Patents

Literature

45results about How to "Formability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

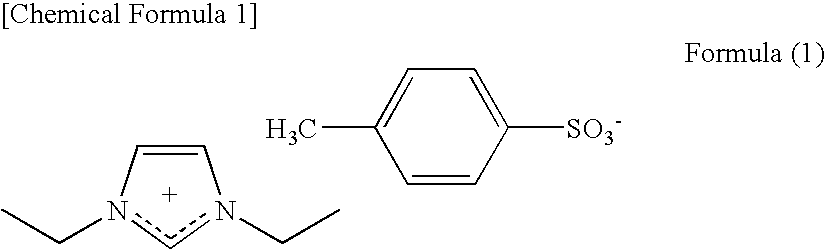

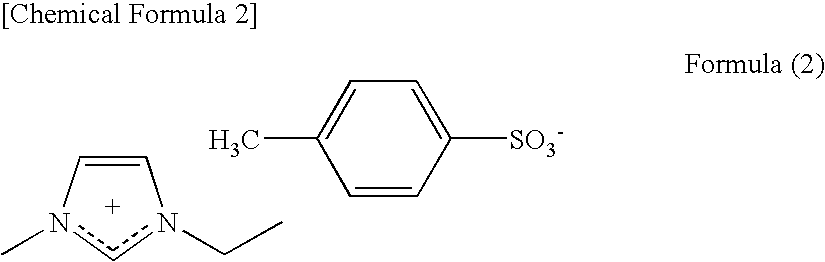

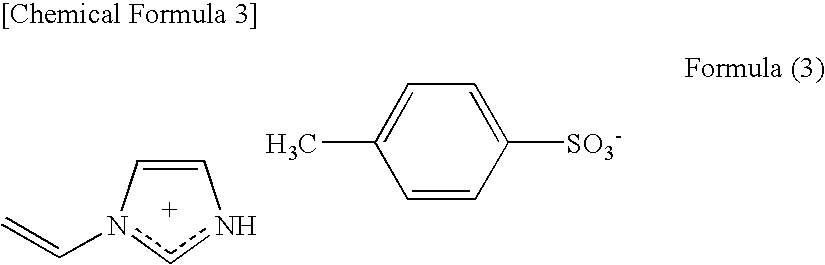

Conductive Composition, Conductive Molded Body and Conductive Gel Composition, and Method for Producing the Same

InactiveUS20080139710A1FormabilityGood formabilityHybrid capacitor electrolytesHybrid capacitor electrodesConductive polymerIonic liquid

A conductive composition containing a conductive polymer and an ionic liquid. At least part of the conductive polymer is dispersed and / or dissolved in the ionic liquid. In such a conductive composition, at least part of the conductive polymer can be dissolved in the ionic liquid. Thus, the film formability, moldability, and workability of a conductive polymer, which is generally insoluble and infusible, can be increased. More specifically, the invention can provide a conductive composition containing a conductive polymer and an ionic liquid and having high film formability, moldability, and workability.

Owner:KANEKA CORP

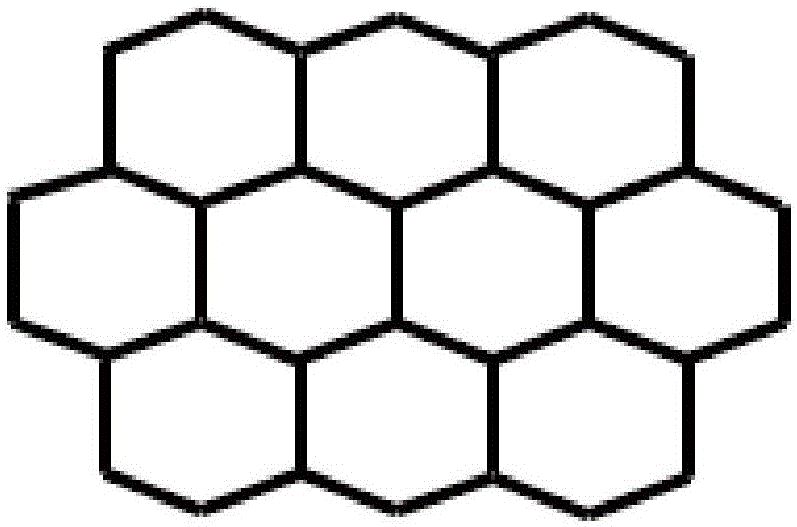

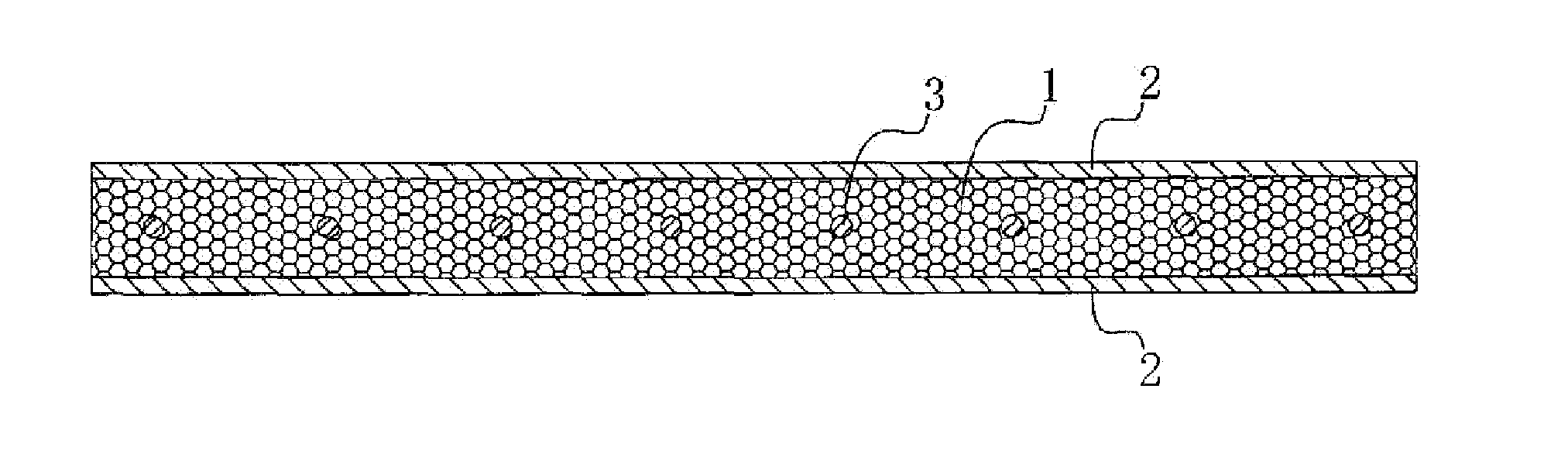

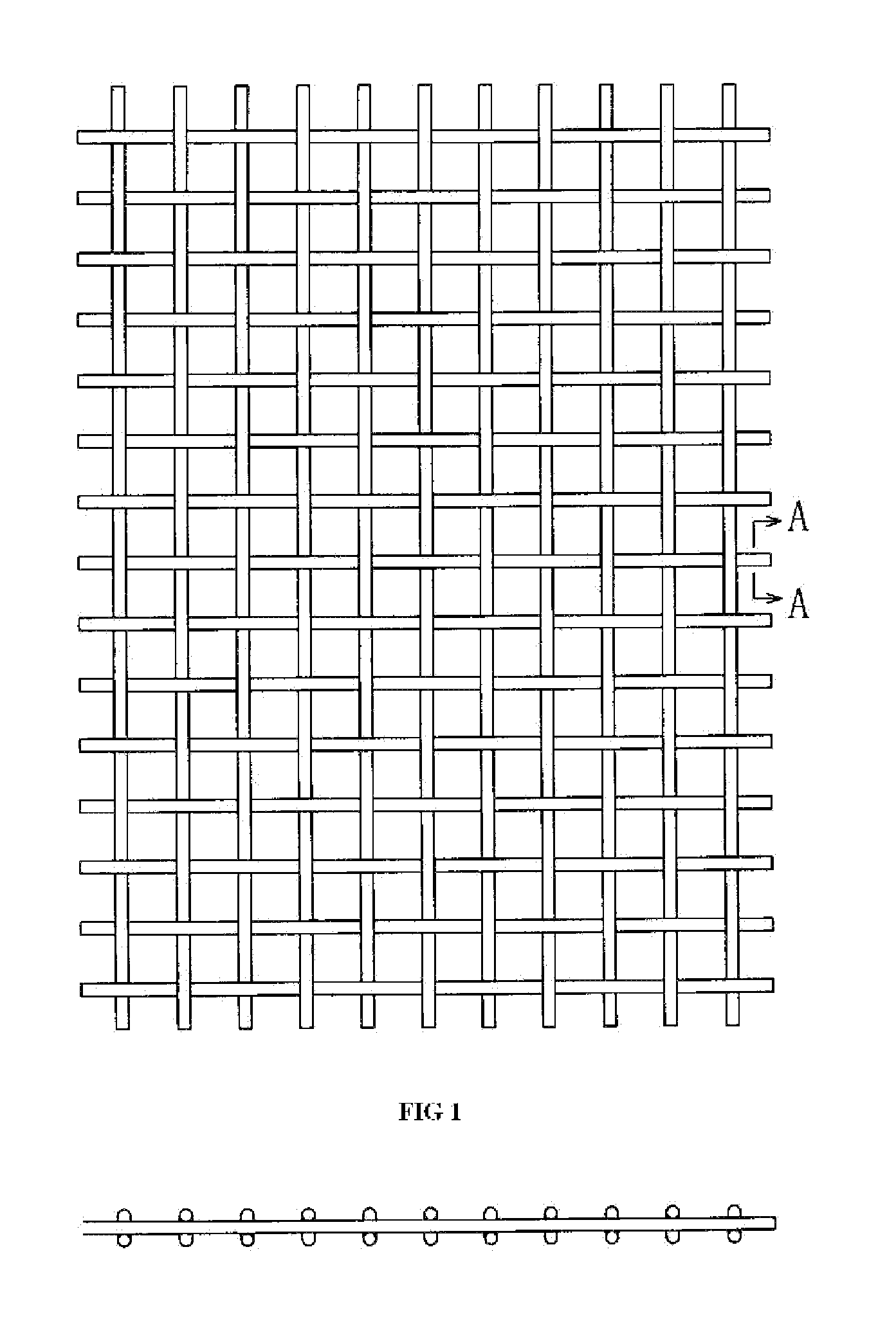

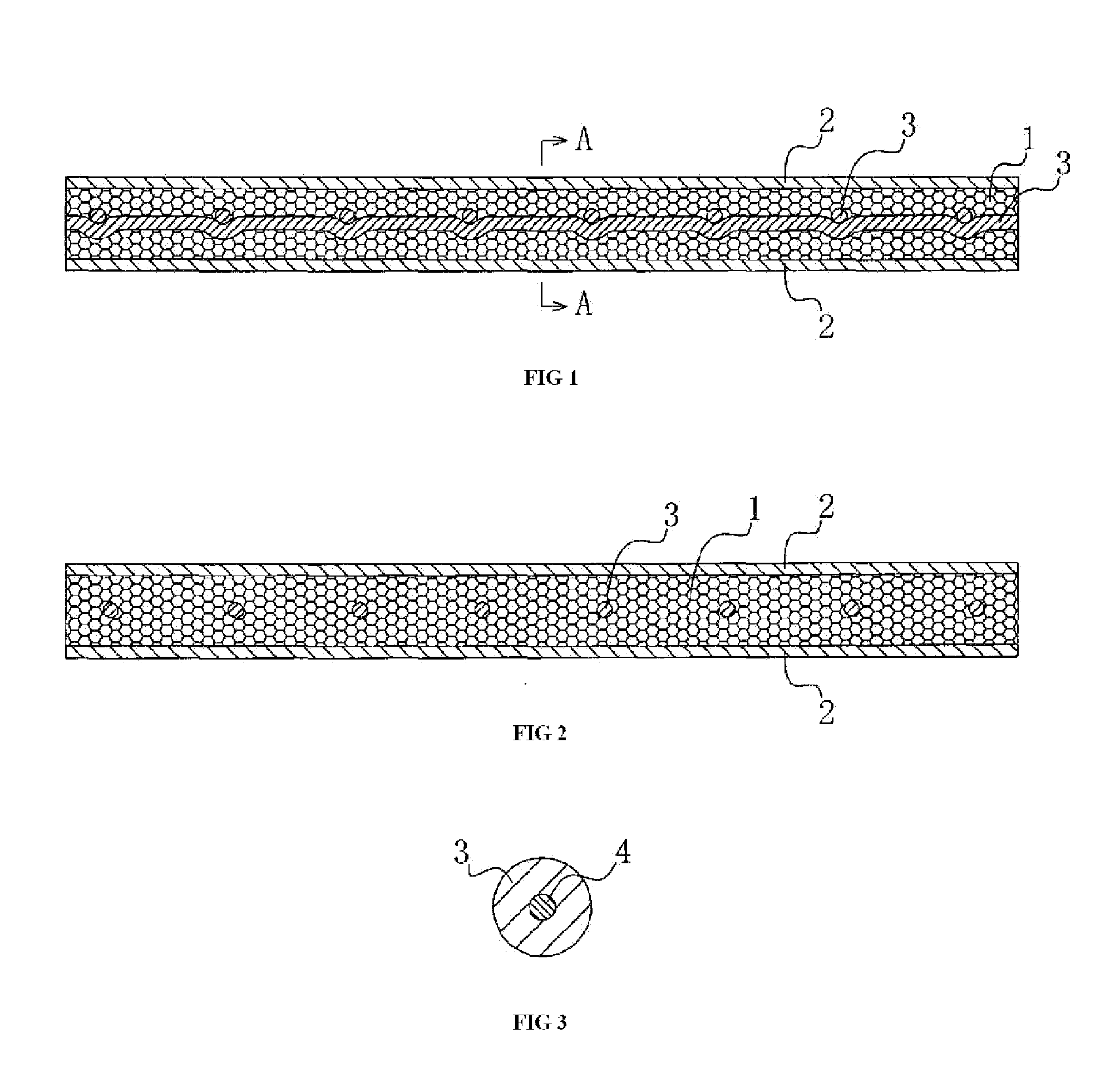

Negative Poisson ratio woven fabric and manufacturing method

InactiveCN106149150AReduce thicknessGood molding effectOrnamental textile articlesFibre typesWoven fabricHoneycomb

