Spinning method of organic cotton modal composite yarn

A technology of organic cotton and modal, applied in the field of yarn spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

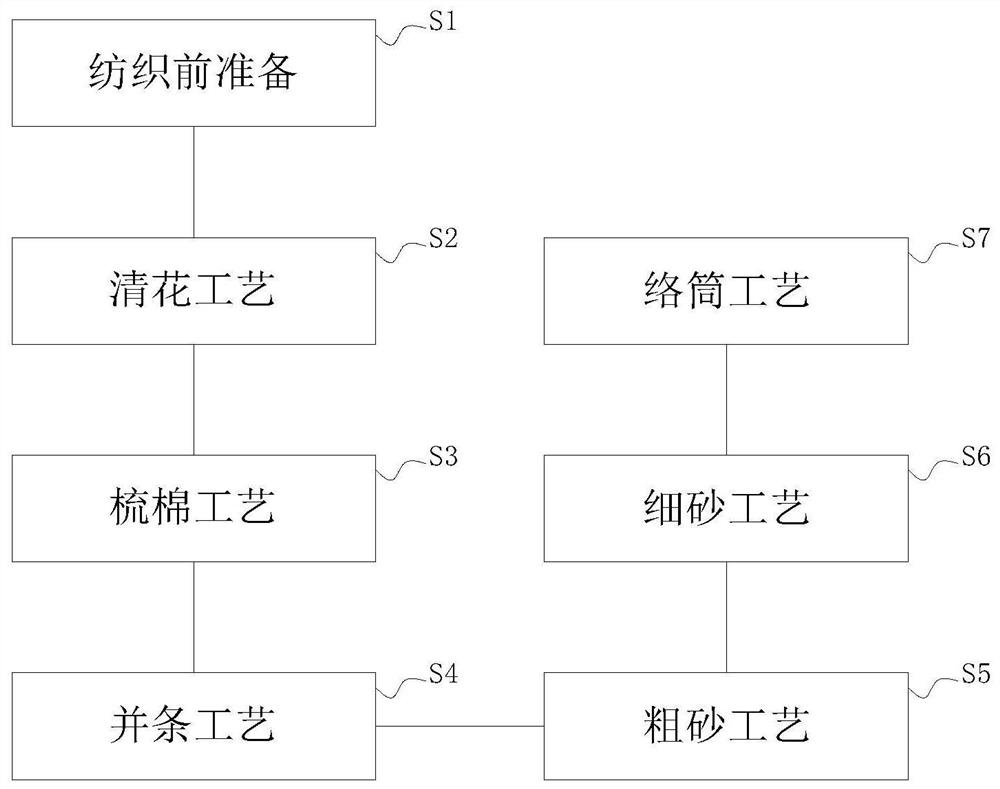

[0028] Such as figure 1 Shown, the spinning method of a kind of organic cotton modal composite yarn that an embodiment of the present invention proposes, comprises the following steps:

[0029] Step S1, pre-spinning preparation: select raw materials as organic cotton fiber and modal fiber, wherein the quality of organic cotton fiber and modal fiber each account for 50%, the organic cotton fiber and modal fiber are heat-treated in a water bath, and placed in an antistatic agent and an antistatic agent after drying. The fluffing agent is mixed with a volume of 2:1, soaked for 2 hours, and then pre-conditioned for 20 hours in a standard atmosphere with a relative humidity of 25%;

[0030] Step S2, Blowing: Use the package mixing process to weigh the organic cotton fiber and the modal fiber, and pre-mix according to the dry weight ratio. When the amount of raw materials is small, feed the raw materials by hand and then pass through the cotton opener (FA106B), vibration Cotton box...

Embodiment 2

[0043] Such as figure 1Shown, the spinning method of a kind of organic cotton modal composite yarn that an embodiment of the present invention proposes, comprises the following steps:

[0044] Step S1, pre-spinning preparation: select raw materials as organic cotton fiber and modal fiber, wherein the quality of organic cotton fiber and modal fiber each account for 50%, the organic cotton fiber and modal fiber are heat-treated in a water bath, and placed in an antistatic agent and an antistatic agent after drying. The fluffing agent is mixed with a volume of 2:1, soaked for 3 hours, and then pre-humidified for 24 hours under a standard atmospheric state with a relative humidity of 35%;

[0045] Step S2, Blowing: Use the package mixing process to weigh the organic cotton fiber and the modal fiber, and pre-mix according to the dry weight ratio. When the amount of raw materials is small, feed the raw materials by hand and then pass through the cotton opener (FA106B), vibration Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com