Cotton fiber and jutecell fiber blended yarn and spinning process thereof

A fiber blending and cotton fiber technology, applied in fiber mixing, fiber treatment, yarn, etc., can solve the problems of short fiber, poor yarn quality, and difficult blending process, and achieve high single yarn strength, Low cost, the effect of improving the fabric feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

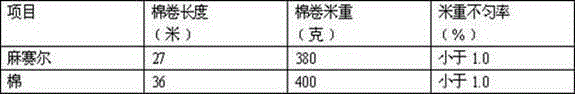

[0025] 1. Blending ratio: velvet cotton / masser is 30 / 70. The cotton fiber fineness is 1.6dtex, and the fiber length is 38mm. The fineness of hempcell fiber is 1.4dtex, and the fiber length is 38mm. Blended yarn count: 14.7tex.

[0026] 2. Process flow:

[0027] FA002A Automatic Grabbing Machine --- A035D Mixing Opener --- FA106 Cotton Opener --- A092E Cotton Feeder --- A076E Roller --- A186G Carding Machine -- Combined Maser + combed sliver --- FA302 draw frame --- THF4433 roving frame --- FA506 spinning frame --- SMARO automatic winder.

[0028] 3. Process configuration and quality control measures.

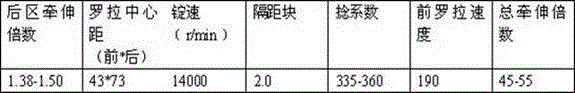

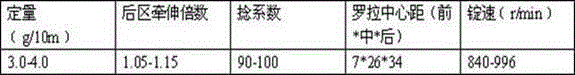

[0029] 3.1 Start cleaning process.

[0030] According to the characteristics of the raw material of Masail, the fiber length is long and the uniformity is good. In the opening and cleaning process, the process principle of "more loosening and less beating, full opening and anti-adhesion" should be adopted. For A035D spinning Masail, the porcupine small Beater, the A092V ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com