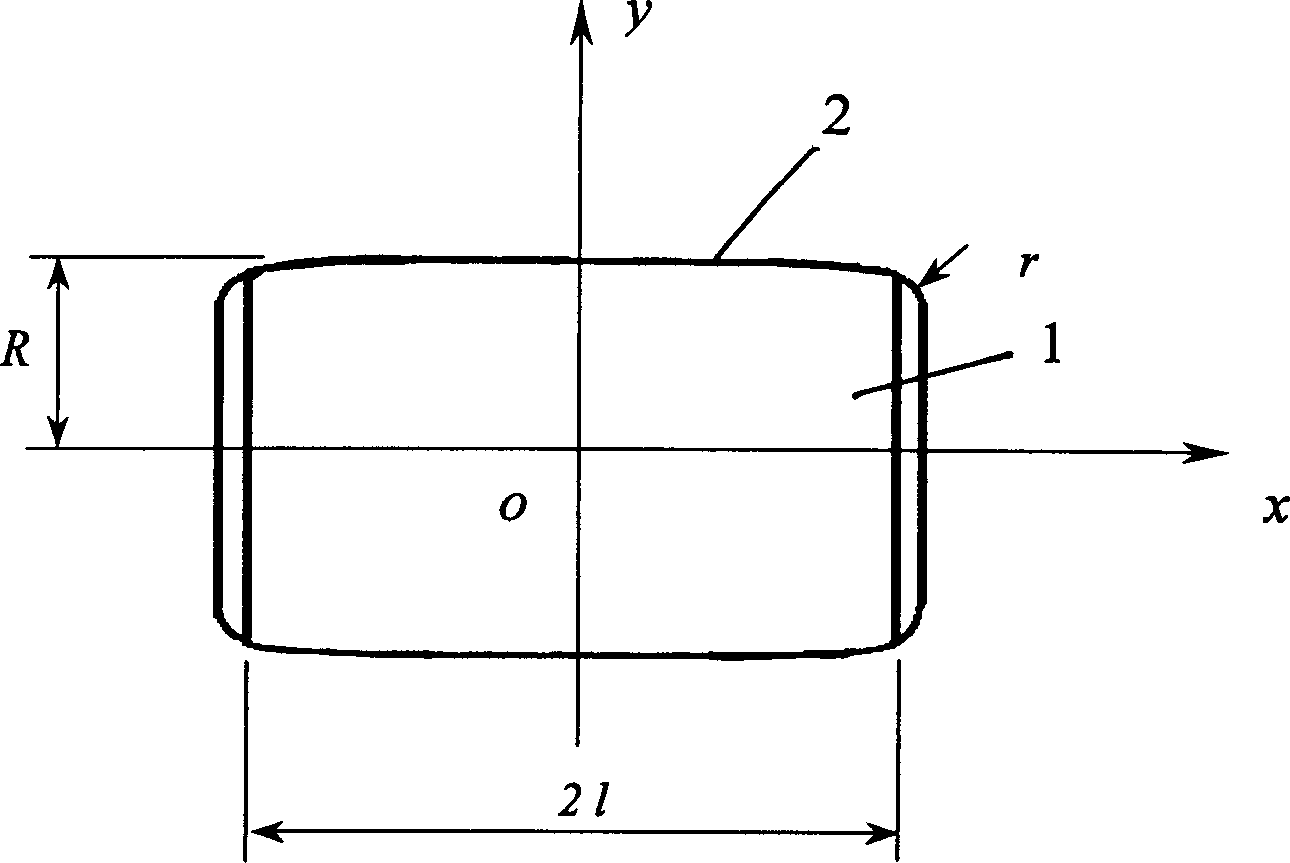

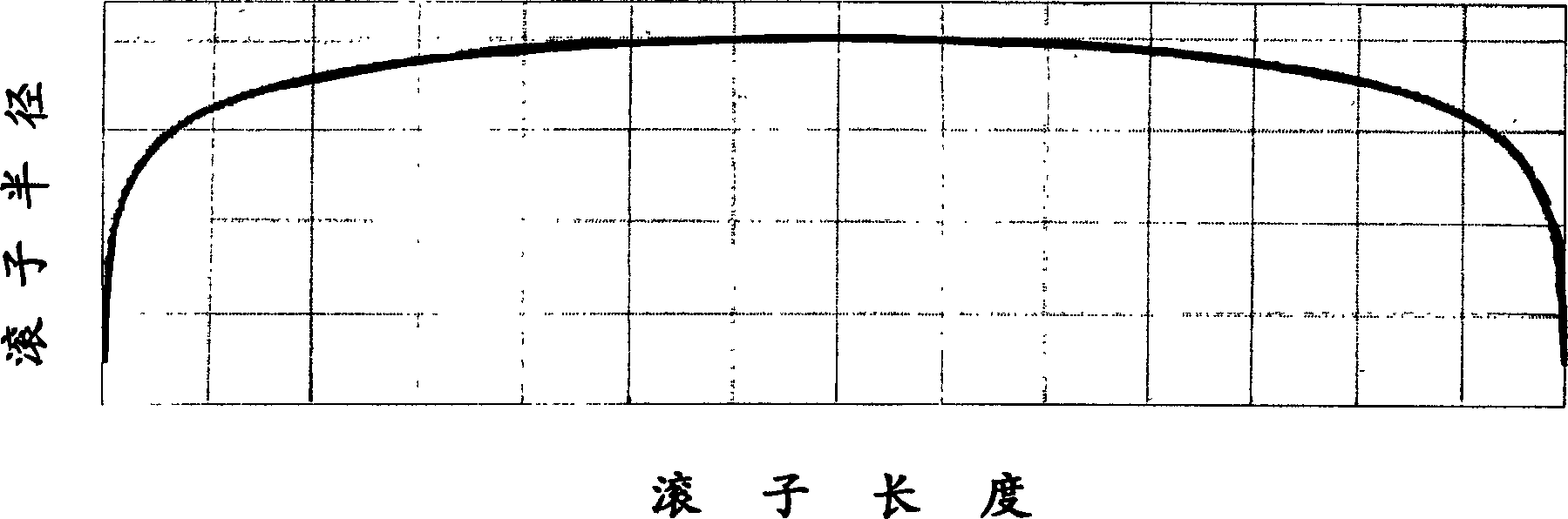

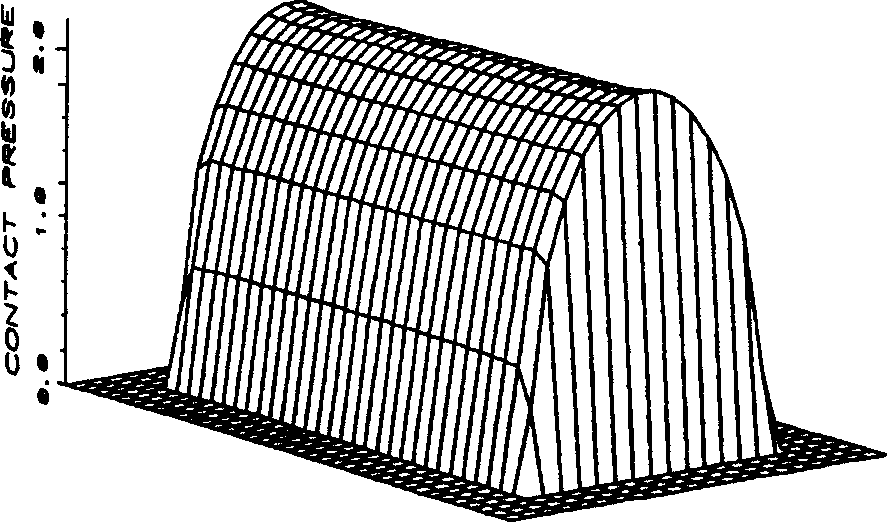

[0021] Such as figure 1 , figure 2 As shown, the shape of the busbar 2 of the bearing surface of the cylindrical roller 1 of the present invention is composed of a symmetrical logarithmic curve from the middle to both sides. The logarithmic curve is slightly raised in the middle of the busbar 2 and slowly decreases to both sides. The two ends of the logarithmic curve generatrix are smoothly connected with two chamfered arcs.

[0022] The logarithmic curve is:

[0023] y = R - K ln 1 ( 1 - ( x l ) 2 ) - - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com