Mechanized oil pipe discharging machine used for oil field

It is a technology of pipe rowing machine and oil pipe, which is applied in the direction of drill pipe, casing pipe, drill pipe, etc. It can solve the problems of high labor intensity of workers and hidden dangers of manual operation safety, and achieve obvious use effect, reduce labor intensity and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

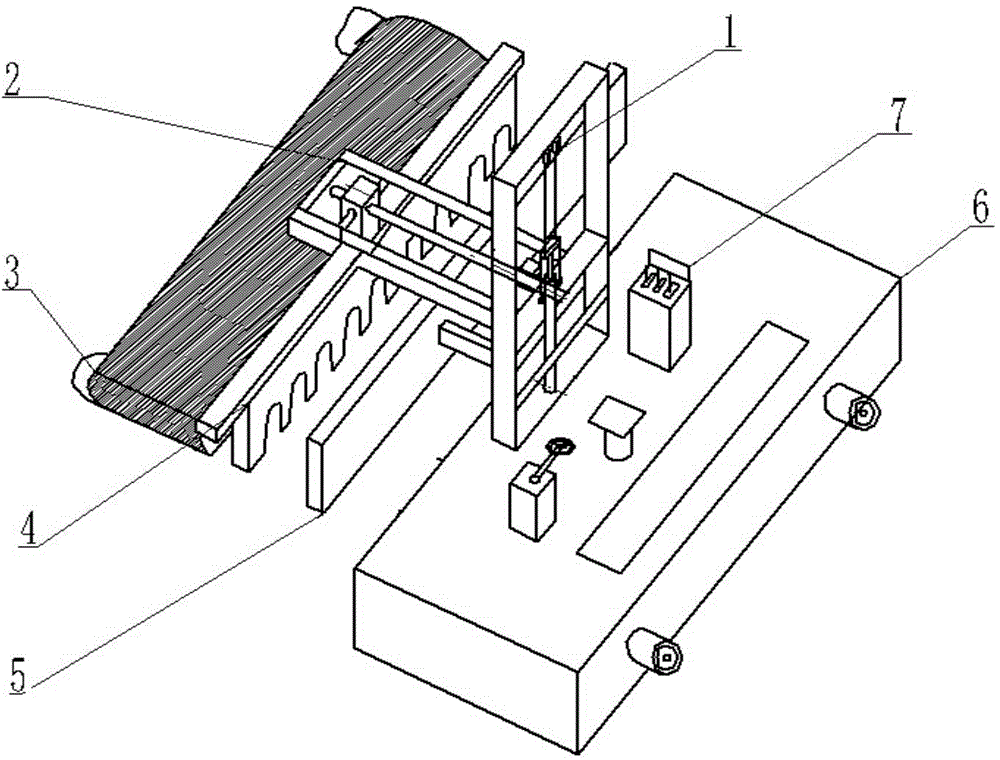

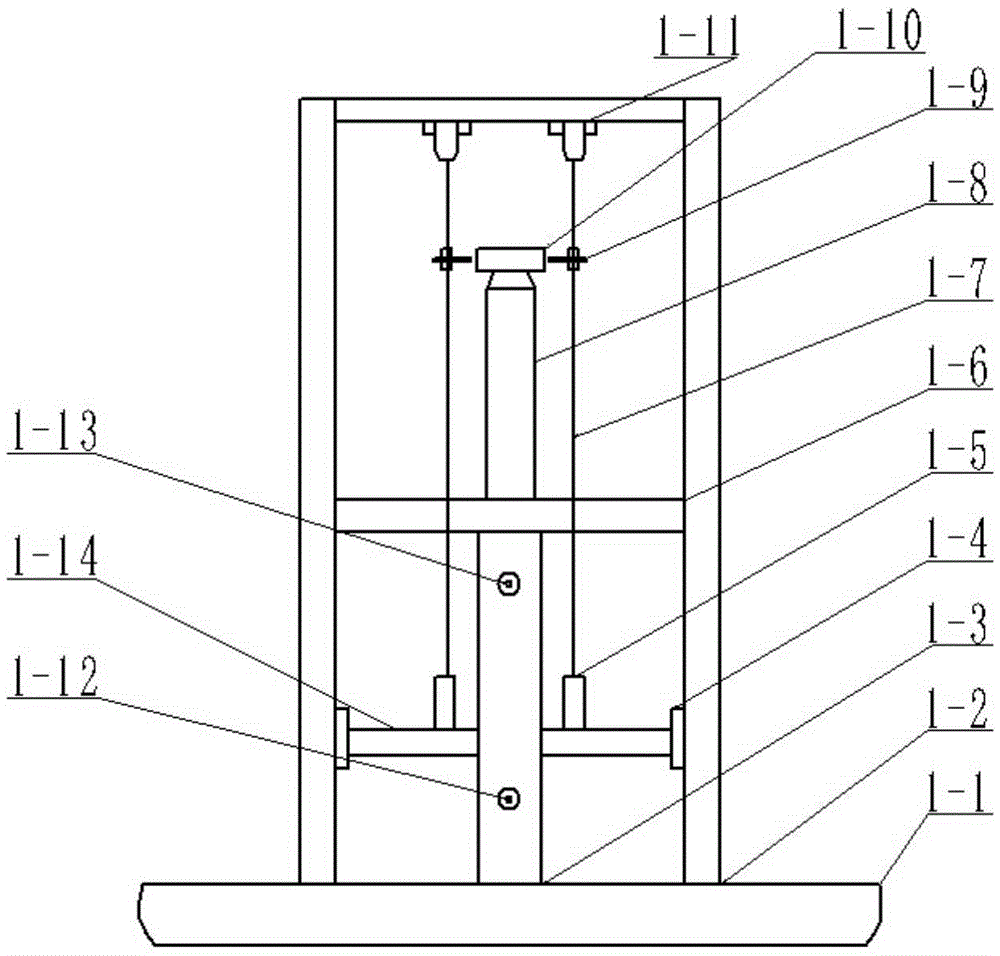

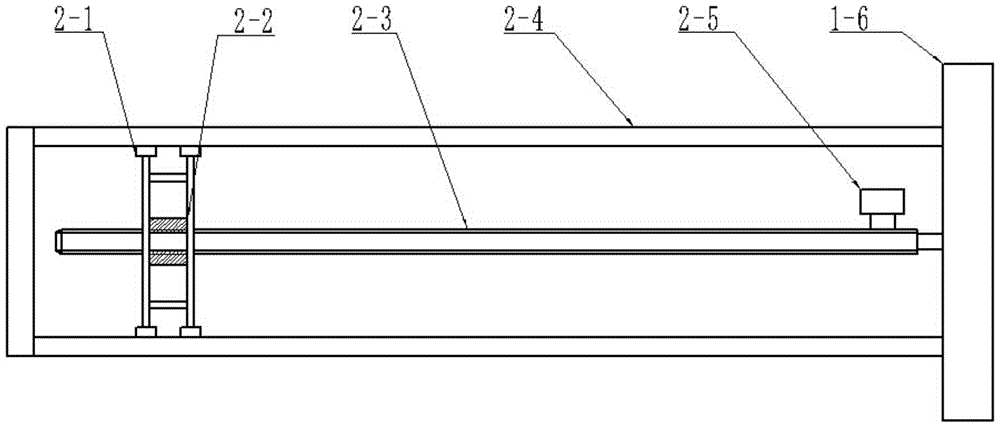

[0027] Refer to attached figure 1 , a mechanized tubing rowing machine for an oil field, comprising a tube lifting mechanism 1, a tube telescoping mechanism 2, a tube pulling mechanism 3, a tube scraper mechanism 4, a tube baffle mechanism 5, an electric traveling mechanism 6, Electric control operating mechanism 7. The pipe lifting mechanism 1 is welded on the frame of the pipe running mechanism 6, the pipe telescopic mechanism 2 is installed on the sliding lifting plate of the pipe lifting mechanism 1, and the pipe pulling mechanism 3 is connected to the pipe scraper mechanism 4 , The pipe scraper mechanism 4 is fixedly connected to the pulley of the pipe telescopic mechanism 2, below the telescopic roller assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com