Patents

Literature

69 results about "Fibre spinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polyacrylonitrile based carbon fibre spinning solution

InactiveCN1401675AEvenly distributedLow viscosityFibre chemical featuresDistilled waterFunction group

A polyacrylnitrile-base carbon fibre spinning liquid is prepared from acrylnitrile, dimethyl formamide, distilled water, azodiisobutylnitrile and chain transfer agent through homopolymerization, introducing ammonia gas to stop reaction, and regulating pH value by ammonia gas. Its advantages are uniform distribution of function groups on macro-molecular chain, simple process and easy control.

Owner:ZHONGJIAN TECH CO LTD

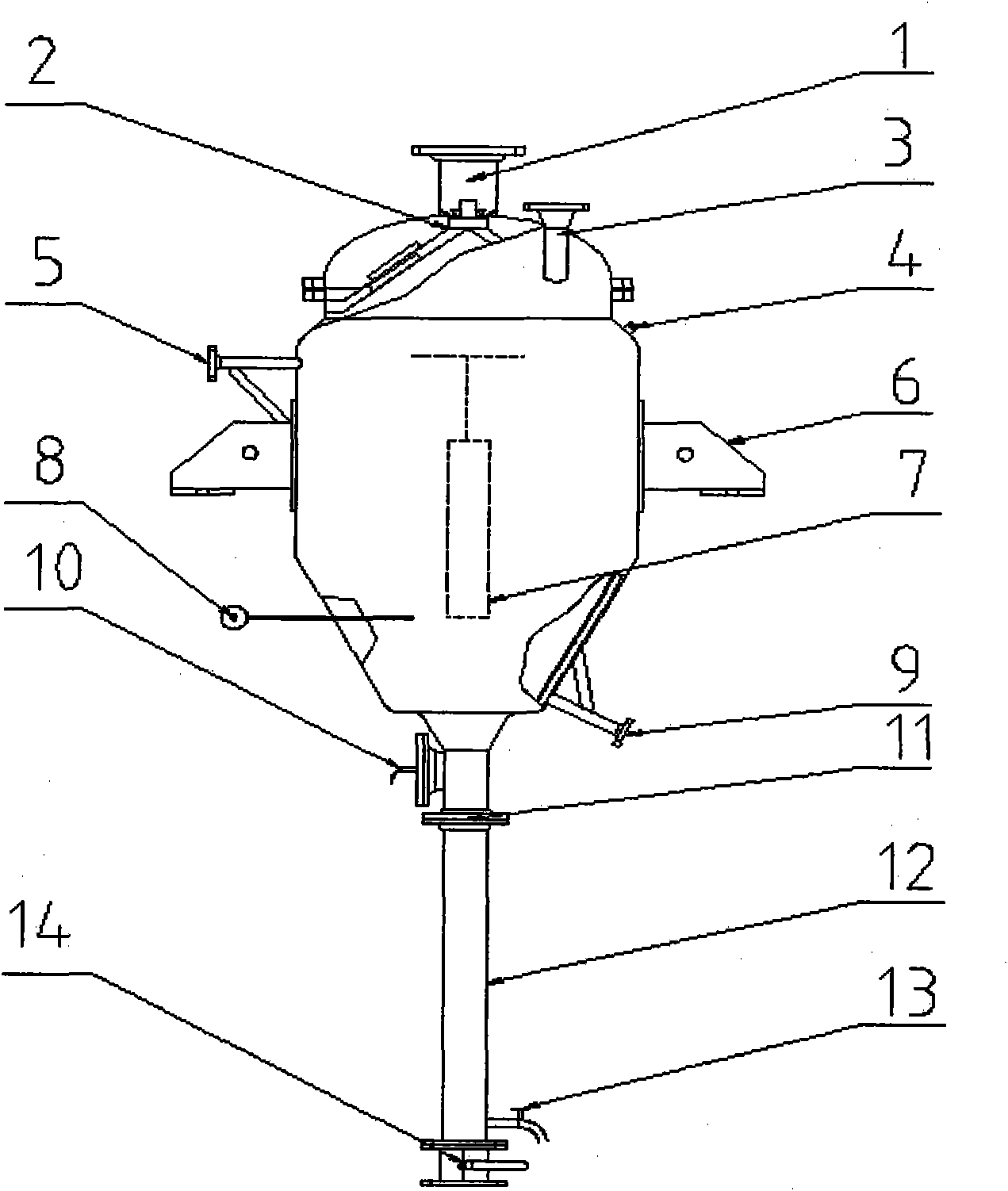

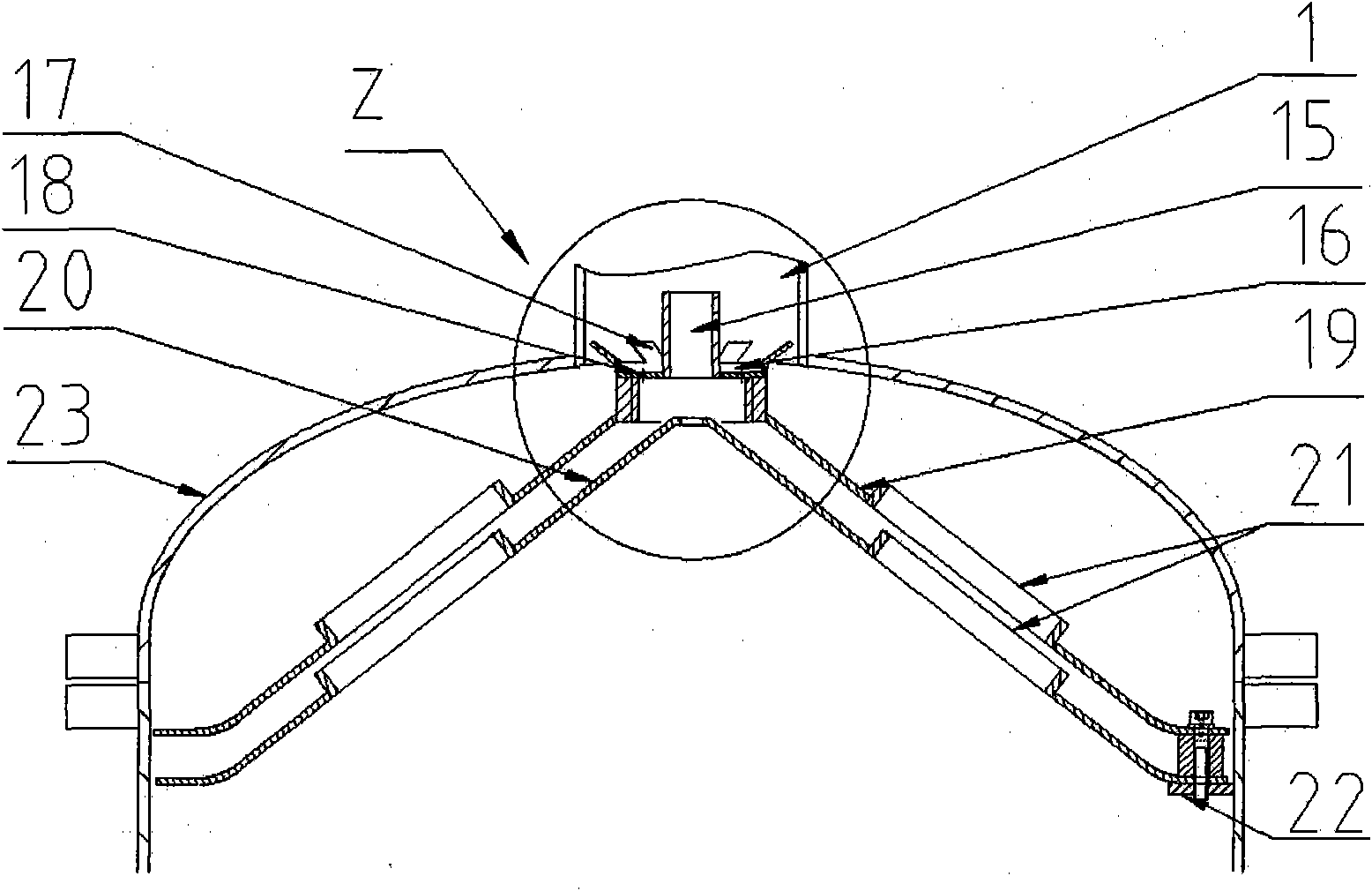

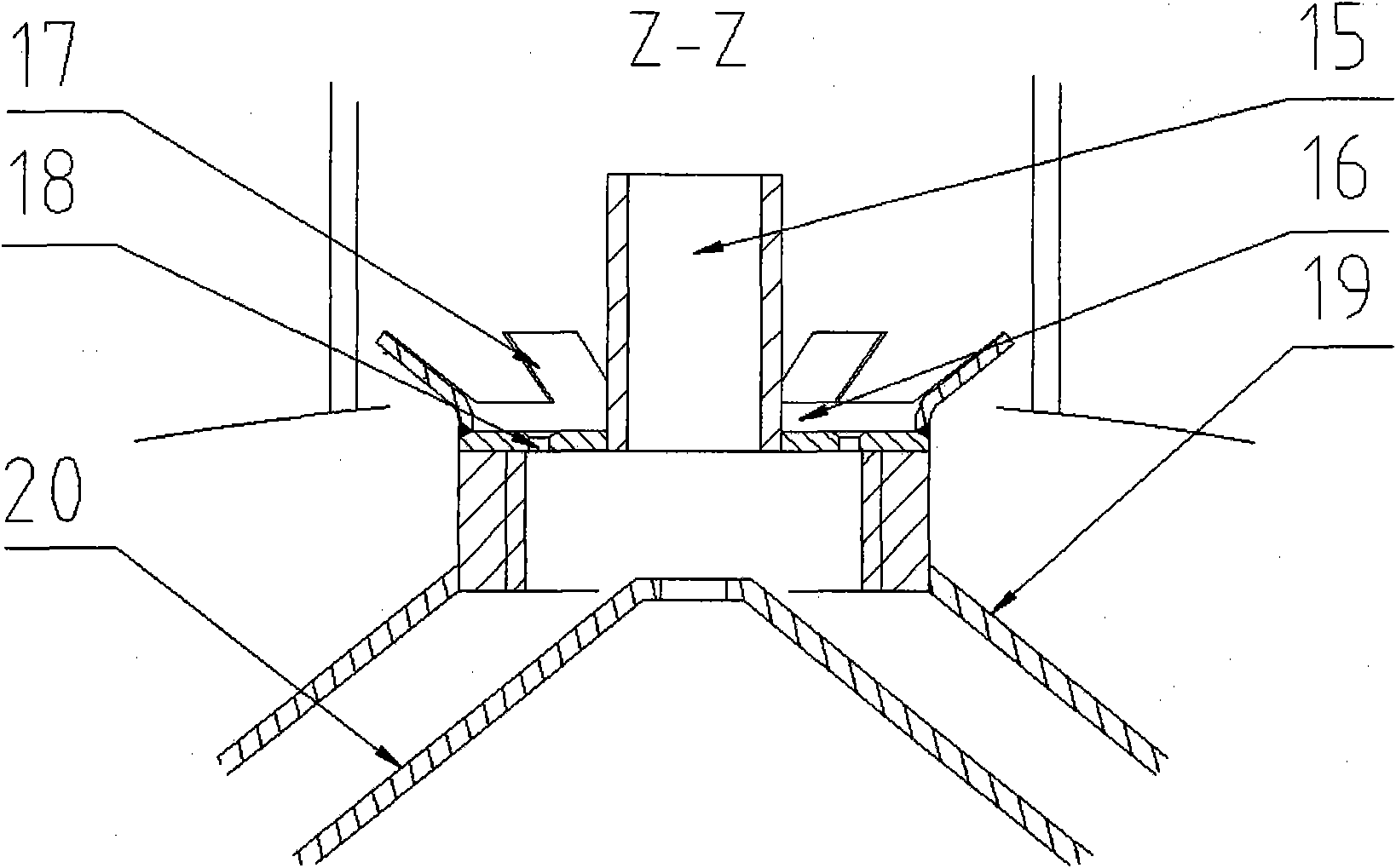

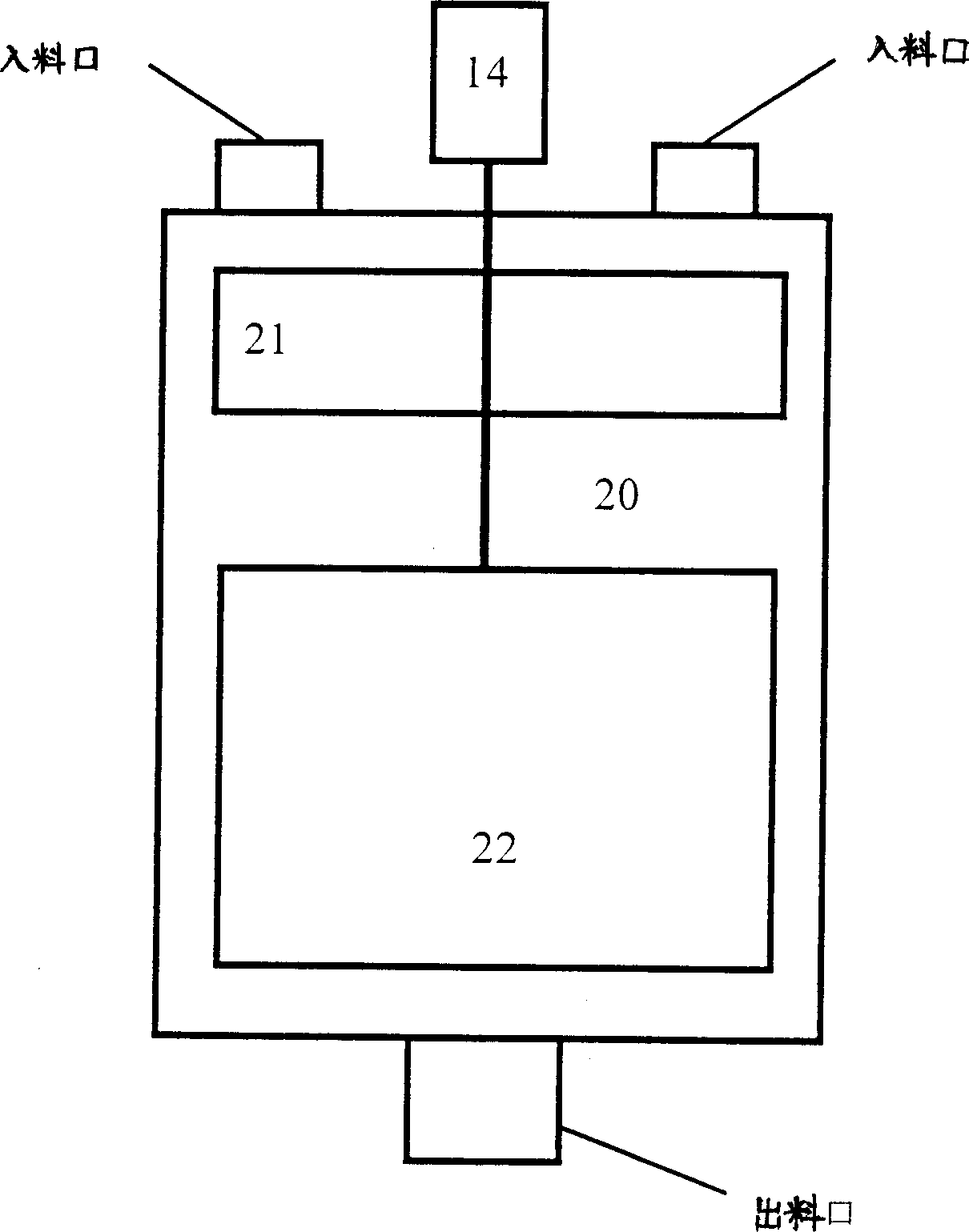

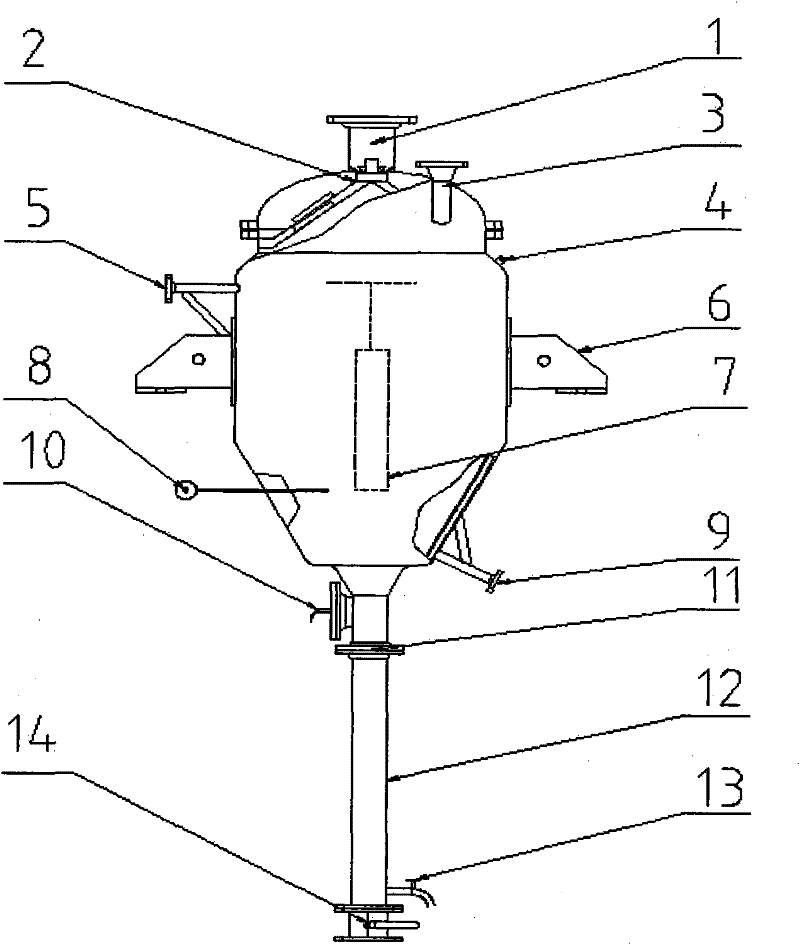

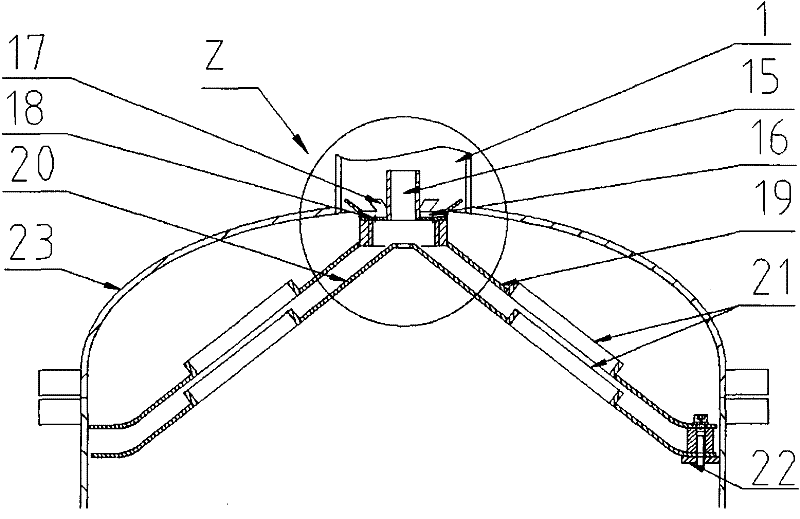

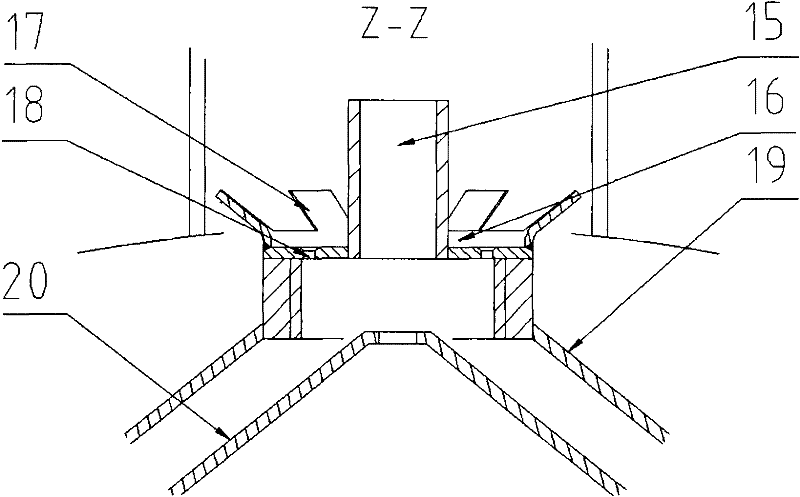

Dynamic demonomerization and defoaming method and device for carbon fiber spinning solution

ActiveCN101856570AContinuous quantitative feedingSingle and degassing continuous dynamicFoam dispersion/preventionCarbon fibersSolvent

The invention discloses a dynamic demonomerization and defoaming method and a dynamic demonomerization and defoaming device for carbon fiber spinning solution. An ultrasonic generator is arranged in the centre of a defoaming kettle; an air guide cylinder and a flow guide disk are arranged on a flow diversion and air guide cover; and the defoaming effect is improved to realize low-temperature high-vacuum demonomerization and defoaming of the spinning solution with different relative molecular masses and different charging rates by the processes of heating a demonomerization and defoaming device, continuous feeding, gravity demonomerization and defoaming, film stretch defoaming and ultrasound-assisted defoaming and controlling the defoaming temperature, the vacuum degree and the rotation speed of a demonomerization tower. The spinning solution obtained by the method has the residual monomer content of less than 0.1 percent, less than 5 small bubbles with diameter of less than 0.03mm and solvent loss of less than 5 percent during the demonomerization and defoaming. The method and the device can realize continuous dynamic demonomerization and defoaming at a low temperature under vacuum condition and has the characteristics of simple and practical process and good defoaming effect.

