Compact-spun combed cotton yarn (300S) and spinning process thereof

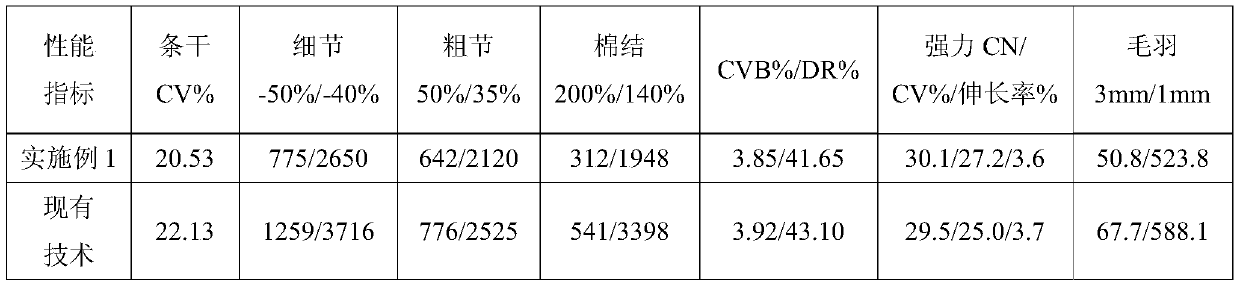

A compact spinning and combing technology, applied in the field of spinning, which can solve the problems of long process, high labor and high cost, and achieve the effects of less yarn defects, less short staple growth and uniform evenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 A kind of compact spinning combed 300 cotton yarn spinning process

[0030] In this embodiment, 100% American long-staple cotton fiber is used for spinning, the length of the cotton lap is 36m, and the weight of the lap is 14.5kg; Axial flow opener—FA022 multi-compartment blending machine—FA106 porcupine opener—FA046 vibrating cotton box—A076F single beater lapping machine—FA201B carding machine—FA305C pre-coiler—A191B sliver coiling machine—A201E combing machine— FA317A Drawing Frame—FA415A Roving Frame—EJM128K Spinning Frame—NO.21C Self-winding;

[0031] This embodiment includes the following steps:

[0032] A. Cleaning process: the beating speed of the cotton fiber automatic catching machine is controlled at 700r / min, the beating speed of the cotton opener is controlled at 500r / min, the beating speed of the single beating machine is 930r / min, and the speed of the lapping roller is 12r / min;

[0033] B. Carding process: the quantitative control is 13.5g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com