Method for regulating pressure of dresser in chemical mechanical polishing

A technology of pressure regulation and chemical machinery, applied in the direction of abrasive surface regulation devices, grinding machine parts, grinding/polishing equipment, etc., can solve the problem of affecting the mechanical grinding and manufacturing of silicon wafers, affecting the global planarization of wafers, and affecting costs and other problems, to achieve the effect of eliminating the edge effect phenomenon, eliminating the excessive consumption of the edge, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments. It should be understood by those skilled in the art. The content specifically described below is illustrative rather than restrictive. Users can make various changes to the following parameters without departing from the mechanism and scope of the invention set forth in the claims. In order not to obscure the essence of the present invention, well-known methods and procedures have not been described in detail.

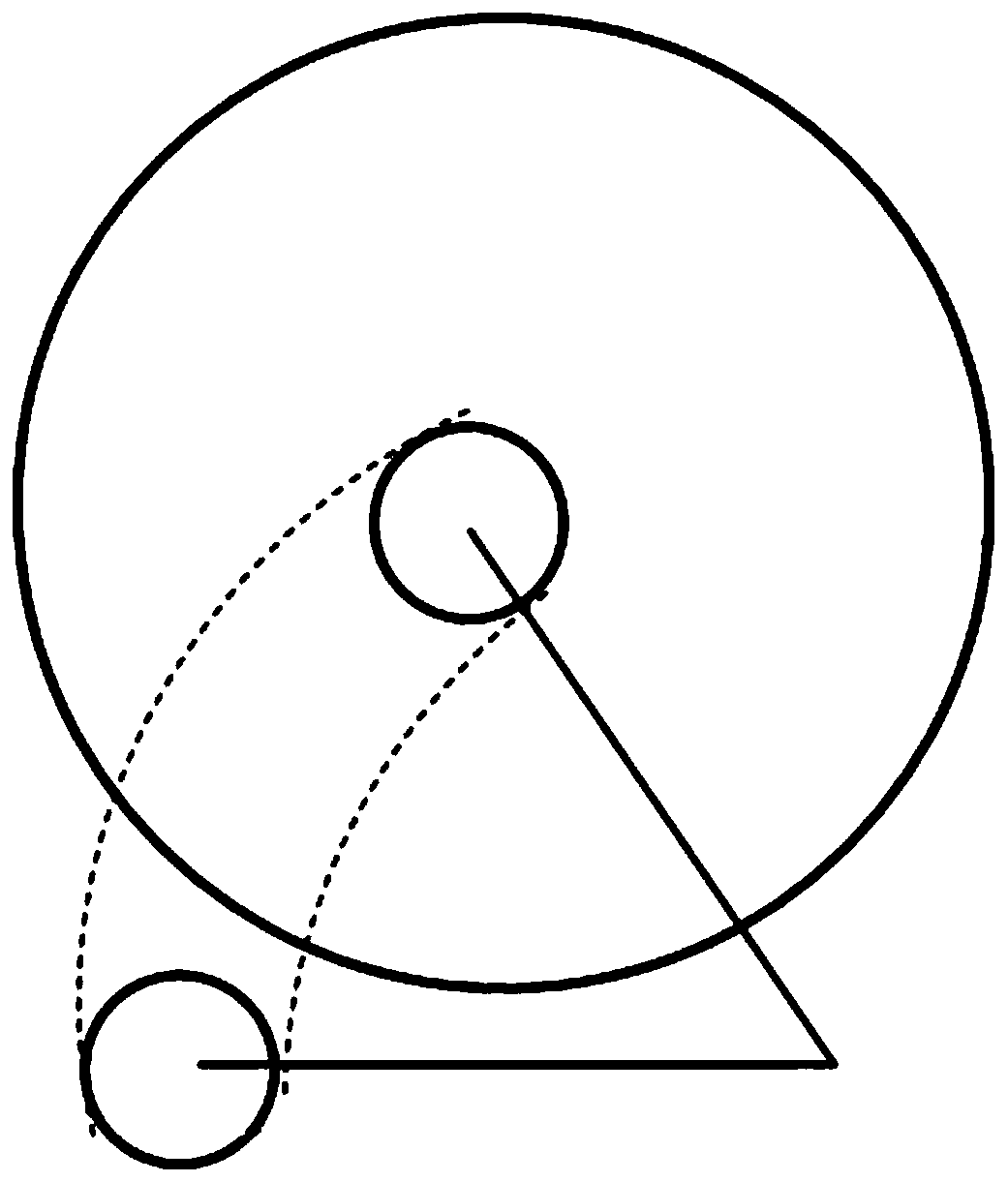