Owner:XIAN KANGBEN MATERIAL

Production of spinning stoste with cellulose base fibre

InactiveCN1818160AImprove protectionGood for healthArtificial filaments from viscoseCELLULOSE FLOURCellulose fiber

The invention opened a preparing method of the cellulose fibre spinning stock solution. The solvent is the intermixture of the [BMIM]Cl and the [BMIM]BF4. The cellulose dissolves in the solvent after breaking up to get the uniform and transparent liquid. So it can save the energy, decrease the pollution and improve the quality of the stock solution.

Owner:DONGHUA UNIV

Preparing method of straw type fibre spinning solution

InactiveCN1955347AAchieve separationQuality improvementMonocomponent cellulose artificial filamentAlcoholSolvent

A process for preparing the spinning dope from the fibrous straw and stalk includes such steps as steam exploding, cyclic countercurrent extracting in water to remove the most of soluble hemicellulose, extracting lignin in the aqueous solution of alcohol, filtering to obtain the alcohol solution of lignin and coarse cellulose, grinding, removing short fibers, bleaching to obtain milk, mixing it with urea, reacting in inertial solvent to obtain cellulose aminoformate, and dissolving it in NaOH solution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

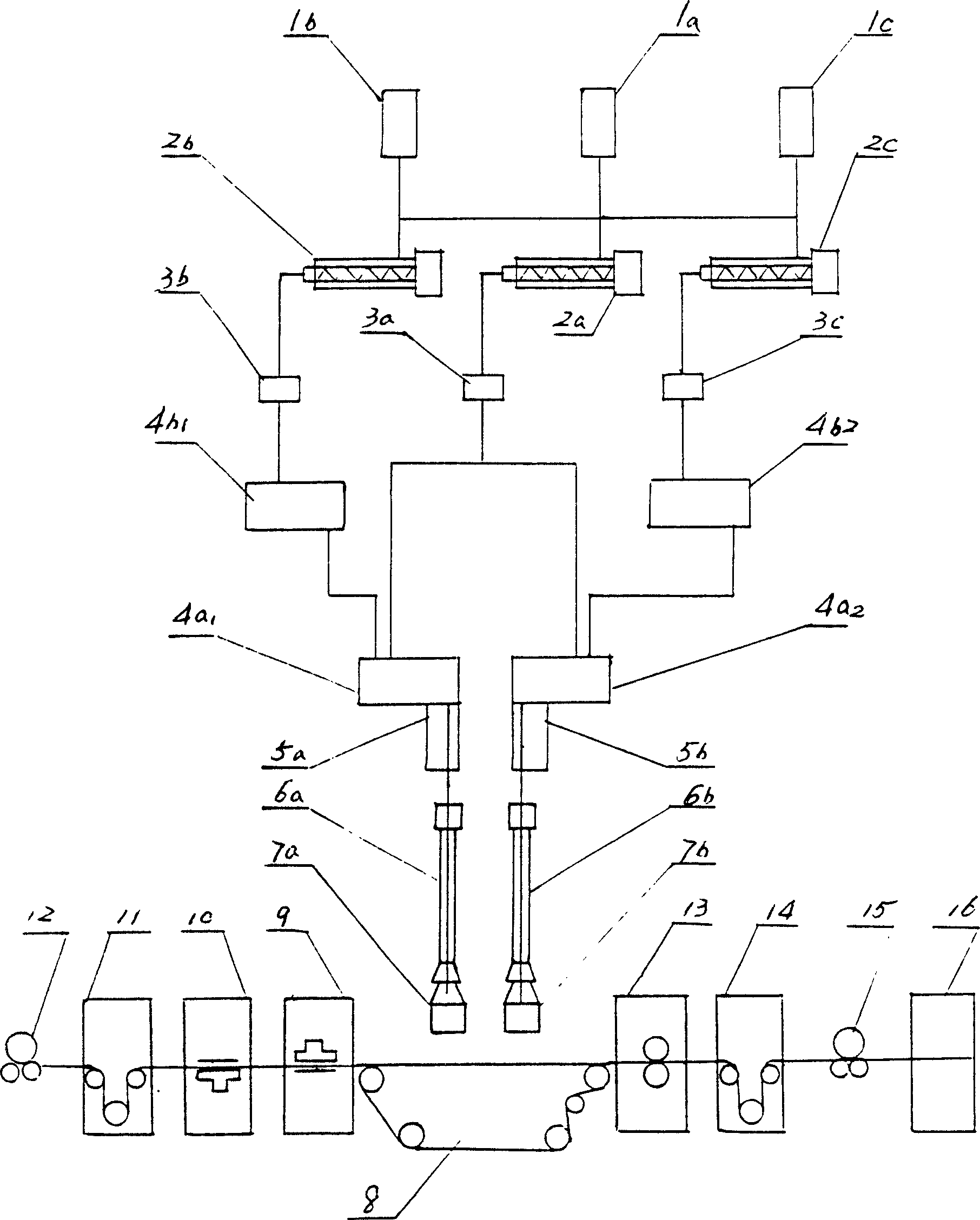

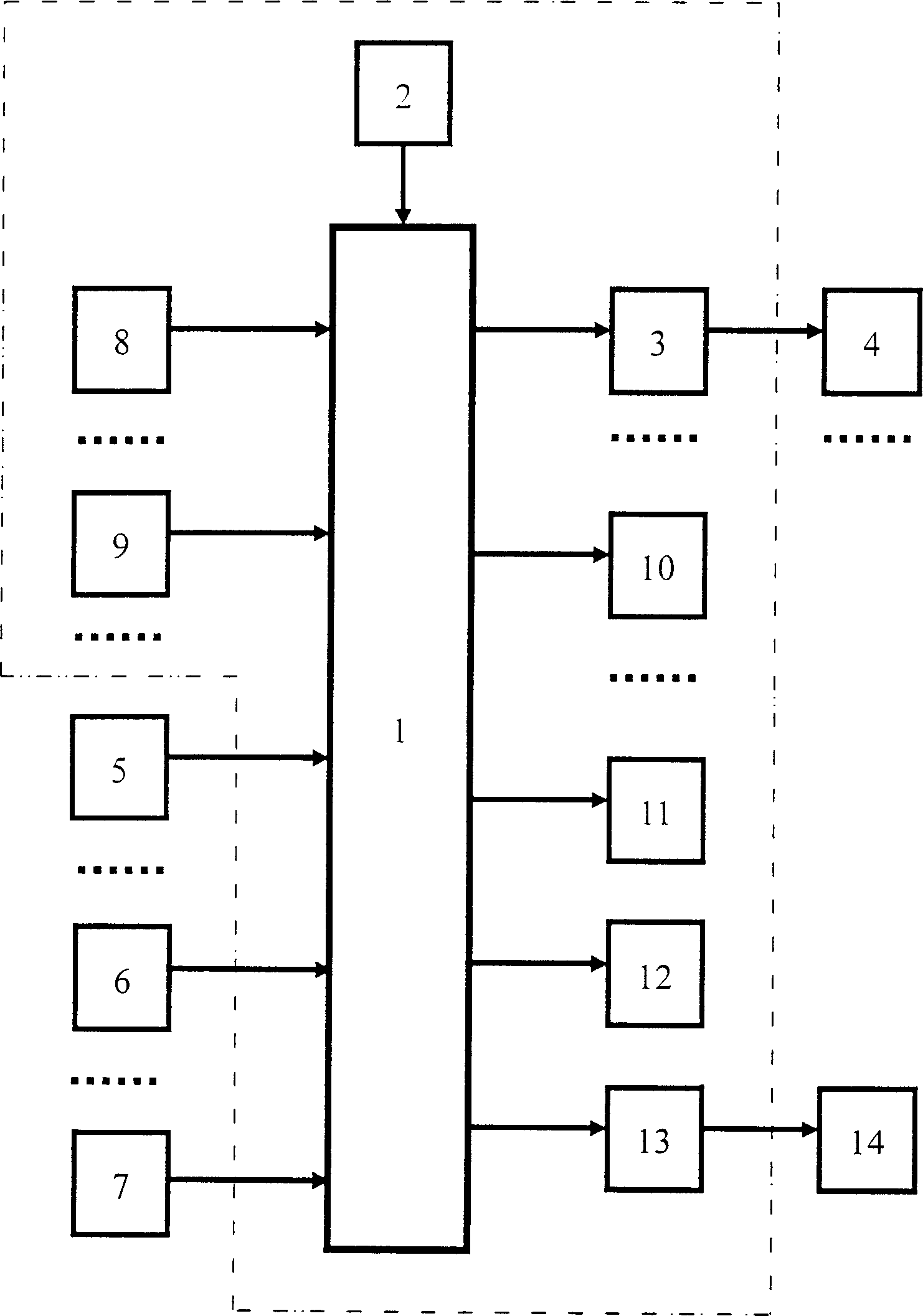

Process for production of multifunctional composite bicomponent fiber spunbond nonwoven fabrics

InactiveCN1523154ALow costEnhanced ability to adapt to market demandArtificial thread manufacturing machinesNon-woven fabricsPunchingPulp and paper industry

The present invention relates to a production method of composite double-component fibre spun-bonded non-woven fabric, said method uses two or three kinds of resin and adopting the following steps: firstly, making every resin respectively undergo the processes of drying, extruding and filtering, feeding one resin into parallelly-arranged two main spinning trunks, feeding other two groups of resin into parallelly-arranged two auxiliary spinning trunks, then feeding them into main spinning trunks, and feeding all the three groups of resins into special-purpose spinning component and making composition in micropore of spinneret, then making the ejected thin flow undergo the processes of cross air blasting, drawing and fibre-swinging treatment and making it into fibre web by means of web-forming machine, and feeding the fibre web into needle-punching machine or hot-rolling machine so as to obtain the invented double-component spun-bonded non-wowen fabric product.

Owner:高雨声 +4

Preparing method for collagen stroma composite medical fibre spinning stoste

InactiveCN1584150AImprove mechanical propertiesGood dimensional stabilityConjugated cellulose/protein artificial filamentsProsthesisEngineeringPre treatment

This invention publishes a plug-anlage complex medical fibre. Choose healthy animals, after butcher, decorticate, wash and degrease the peltry. Then, hydrolyze and purify it by using the complex enzym-skin glue disposer and chemical substance. Let it receive animal skin glue with good biology consistence and biology activity. Hydrolyzed animal skin glue can gain glue anlage complex medical fibre filature original liquid when mixed with shell-polysacharide after ulteriorly purification. The original liquid can be used to make biology medical velum, operation medical suture and glue-anlage complex medical fibre original liquid.