Owner:THE HONG KONG POLYTECHNIC UNIV

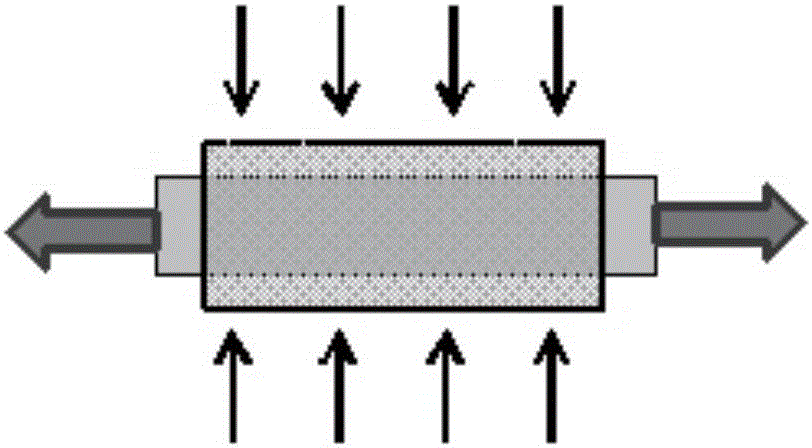

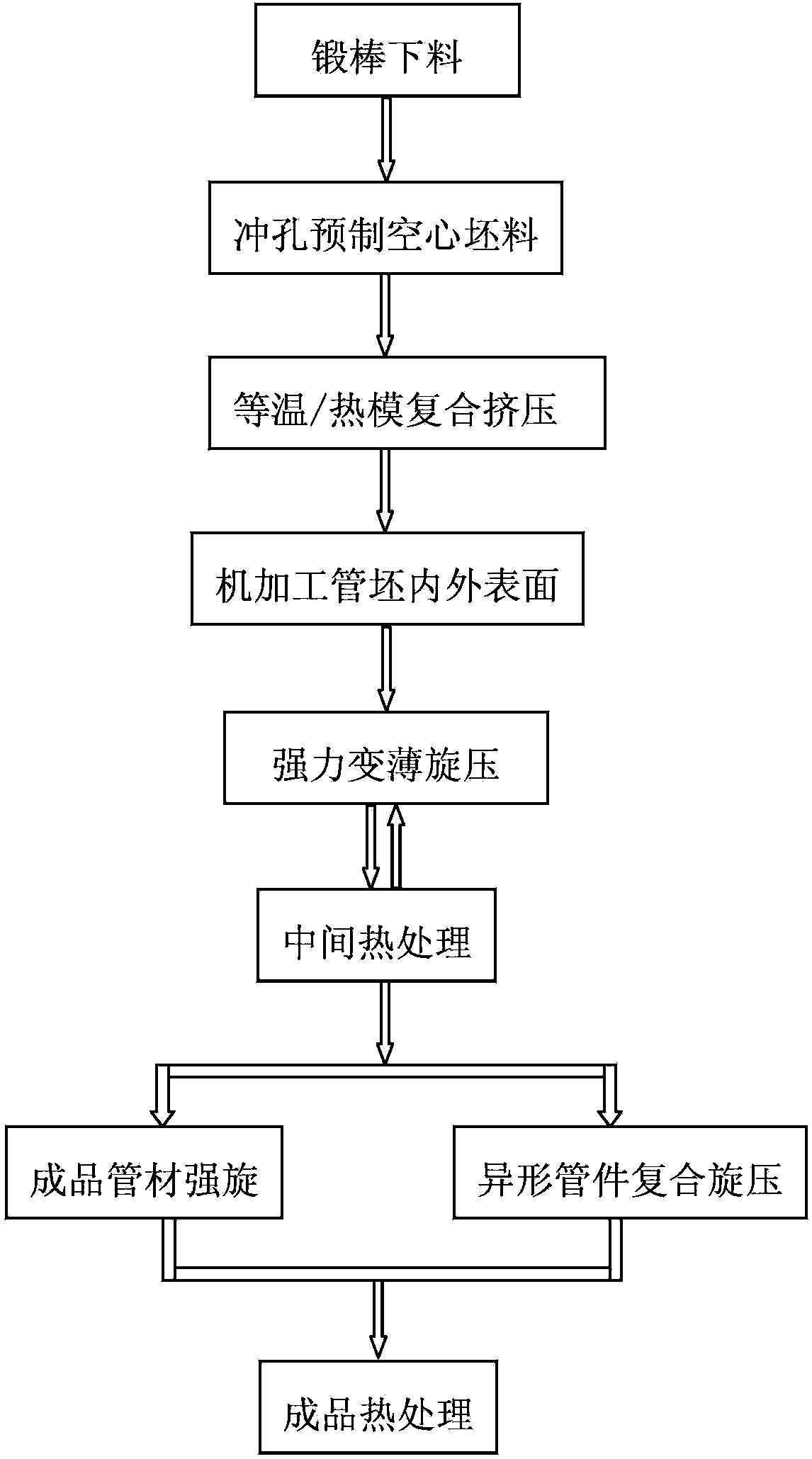

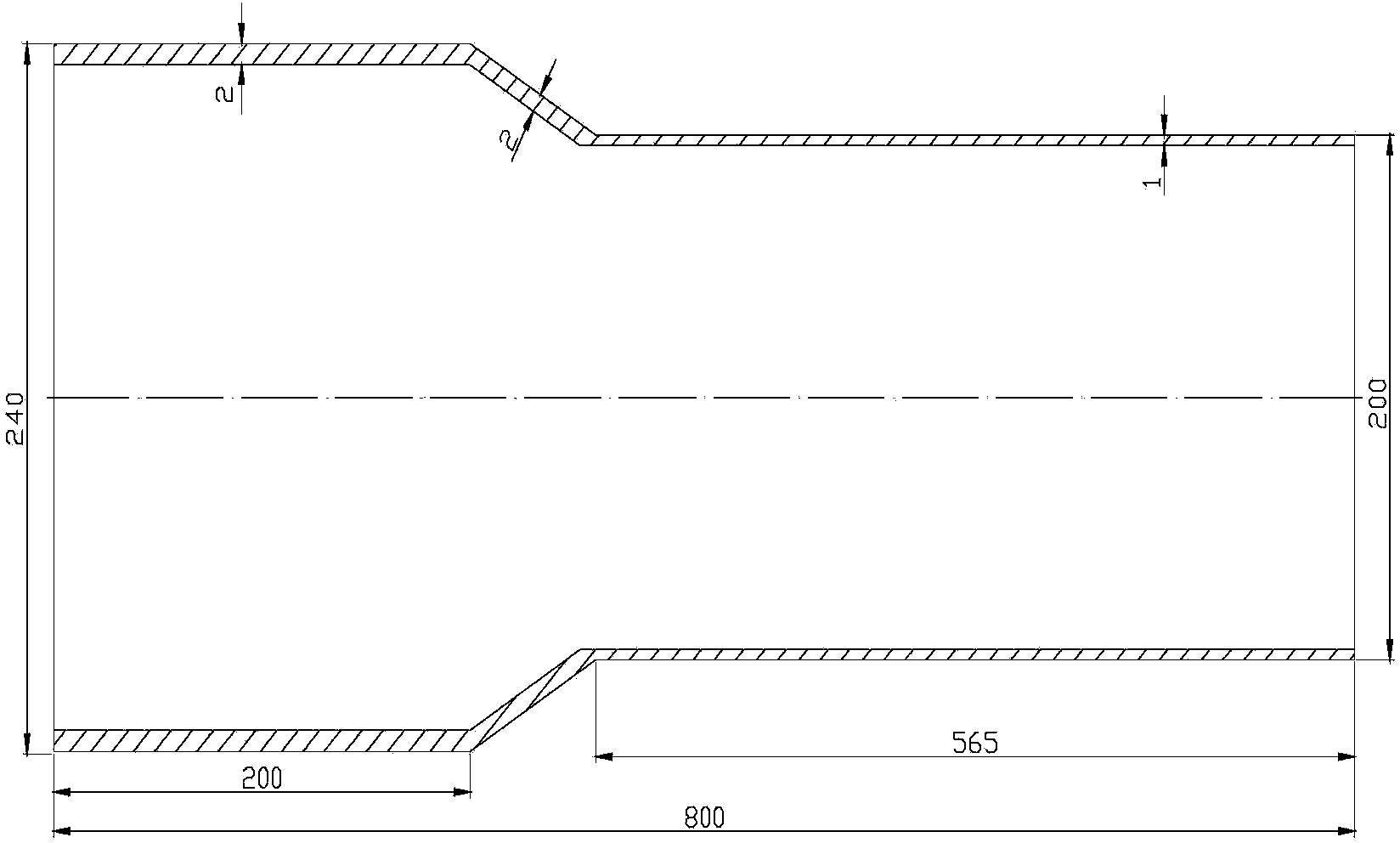

Preparation machining method of large-diameter pipe material and special-shaped pipe fitting

ActiveCN103846305AFormabilityForming labor-savingExtrusion control devicesSocial benefitsSolution treatment

The invention belongs to the technical field of metal machining, and particularly relates to a preparation machining method of a large-diameter pipe material and a special-shaped pipe fitting. The preparation machining method comprises the following steps of prefabricating a hollow blank by punching, carrying out isothermy or hot mould combined extrusion on the hollow blank, machining the inner and outer surfaces of an extruding tube blank, and carrying out multi-pass cold or hot power cone spinning on the machined tube blank; carrying out intermediate heat treatment (which can be annealing or solution treatment) on a semi-finished pipe material product; repeatedly and alternately carrying out multi-pass power cone spinning and the intermediate heat treatment, and carrying out power spinning on the finished pipe material product; carrying out multi-pass composite spinning forming on the semi-finished pipe material product after heat treatment so as to obtain the special-shaped pipe fitting; and carrying out acid pickling and cleaning on the obtained pipe fitting and special-shaped pipe fitting and then carrying out thermal treatment on the finished product. The preparation machining method of the large-diameter pipe material and the special-shaped pipe fitting provided by the invention has the advantages that the large-diameter pipe material and the special-shaped pipe fitting are prepared and machined, the product organization is uniform, the combination property is high, the forming is effort-saving, the additional value is high, and a product has good popularization and application prospect and definite economic benefits and social benefits.

