Lifting and swinging hydraulic device for snow remover and snow remover with same

A hydraulic device and snow blower technology, which is applied in snow cleaning, cleaning methods, construction, etc., can solve the problems of high labor intensity in snow clearing operations, low transmission efficiency of snow blowers, and short service life, and achieve large torque and high torque Good effect of enlargement and dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

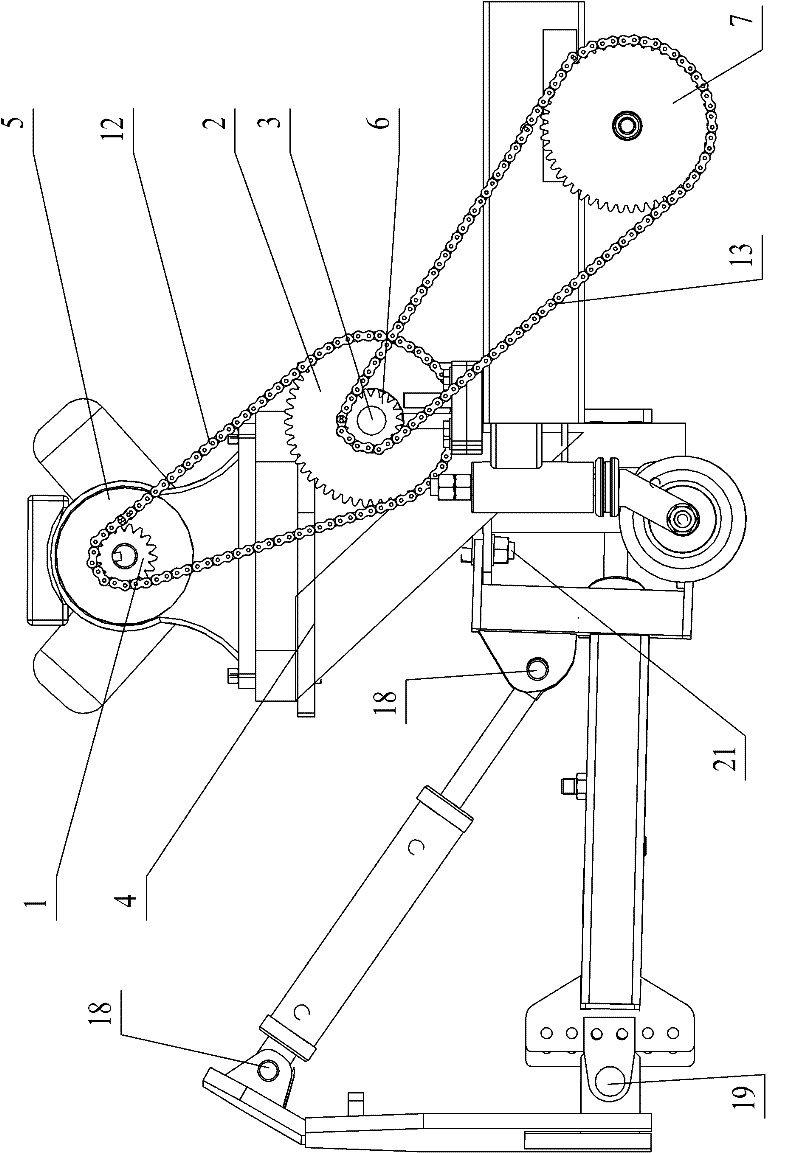

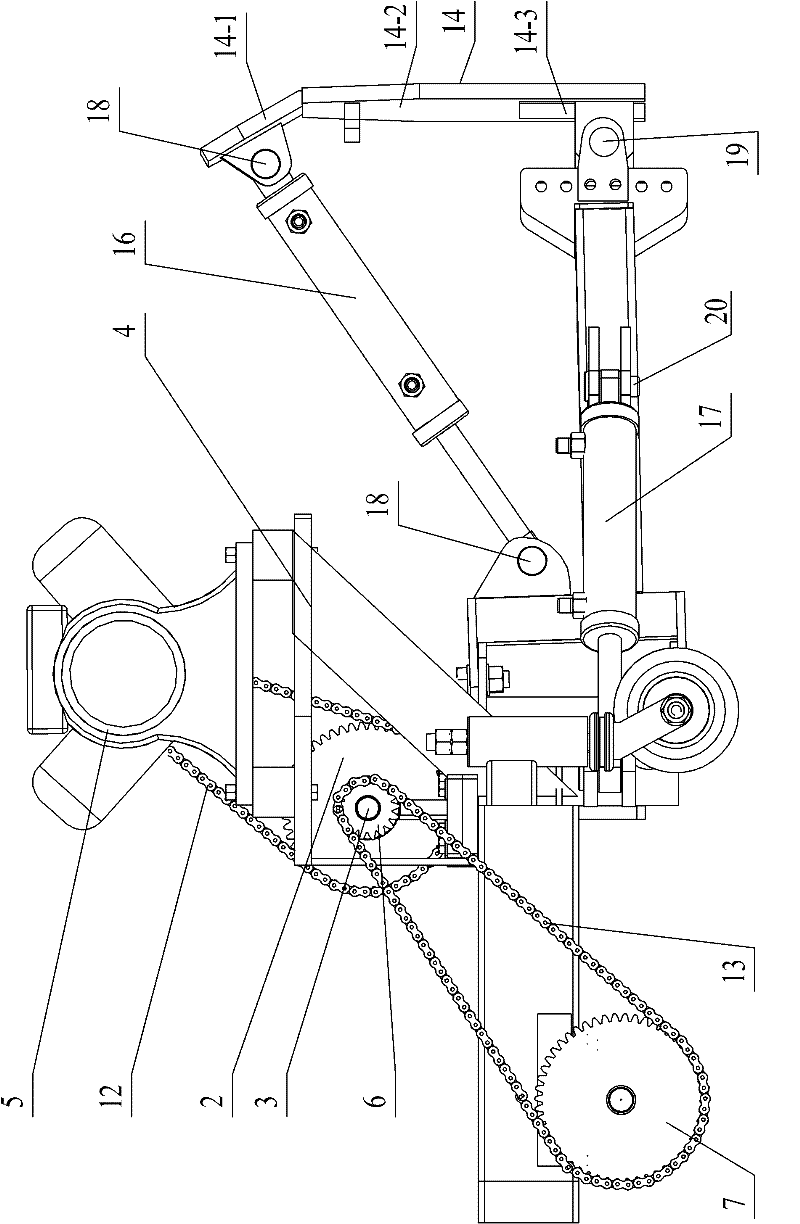

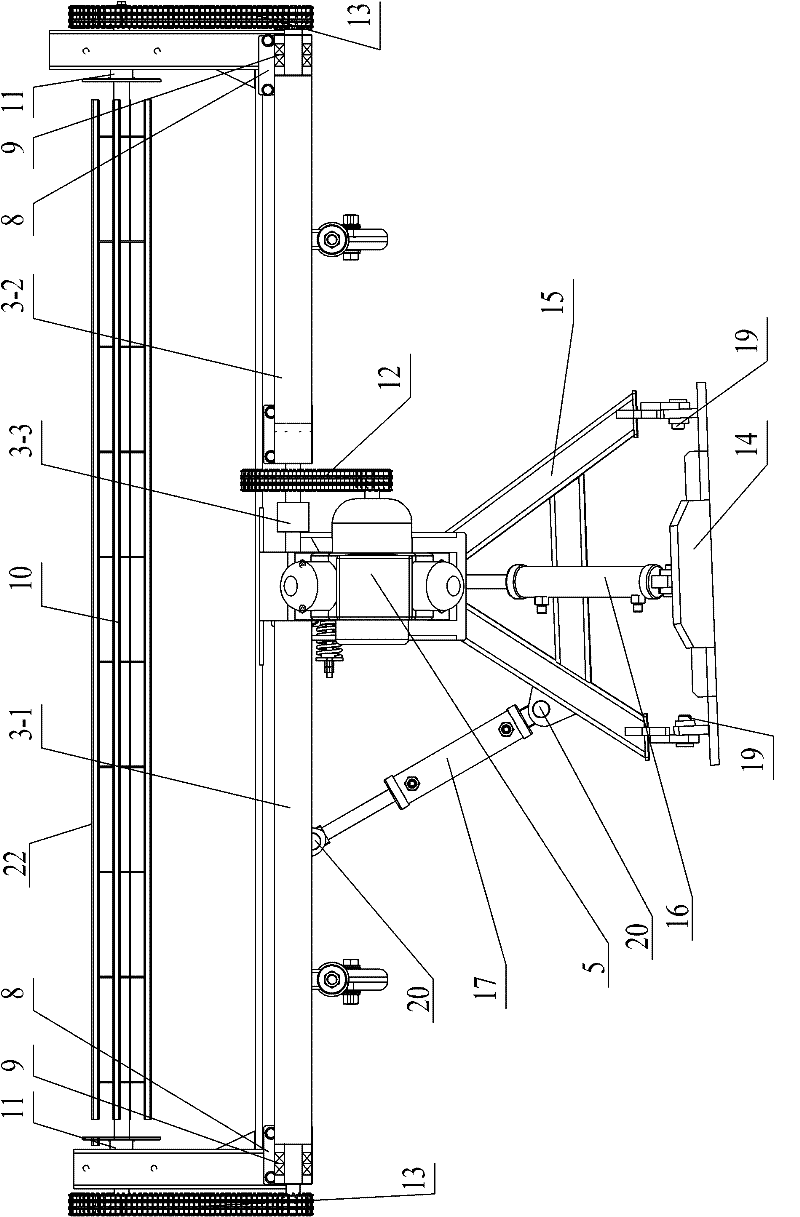

[0011] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, the lifting and swinging hydraulic device for the snow blower described in this embodiment includes a vertical plate 14, an A-shaped frame body 15, a lifting cylinder 16 and a swinging cylinder 17, and the cylinder bottom end surface of the lifting cylinder 16 is The connecting ear of the upper part of the vertical plate is hinged with the connecting ear on the upper part of the vertical plate 14 through the movable pin shaft 18 of the lifting cylinder, and a diagonal rod end at the bottom end of the tower of the A-shaped frame body 15 is