Owner:SICHUAN UNIV

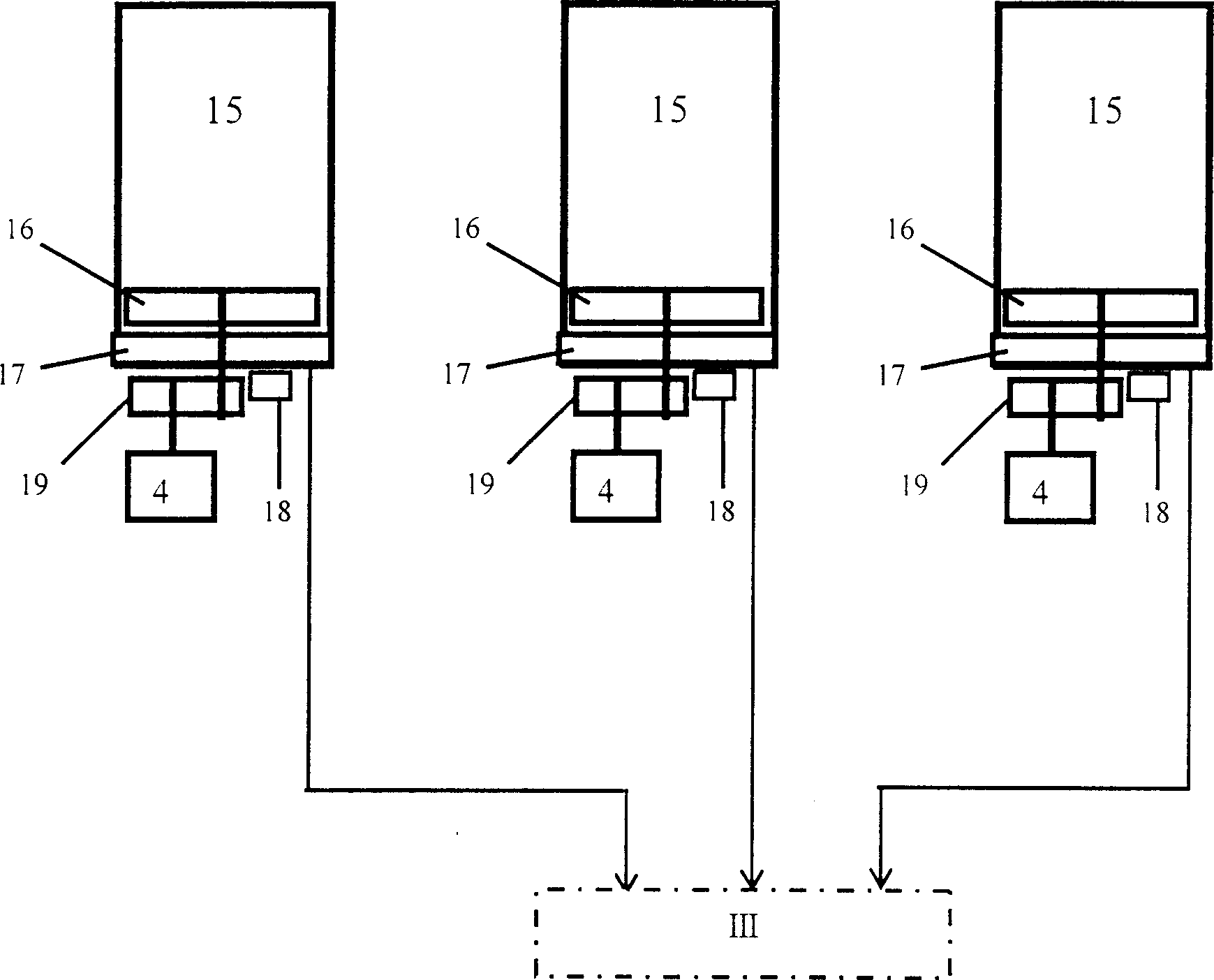

Continuous automatic feed proportioning machine and its application

InactiveCN1513740APrecise ratioAvoid replacementConveyor partsSpecial purpose weighing apparatusControl systemProcess engineering

An automatic continuous batching apparatus for dynamically proportioning multiplex raw granular materials, stirring them and supplying the mixture to the chemical fibre spinning machine or plastic injection moulding machine features that the PLC plus step motor are used to constitute an automatic metering control system with high precision up to 0.01% or more, the software can find out the number of dropping holes for each material within one metering period, and the self-cleaning and pre-mixing apparatuses are used for higher reliability and uniformity.

Owner:TAIYUAN UNIV OF TECH

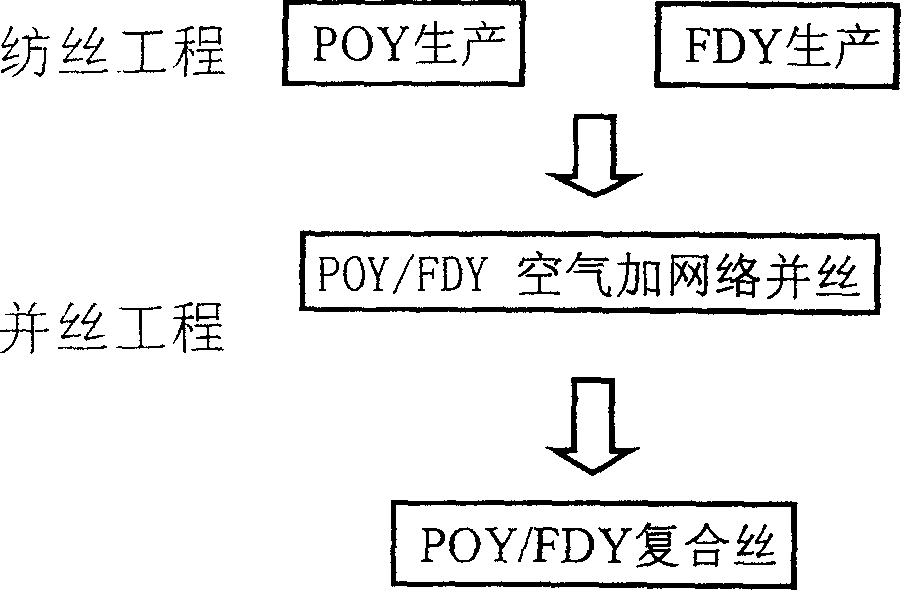

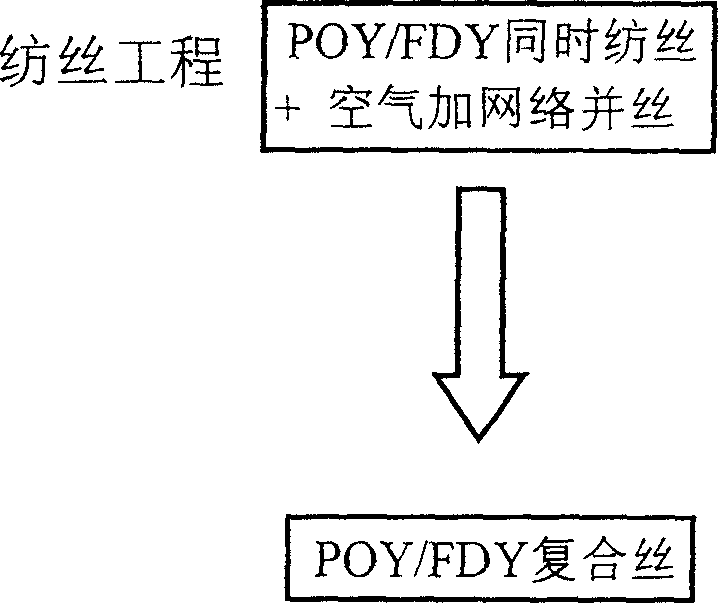

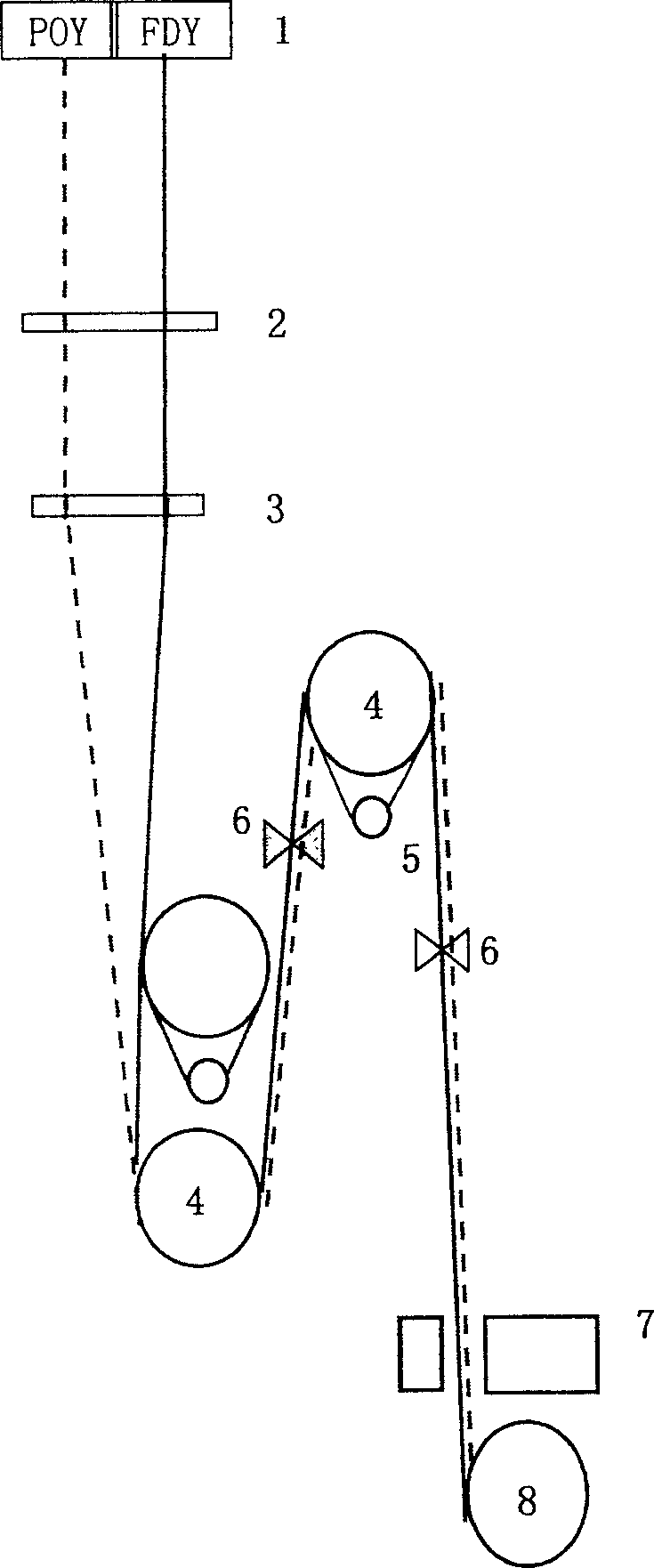

Polyester melt POY, FDY compound silk spinning method

InactiveCN1888157AImprove qualityMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterChemistry

The present invention discloses a composite fibre spinning process. It is characterized by that said spinning process can simultaneously produce polyester melt POY fibre and FDY fibre, and can directly conjugate them together by means of one-step operation, so that its production process is simple and its production cost is low.