Owner:GRIMAT ENG INST CO LTD

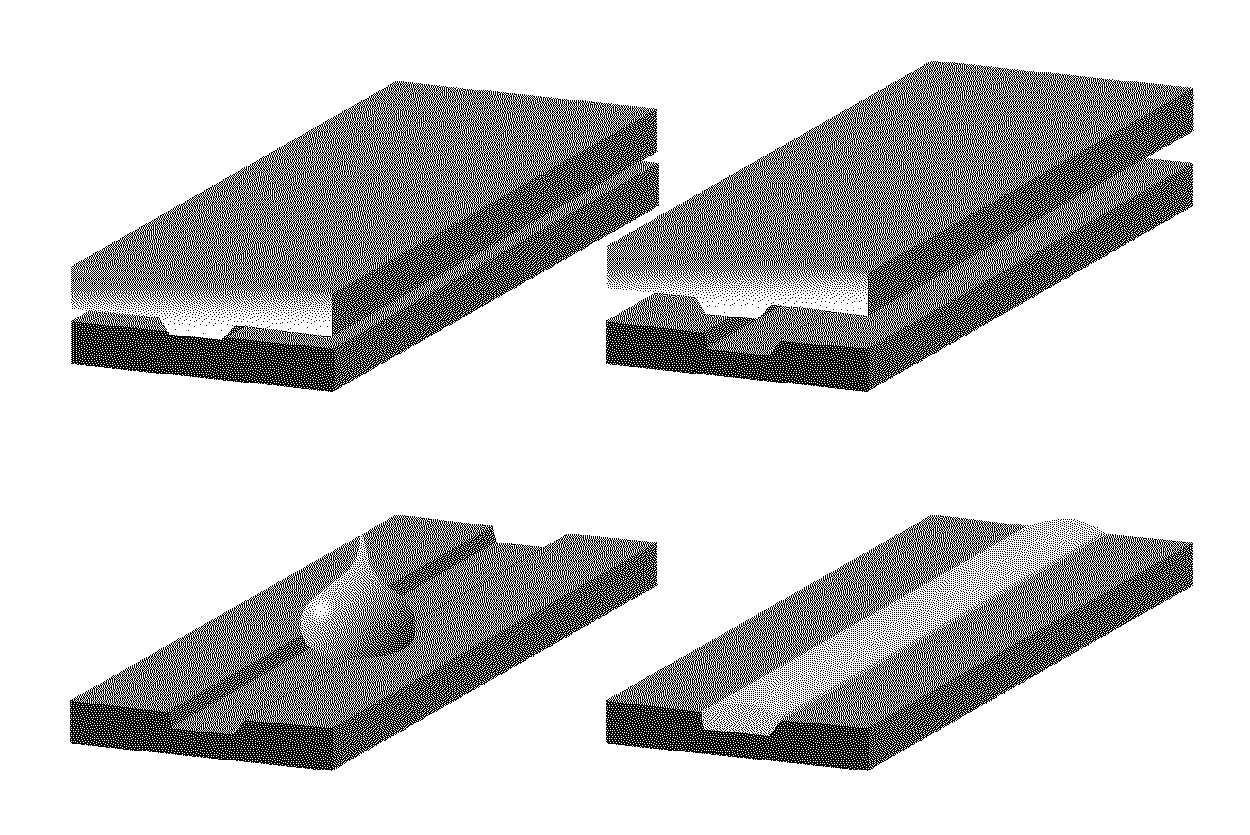

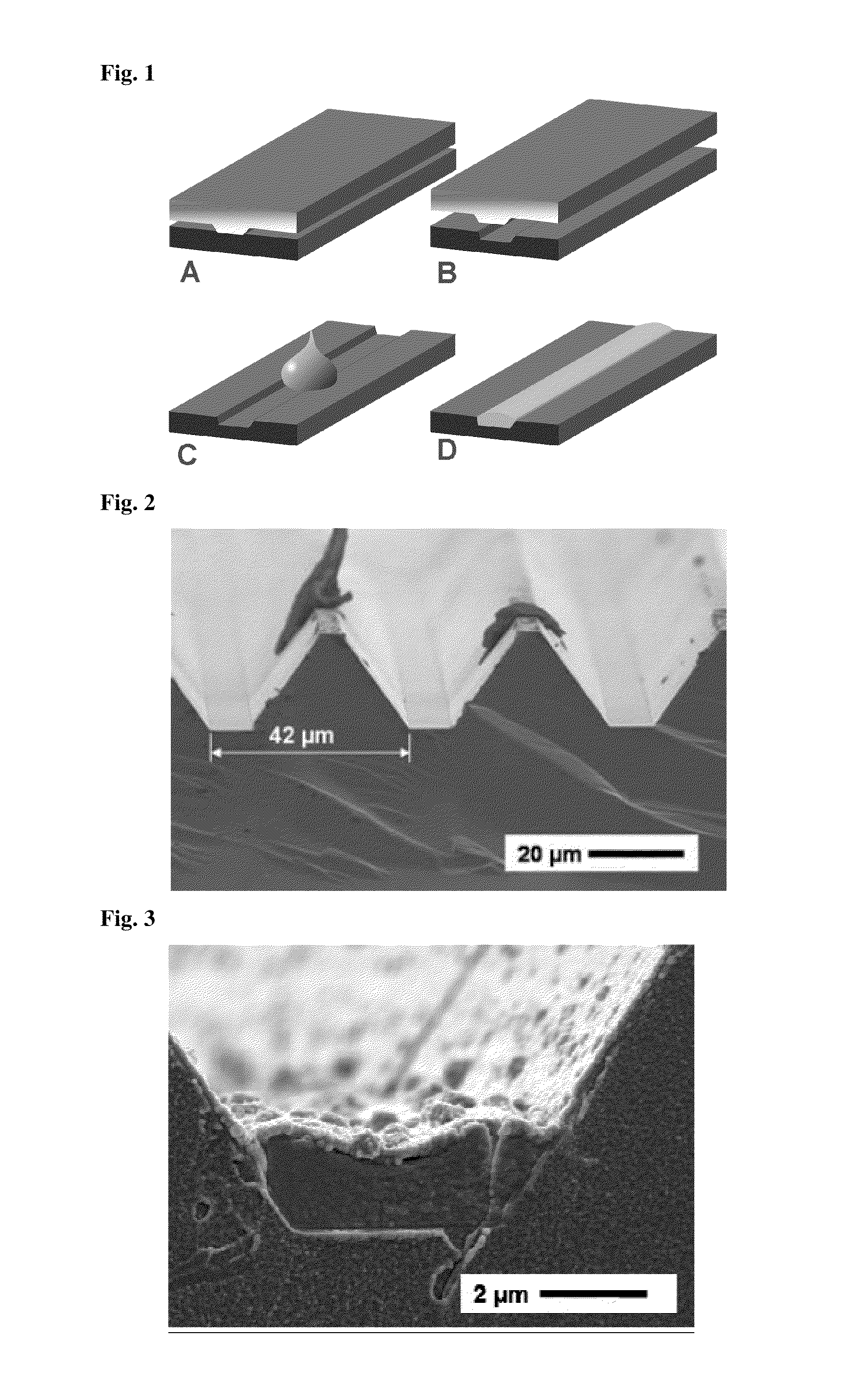

Method for fabricating minute conductive structures on surfaces

InactiveUS20090061213A1High flexibilityLow densityLayered productsSemiconductor/solid-state device manufacturingMicrostructureCapillary action

Method for producing small and micro conductive structures on surfaces by (hot) stamping and / or nanoscale imprinting microstructures on the surfaces, targeting conductive material into the channels thus created with the aid of capillary action, and appropriately after-treating the conductive material.

Owner:CLARIANT INT LTD +1

Scratch-resistant-coated polycarbonates with high transparency, process for their production, and their use

ActiveUS20120262664A1Easy to testExcellent surface appearanceSynthetic resin layered productsPolyurea/polyurethane coatingsNanoparticleReactive diluent

The present invention relates to a process for the coating of polycarbonate substrates, in particular of transparent polycarbonate substrates, by applying a transparent coating composition encompassing at least one radiation-curing binder resin (A) and / or reactive diluent (C), nanoparticles (B), optionally solvent and at least one light stabilizer (L), to a polycarbonate substrate, wherein the coating composition comprises at least one light stabilizer (L) which comprises, per molecule, an average of at least one ethylenically unsaturated group bonded by way of a urethane group.The present invention also relates to the coating compositions used in said process, and to the coated polycarbonate substrates obtainable via is the process, and to their use.

Owner:BASF COATINGS GMBH

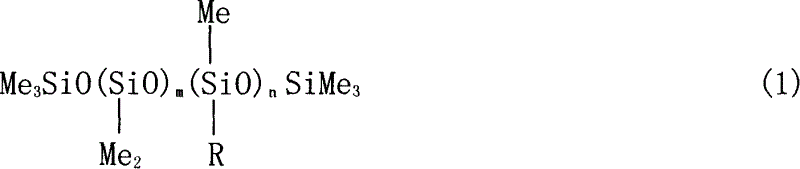

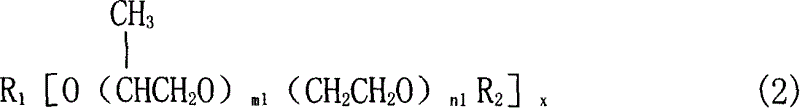

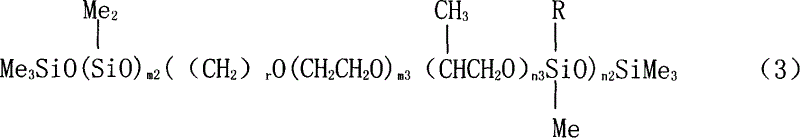

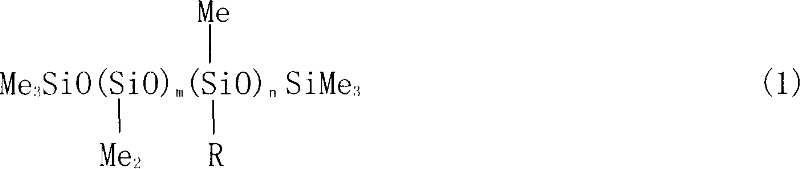

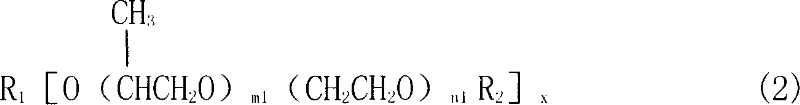

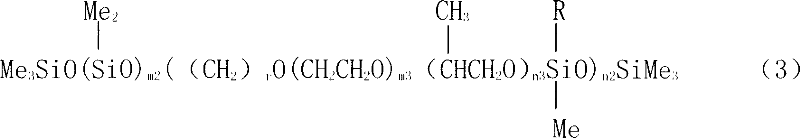

Oil preparation agent in use for spinning in urethane elastic fiber

The invention discloses a polyurethane fibre spinning oil. Its composition includes (by wt%) 5-80% of mineral oil, 10-75% of silicone oil, 0.5%-30% of epoxyethane and epoxypropane copolyether, 0.5%-50% of polyether silicone oil, 0.5-15% of antistatic agent and 0.1-10% of anti-sticking property improving agent.

Owner:CHINA PETROCHEMICAL CORP +1

Functional cornstalk board and preparation method thereof

InactiveUS20090104458A1FormabilityImprove mechanical propertiesSynthetic resin layered productsWood treatment detailsShell moldingFlexural strength

Disclosed is a functional cornstalk board and a preparation method thereof. The functional cornstalk board of the present invention includes 1 to 10 parts by weight of a curing agent, based on the total weight of the mixture of 6 to 10 parts by weight of cornstalk and 0.2 to 2 parts by weight of a binder or silicate, wherein the functional cornstalk board is obtained by molding the raw material at a molding temperature of 120 to 210° C. and a molding pressure of 10 to 30,000 kgf / cm2 for a molding time of 0.5 to 20 minutes using the semiautomatic or multistage automatic heat press device. The functional cornstalk board of the present invention is a cornstalk plywood material having a bending strength of 300 to 750 kgf / cm3, a density of 0.5 to 0.8 g / cm3, and capable of manufacturing the cornstalk plywood material into various shapes and desired standards of a woodcut, scantling, plywood, construction materials and a slate due to its easy molding by the pressure and the extrusion, and therefore the functional cornstalk board may be environment-friendly, mass-produced and economical since the cornstalk is used as the unlimited resource without adversely affecting the forests so as to obtain woods or plywoods, and particularly it may be light in weight, easily processed in molding and cutting, and also used for application products into which the colors are added.