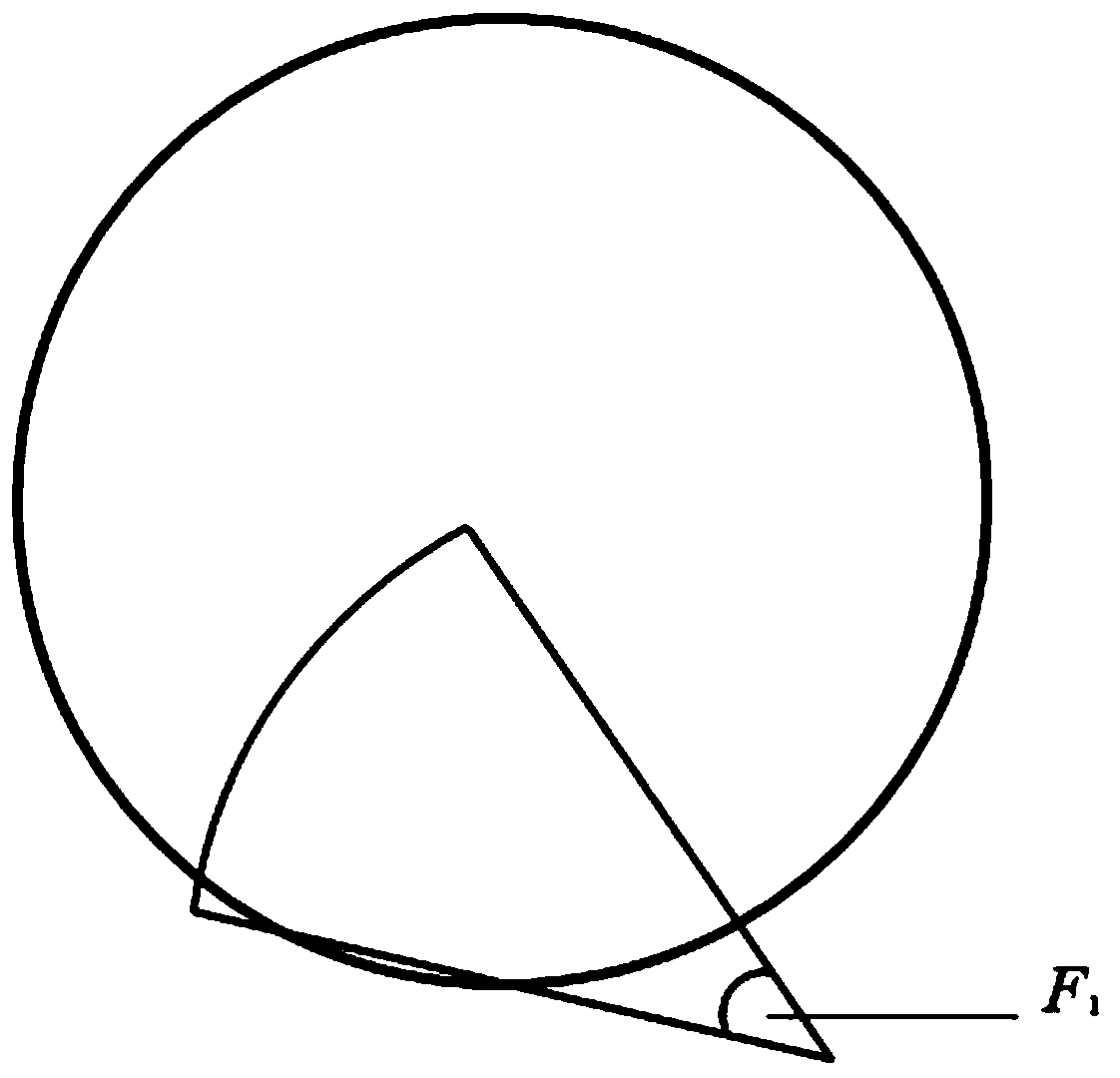

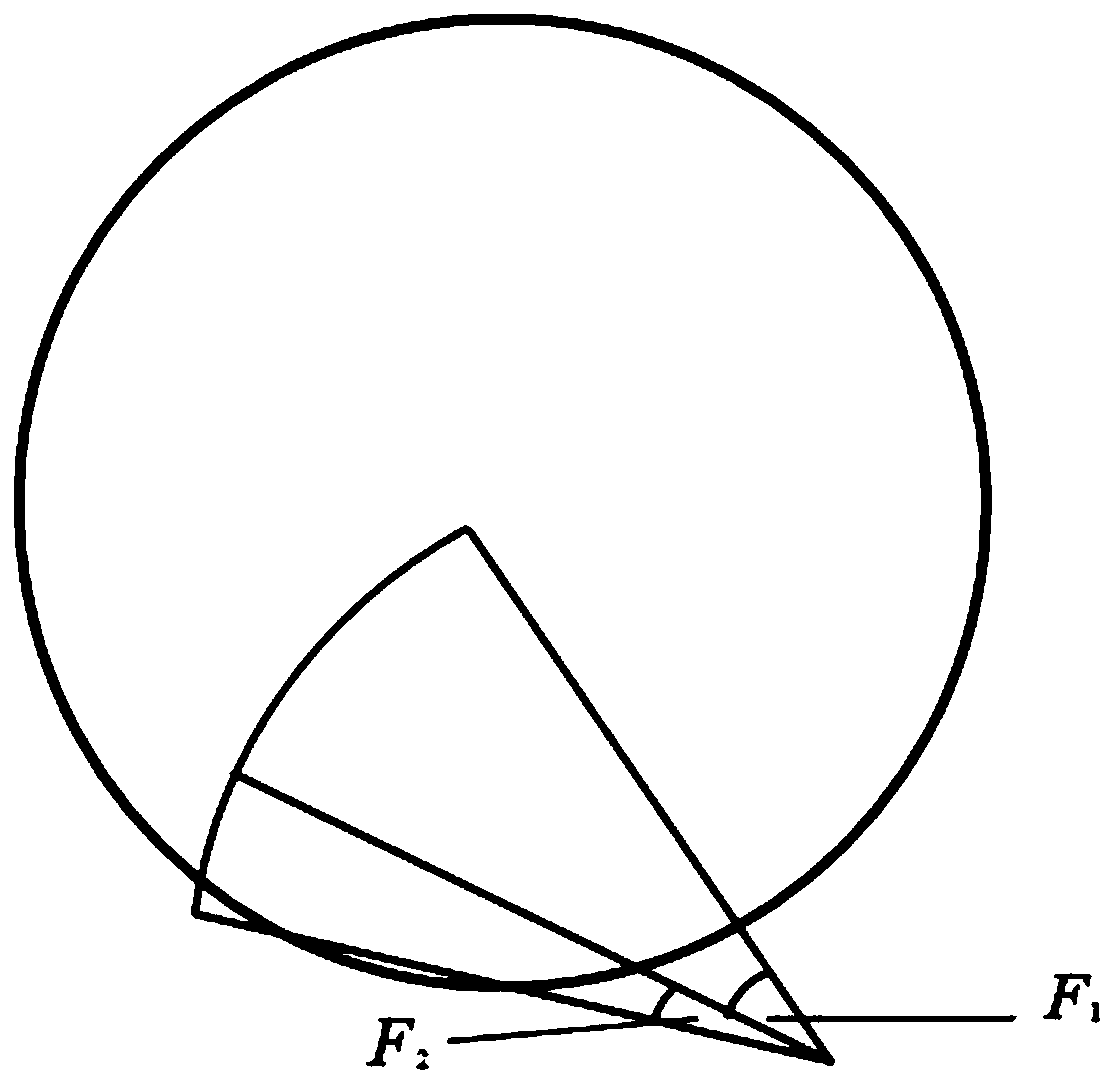

[0024] figure 1 The walking path of the dresser on the grinding pad is shown; figure 2 Schematic diagram showing the pressure distribution of the dresser on the polishing pad before modification, F 1 Set parameters for constant; image 3 Shows the pressure distribution of the dresser on the polishing pad in different regions after the modification of the dresser pressure adjustment method in chemical mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com