Owner:GAOHE QINGDAO

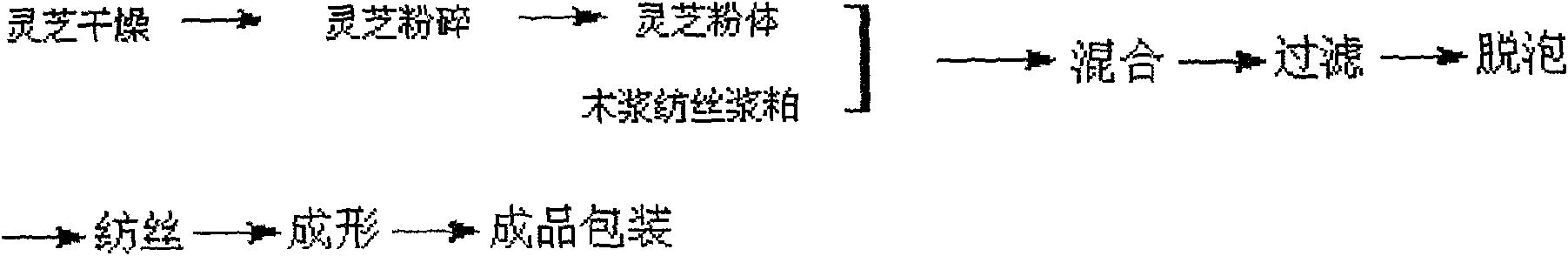

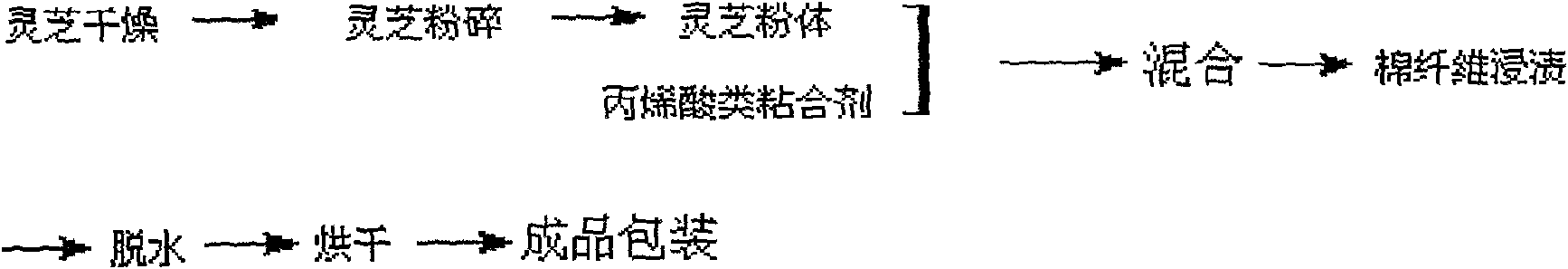

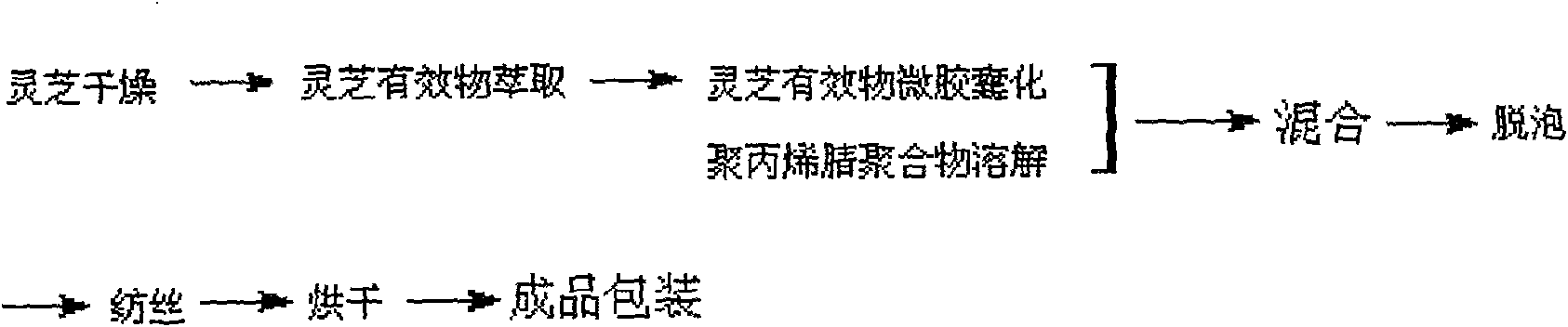

Ganoderma lucidum fibre with function of health care and preparation method thereof

InactiveCN101634055AImprove the immunityImprove immunityMonocomponent protein artificial filamentSynthetic fibresDiseaseNylon 66

The invention relates to ganoderma lucidum fibre with the function of health care and a preparation method thereof. The fibre contains traditional Chinese medicine ganoderma lucidum components; the preparation method comprises the following steps: adding the ganoderma lucidum components into regenerated cellulose fibre spinning liquid, regenerated protein fiber spinning liquid, terylene fibre spinning liquid, orlon fibre spinning liquid and nylon 6 or nylon 66 fibre spinning liquid and adopting conventional spinning to obtain the ganoderma lucidum fibre. The fibre can reinforce the resistance and immunity of an organism, eliminates in-vivo free radicals, resists radiation and has the effects of preventing and treating diseases, building the body, strengthening the body and prolonging the life; the invention has simple preparation method and is suitable for industrialized production.

Owner:陈对范 +1

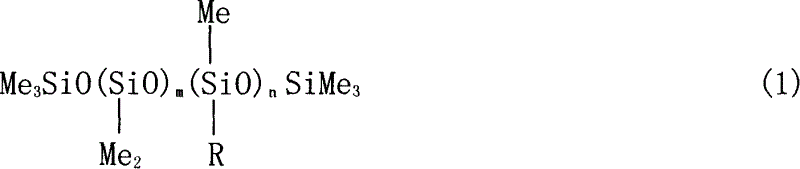

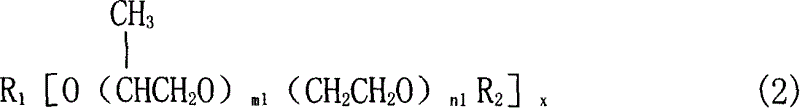

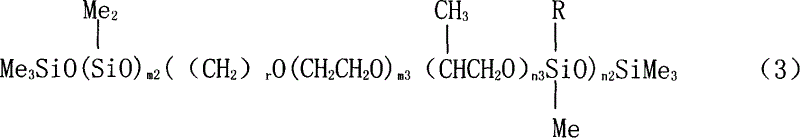

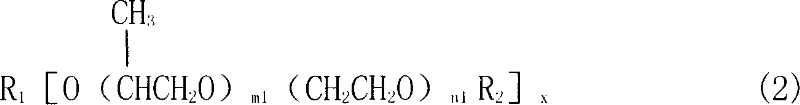

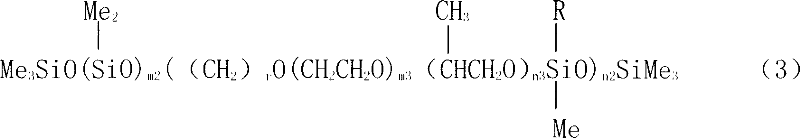

Oil preparation agent in use for spinning in urethane elastic fiber

The invention discloses a polyurethane fibre spinning oil. Its composition includes (by wt%) 5-80% of mineral oil, 10-75% of silicone oil, 0.5%-30% of epoxyethane and epoxypropane copolyether, 0.5%-50% of polyether silicone oil, 0.5-15% of antistatic agent and 0.1-10% of anti-sticking property improving agent.

Owner:CHINA PETROCHEMICAL CORP +1

D-glass fibre

D-glass fiber consists of SiO2, Al2O3, CaO, MgO, B2O3 and Fe2O3. It has a lower dielectric constant, viscosity temperature of Log3 is <1300íÒC, liquefaction temperature is <1100íÒC, the difference between the both is above 75íÒC. It can prevent fibre spinning and crystallizing, has good wetting-resistant performance and lower electricity consumption. It can be used for substrate materials for printing circuit board.

Owner:浙江显峰汽车配件有限公司驻珠海办事处

Mercerized fiber dyed yarn and fabricating method

InactiveCN1600915ADyeing speed is fastHigh glossMercerising of yarns/threads/filamentsYarnYarnEngineering

Owner:WUXI NATURAL GREEN FIBER TECH

Silver-element fibre spinning technology

The invention relates in particular to a new sliver-element fibre spinning technology, belonging to the spinning engineering field of textile industry production, comprising the following steps: pre-opening silver-element fibre to 80% by an opening machine; maintaining the blowing integrated beater speed in the blowing process of less than 600r / m and the beater frequency of sliver-element fibre per gram of less than 0.55; blocking the noil airdraft opening when carding cotton; using a flatbed drawing frame and a wool-top-proof conducting bar device with the drawing funnel caliber of 5.2mm; keeping the roving cycles of 33-38 cycle / 10cm, spinning frame guide stroke of 3-6mm; maintaining the groove drum speed in spooling less than or equal to 700 meter / minute and using a photoelectric type flaw-cutting device. Compared with the existing technology, the invention has the advantages of effective control of noil rate of blowing and cotton carding, small fibre damage, little nep, removal of belt roller wound by drawing and roving, smooth passage and winding, less broken ends, higher intrinsic quality of semi-manufactured goods, less flaws and better resultant yarn quality.

Owner:SHANGHAI FEILIAN TEXTILE

Multi-fibre knitted fabric

InactiveCN102454111ADifferent finenessDifferent lengthWeft knittingBiochemical fibre treatmentEngineeringMilk protein

The invention relates to multi-fibre knitted fabric, which is obtained by taking green multi-fibre spinning, soybean fibre spinning and milk protein fibre spinning as raw materials, adopting one or more tissues of a primary tissue, a variable tissue and knitted dobby, processing shell fabric obtained later by using bio-enzyme, and coating a nano protection solution on the surface. According to the multi-fibre knitted fabric disclosed by the invention, the green raw materials are interweaved, so that advantages of various raw materials are complementary; the multi-fibre knitted fabric corresponds with requirements of comfortableness, functionality, health and green of the new generation of textiles; and the multi-fibre knitted fabric can be widely applied to manufacturing various knitted clothing.

Owner:CHANGSHU XINTEDU GARMENTS

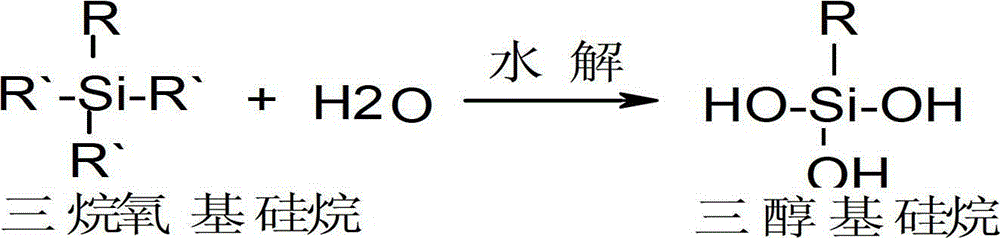

Impregnating agent for high-strength industrial glass fibre spun yarns and preparation method thereof

The invention discloses an impregnating agent for high-strength industrial glass fibre spun yarns and a preparation method thereof. The impregnating agent comprises the following raw materials by weight percent: 4-5% of modified starch, 0.2-0.3% of hydrogenated vegetable oil, 0.72-1.02% of vegetable oil emulsifying agent, 0.4-0.5% of water-borne epoxy resin, 0.1-0.2% of softening agent, 2.0-2.5% of polyethylene glycol, 0.03-0.05% of glacial acetic acid, 0.4-0.6% of coupling agent and the balance of water, wherein the coupling agent is an aminosilane coupling agent; the emulsifying agent is a polyoxyalkyl emulsifying agent; and the softening agent is a cationic softening agent. The impregnating agent has the advantages that the impregnating agent can endow yarns with weaving performances needed when the yarns are used as industrial fabrics; the yarns have good wear resistance and high strength and are not easy to break in the weaving process; meanwhile, the bondability between the yarns and resins can be improved; and the impregnating agent is relatively simpler to prepare and is easy to achieve.