Owner:HONG HOOK +1

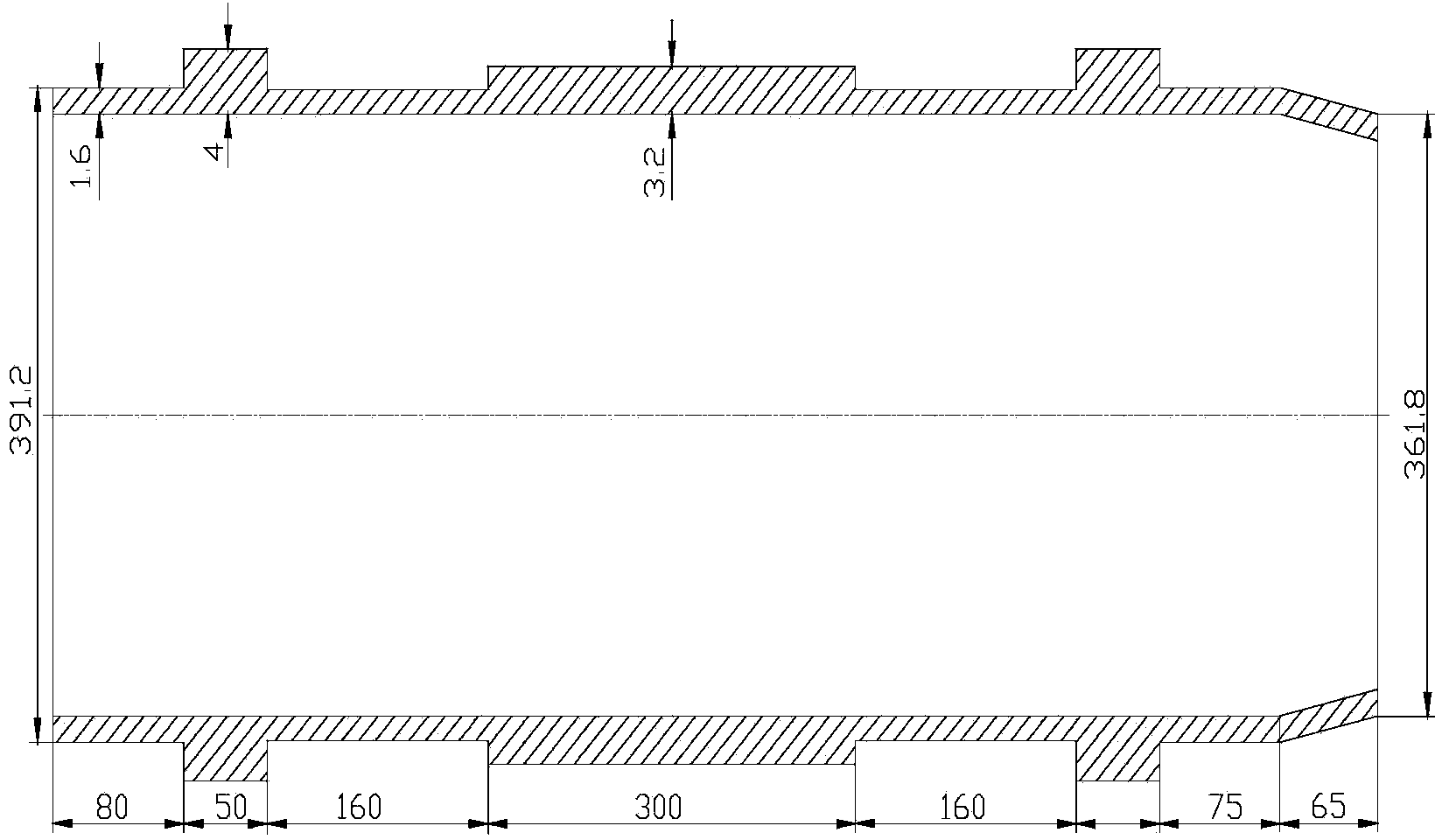

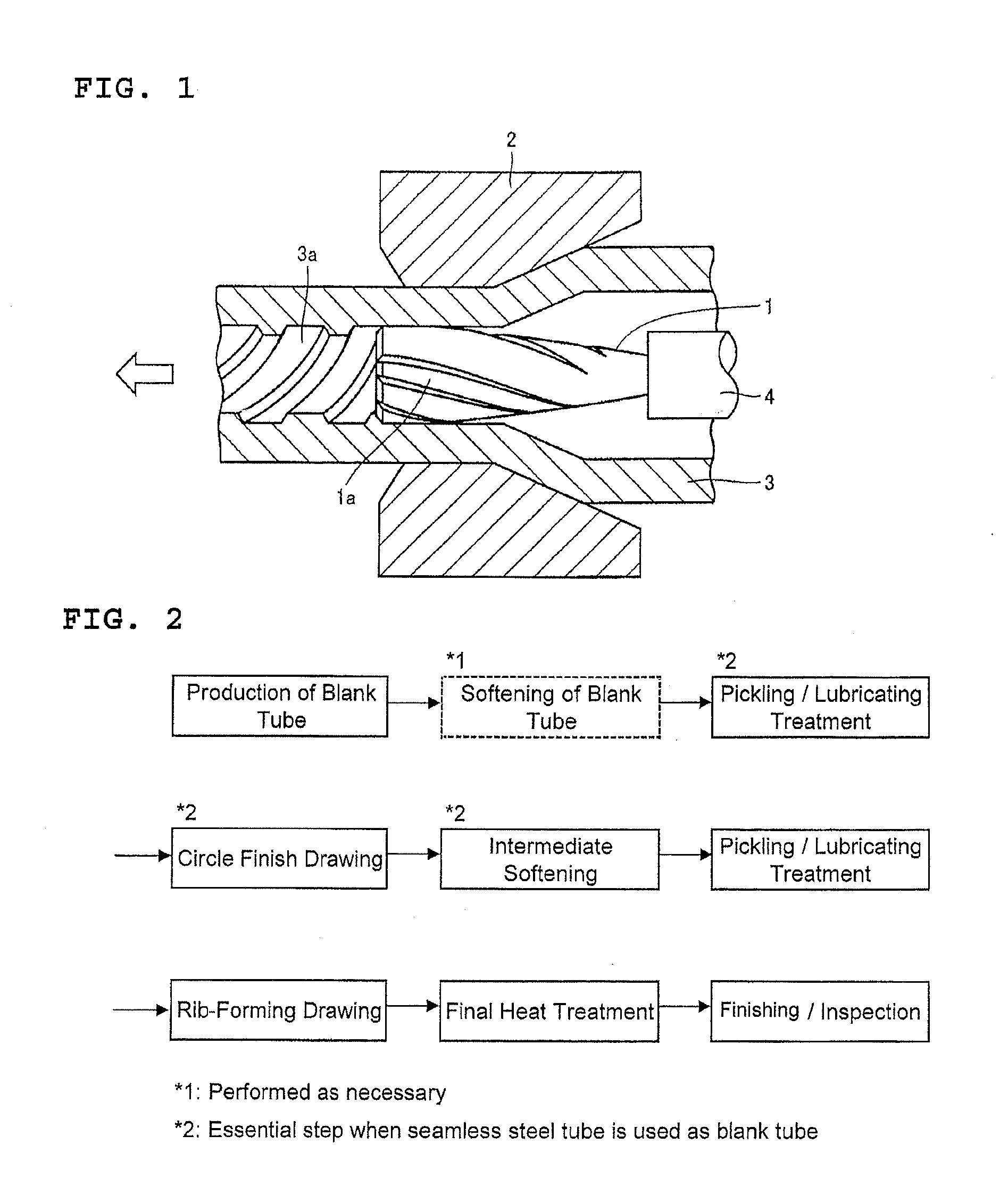

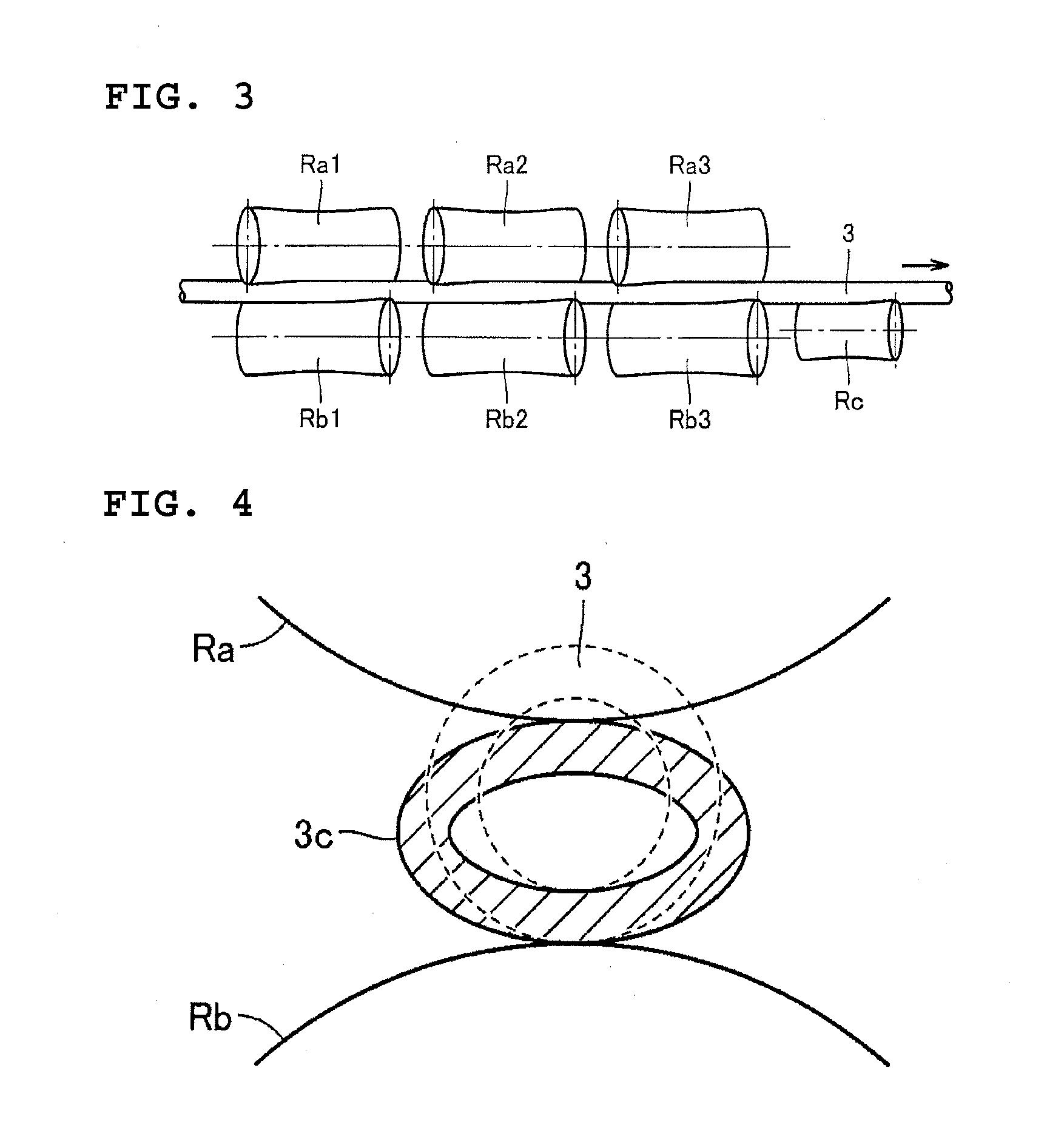

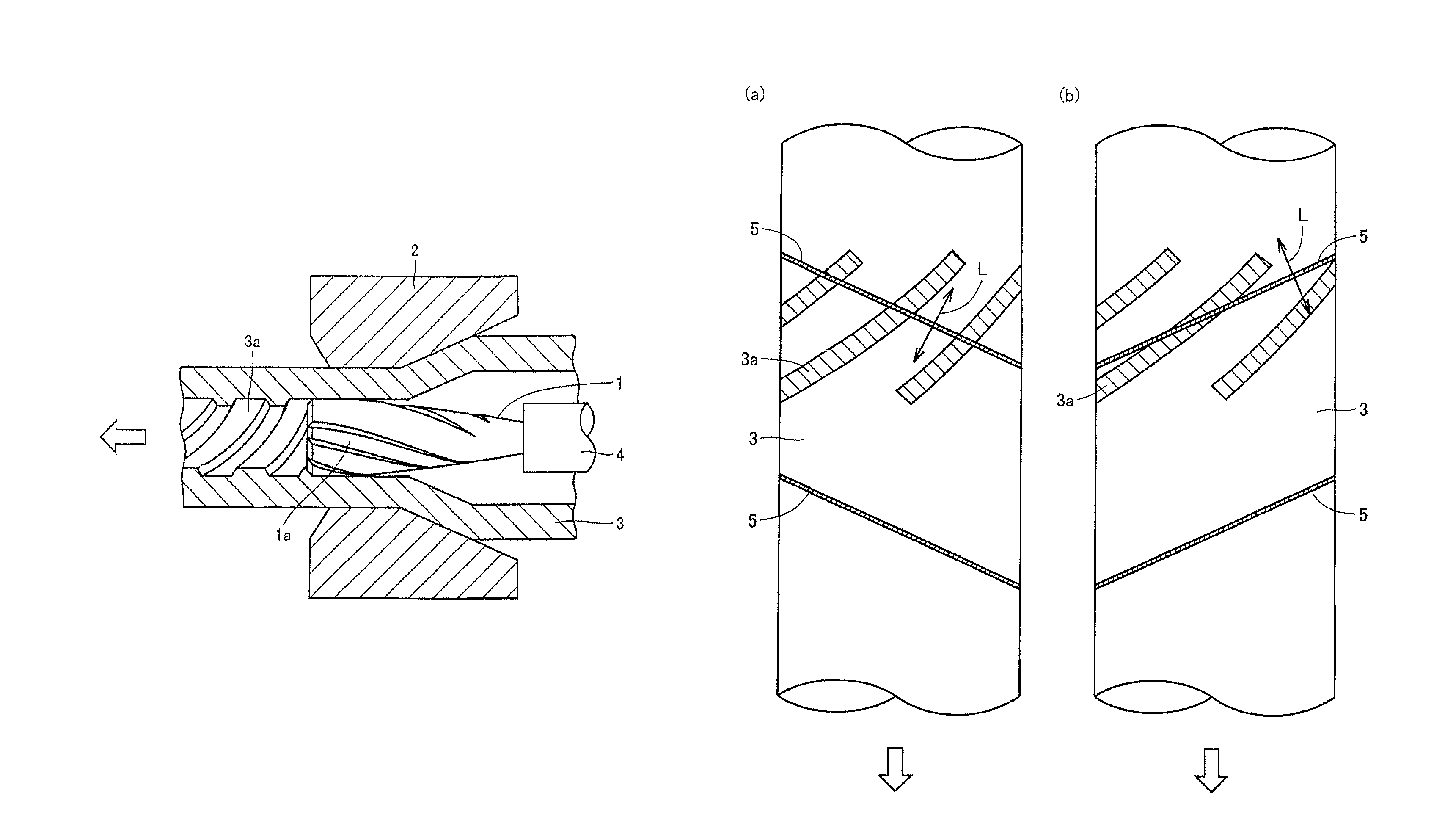

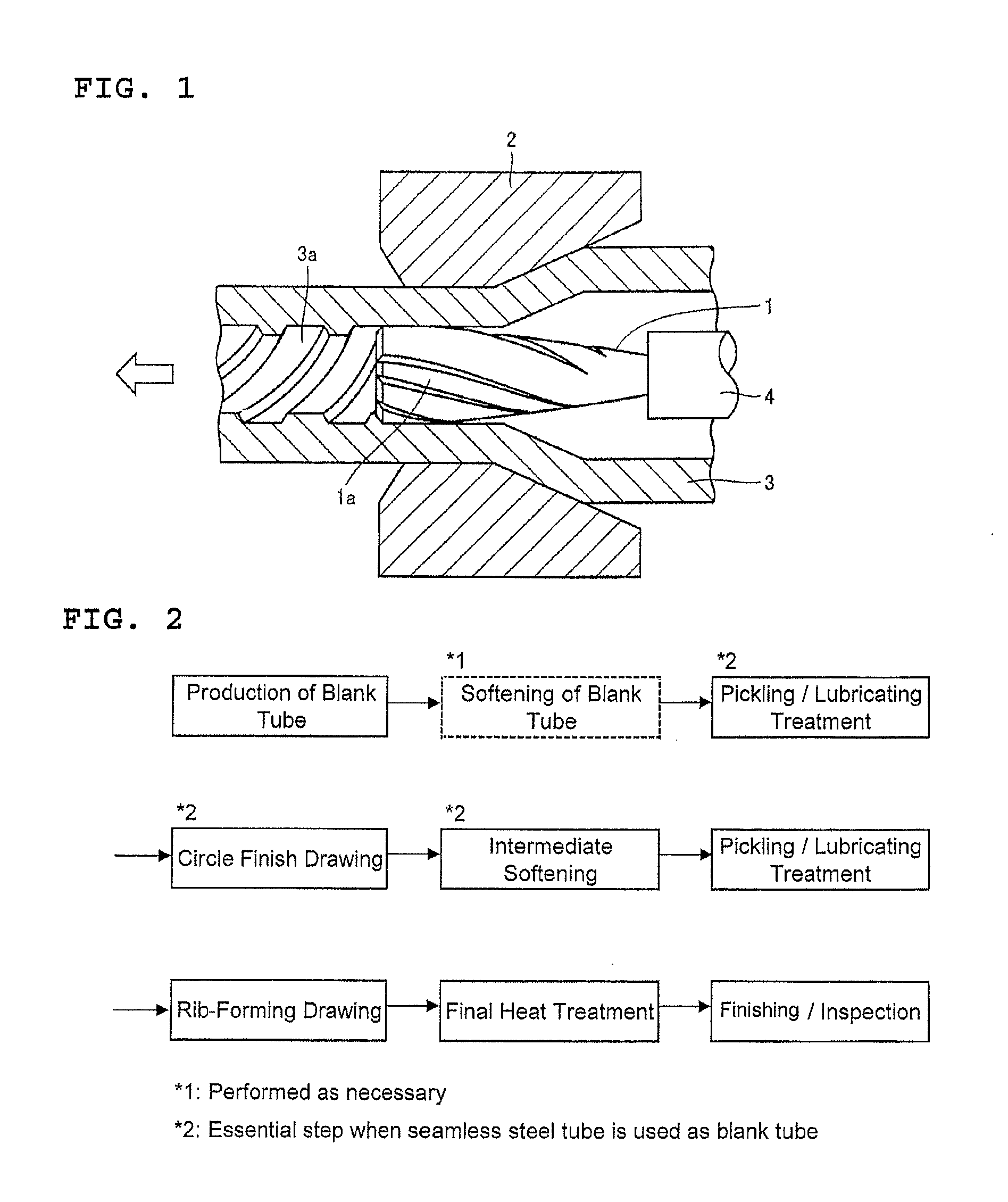

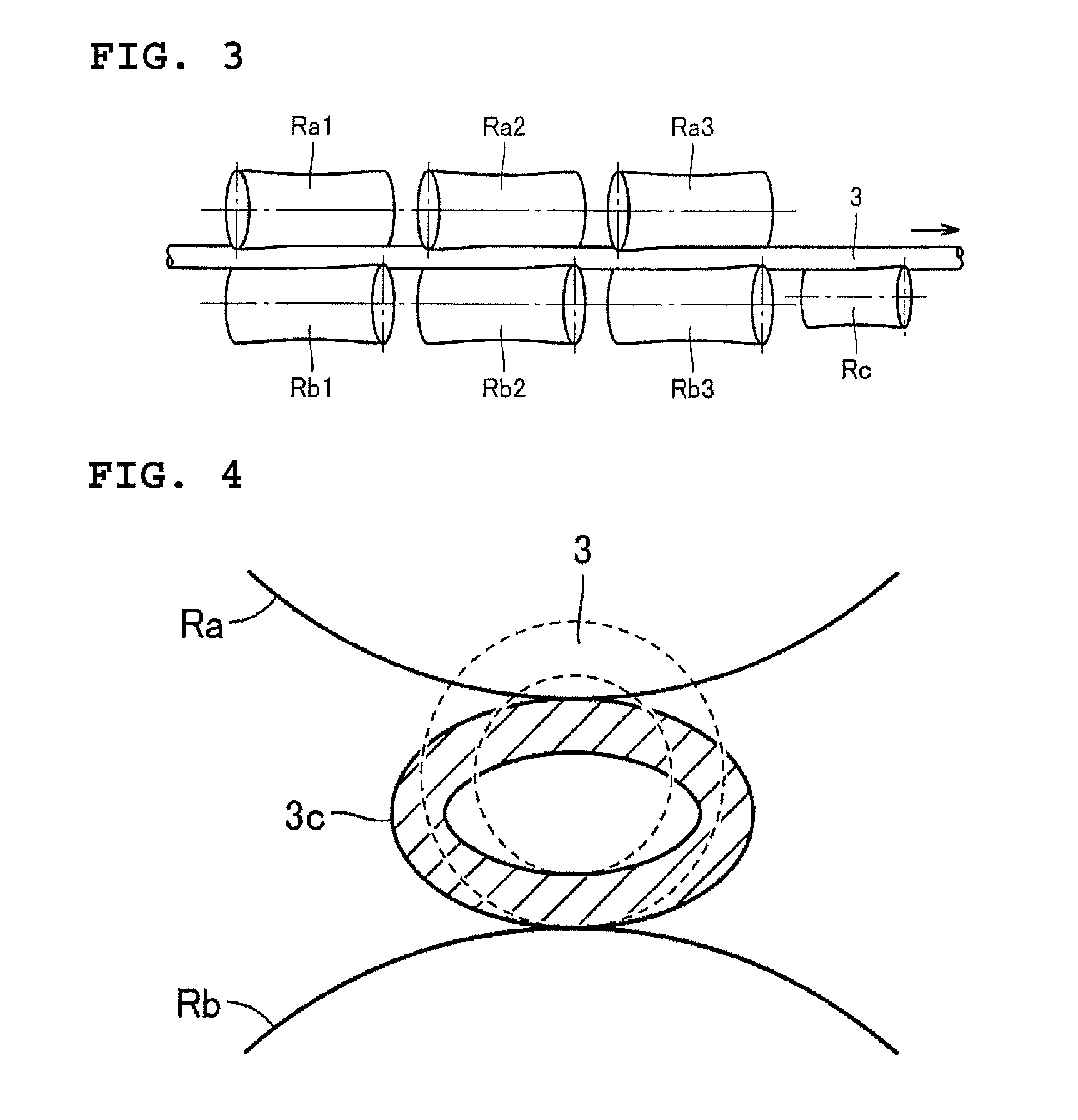

Production method of internally ribbed steel tube and the internally ribbed steel tube

ActiveUS20100193171A1Curb troubleGood formabilityBoiler water tubesWater-tube boilersEngineeringHigh pressure

There is provided a production method of an internally ribbed steel tube, capable of forming spiral ribs stably so as to reduce troubles at the time of cold drawing for forming the spiral ribs of the steel tube. In this production method, the spiral ribs can be formed stably so as to reduce troubles at the time of cold drawing for forming the spiral ribs by straightening bends of a blank tube before the cold drawing for forming the spiral ribs, by optimizing the direction of the spiral rib formation after the bend straightening, and by correcting the drawing schedule depending on the blank tube. The obtained internally ribbed steel tube is well applicable to an increased capacity and a higher temperature / higher pressure operation of a boiler because the steel tube is provided with high formability and excellent quality as a boiler steel tube.

