Light high-strength launch barrel

A high-strength, launch tube technology, applied in the field of launch tubes, can solve the problems that affect the operational performance of the launch system, it is difficult to meet the requirements of light weight, high strength, and the launch platform occupies a large space, so as to improve the operational performance of the aircraft, adapt to the The effect of high installation, reducing space and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

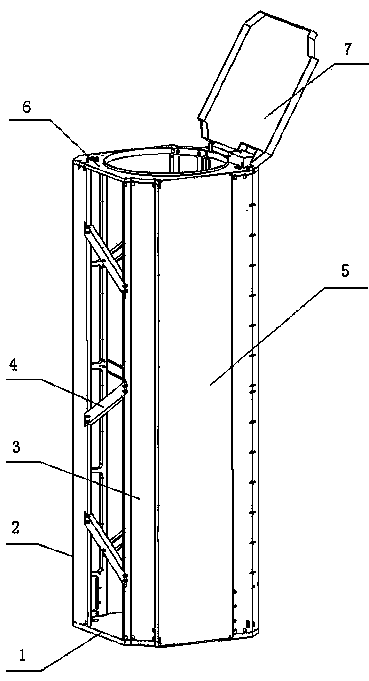

[0015] like figure 1 Shown is a schematic structural view of the launch tube of the present invention. The launch tube includes a cylinder body, a top cover 7, and a base plate 1, and the cylinder body is integrated with the top cover 7 and the base plate 1 by screws. The cylinder body includes a square frame 2, a truss 4, and a thin skin 5. Three trusses 4 are installed on the four sides of the square frame 2 through screws, and two adjacent trusses connected to two adjacent columns form a set. The included angle is to strengthen the strength of the launch tube body, so that the launch tube can withstand a large force, which is safe and reliable. The thin skin 5 surrounds the square frame 2 and is connected with the square frame 2 by screws. The square frame 2 includes four uprights 3 and a top frame 6, each upright 3 is processed with several grooves, the angle and number of the grooves are corresponding to the truss 4, and one surface of each upright 3 in this example Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com