Blended yarn and preparation method and application thereof

A technology of blended yarn and process, applied in the field of blended yarn and its preparation, can solve the problems of high cost performance, high falling and cost, easy breakage and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] The pretreatment of embodiment 1 seaweed fiber 1#

[0080] The raw material seaweed fiber is carried out health preservation pretreatment, weighs 100Kg seaweed fiber and antistatic agent aqueous solution and mixes, and the weight ratio of seaweed fiber and antistatic agent aqueous solution is 50:1, and the weight ratio of antistatic agent and water is 1:10, will Spray the antistatic agent aqueous solution evenly on the surface of the seaweed fiber with a sprayer, wrap it in a plastic bag, seal it, and let it stand for 24 hours. The temperature in the health care room is controlled at 45°C-55°C, so that the antistatic agent solution can be evenly diffused into the fiber under high temperature. , The antistatic agent is a silicone surface active antistatic agent, and the seaweed fiber 1# is obtained.

Embodiment 2

[0081] The pretreatment of embodiment 2 seaweed fiber 2#, 3# and contrast seaweed fiber D1#, D2#

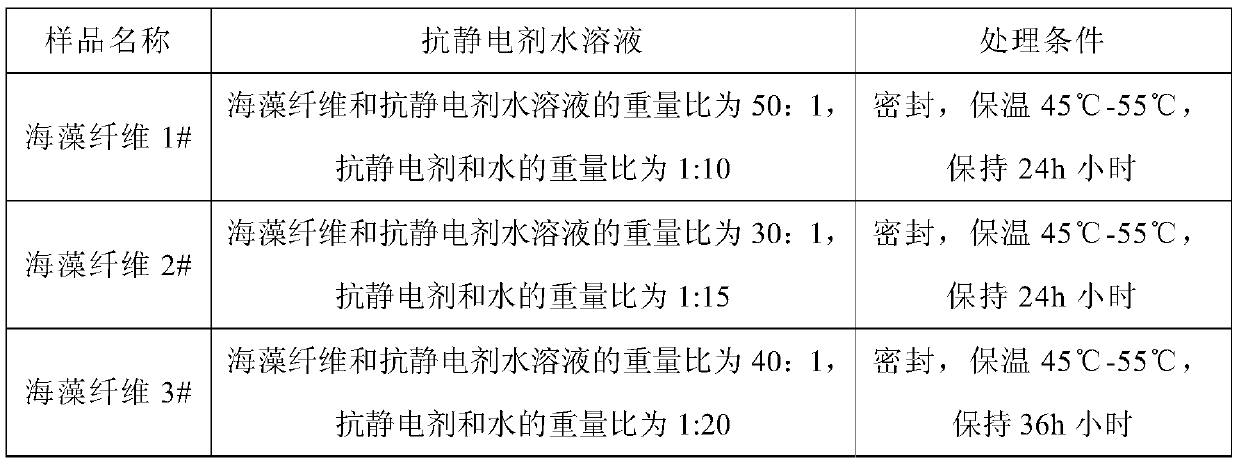

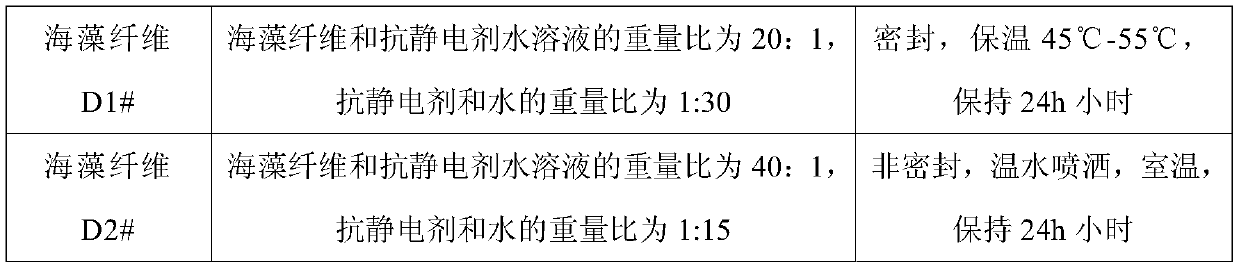

