Intelligent control method for hydraulic excavator

A hydraulic excavator, intelligent control technology, applied in the direction of mechanically driven excavator/dredger, program control, general control system, etc. Re-disassembly and other problems to achieve the effect of improving the control performance and operation ability, the default parameters are accurate and comprehensive, and the operation performance is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

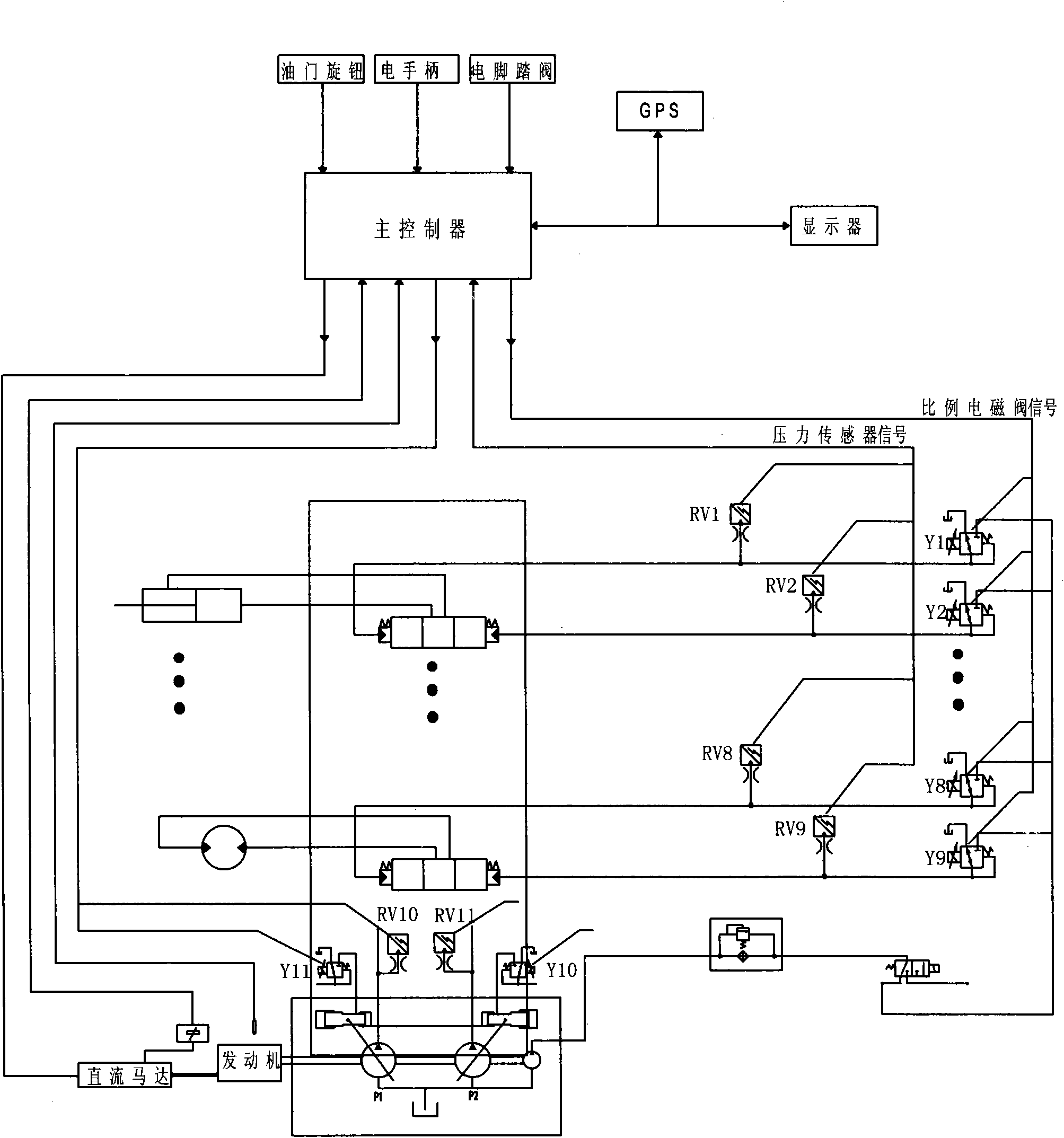

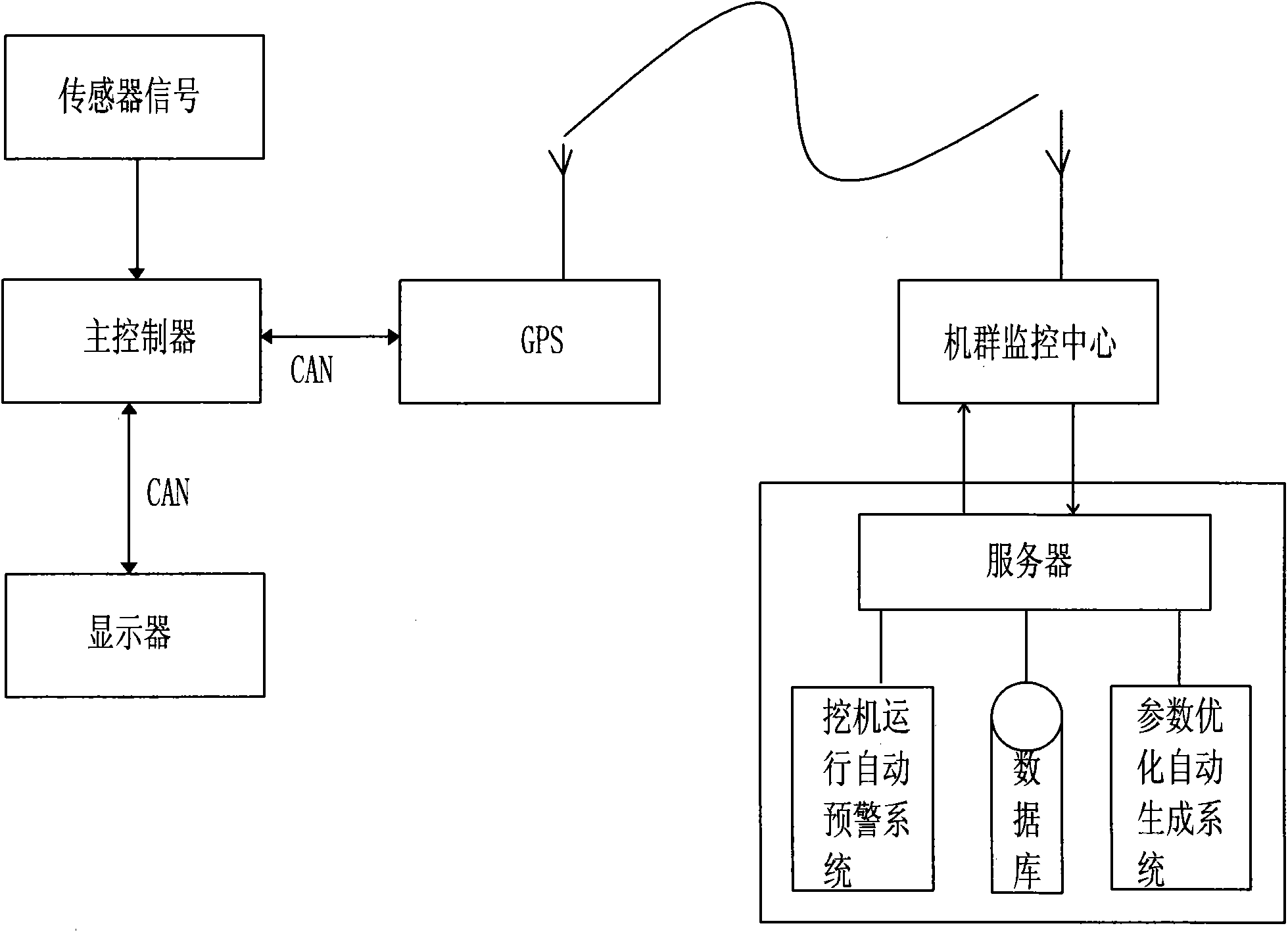

