Robot programming control method

A programming control and robotics technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of large workload, poor popularization, cumbersome coding process, etc., to improve operation performance, good versatility and standardization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

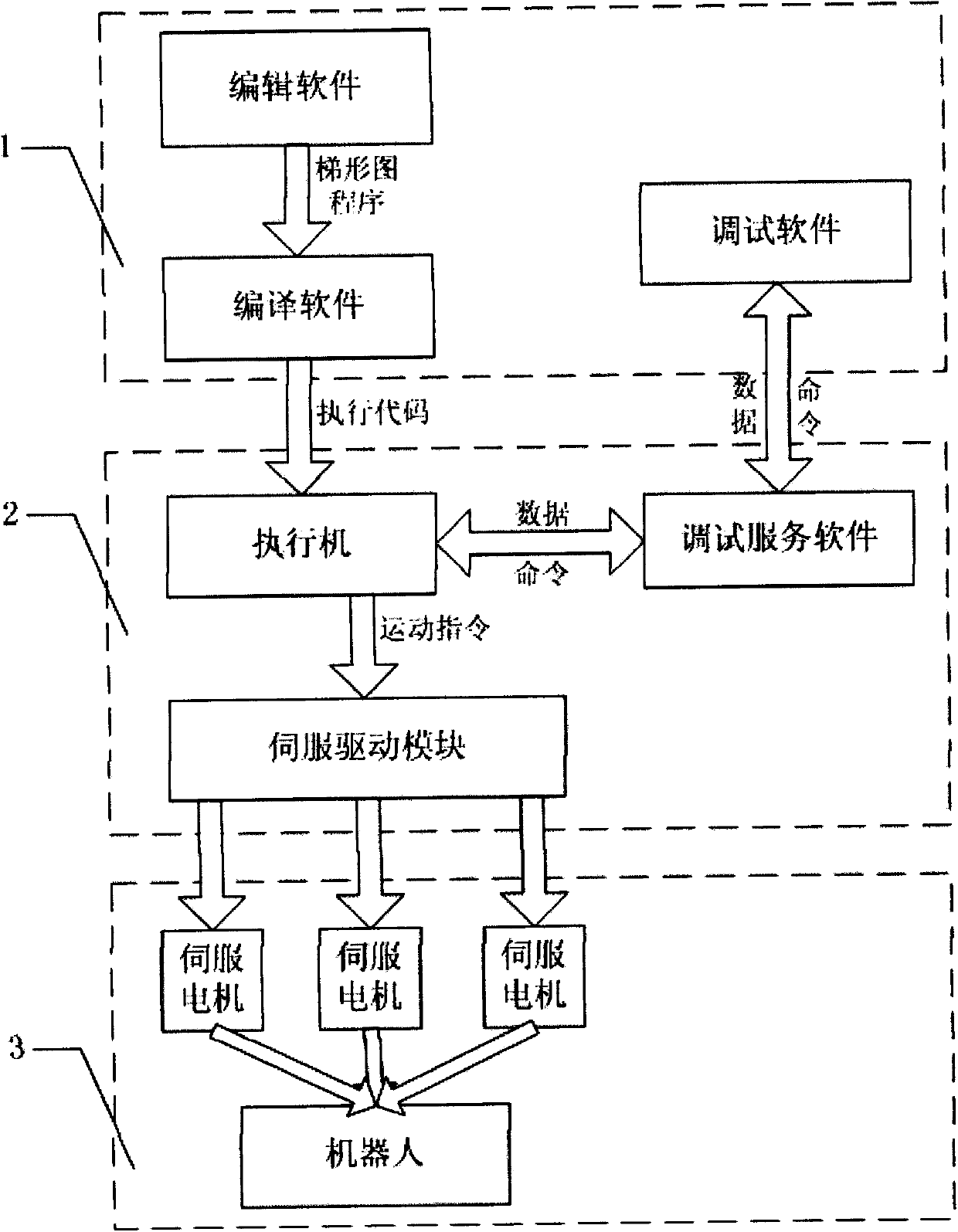

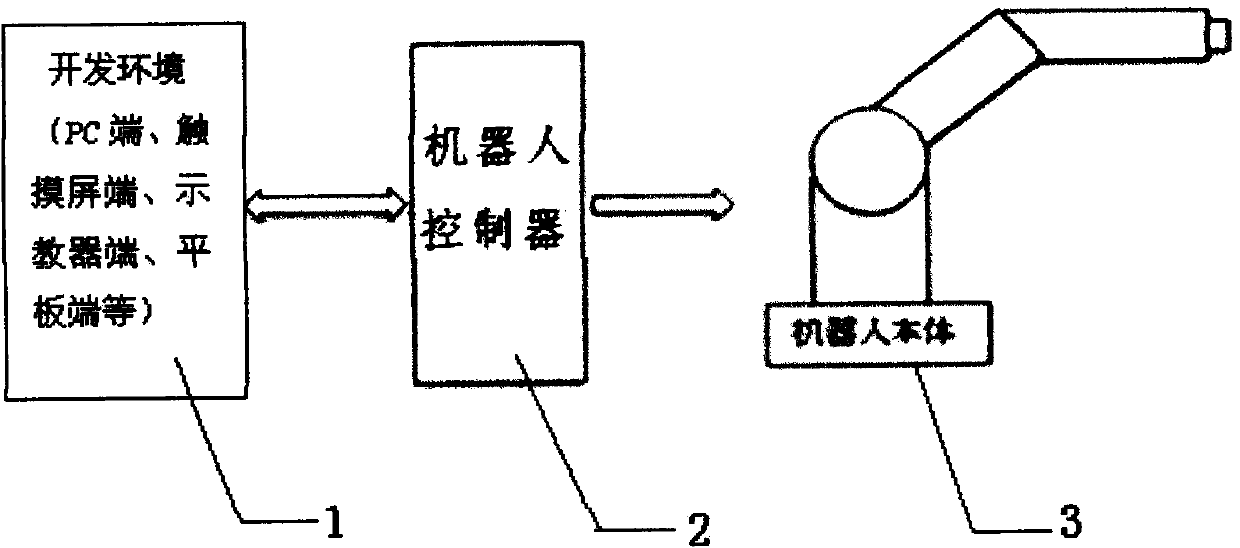

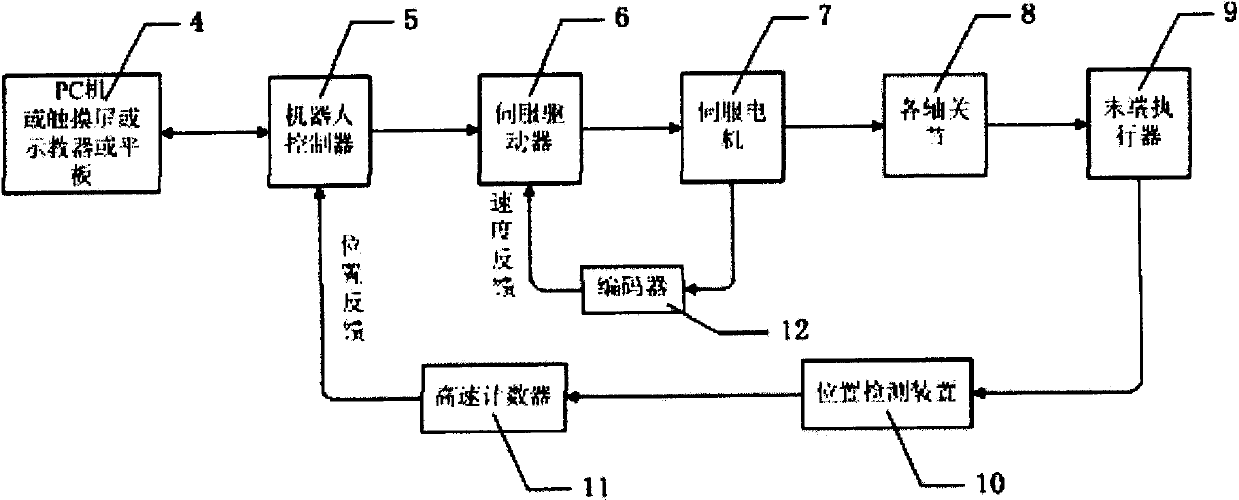

[0014] figure 1 , figure 2 Described, relate to a kind of robot programming control method, comprise the following steps: 1) in the program editor of development interface 1, edit all operating instructions of robot 3 with ladder diagram programming, and this operating instruction is used to control robot 3 Motion process and posture; 2) generate the instruction code that robot controller 2 can execute by the described operation instruction of above-mentioned ladder diagram programming mode design by compiling module; 3) send above-mentioned instruction code to the servo drive module in the robot controller, Thereby driving the servo motor drives the robot 3 to complete all actions in the space. Wherein, the described development interface 1 in step 1) also includes debugging software, and the debugging software sends the debugging command to the executive body through the debugging service software in the robot controller 2; The debugging service software feeds back variab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com