Fabric and preparation method thereof

A production method and fabric technology, applied in the direction of fabric, fabric elongation, fabric surface trimming, etc., can solve the problems of easy arching and deformation of clothing, uncomfortable wearing, and the wearer's sense of restraint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In the present invention, the cotton / tencel blended yarn and the core-spun yarn are woven in a 3 / 1 right-hand oblique manner to obtain a gray cloth, and the core-spun yarn includes Sorona staple fiber / polyester / cotton blended outer fiber and X4 zol TM -J single hole spandex filament inner core. The present invention has no special limitation on the preparation process of the core-spun yarn, and the preparation method well known to those skilled in the art can be used. Specifically, the core-spun yarn is prepared by siro spinning. In the present invention, the preparation method of the core-spun yarn preferably comprises the following steps:

[0032] Sorona staple fiber / polyester (T) / cotton (C) blended outsourcing fibers are sequentially processed through blending, cleaning, carding, drawing and roving to prepare roving;

[0033] Feed two rovings parallel to the bell mouth through the spinning frame at the same time;

[0034] Will X4 zol TM -J single-hole spandex fi...

Embodiment 1

[0043] Sorona staple fiber / polyester / cotton blended outsourcing fibers are sequentially processed through blending, cleaning, carding, drawing and roving to prepare roving;

[0044] Feed two rovings parallel to the bell mouth through the spinning frame at the same time;

[0045] Will X4 zolTM -J single-hole spandex filament is introduced into the godet wheel through the spandex device, and the pre-drawing ratio of the filament is 3 to 3.5 times;

[0046] The roving prepared by the outsourcing fiber and the single-hole spandex filament are merged in front of the nip of the front roller. At the same time, the spandex filament is placed between the two roving filaments by using the siro spinning method. After being output by the front roller, it is twisted The spandex yarn is wrapped inside to make a core-spun yarn.