Owner:NIPPON STEEL CORP

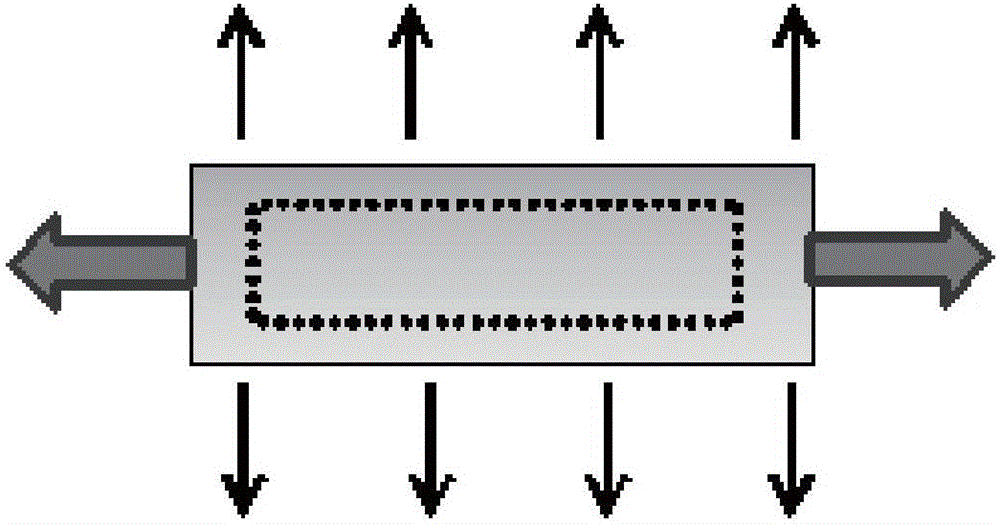

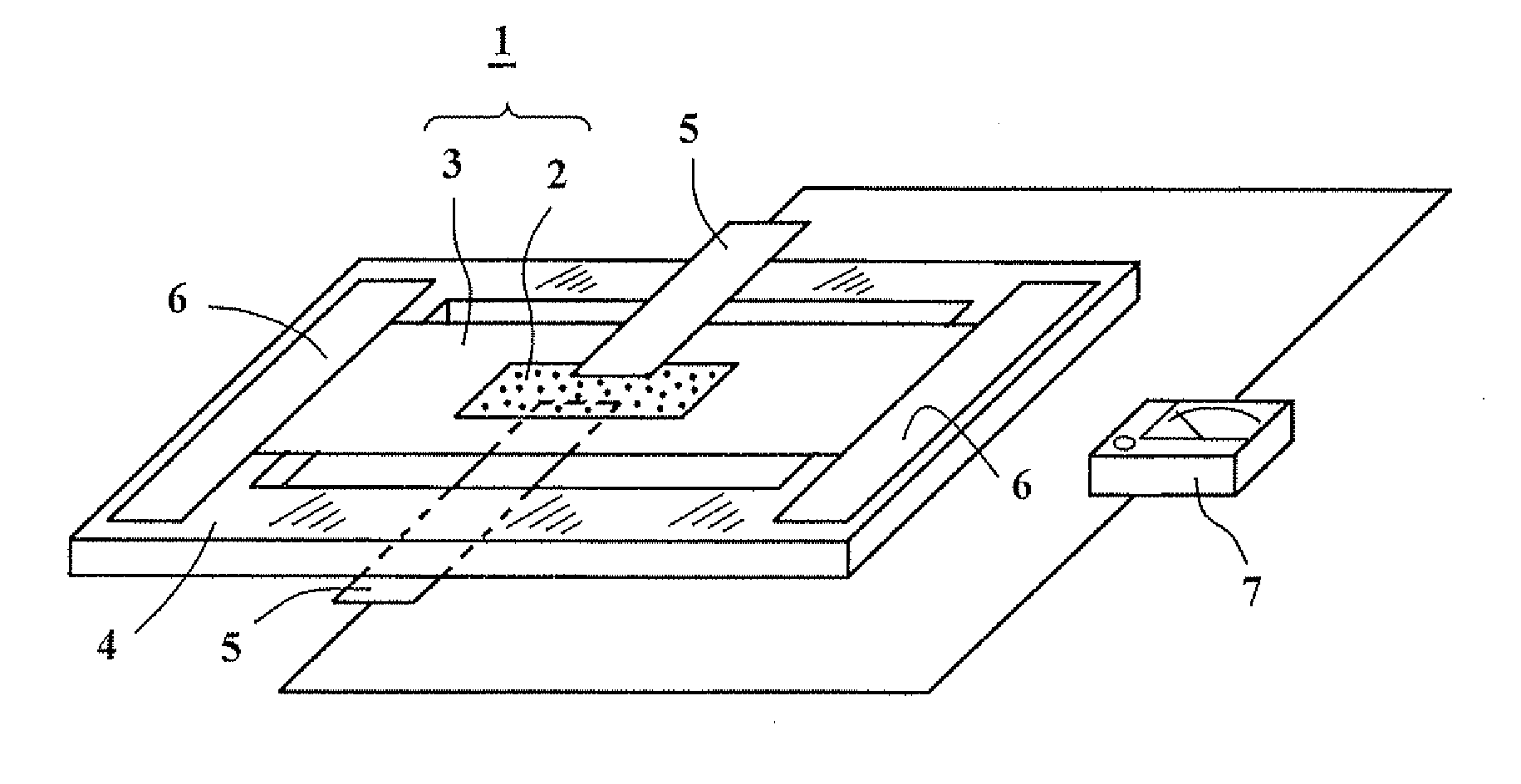

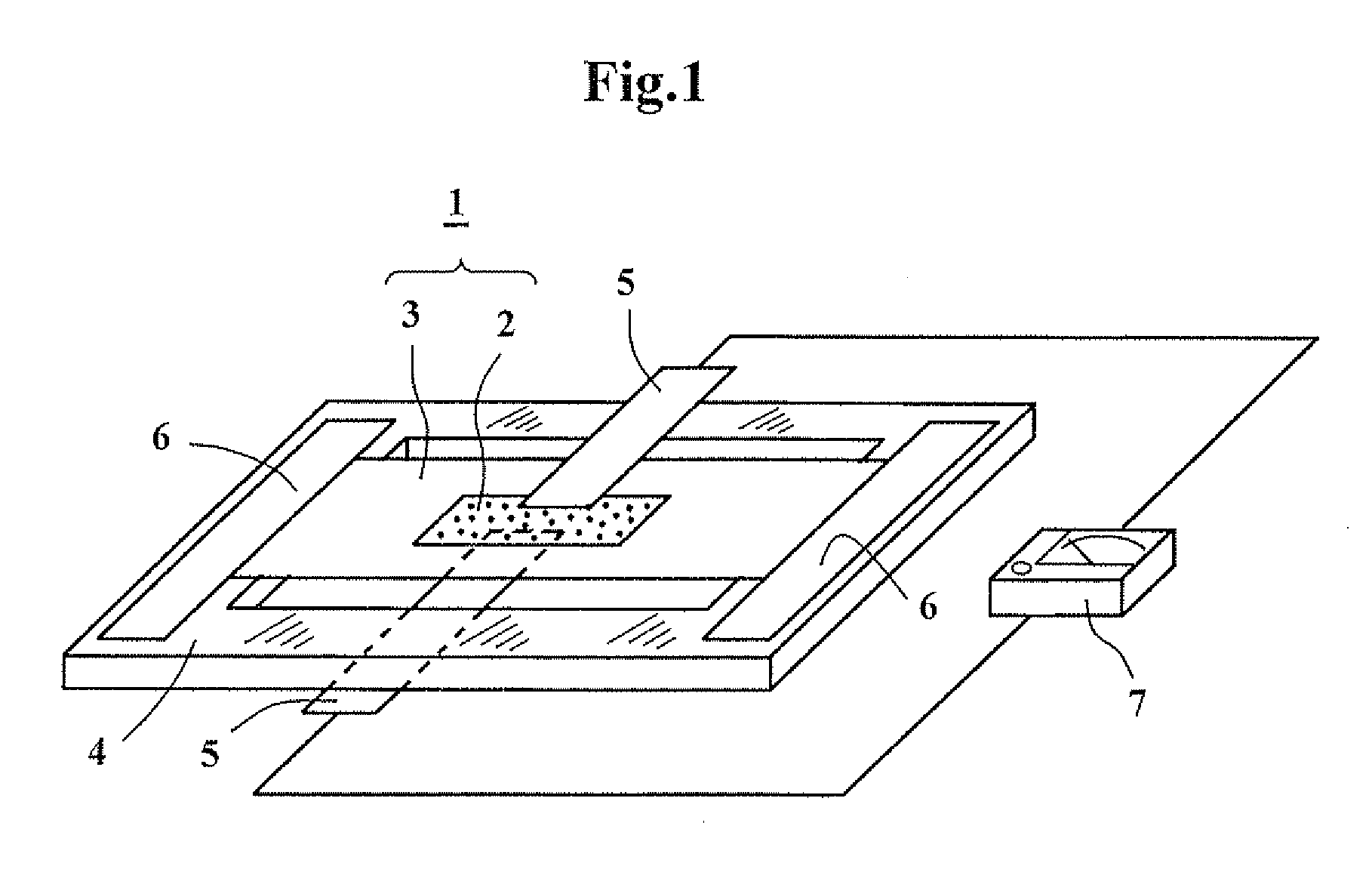

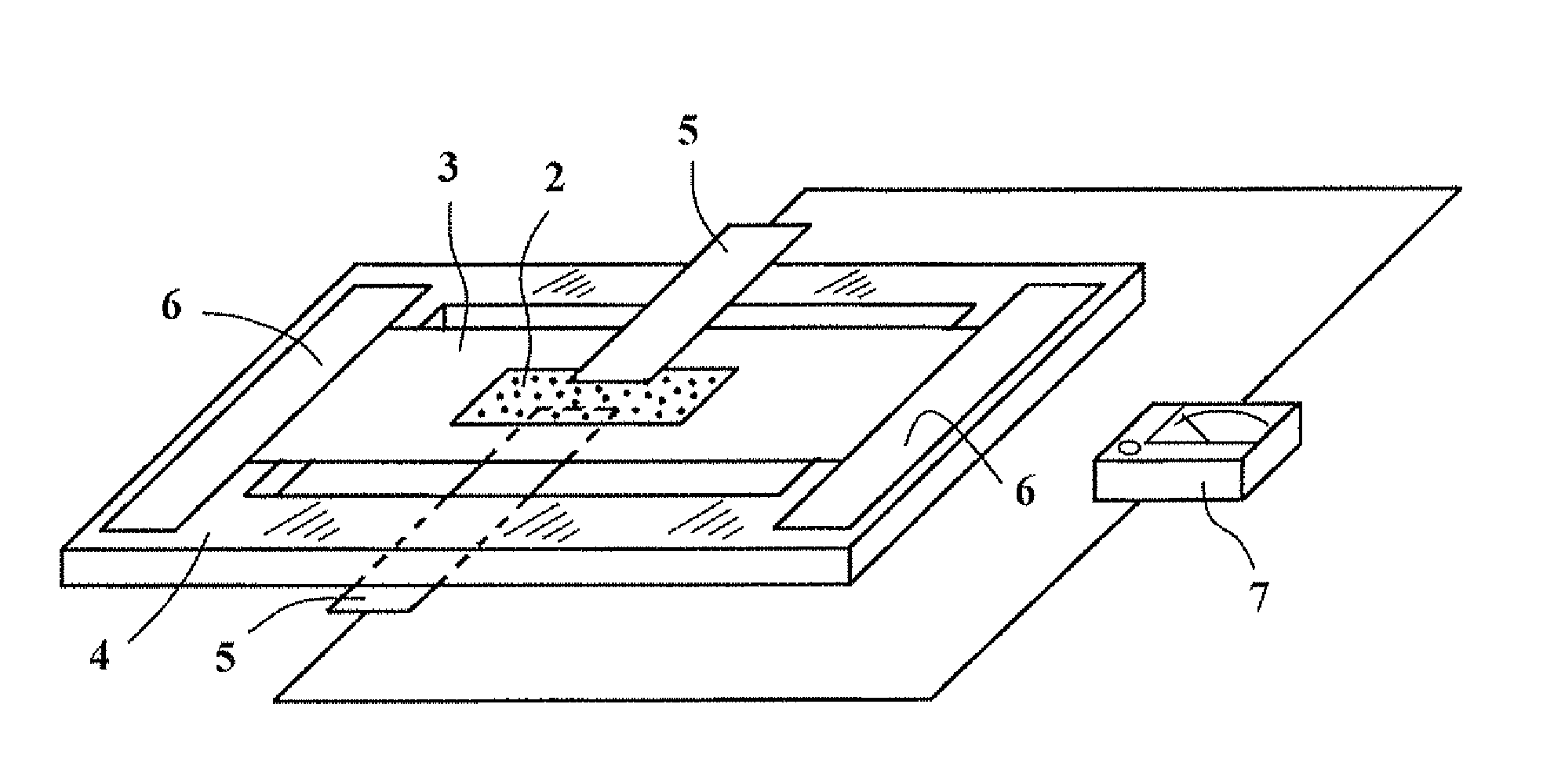

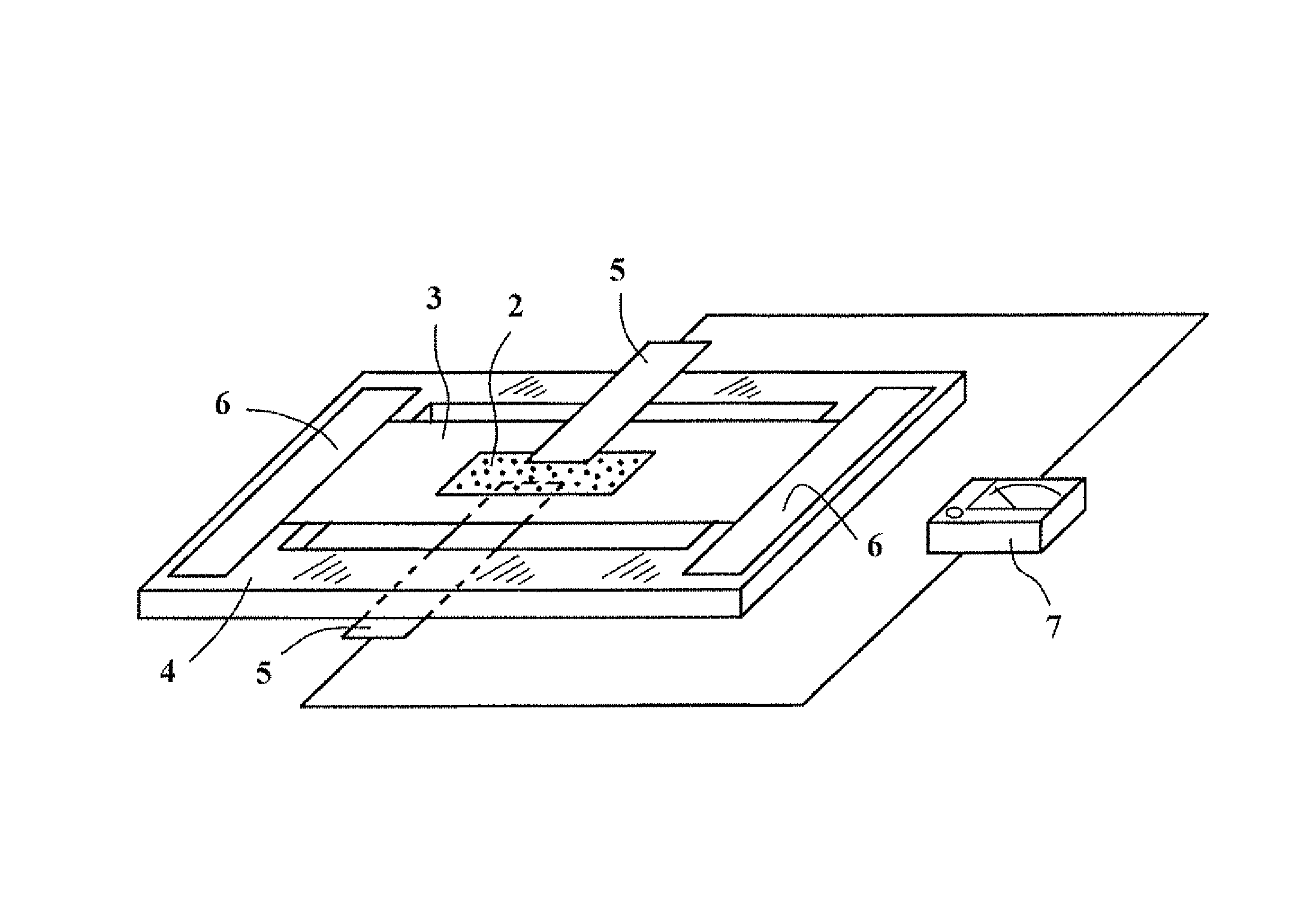

Dielectric material for polymeric actuator, and polymeric actuator using the same

InactiveUS20110018400A1High dielectric constantGuaranteed uptimePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionElectric fieldHigh dielectric permittivity

It is intended to provide a dielectric material for polymeric actuator, which has a high dielectric constant, low Young's modulus and excellent operation performance, which can be simply formed, and which has high production efficiency. It is also intended to provide a polymeric actuator which comprises the dielectric material and has excellent operation performance.The dielectric material for a polymeric actuator comprised of a moveable part of the polymeric actuator driven by an electric field comprising;a block copolymer (A) having a microphase-separated structure including a polymer block (B1) and a polymer block (B2) both of which are immiscible with each other,wherein a main compositional unit in both of the polymer block (B1) and the polymer block (B2) is a (meth)acrylic ester unit, the polymer block (B1) has an alpha-dispersion temperature of 70° C. or more, and the polymer block (B2) has an alpha-dispersion temperature of 25° C. or less. The polymeric actuator comprises the dielectric material provided between electrodes.