Owner:山东中玻节能环保发展有限公司 +1

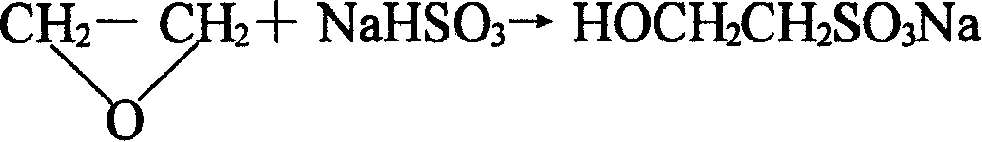

Prolon spinning dope for wig and its production method

The present invention relates to a protein synthetic fibre spinning dope for wig and its production method. Its dope composition is formed from (by weight portion) 30-70 portions of protein, 0.5-3 portions of fire-resistant agent, 1-3 portions of sodium ethanol sulfonate and 28.5-64 portions of polyvinyl alcohol or acrylic nitrile first monomer or acrylic nitrile first monomer and methyl methacrylate or butyl methacrylate or hydroxyethyl methacrylate second monomer. The said raw materials are undergone the processes of copolymerization reaction, curing, heat-insulating and stirring so as to obtain the invented product.

Owner:宋惠远 +2

Fire resistant viscose acetal fibre spinning solution and preparation method thereof

InactiveCN101597806AImprove flame retardant performanceHas a smoke suppressant effectFlame-proof filament manufactureArtificial filaments from viscosePhosphateOxygen

The invention relates to a fire resistant viscose acetal fibre spinning solution and a preparation method thereof. The viscose acetal fibre spinning solution is obtained by mixing sodium silicate and an organophosphorus ester compound to obtain a flame retardant and adding proper dispersant into viscose acetal fibres and has the characteristics of stable dispersion and no flocculation. The sodium silicate and organic phosphate flame retardant is an environmental-friendly product with no toxin, odor and armless and has good dispersivity and low cost. The viscose acetal fibres obtained during spinning with the spinning solution generate no harmful gases, can reduce pollution to environment, has good fire resistance and limited oxygen index being over 28 and achieves the national fire resistant requirement of textile.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing flame resistance anti-thawing fibre spinning dope through solvent method

ActiveCN101649495ASimple processProcess environmental protectionArtificial filaments from cellulose solutionsSpinning solutions preparationPolymer scienceSolvent

The invention discloses a method for preparing flame resistance anti-thawing fibre spinning dope through solvent method which is suitable for industrialized production. The method comprises the following steps: grinding fibre with the degree of polymerization of 300-1000, humidifying, then mixing the obtained material with ionic liquid water solution in a weight ratio of 10:90-20:80 evenly, addingsolving liquid with silicate to dissolve and mix, and then defoaming and filtrating to obtain flame resistance anti-thawing fibre spinning dope. When mixing cellulose powder with ionic liquid water solution, the materials are firstly sent to a tempering tank with an agitator for preliminary mixing and then to a double-screw extruder to mix at 70-100 DEG C for 10-60min. The technical solution of the invention is adopted so as to ensure that the production process of the flame resistance anti-thawing fibre spinning dope is easier and more environmentally friendly, improve the wet strength of regenerated cellulose material and reduce the energy consumption, thus being applicable to industrialized production.

Owner:潍坊欣龙生物材料有限公司

Spinning process for antistatic and antibacterial nylon 6DTY high elastic filament

InactiveCN102766933AWith mechanical propertiesImprove antibacterial propertiesElectroconductive/antistatic filament manufactureMelt spinning methodsPolymer scienceNylon 6

The present invention relates to a spinning process for an antistatic and antibacterial nylon 6DTY high elastic filament, which is prepared from raw materials comprising nylon 6 chips and additives by a POY-DTY process. The prepared DTY high elastic filament has antistatic and antibacterial function and good stability, and can meet different requirements of post-weaving finishing.

Owner:WUJIANG YATAI CHEM TEXTILE

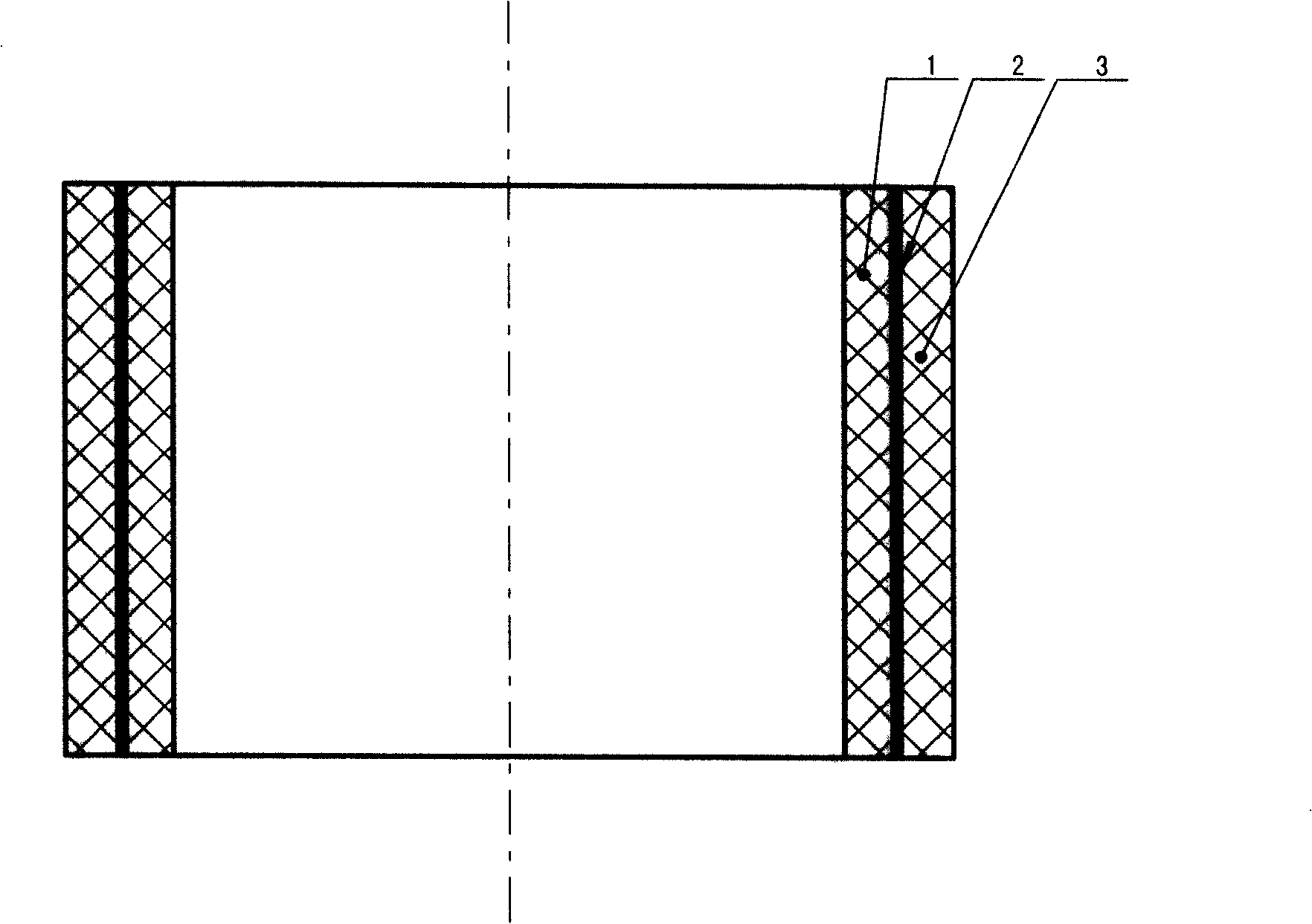

High-speed chemical fibre spinning thread-guiding rubber ring and manufacturing method thereof

The invention relates to a high speed chemical fiber spinning guide wire apron for a spinning machine, which is formed by integrally curing an inner layer rubber apron, core-spun yarn and an outer layer rubber apron together. The rubber apron comprises the following components in portion by weight: nitrile-butadiene rubber NBR 100, polyvinyl chloride HPVC 40-80, dibutyltin C-102 1.8-2.8, polyurethane PU 20-30, barium stearate 1.2-2, zinc stearate 0.2-0.4 , anti-aging agent D 1-2, stearic acid 1, zinc oxide 6-10, titanium dioxide 4-10, silica 30, dibutyl phthalate 10-20, colorant 4, accelerant 5.5-10.8. During manufacture, high polar nitrile-butadiene rubber NBR and polyvinyl chloride PVC are adopted as main materials; the obtained high speed chemical fiber spinning guide wire apron has the advantages of high strength, good wear resistance performance, stable running, and long service life. The apron has soft surface, moderate friction coefficient, does not wind fiber, and is capable of effectively improving the quality of spinning products.

Owner:TIANJIN JINGLONG TEXTILE RUBBER

Pearl anion antibacterial underclothes

InactiveCN102726841AImprove immunityNormal blood pressureBaby linensMonocomponent polyesters artificial filamentPolyesterAntibacterial agent

The invention discloses pearl anion antibacterial underclothes, comprising an underwear and pants, wherein the fabrics of the underwear and the pants are weaved by pearl anion antibacterial fibres. The pearl anion antibacterial fibres are polyester fibres spun by adding a pearl powder, a tourmaline powder and a silver-series antibacterial agent. The underclothes can improve body microcirculation, improve brain function, act a calming effect on the spirit, remove fatigue, continuously release anions, and have an antibacterial function; the underclothes are natural and environment-friendly, multifunctional, and convenient to wash; and an inspection indicates that after the underclothes are washed for 50 times, the functions still achieve more than 99%.

Owner:ZHANGJIAGANG ANSHUN TECH DEV

Preparation method of high-density regenerated fibre spinning solution

InactiveCN101736412ASimple filterDegassing reachedArtificial filaments from cellulose solutionsSpinning solutions preparationOrganic solventHigh density

The invention relates to a preparation method of high-density regenerated fibre spinning solution. The invention adds organic solvent with low boiling point into commonly prepared regenerated fibre spinning solution to dissolve regenerated fibre spinning solution system; the obtained spinning solution is defoamed after being filtered to obtain the regenerated fibre spinning solution with high density. The preparation method of the high-density regenerated fibre spinning solution of the invention is different from traditional spinning technology. The organic solvent with low boiling point is added into traditional regenerated fibre spinning solution, so that density same with the common spinning liquid needs to be prepared when preparing spinning solution; the adopted spinning procedure is characterized in that the spinning solution is defoamed after being filtered; the reason is as follows: spinning solution is easy to filter under low density and low viscosity, organic solvent with low boiling point can be removed in the defoaming procedure because defoaming is carried out under certain vacuum degree at high temperature; and spinning liquid with high density can be obtained by removing organic solvent with low boiling point.