hinged with the connecting ear on one side of the lower part of the vertical plate through the integral movable pin shaft 19. , the other oblique rod end of the tower bottom end of the A-shaped frame body 15 is hinged with the connecting ear on the other side of the lower part of the vertical plate through the integral movable pin shaft 19, and the ...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination Figure 1~4 Describe this embodiment, the vertical plate 14 in this embodiment is composed of a slant plate 14-1, a main plate 14-2 and two sub-plates 14-3, the slant plate 14-1 is connected to the upper end surface of the main plate 14-2 As a whole, two sub-boards 14-3 are separated on both sides of the lower end of the main board 14-2, and each sub-board 14-3 is connected with the lower end surface of the main board 14-2; The connecting ear on the top and the connecting ear on the inclined plate 14-1 are hinged through the movable pin shaft 18 of the lifting cylinder, and a rod end at the bottom end of the tower of the A-shaped frame body 15 and the connecting ear on the corresponding sub-plate 14-3 pass through the whole The movable pin shaft 19 is hinged, and the other rod end of the tower bottom end of the A-shaped support body 15 is hinged with the connecting ear on the corresponding another rod end sub-board 14-3 by t...

specific Embodiment approach 3

[0013] Specific implementation mode three: combination Figure 1 ~ Figure 3 To illustrate this embodiment, the snow blower with the lifting and swinging hydraulic device described in the first or second embodiment includes a snow removal roller 22, a main frame 4 and a toothed chain output transmission device. The snow blower also includes lifting and swinging hydraulic devices for the snow blower; the toothed chain output transmission device includes a driving small-toothed sprocket 1, a driven large-toothed sprocket 2, a drive shaft 3, and an air-cooled double Cylinder diesel engine 5, roller brush shaft 10, toothed chain 12, two transmission small sprockets 6, two transmission large sprockets 7, two bearing housings 8, two rolling bearings 9, two belt seat bearings 11 and two Drive chain 13; the air-cooled two-cylinder diesel engine 5 is fixedly installed on the upper end of the main frame 4, and the output shaft of the air-cooled two-cylinder diesel engine 5 is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com