Organic cotton fiber bunchy yarn and manufacturing process thereof

A production process, organic cotton technology, applied in the direction of yarn, textiles and papermaking, etc., to achieve the effect of good wear resistance, small machine footprint, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

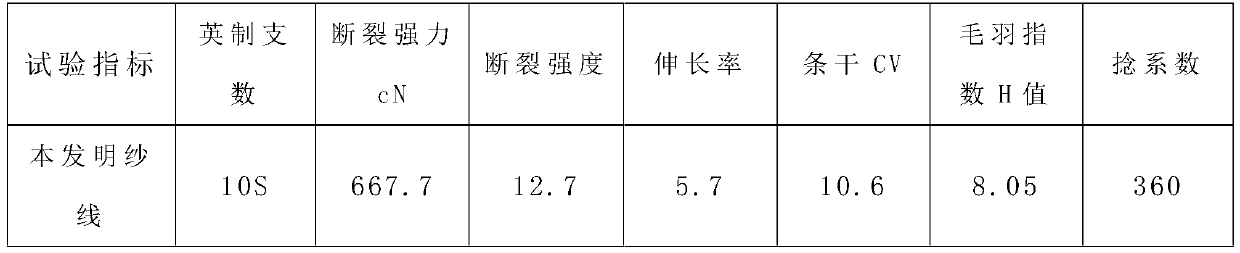

Examples

Embodiment

[0043] Due to market demand, in order to improve people's clothing experience, new environmentally friendly fiber fabrics have become a research hotspot. The present invention caters to the market and provides the market with a manufacturing process of organic cotton fiber slub yarn. The technical scheme is as follows:

[0044] A kind of manufacture technology of organic cotton fiber slub yarn, comprises the steps:

[0045] Cotton cleaning, the organic cotton fiber rolls are sequentially put into the automatic plucking machine, mixed cotton opener and cotton opener whose operating parameters have been adjusted to obtain the organic cotton fiber cotton layer;

[0046] Carding, put the organic cotton fiber cotton layer into the carding machine whose operating parameters have been adjusted to obtain raw cotton sliver;

[0047] Drawing frame, put the raw cotton sliver into the drawing frame machine, carry out the first and second parallel drawing, and obtain the cooked cotton sliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com