Owner:KURARAY CO LTD +1

Thermoplastic Resin Composition For Masterbatches, Method Of Producing Molding Material Thereof, And Thermoplastic Resin Composition Using Them And Method Of Production Thereof

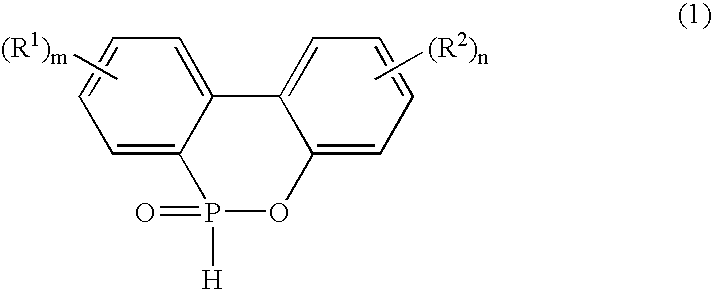

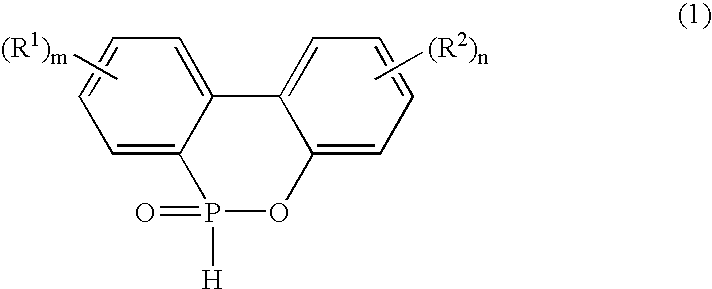

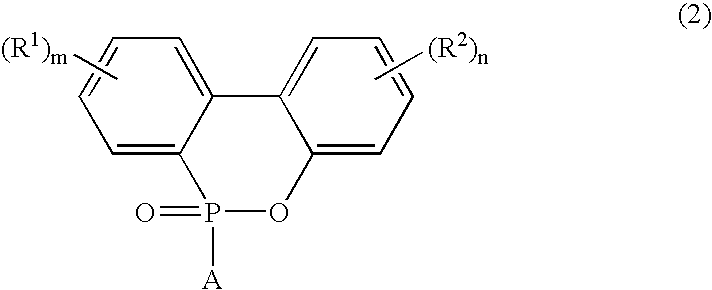

InactiveUS20070194479A1High in phosphorusEasily and uniformly mixedHalogenOrganophosphorous compounds

The present invention related to a thermoplastic resin composition for masterbatches, comprising an organophosphorus compound represented by General Formula (1): wherein R1 and R2 each represent an organic group or a halogen atom, and m and n each represent an integer of 0 to 4, and when m or n is an integer of 2 to 4, R1 and R2 may be the same or different, and a thermoplastic resin, wherein the thermoplastic resin composition for masterbatches contains a phosphorus content of 5000 ppm or more. The thermoplastic resin composition for masterbatches can easily be molded even when it has high phosphorus content and thus flame retardancy.

Owner:TOYO TOYOBO CO LTD

Aluminum plated steel sheet having excellent corrosion resistance with respect to alcohol or mixed gasoline of same and appearance and method of production of same

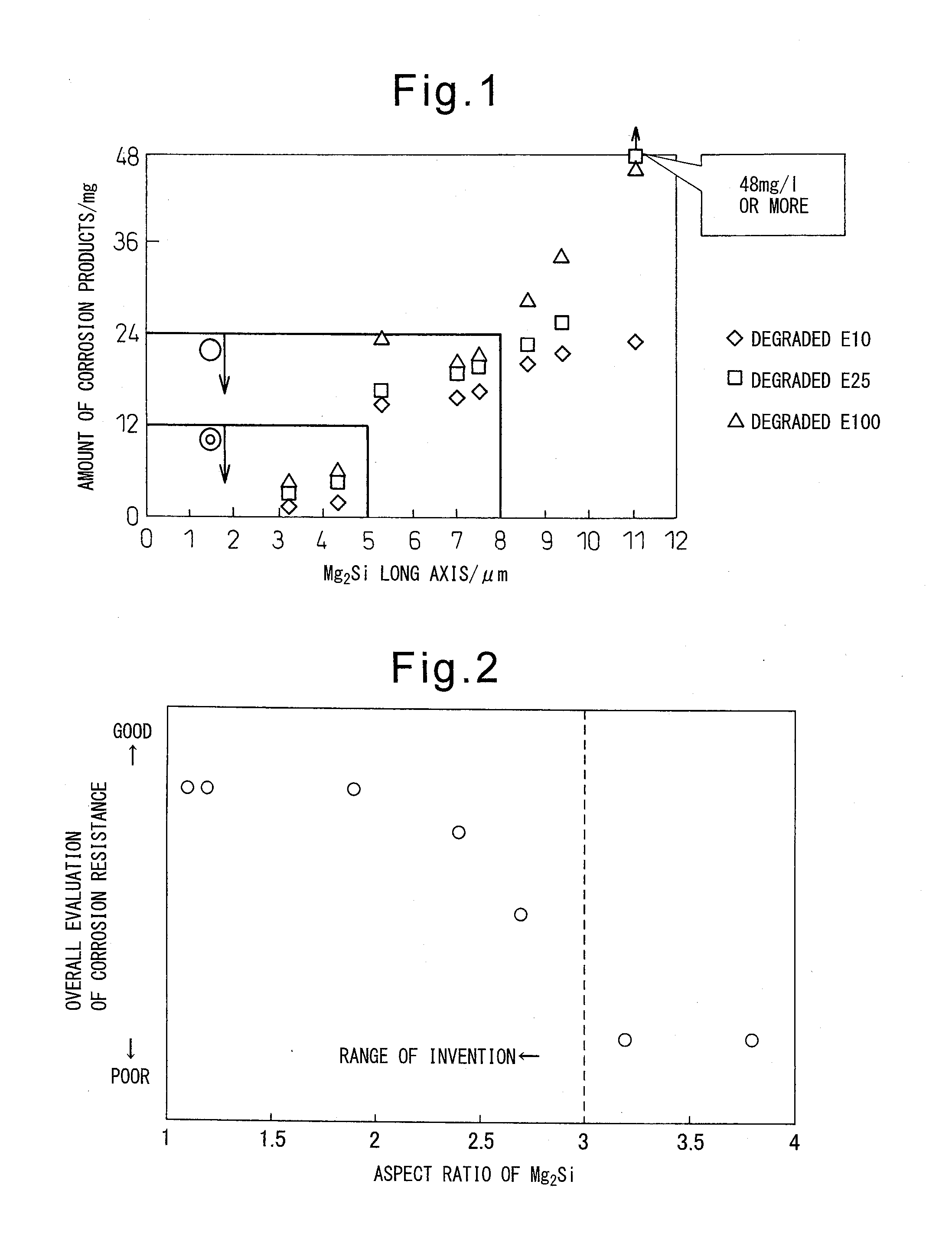

ActiveUS20140205857A1Excellent appearanceHigh flexibilityHot-dipping/immersion processesPretreated surfacesAspect ratioCorrosion

The present invention relates to aluminum plated steel sheet which does not require coating after plating and is high in production flexibility enabling application of conventional production processes as they are or exhibits excellent corrosion resistance to flex fuels and further is excellent in appearance and to fuel tanks characterized by being produced using the steel sheet.The means for solving this is characterized by defining the Si, Mg, Ca, and Ti ingredients in the aluminum plating layer and controlling the cooling method after hot dip aluminum coating so as to make Mg2Si particles with a long axis of 10 μm or less and an aspect ratio of 1 to 3 finely disperse in the plating layer. Due to the Mg2Si particles, it is possible to give an excellent corrosion resistance to flex fuels and suppress the deterioration in appearance due to MgO.

Owner:NIPPON STEEL CORP

Thermoplastic resin composition having excellent chemical resistance and easy vacuum formability

InactiveUS20040054077A1Good physical propertiesGood vacuum formabilityDomestic articlesCyanide compoundEmulsion polymerization

The resin composition according to the present invention comprises (A) a graft polymer prepared by grafting in emulsion polymerization 100 parts by weight of monomer mixture comprising 20-30% by weight of vinyl cyanide compound and 70-80% by weight of vinyl aromatic compound to 20-60 parts by weight of diene rubber, (B) a graft polymer prepared by grafting in emulsion polymerization 100 parts by weight of monomer mixture comprising 20-30% by weight of vinyl cyanide compound and 70-80% by weight of vinyl aromatic compound to 20-60 parts by weight of acrylic rubber, (C) a linear copolymer prepared by polymerizing 40-50% by weight of vinyl cyanide compound and 50-60% by weight of vinyl aromatic compound, and (D) a branched copolymer prepared by 30-35% by weight of vinyl cyanide compound and 65-70% by weight of vinyl aromatic compound.

