Processing technology of multifunctional photocatalytic knitwear

A processing technology and photocatalyst technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of unrealistic industrial production and retention, and achieve the effect of improving flatness and preventing accidental drafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] 1. Preparation of multifunctional photocatalyst textiles:

[0038] Multifunctional photocatalyst knitwear processing technology, including three processes of yarn forming, weaving and dyeing and finishing,

[0039] (1) In the yarn forming process described above, one of cotton fiber, bamboo fiber, and tencel and photocatalyst polyester respectively go through opening → carding, according to the process: drawing (one) → drawing (two) And) → combing → drawing (three parallels) → drawing (four parallels) → roving → spun yarn, to obtain photocatalyst blended yarn;

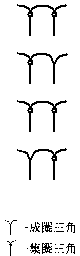

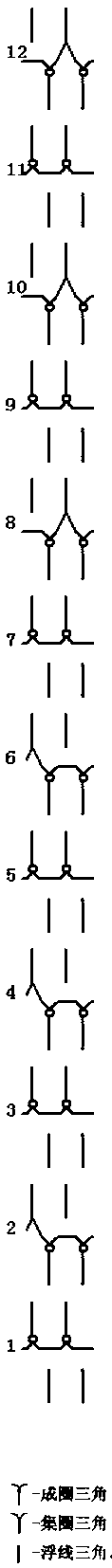

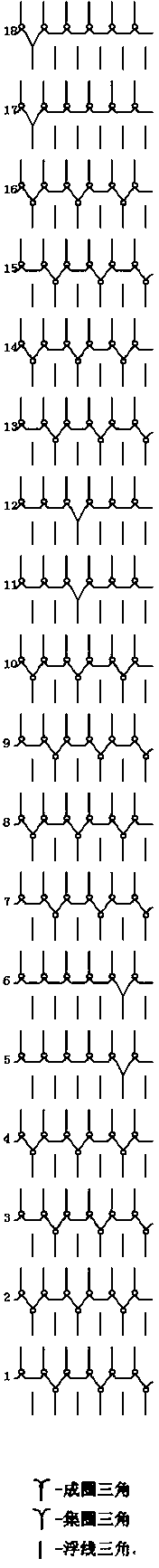

[0040] (2) In the weaving process, the photocatalyst blended yarn obtained in step (1) is woven according to different knit triangles, tuck triangles and float triangles to obtain the original fabric;

[0041] (3) The dyeing and finishing process is to dye and finish the raw fabric in step (2) in sequence according to the following steps: singeing → desizing → bleaching → pre-soaping → cationic dyeing → reactiv...

Embodiment 2

[0130] The principle and procedure of this embodiment are the same as in Example 1, the difference is that the washing temperature of the pre-soaping is 85°C and the time is 25 minutes; the washing temperature of the post-soaping is 85°C and the washing time is 40 minutes; the cationic dye is red X-GRL, the reactive dye is Anoxol Dye Crimson L-4B, the softening temperature is 45°C, soaked for 55 minutes, and the liquor ratio is 4%.

Embodiment 3

[0132] The principle and process of this embodiment are the same as in Example 1, the difference is that the washing temperature of the pre-soaping is 80°C and the time is 25 minutes; the washing temperature of the post-soaping is 85°C and the washing time is 40 minutes; the cationic dye is black X-RBL, the reactive dye is Anoxol dye Zhiqing L-3G, the softening temperature is 50°C, soaked for 60 minutes, and the liquor ratio is 5%.

[0133] Comprehensive Performance Analysis of Fabrics

[0134] The present invention mainly conducts comprehensive analysis on 5 kinds of fabrics (6#, 7#, 8#, 9#, 10#) woven, and the comprehensive comparison of experimental data is shown in Table 11.

[0135] Table 11 Comprehensive comparison of test results of usability indicators

[0136]

[0137] It can be concluded from Table 11 that 6#~10# fabrics all have a certain degree of deodorization, anti-ultraviolet performance, antistatic performance, anti-pilling performance ≥ 3-4 grades; anti-ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air flow | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com