Siro core-spun yarn blended with soybean fiber and bamboo fiber and its spinning process

A soybean fiber and bamboo fiber technology, which is applied in the field of core-spun yarn spinning, can solve the problems that the characteristics of soybean fiber cannot be fully reflected, the added value of the product is low, and the yarn strength is low, so as to achieve flexible spinning forms, improve fabric feel, The effect of high single yarn strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

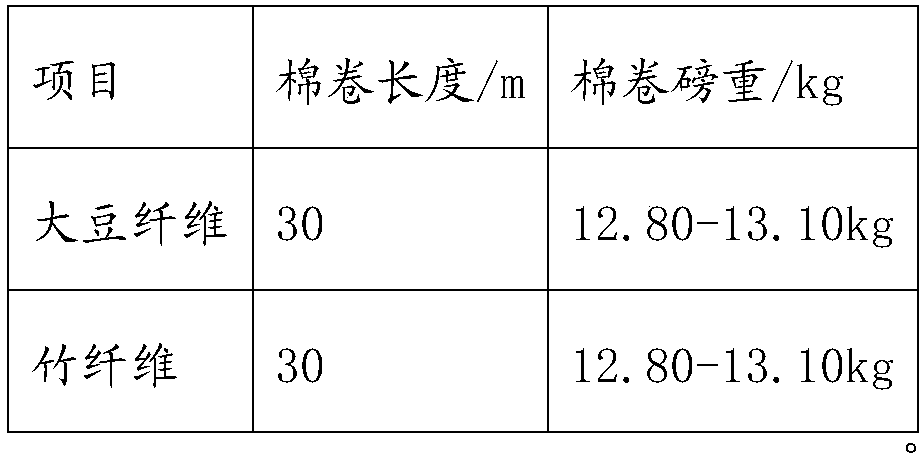

[0036] Soybean fiber: manual feeding→FA106B opener→FA046 type vibrating box feeder→A076F type single beater hand-rolling machine→FA201B carding machine→FA317A type draw frame (pre-combining);

[0037] Bamboo fiber: manual feeding→FA016 type mixed opener→FA022 type multi-bin cotton blender→FA106B opener→FA046 type vibrating box feeder→A076F type single beater lap machine→FA201B type carding machine→ FA317A type draw frame (pre-combination);

[0038] Soybean fiber pre-drawing + bamboo fiber pre-drawing warp: FA317A blending (triple)→FA317A drawing frame→FA317A drawing frame→FA415A roving frame→FA506 spinning frame→NO.21C automatic winding machine.

[0039] 1.1- Soy fiber health treatment:

[0040] Soybean fiber has poor moisture absorption capacity and fast moisture dissipation. It needs to be sprayed with antistatic agent aqueous solution (F08 silk and fiber antistatic agent, Wuhan Changyu Technology Co., Ltd.) (one ton of soybean fiber requires 10 kg of antistatic agent, antistatic ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com