Oil preparation agent in use for spinning in urethane elastic fiber

An oil and spinning technology, applied in the field of oil for synthetic fibers, can solve the problems of poor antistatic performance, poor unwinding, easy slump, etc., and achieve the effects of small friction coefficient, good formability and less broken wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

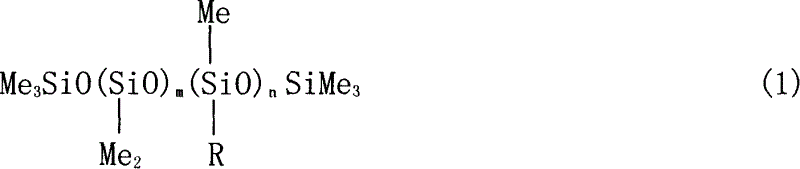

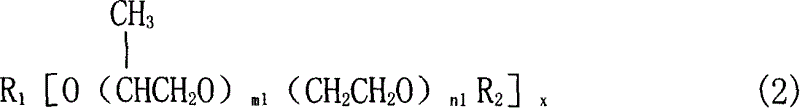

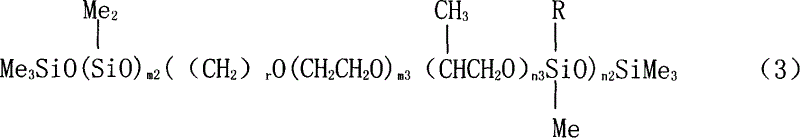

[0030] Get 15 grams of refined mineral oil successively (the kinematic viscosity of 40 ℃ is 1.8mm 2 / S), 55 grams of methylphenyl silicone oil (m=30, n=2), 13 grams of polyether (m1=37, n1=55, R 1 and R 2 Respectively octadecyl, x=1), 12 grams of polyether silicone oil (R is methyl, m2=25, n2=30, m3=100, n3=80, r=2), 2.0 grams of dodecyl Potassium phosphate and 3 grams of zinc eicosate were placed in a 500ml reactor, heated to 75°C, stirred for 30 minutes, and then cooled to 30°C while stirring.

example 2

[0032] Get 8.0 grams of refined mineral oil successively (the kinematic viscosity of 40 ℃ is 15.5mm 2 / S), 63 grams of methylphenyl silicone oil (m=30, n=4), 12 grams of polyether (m1=37, n1=55, R 1 and R 2 Respectively octadecyl, x=1), 12 grams of polyether silicone oil (R is methyl, m2=25, n2=30, m3=100, n3=80, r=2), 2.0 grams of dodecyl Potassium phosphate and 3 grams of zinc eicosate were placed in a 500ml reactor, heated to 105°C, stirred for 30 minutes, and then cooled to 30°C while stirring.

example 3

[0034] Get 20 grams of refined mineral oil successively (the kinematic viscosity of 40 ℃ is 20.0mm 2 / S), 47 grams of methylphenyl silicone oil (m=20, n=4), 15 grams of polyether (m1=37, n1=55, R 1 and R 2 Respectively octadecyl, x=1), 12 grams of polyether silicone oil (R is phenyl, m2=25, n2=30, m3=100, n3=80, r=2), 3.0 grams of dodecyl Potassium phosphate and 3 grams of magnesium eicosate were placed in a 500ml reactor, heated to 110°C, stirred for 30 minutes, and then cooled to 30°C while stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com