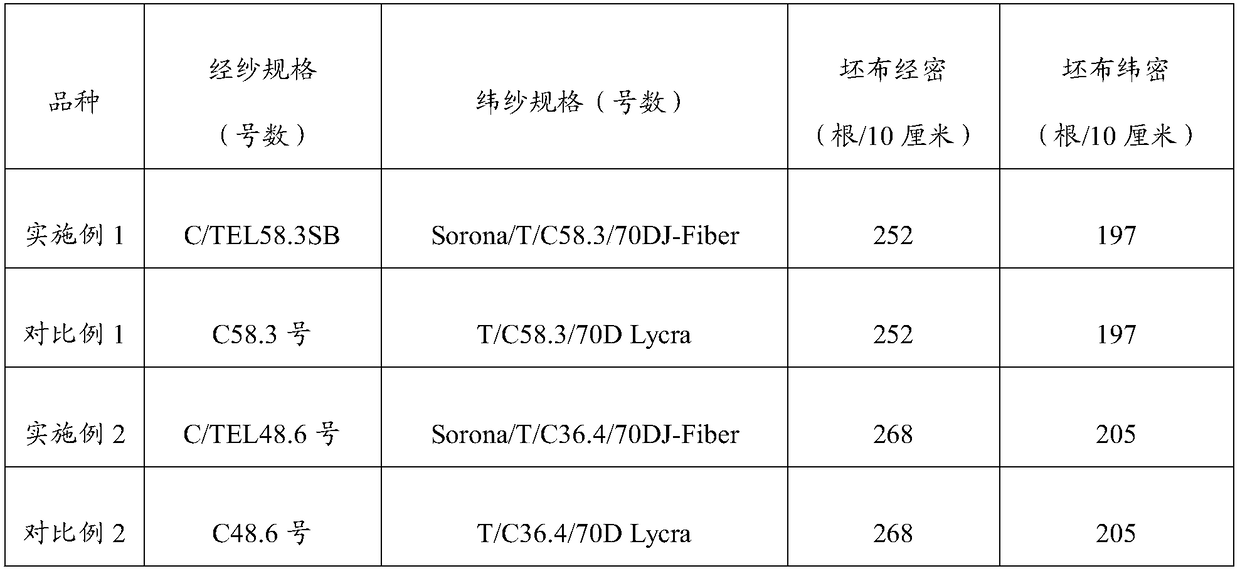

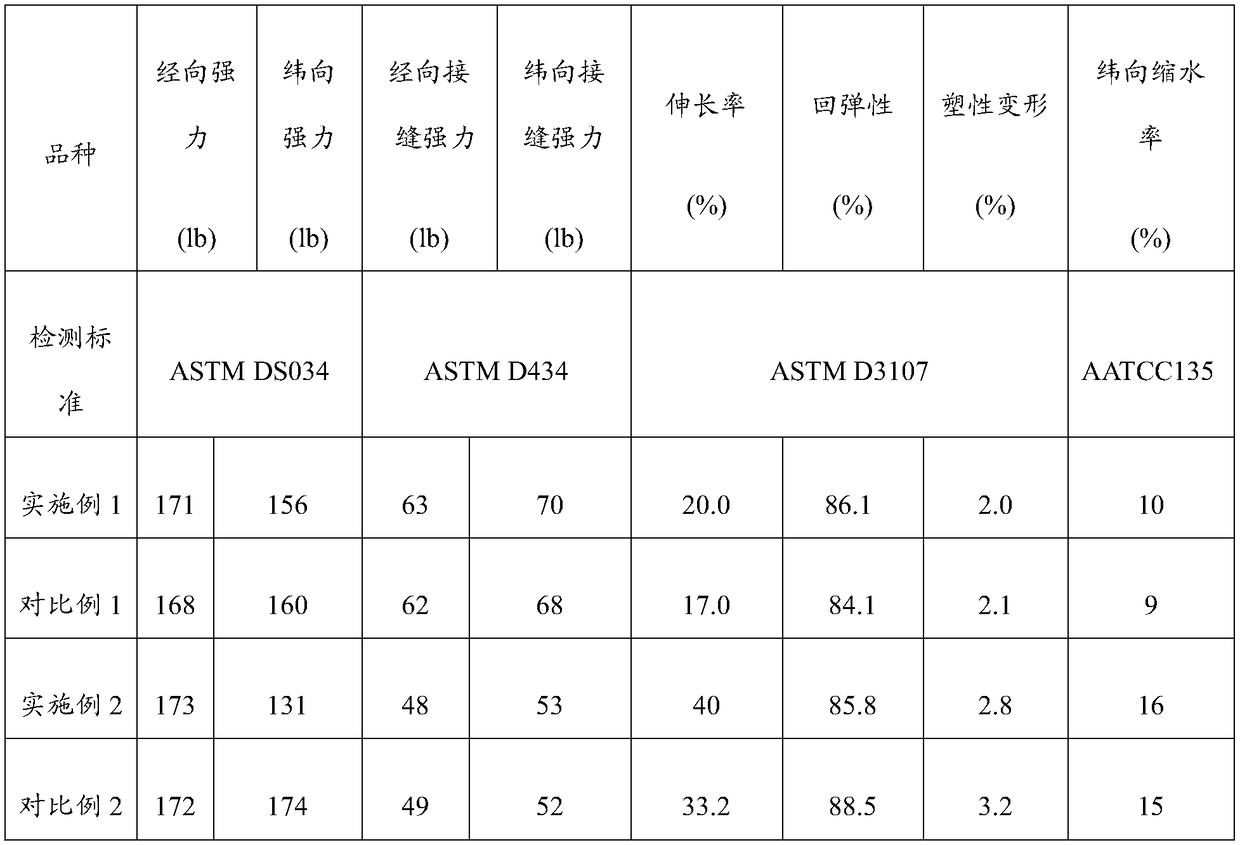

[0047] The warp direction of the fabric is cotton / tencel blended (the blending ratio of cotton and tencel is 80 / 20), and the weft direction of the fabric is Soron...

Embodiment 2

[0052] Prepare gray cloth according to the preparation method of Example 1 according to the raw materials in Table 1, and then obtain fabric according to the method of Example 1. The difference is that the temperature of the hot air beating is 150°C, the frequency of the hot air beating is 2.1 seconds / time, and the running speed of the gray cloth during the hot air beating is 40m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com