Owner:INST OF CHEM CHINESE ACAD OF SCI

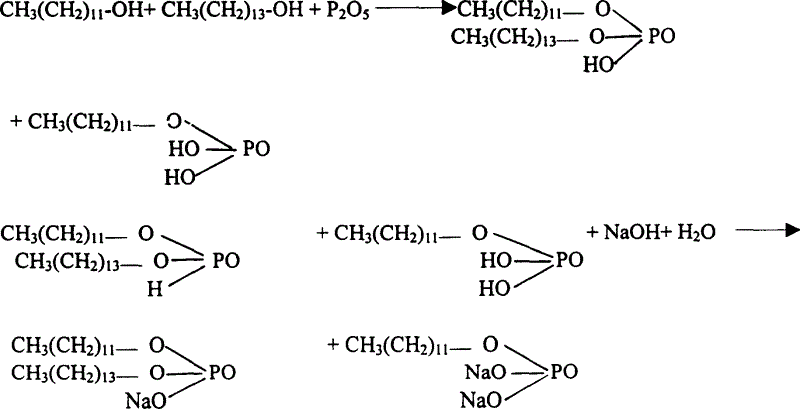

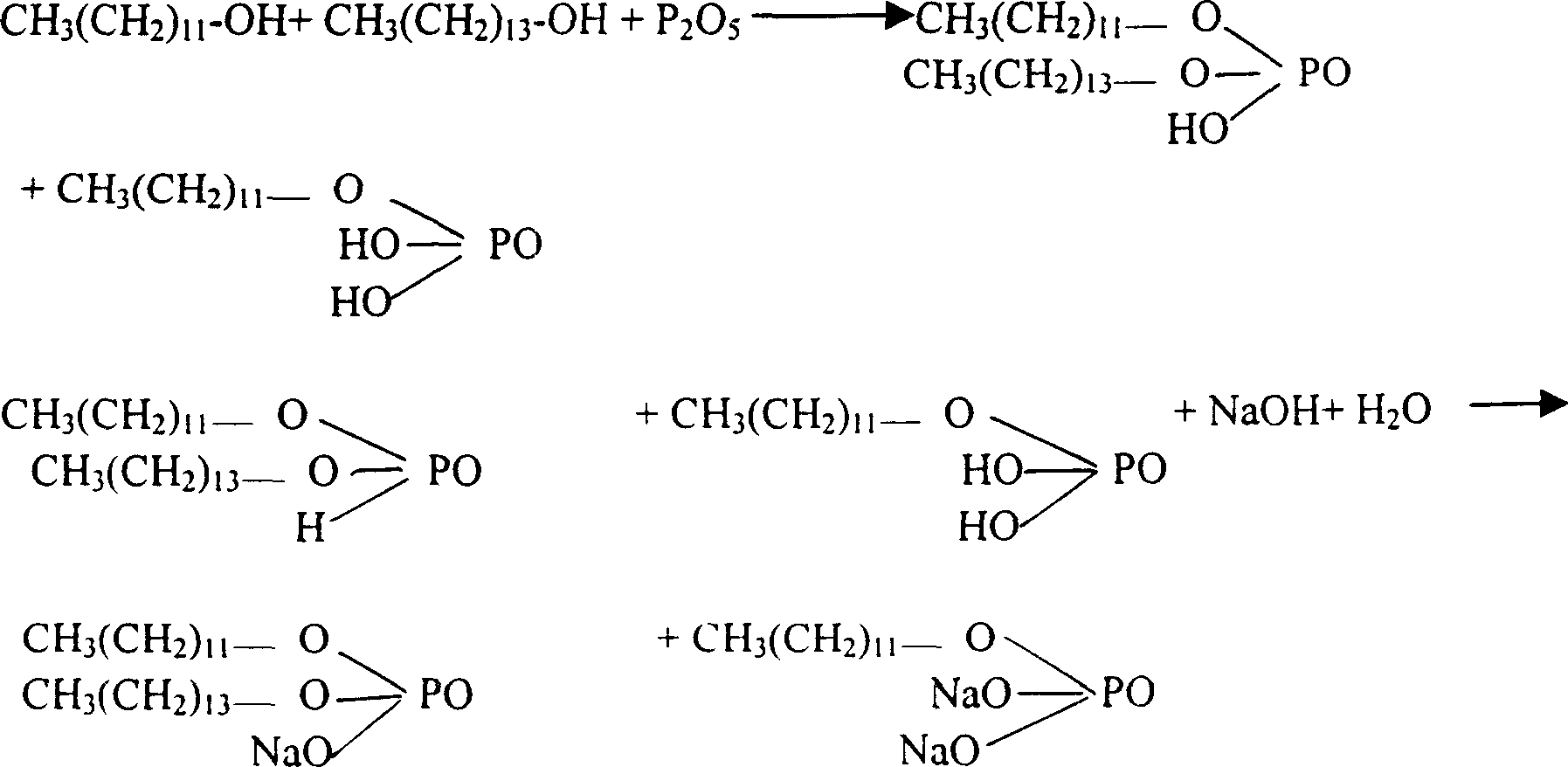

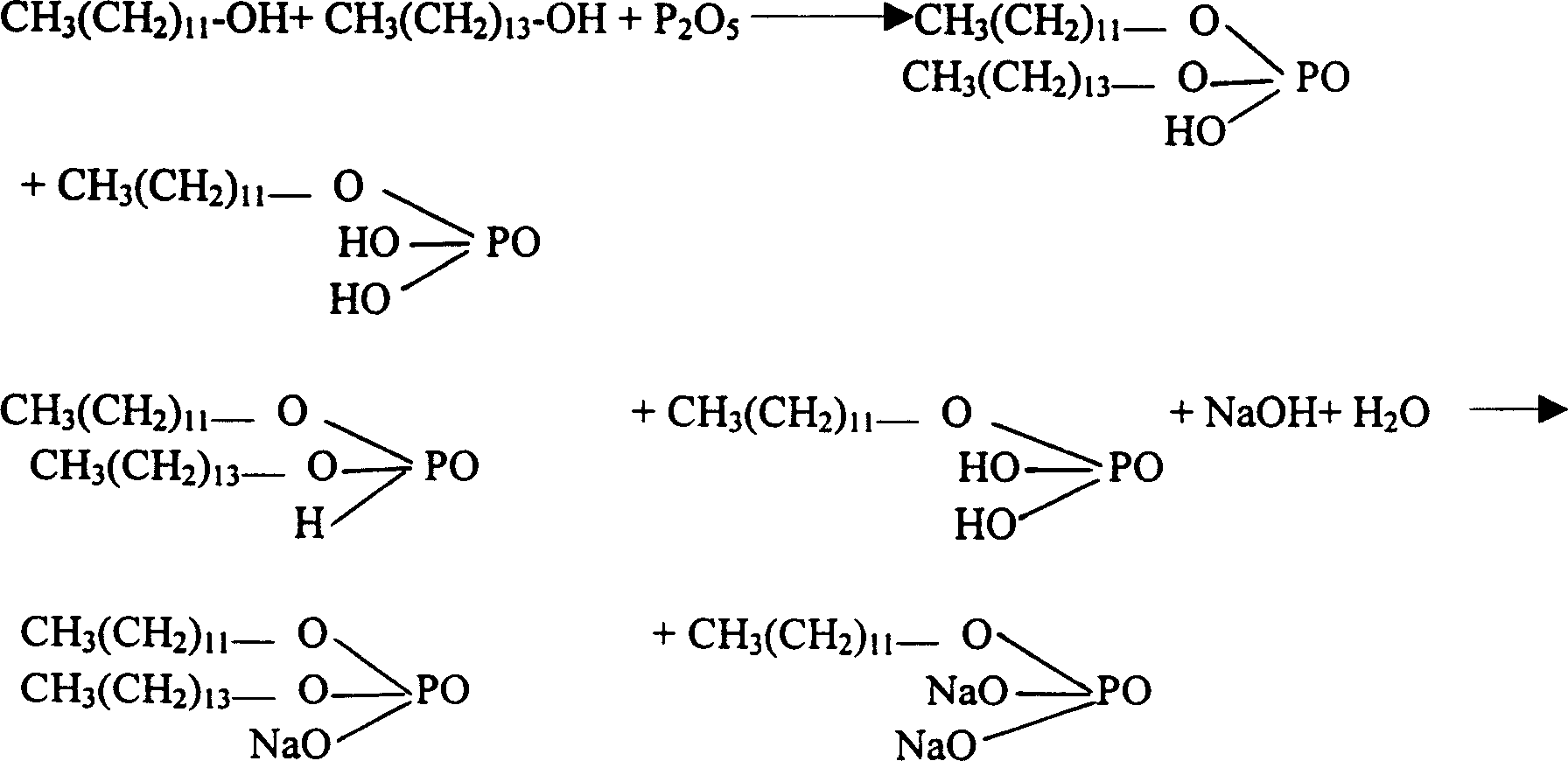

Spinning oil for terylene staple and preparation method thereof

InactiveCN1558018AImprove the lubrication effectImprove spinnabilityFibre treatmentAlcoholCoconut oil

The oil preparation for spinning dacron staple fiber includes two components of component an and component B in the weight ratio of 3-6. The component A has mixed dodecyl and tetradecyl alcohol with weight ratio between dodecyl alcohol and tetradecyl alcohol of 1-3, P2O5 and NaOH as main material and produces phosphate sodium salt of the mixed alcohol. The component B is compounded with fatty alcohol-polyoxyethyleneether ammonium sulfate coconut oil biethyl alcohol acylamine in the weight ratio of 1 to 0.5-1.5. The present invention has low production cost, and results in less breaking during spinning and good forming performance.

