Semiconductor wafer electro-deposition method and semiconductor wafer electro-deposition device

An electrodeposition device, semiconductor technology, applied in the direction of semiconductor devices, circuits, electrolytic components, etc., can solve the problems of lower production efficiency, deposition layer color, abnormal appearance and quality of deposition layer, etc., to improve uniformity and eliminate electrodeposition edges The effect of improving efficiency and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

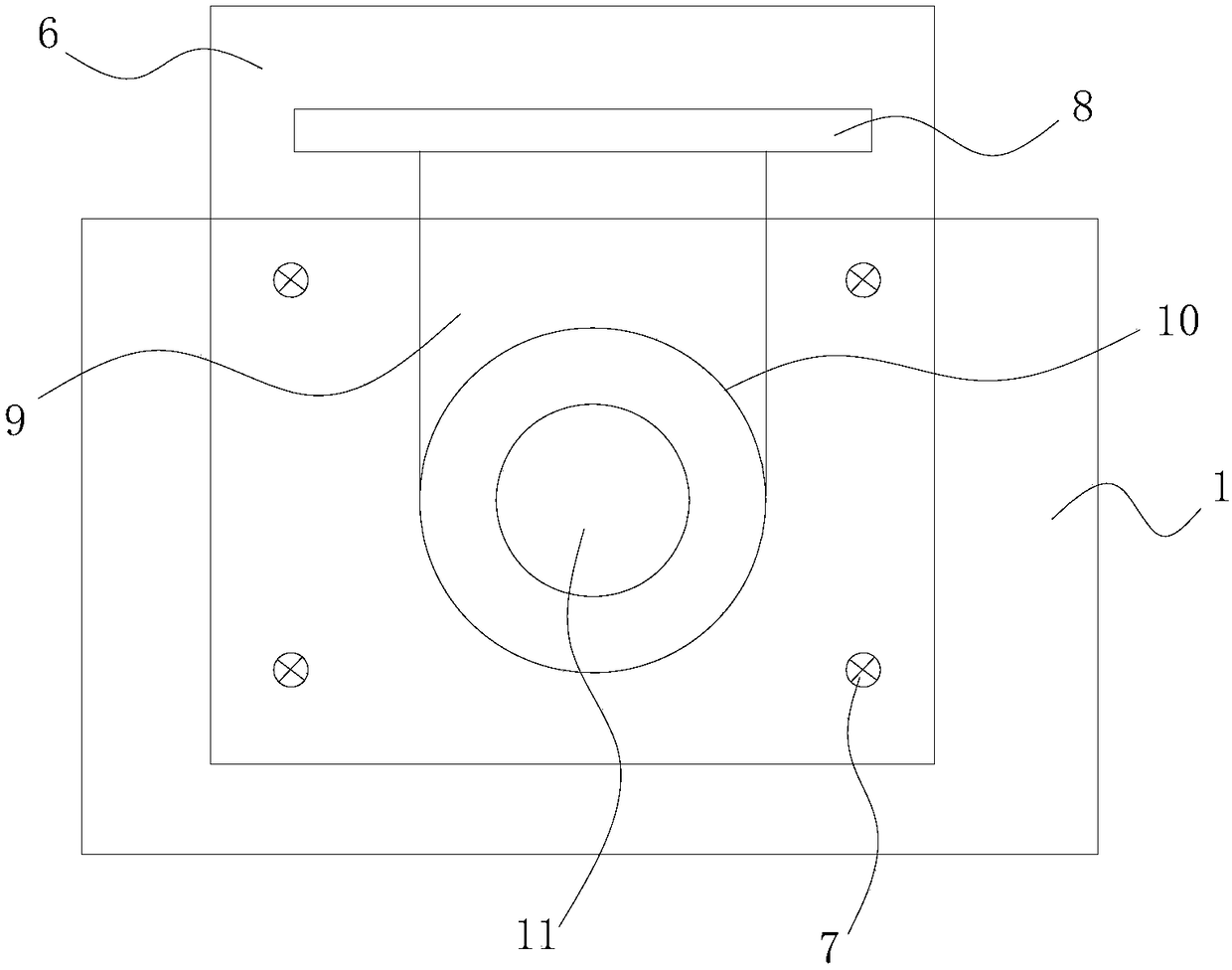

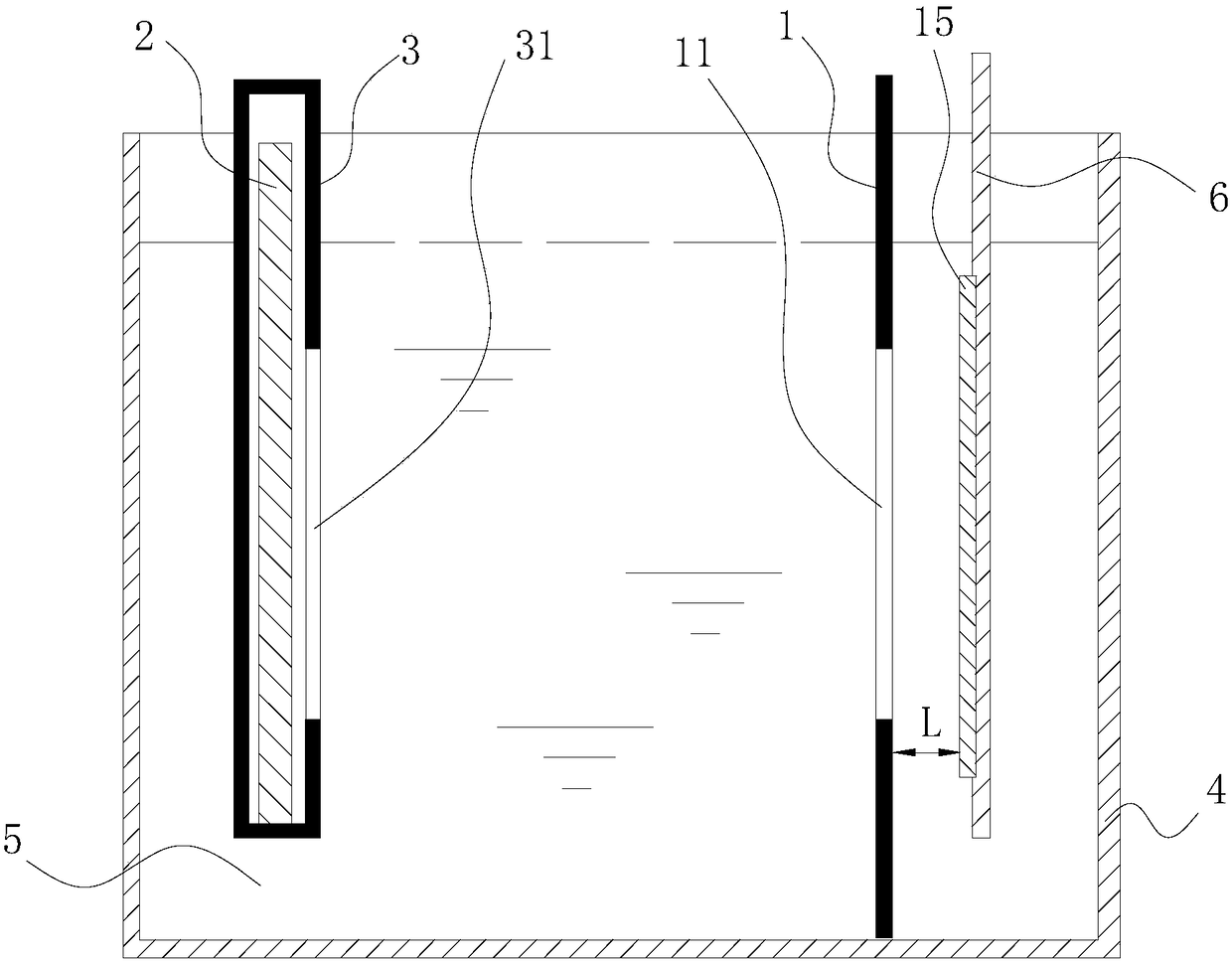

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0025] Preferred embodiment:

[0026] The preferred embodiment discloses a semiconductor wafer electrodeposition method. In the electrodeposition method, the anode only conducts electrodeposition on the middle of the semiconductor wafer to be electrodeposited, so as to avoid the concentration of electric field lines at the edge of the semiconductor wafer to be electrodeposited and produce edge effects. The specific area, shape, and area percentage of the "middle part" on the entire semiconductor wafer to be electrodeposited are not limited, and can be determined according to specific needs, so as to avoid electric field lines on the semiconductor wafer to be electrodeposited. The purpose of concentrating at the edges and creating edge effects is sufficient.

[0027] like figure 1 and figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com