Mildew-proof yarn and spinning process

A yarn and process technology, applied in the field of mildew-proof yarn and spinning process, can solve the problems of reducing the service life of the yarn and the yarn moldy, and achieve the effect of improving the grade, less knots, and lasting antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

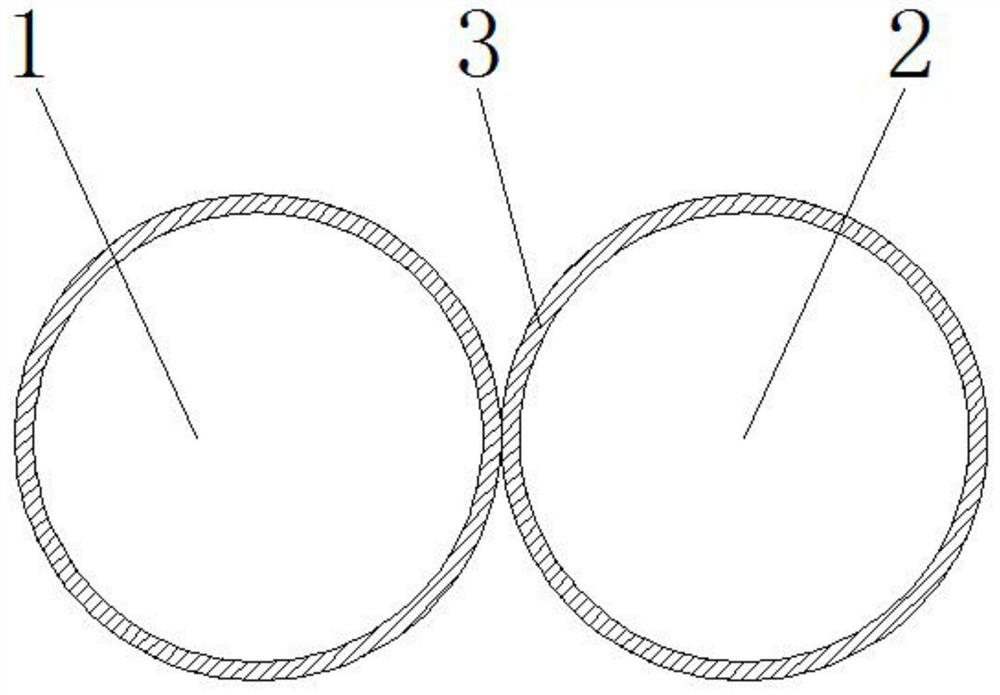

[0035] like figure 1 As shown, a mildew-resistant yarn includes a first yarn 1 and a second yarn 2, the first yarn 1 and the second yarn 2 are spirally wound, and the outer sides of the first yarn 1 and the second yarn 2 are provided with Anti-mildew layer3.

[0036] Wherein, the first yarn 1 is corn fiber yarn.

[0037] Wherein, the second yarn 2 is cotton fiber yarn.

[0038] A spinning process of mildew-resistant yarn, comprising the following steps;

[0039] S1, prepare corn fiber raw material, cotton fiber raw material;

[0040] Corn fiber balance treatment process: the corn fiber raw material is pre-stored in a 58% storage environment at 30°C for balance treatment;

[0041] S2. Cleaning process: use the cotton opener to loosen the cotton fiber raw material into small cotton blocks or cotton bundles to facilitate mixing and removal of impurities; then use the cotton cleaner to remove most of the impurities and impurities in the cotton fiber raw material after opening ...

Embodiment 2

[0052] like figure 1 As shown, a mildew-resistant yarn includes a first yarn 1 and a second yarn 2, the first yarn 1 and the second yarn 2 are spirally wound, and the outer sides of the first yarn 1 and the second yarn 2 are provided with Anti-mildew layer3.

[0053] Wherein, the first yarn 1 is corn fiber yarn.

[0054] Wherein, the second yarn 2 is cotton fiber yarn.

[0055] A spinning process of mildew-resistant yarn, comprising the following steps;

[0056] S1, prepare corn fiber raw material, cotton fiber raw material;

[0057] Corn fiber balance treatment process: the corn fiber raw material is pre-stored in a 58% storage environment at 30°C for balance treatment;

[0058] S2. Cleaning process: use the cotton opener to loosen the cotton fiber raw material into small cotton blocks or cotton bundles to facilitate mixing and removal of impurities; then use the cotton cleaner to remove most of the impurities and impurities in the cotton fiber raw material after opening ...

Embodiment 3

[0069] like figure 1 As shown, a mildew-resistant yarn includes a first yarn 1 and a second yarn 2, the first yarn 1 and the second yarn 2 are spirally wound, and the outer sides of the first yarn 1 and the second yarn 2 are provided with Anti-mildew layer3.

[0070] Wherein, the first yarn 1 is corn fiber yarn.

[0071] Wherein, the second yarn 2 is cotton fiber yarn.

[0072] A spinning process of mildew-resistant yarn, comprising the following steps;

[0073] S1, prepare corn fiber raw material, cotton fiber raw material;

[0074] Corn fiber balance treatment process: the corn fiber raw material is pre-stored in a 58% storage environment at 30°C for balance treatment;

[0075] S2. Cleaning process: use the cotton opener to loosen the cotton fiber raw material into small cotton blocks or cotton bundles to facilitate mixing and removal of impurities; then use the cotton cleaner to remove most of the impurities and impurities in the cotton fiber raw material after opening ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com