Magneto-rheological supporting device and method for spherical crown thin-wall part

A support device, magnetorheological technology, applied in positioning devices, supports, metal processing machinery parts, etc., can solve the problems of vibration, deformation, lack of rigidity, etc., to achieve high magnetic field strength, good magnetic field continuity, good adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention are further explained below in conjunction with the examples and accompanying drawings, but are not intended to limit the present invention.

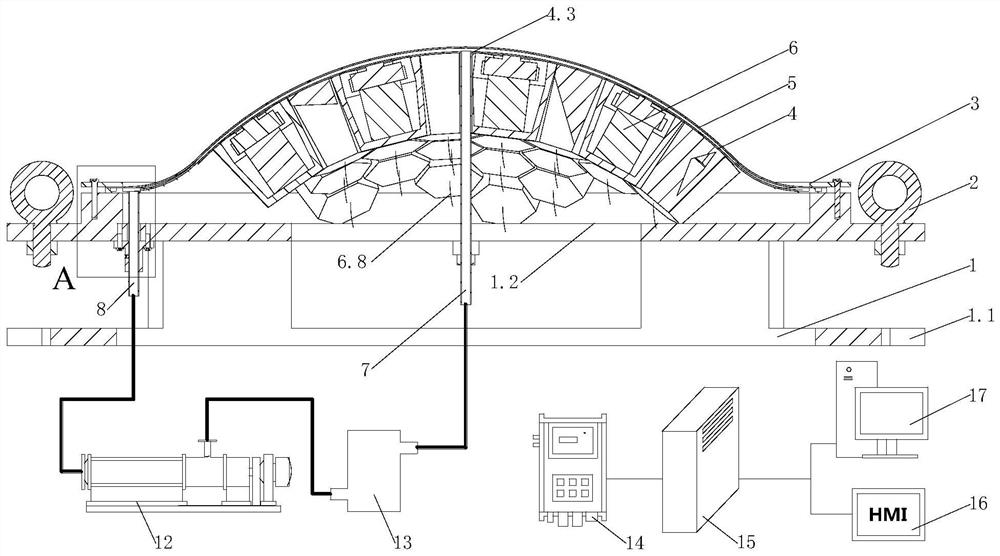

[0026] In this embodiment, the spherical crown 5 is formed by integral spinning of an aluminum alloy plate, the diameter of the bottom circle is 800 mm, the arch height is 160 mm, and the thickness is about 1.5 mm. The magnetorheological fluid is made of 40% volume fraction of carbonyl iron powder and 60% volume fraction of silicone oil, with a density of 3.55g / ml.