Owner:江阴市澄江化工有限公司

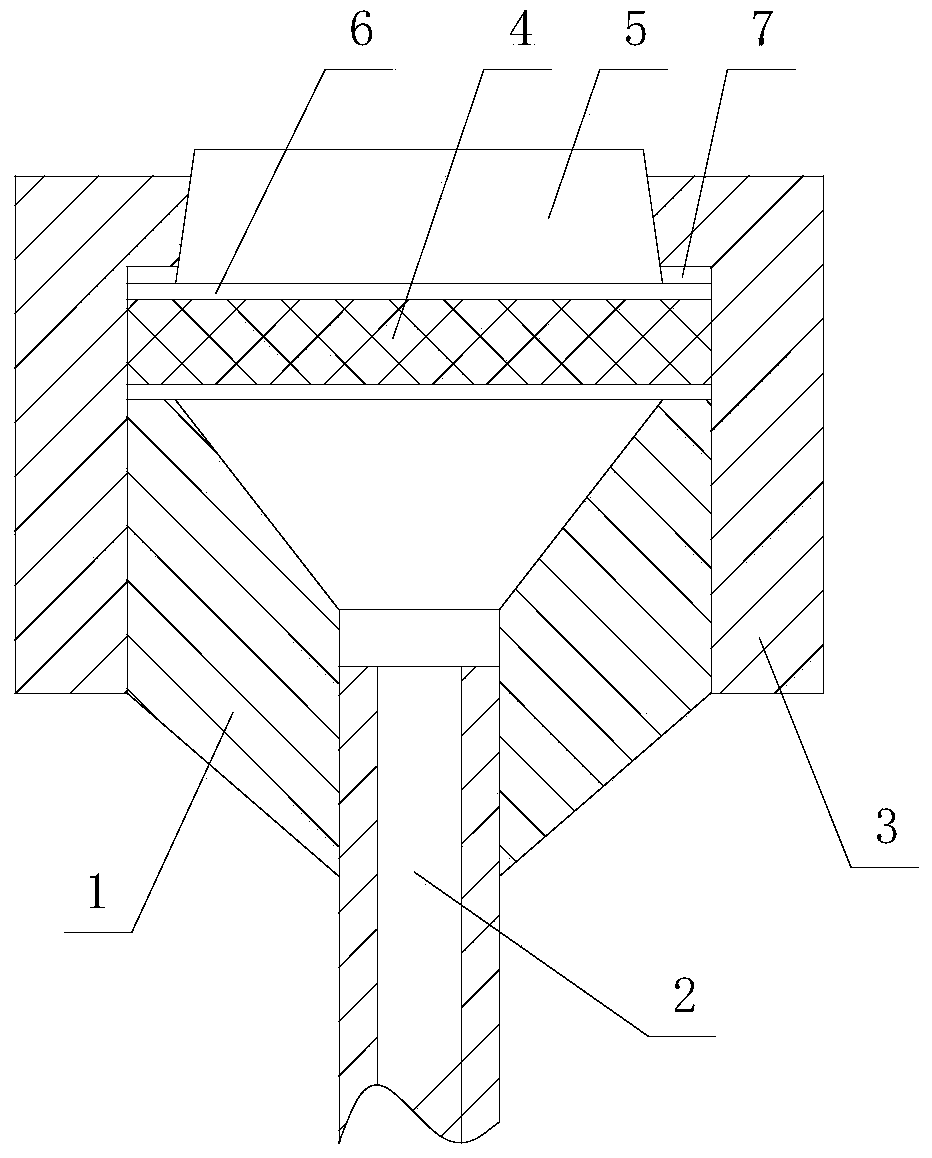

Spinning jet device

InactiveCN104073891AFilter in timeAvoid cloggingSpinnerette packsFilament-forming treatmentOxide ceramicCompressive resistance

The invention relates to the technical field of spinning accessories, in particular to a spinning jet device used for chemical fibre spinning. The spinning jet device comprises a nut seat arranged on a gooseneck tube in a sleeving manner, wherein a spinneret nut is arranged outside the nut seat; a filter plate is arranged in a cavity formed between the nut seat and the spinneret nut; a filter cloth wraps outside the filter plate; a spinneret is arranged above the filter cloth; a sealing ring is arranged at the contact portions of the spinneret and the spinneret nut. The spinning jet device disclosed by the invention is convenient to use and easy to operate; large-particle substances are filtered out in time during a spinning process, thus preventing the occurrence of blockage phenomenon of the through hole of a jet plate; meanwhile, the spinneret is made from oxide ceramic, corrosion-resistant and high in compressive resistance, thus prolonging the service life of the spinneret, and ensuring the production efficiency.

Owner:杨永坚

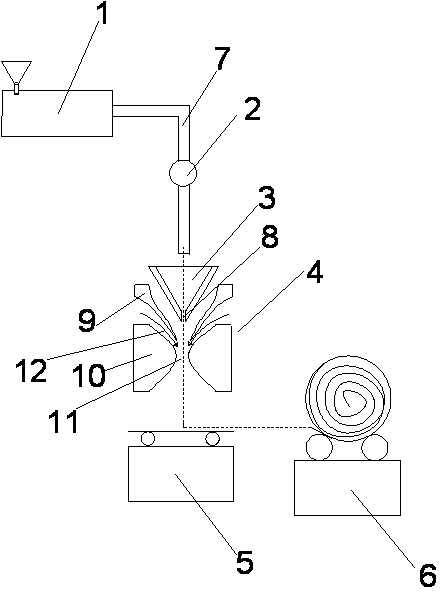

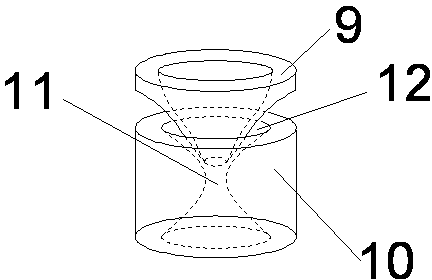

Throat-tube type cold-wind-drafted and melt micro-fibre spinning device

InactiveCN104073897AReduce thermal stressEmission reductionArtificial thread manufacturing machinesMelt spinning methodsEngineeringTubes types

The invention discloses a throat-tube type cold-wind-drafted and melt micro-fibre spinning device. The throat-tube type cold-wind-drafted and melt micro-fibre spinning device specifically comprises an extruder, a metering pump, a spinneret plate, a throat-tube type airflow drafter, a receiving device and a winding device, wherein the extruder penetrates through the metering pump through a conveying tube and is connected with the spinneret plate; the spinneret plate is arranged at the upper end of the throat-tube type airflow drafter; a spinneret is arranged at the lower end of the spinneret plate; the throat-tube type airflow drafter comprises an upper portion and a lower portion; a first airflow channel is formed between the upper portion and the lower portion; the centre of the lower portion is a second airflow channel; the receiving device is arranged just below the second airflow channel; the winding device is located at one side of the receiving device. According to the throat-tube type cold-wind-drafted and melt micro-fibre spinning device disclosed by the invention, production energy consumption is greatly reduced, energy is saved, and carbon emission is reduced.

Owner:JIANGSU LIYANG NEW MATERIALS CO LTD

Dynamic demonomerization and defoaming method and device for carbon fiber spinning solution

ActiveCN101856570BContinuous quantitative feedingSingle and degassing continuous dynamicFoam dispersion/preventionThermodynamicsCarbon fibers

The invention discloses a dynamic demonomerization and defoaming method and a dynamic demonomerization and defoaming device for carbon fiber spinning solution. An ultrasonic generator is arranged in the centre of a defoaming kettle; an air guide cylinder and a flow guide disk are arranged on a flow diversion and air guide cover; and the defoaming effect is improved to realize low-temperature high-vacuum demonomerization and defoaming of the spinning solution with different relative molecular masses and different charging rates by the processes of heating a demonomerization and defoaming device, continuous feeding, gravity demonomerization and defoaming, film stretch defoaming and ultrasound-assisted defoaming and controlling the defoaming temperature, the vacuum degree and the rotation speed of a demonomerization tower. The spinning solution obtained by the method has the residual monomer content of less than 0.1 percent, less than 5 small bubbles with diameter of less than 0.03mm andsolvent loss of less than 5 percent during the demonomerization and defoaming. The method and the device can realize continuous dynamic demonomerization and defoaming at a low temperature under vacuum condition and has the characteristics of simple and practical process and good defoaming effect.

Owner:XIAN KANGBEN MATERIAL

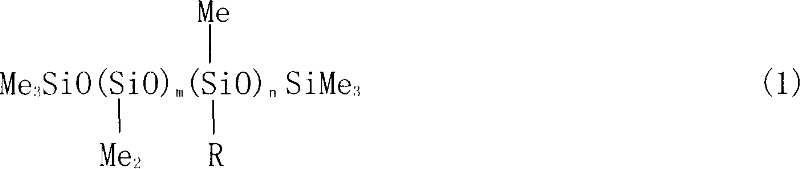

Oil preparation agent in use for spinning in urethane elastic fiber

The invention discloses a polyurethane fibre spinning oil. Its composition includes (by wt%) 5-80% of mineral oil, 10-75% of silicone oil, 0.5%-30% of epoxyethane and epoxypropane copolyether, 0.5%-50% of polyether silicone oil, 0.5-15% of antistatic agent and 0.1-10% of anti-sticking property improving agent.

Owner:CHINA PETROCHEMICAL CORP +1

Anion health-care functional fibres and preparation method thereof

ActiveCN111286806ALong-lasting negative ion release functionImprove washing resistanceMicroballoon preparationMonocomponent polyesters artificial filamentPolymer scienceNatural mineral

The invention discloses anion health-care functional fibres and a preparation method thereof, wherein the anion health-care functional fibres are obtained by blended spinning of polylactic acid spinning solution, anion health-care microcapsules, natural mineral powder and a dispersing agent; the mass ratio of the various components is 150:(7-18):(1-2.5):(0.5-1.5); the preparation method of the anion health-care functional fibres comprises the steps of: by the mass fraction, mixing 150 parts of polylactic acid spinning solution, 7-18 parts of anion health-care microcapsules, 1-2.5 parts of natural mineral powder and 0.5-1.5 parts of the dispersing agent at 185-190 DEG C, and stirring with the speed of 550-650 rpm, so that anion health-care functional fibre spinning solution is obtained; and, preparing the anion health-care functional fibre spinning solution into nascent fibres, and stretching and thermally setting the nascent fibres at 160 DEG C after winding, so that the anion health-care functional fibres are obtained. The anion health-care functional fibres in the invention are very long-acting in anion release function, and have excellent washable property.

Owner:ZHUHAI TENGBAI PHARM CO LTD

LDPE/PA6 sea-island fiber and preparation method thereof

ActiveCN113388919AGood for weight lossHigh speed reductionTextile/flexible product manufactureConjugated synthetic polymer artificial filamentsPolymer scienceMicrofiber

The invention relates to LDPE / PA6 sea-island fiber and a preparation method thereof. The crystallinity of LDPE in the LDPE / PA6 sea-island fiber is less than or equal to 11%. The preparation method comprises the following steps of (1) preparing raw materials: adopting LDPE and PE wax as a sea phase material, and adopting PA6 as an island phase material, wherein the mass of the PE wax is 0.2-0.8 wt% of that of the LDPE; (2) performing spinning: preparing the LDPE / PA6 sea-island fiber by adopting a double-screw sea-island composite spinning method, wherein the spinning speed is 350-800 m / min; (3) performing cooling: performing cooling to obtain sea-island fiber nascent filaments, wherein a blowing mode is the combination of annular air suction and annular air blowing; (4) performing bundling and oiling; (5) performing drafting: drafting the bundled and oiled fiber in a water bath at the drafting temperature of 90-95 DEG C; (6) performing crimping; and (7) performing loosening and setting to obtain the LDPE / PA6 sea-island fiber. According to the preparation method of the LDPE / PA6 sea-island fiber, the PE wax is added into the sea phase, and the high-temperature drafting process is carried out, so that the crystallinity in the sea-island fiber can be effectively prevented from being improved; and when the prepared sea-island fiber is applied to preparation of microfiber base cloth, the amount is easy to reduce.

Owner:江苏华峰超纤材料有限公司

Polyester-based mixed fibre spinning

InactiveCN1854354AImprove anti-pilling performanceSoft touchFilament/thread formingConjugated synthetic polymer artificial filamentsPolyethylene terephthalateEngineering

A combined filament yarn made by the following way:Cation dyeability polyester(CDP) and polyethylene terephthalate(PET)were spit out by separate die-spinning nozzles on the same board and they were wind to form the yarn. The combined filament yarn composed with 40-70% CDP and PET the rest by weight percentage. Textile made by this kind of yarn is tender, fluff-resistant and shows various styles.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com