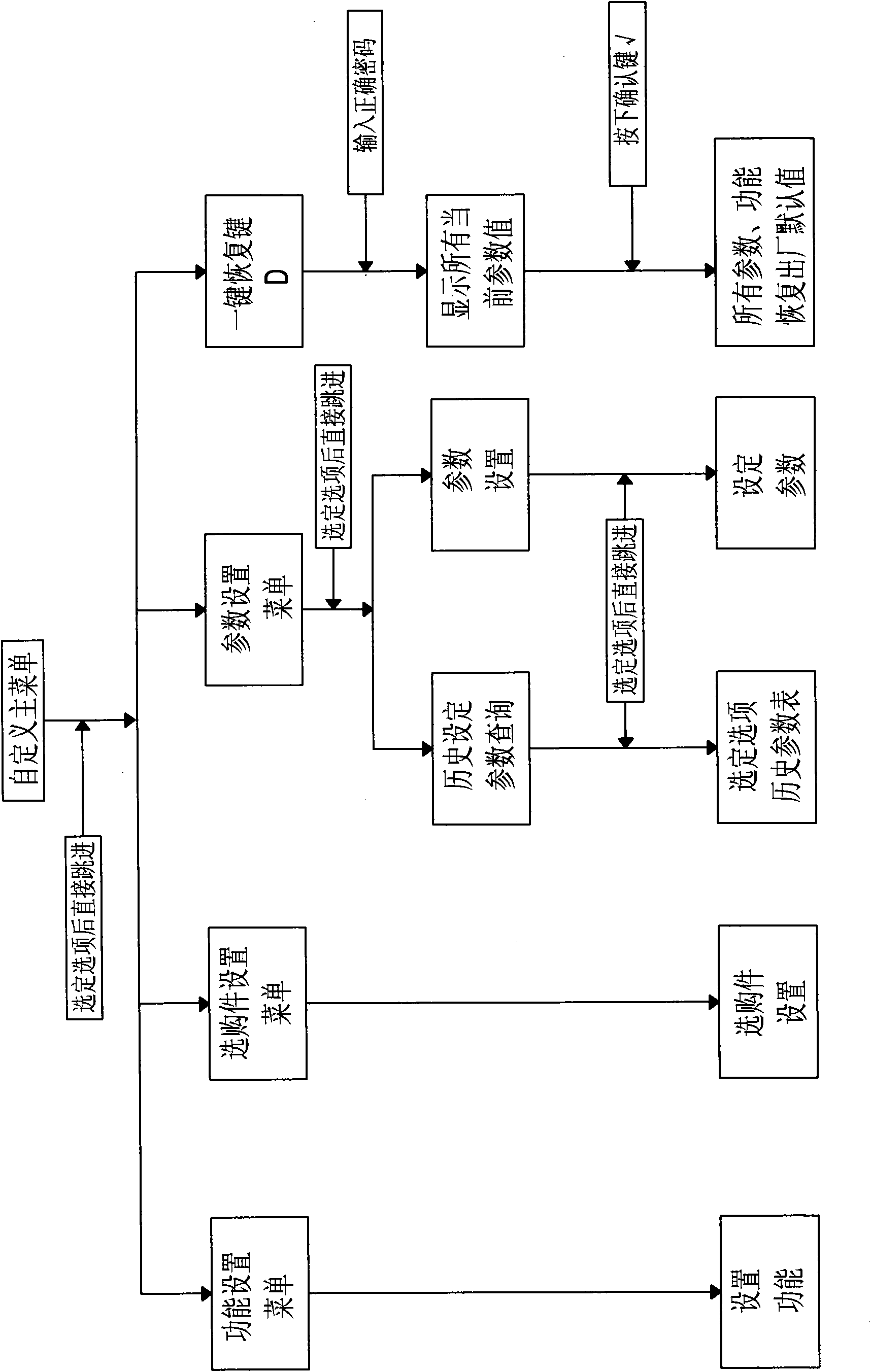

[0035] Embodiment one: see Figure 1~3As shown, an intelligent control method for a hydraulic excavator, the database set in the main controller is divided into a setting area and a recovery area, and the factory default data are stored in the setting area and the recovery area respectively, and the main controller Connect with the display modification interface through the CAN bus, the operation method is as follows:

[0036] a. Data modification:

[0037] (1) The main controller detects data, such as figure 1 As shown, including handle signal, each pilot pressure sensor signal RV1~RV9 on the excavator, main pressure signals RV10, RV11 of the front and rear pumps, and ambient temperature sensor signal, the control parameters of the excavator and the adjustment range of the engine output power can be obtained through logical operation;

[0038] (2) The operator sets the control parameters of the excavator and the output power of the engine on the display modification interfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com