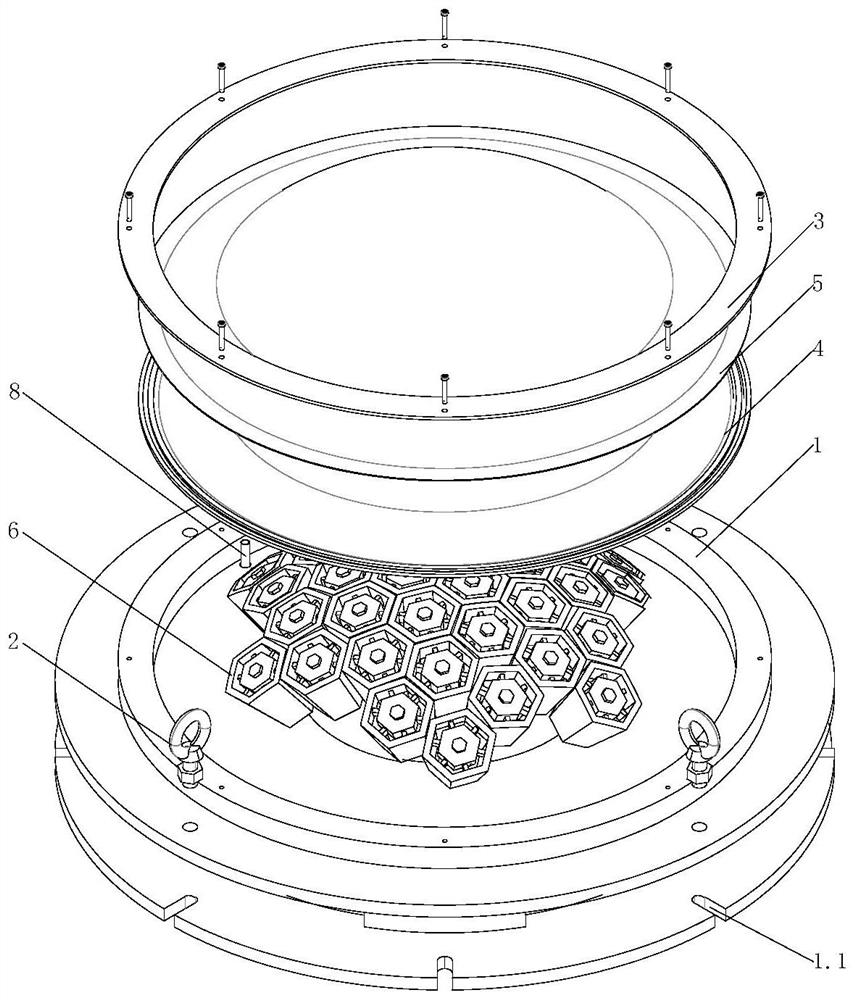

[0027]First, assemble the magnetorheological support device, such as figure 1 and figure 2 . The magnetorheological support device is composed of a spherical array excitation device, a perfusion module and a control module.

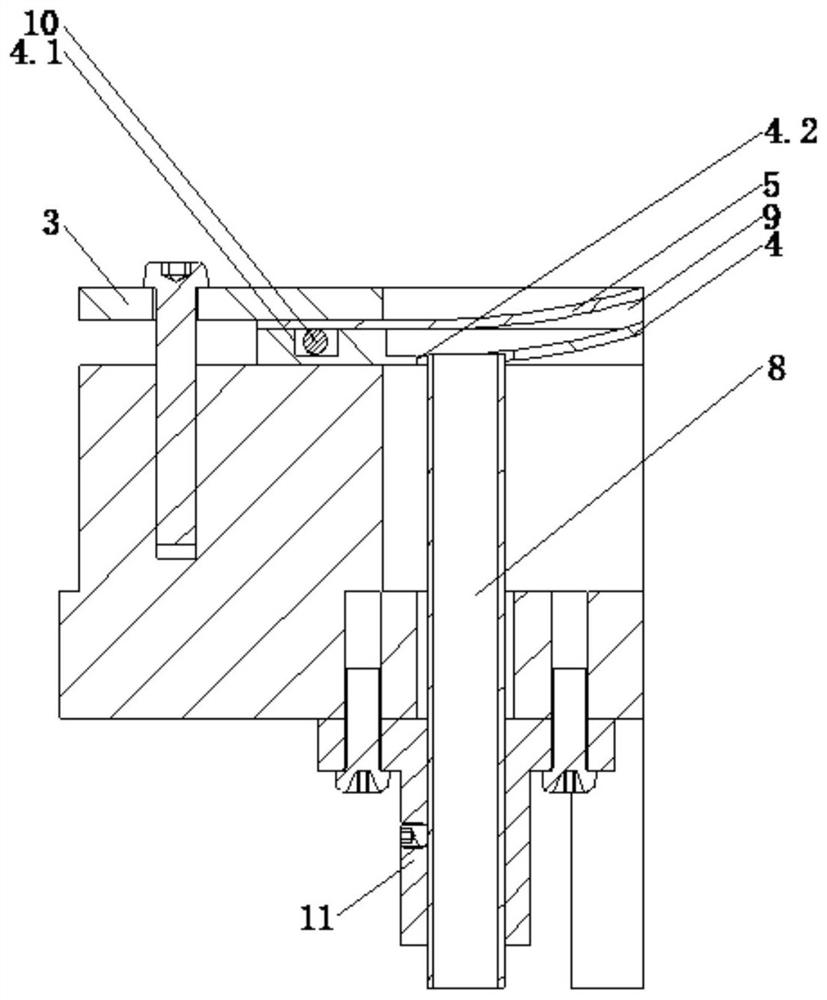

[0028] The spherical array excitation device includes a base 1 , a suspension ring 2 , an excitation unit 6 , a spherical mold 4 , a spherical crown 5 , a sealing ring 10 and a bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com