Blended yarn of tussah silk and cotton fiber and spinning method of yarn

A technology of blending yarn and tussah silk, which is applied in the direction of yarn, textiles and papermaking, and can solve problems such as low utilization rate, increased production cost, and difficulty in preparing high-quality cotton fiber and tussah silk blended yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

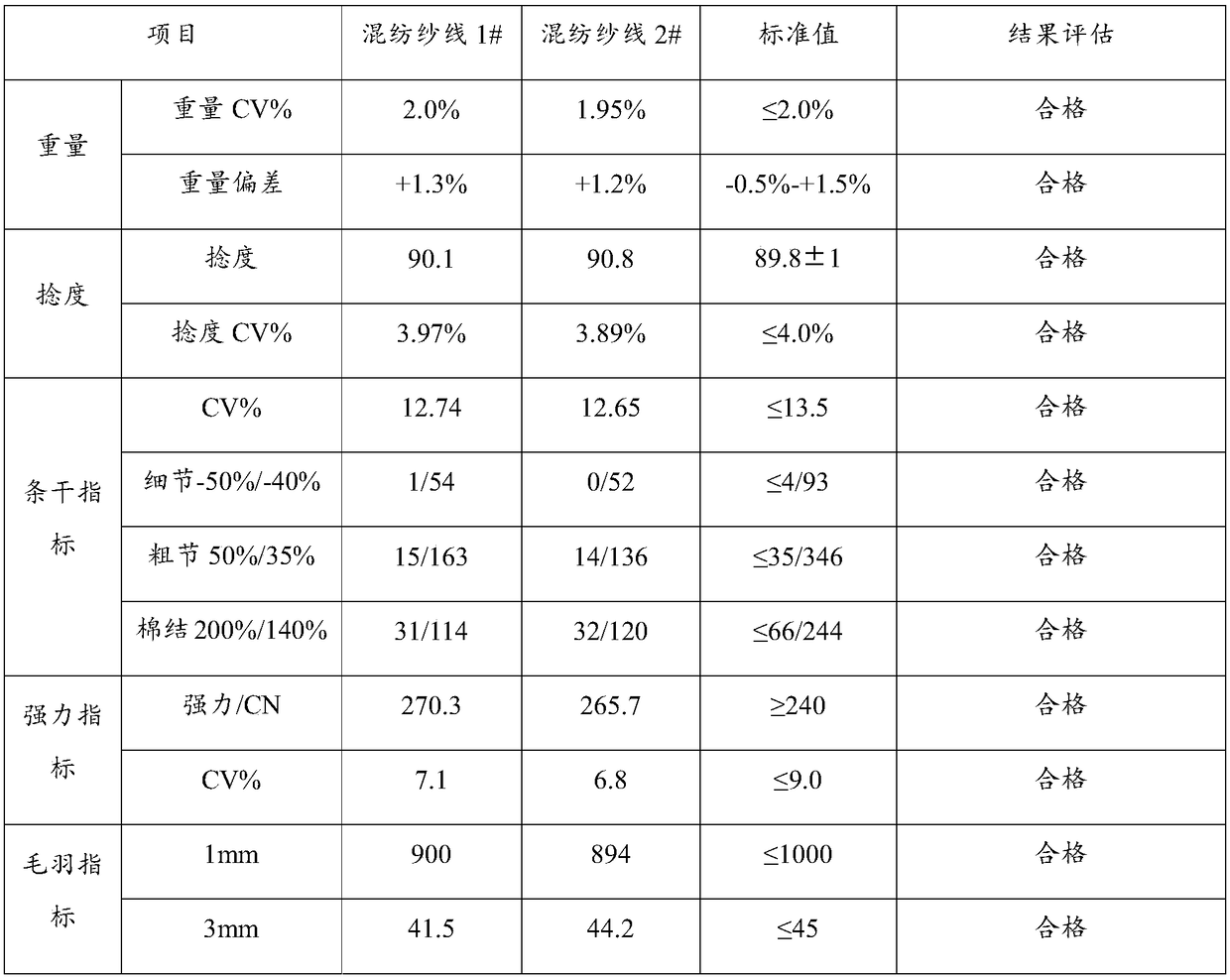

Embodiment 1

[0069] The concrete spinning method of blended yarn 1# comprises the following steps:

[0070] 1.1 Cleaning process:

[0071] The long-staple cotton is processed by automatic plucking machine, mixed opener, multi-bin blender, cotton opener, vibrating cotton box feeder, and single beater lapping machine. The beater speed of the automatic plucking machine is controlled at 720r / min, the beater speed of the cotton opener is controlled at 480-540r / min, the beater speed of the single hand lapper is 1000r / min, and the speed of the lap roller is 10r / min, which is fully opened and free of holes; the weight is 12.9kg, Moisture regain: raw material 5.5%, cotton lap 5.3%; ambient temperature / humidity 30℃ / 65%;

[0072] 1.2 Carding process:

[0073] For cleaning cotton: the gauge of the upper / lower cotton web cleaner before each gauge of the carding machine is 12-15‰ British silk / 12-15‰ British silk, and the gauge of the licker-in roller and dust removal knife is adjusted to 12-15‰ For ...

Embodiment 2

[0092] The present embodiment prepares blended yarn 2# and the spinning method difference of blended yarn 1# is:

[0093] The blending ratio of combed long-staple cotton / tussah silk in blended yarn 2# is 90% / 10%.