[0082] The difference between the pretreatment of seaweed fiber 2#, 3# and contrast seaweed fiber D1#, D2# and embodiment 1 is the addition amount of antistatic agent aqueous solution, the concentration of antistatic agent aqueous solution, whether pretreatment is sealed and pretreatment temperature is different . The specific process parameters of embodiment 2 are shown in table 1 below.

[0083] The process parameter of table 1 embodiment 2 seaweed fiber pretreatment

[0084]

[0085]

Embodiment 3

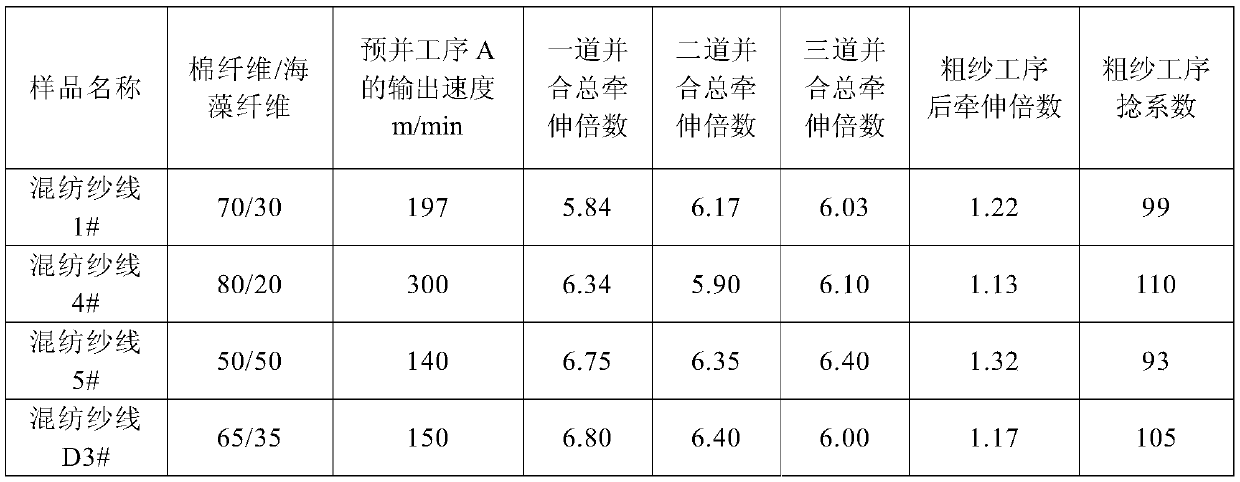

[0086] The preparation of embodiment 3 blended yarn 1#-3# and contrast blended yarn D1#, D2#

[0087] The seaweed fiber 1#, seaweed fiber 2#, seaweed fiber 3#, comparison seaweed fiber D1# and contrast seaweed fiber D2# prepared in Example 1 and Example 2 were prepared in the same way as blended yarns, and blended yarns were prepared respectively Yarn 1#, blended yarn 2#, blended yarn 3#, contrast blended yarn D1#, contrast blended yarn D2#. Taking seaweed fiber 1# and cotton fiber to prepare blended yarn 1# as an example to illustrate the preparation method of blended yarn.

[0088] The raw material of blended yarn 1#: the weight ratio of cotton fiber and seaweed fiber 1# is 70:30.

[0089] The preparation method of blended yarn 1#, comprises the steps:

[0090] 1) The pretreated seaweed fiber 1# is sequentially processed through cleaning process A, carding process A and pre-merging process A;

[0091] Cleaning process A: the weight of seaweed fiber 1# is 12.90kg, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com