[0094] 1.2 Carding process: carding 20.5g / 5m

[0095] 1.4 Combing process

[0096] The combing process includes the following steps: the vehicle speed is 135 nips / min, the brush speed is controlled at 1000r / min, the draft gauge is 12mm, the noil gauge is 11.0mm, and the noil rate in the combing test is 16.30%;

[0097] Combed cotton quality: combed sliver weight 21.3g / 5m, noil rate 17.40%; ambient temperature / humidity 34°C / 59%;

[0098] 1.5 Mixing process

[0099] The pre-merged tussah silk sliver and the combed cotton fiber slivers are mixed for the second time, and the mixing conditions are controlled to obtain the mixed yarn; the ambient temperature / humidity is 31°C / 61%;

[0100] Mixed yarn: the mass ratio of CMC / tussah silk is 90% / 10%, and its fineness is 40...

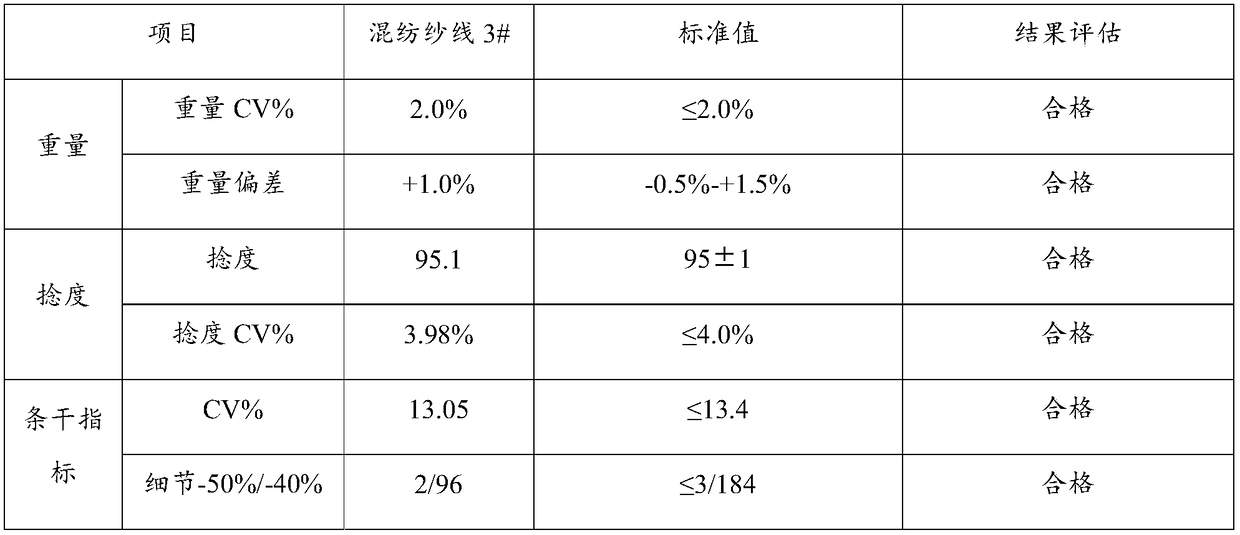

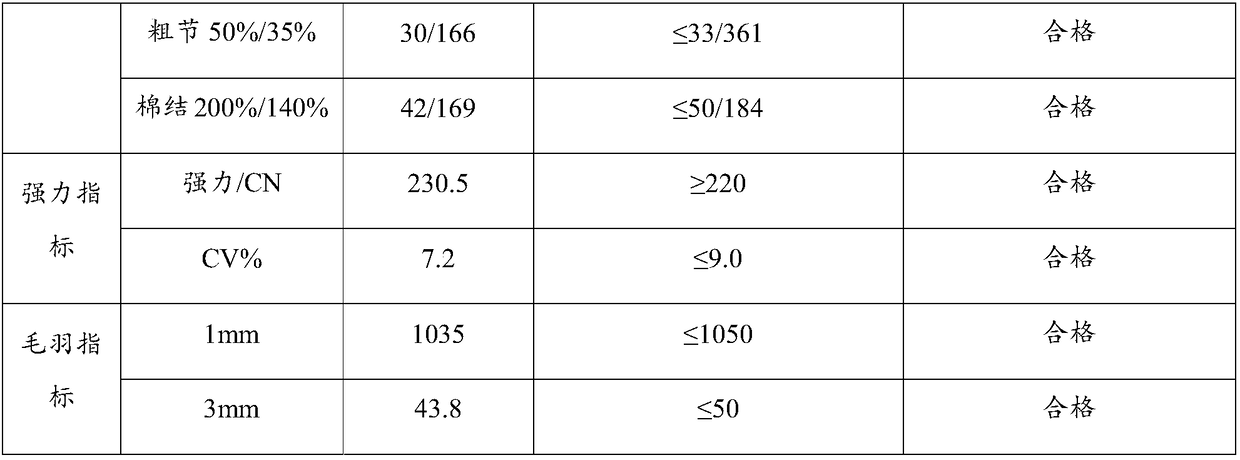

Embodiment 3

[0110] The present embodiment prepares blended yarn 3# and the spinning method difference of blended yarn 1# is:

[0111] The blending ratio of combed long-staple cotton / tussah silk of blended yarn 3# is 50% / 50%.

[0112] 1.2 Carding process: the distance between the licker-in roller and the dedusting knife is adjusted to 15-18‰ British silk, and the carding is 20.5g / 5m.

[0113] 1.3 Combed cotton fiber pre-combed process: total draft / draft ratio of rear area 6.15 / 1.76.

[0114] 1.4 Combing process

[0115] The combing process includes the following steps: the vehicle speed is 135 nips / min, the brush speed is controlled at 1000r / min, the draft gauge is 12mm, the noil gauge is 11.0mm, and the noil rate in the combing test is 16.30%;

[0116] Combed cotton quality: combed sliver basis weight 19.0g / 5m, noil rate 17.40%; ambient temperature / humidity 33°C / 60%;

[0117] 1.5 Mixing process

[0118] The pre-merged tussah silk sliver and the combed cotton fiber slivers are mixed fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com