Owner:CHEIL IND INC

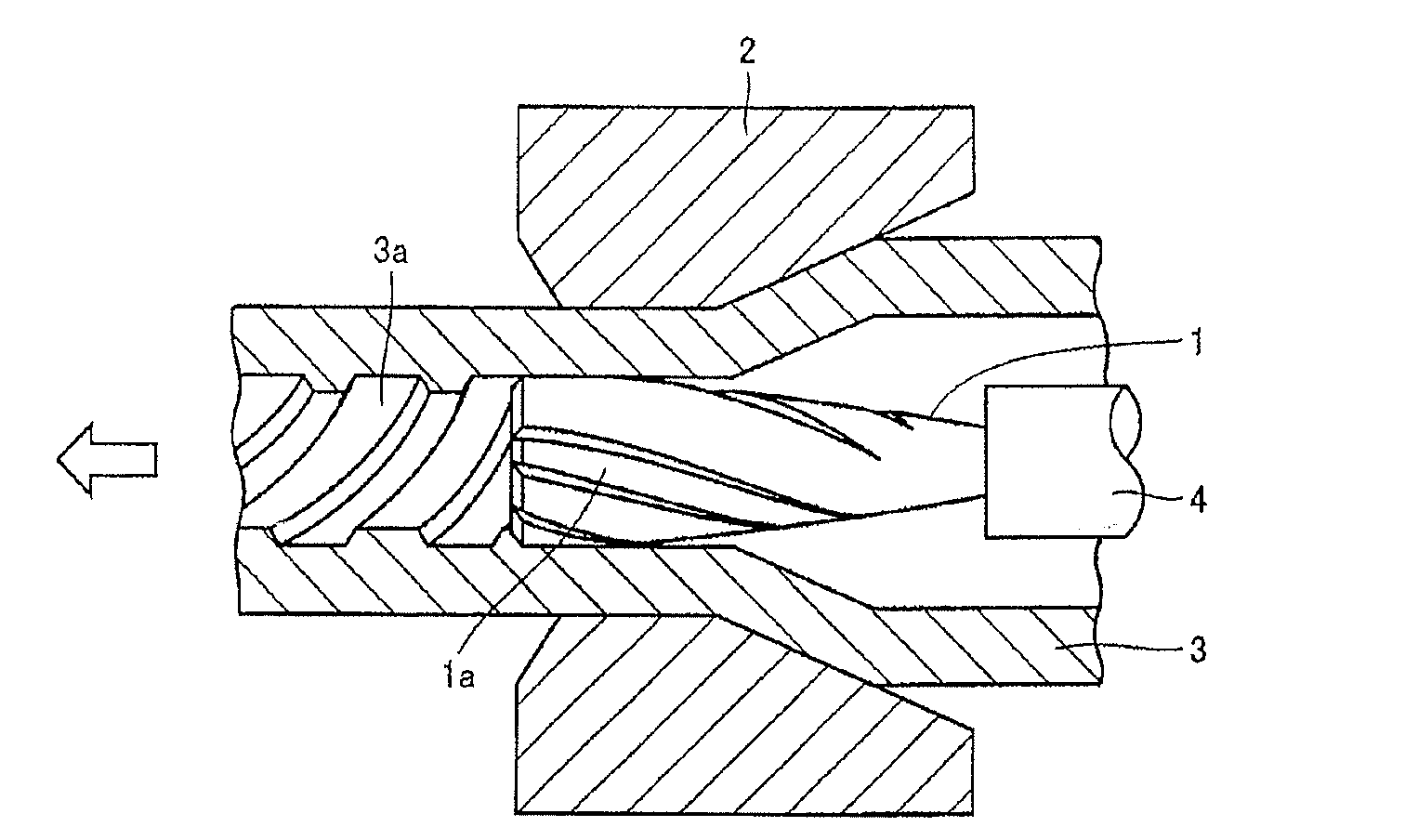

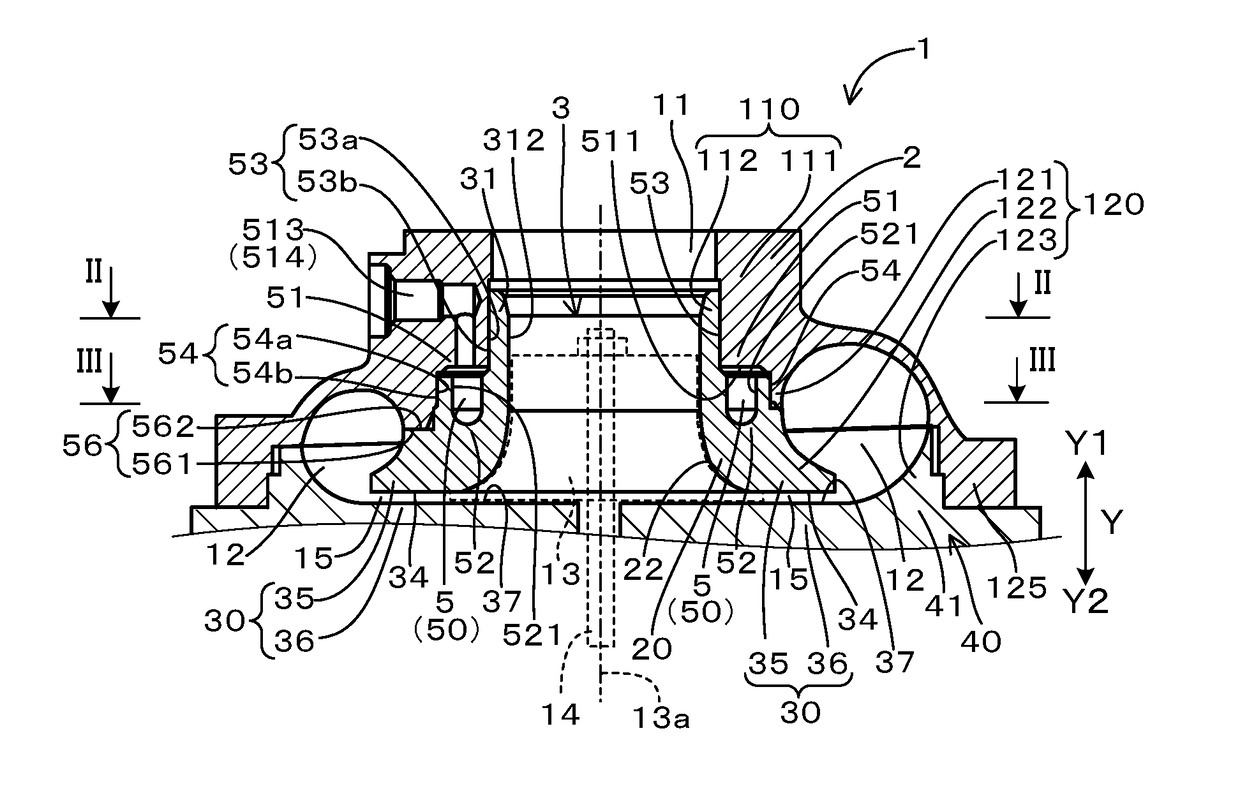

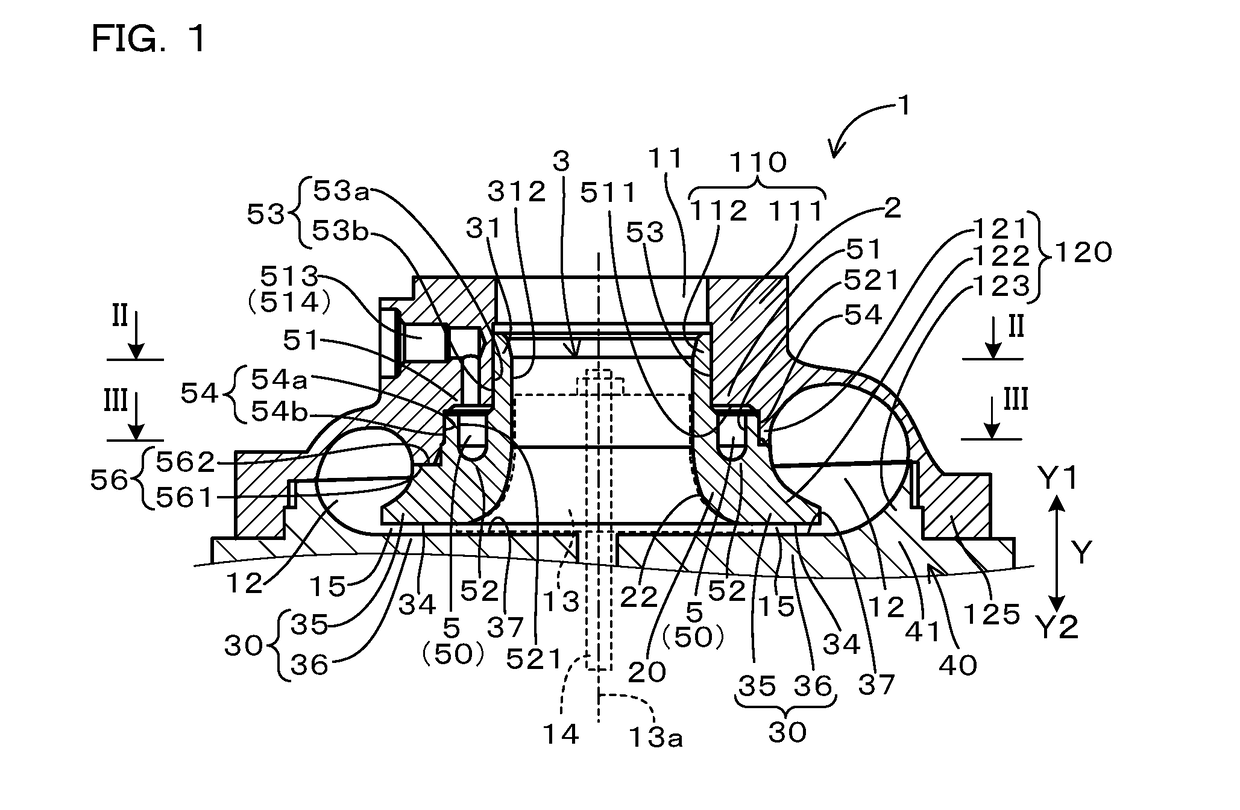

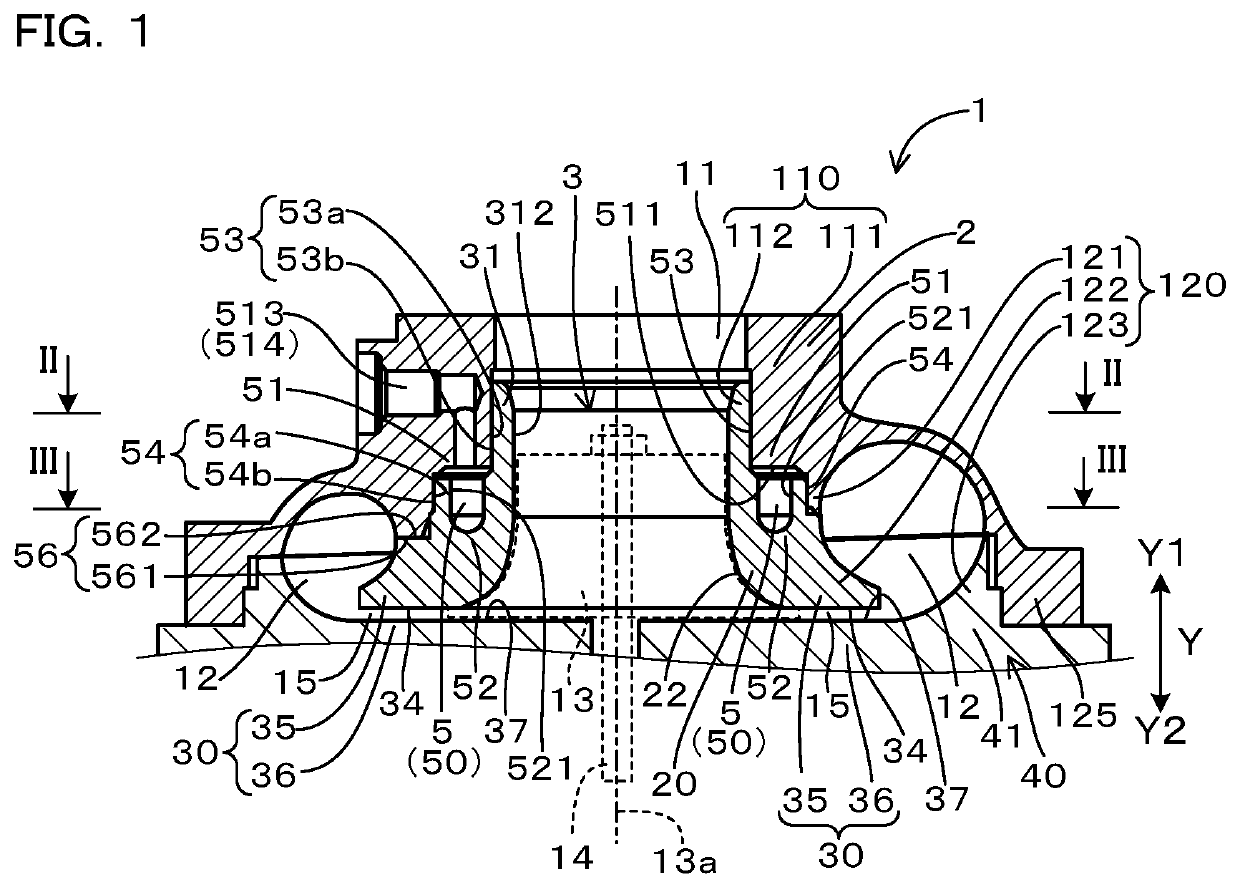

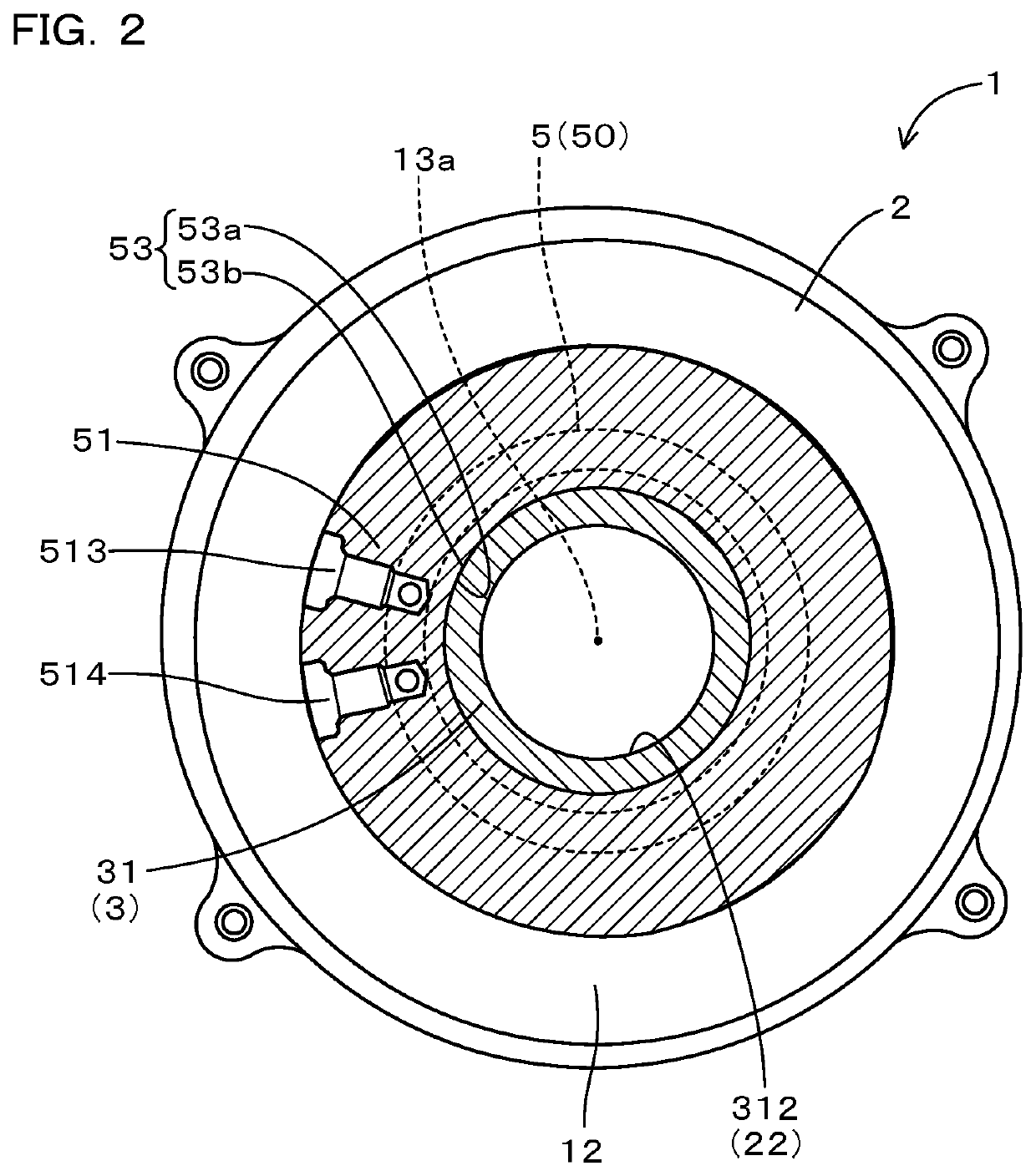

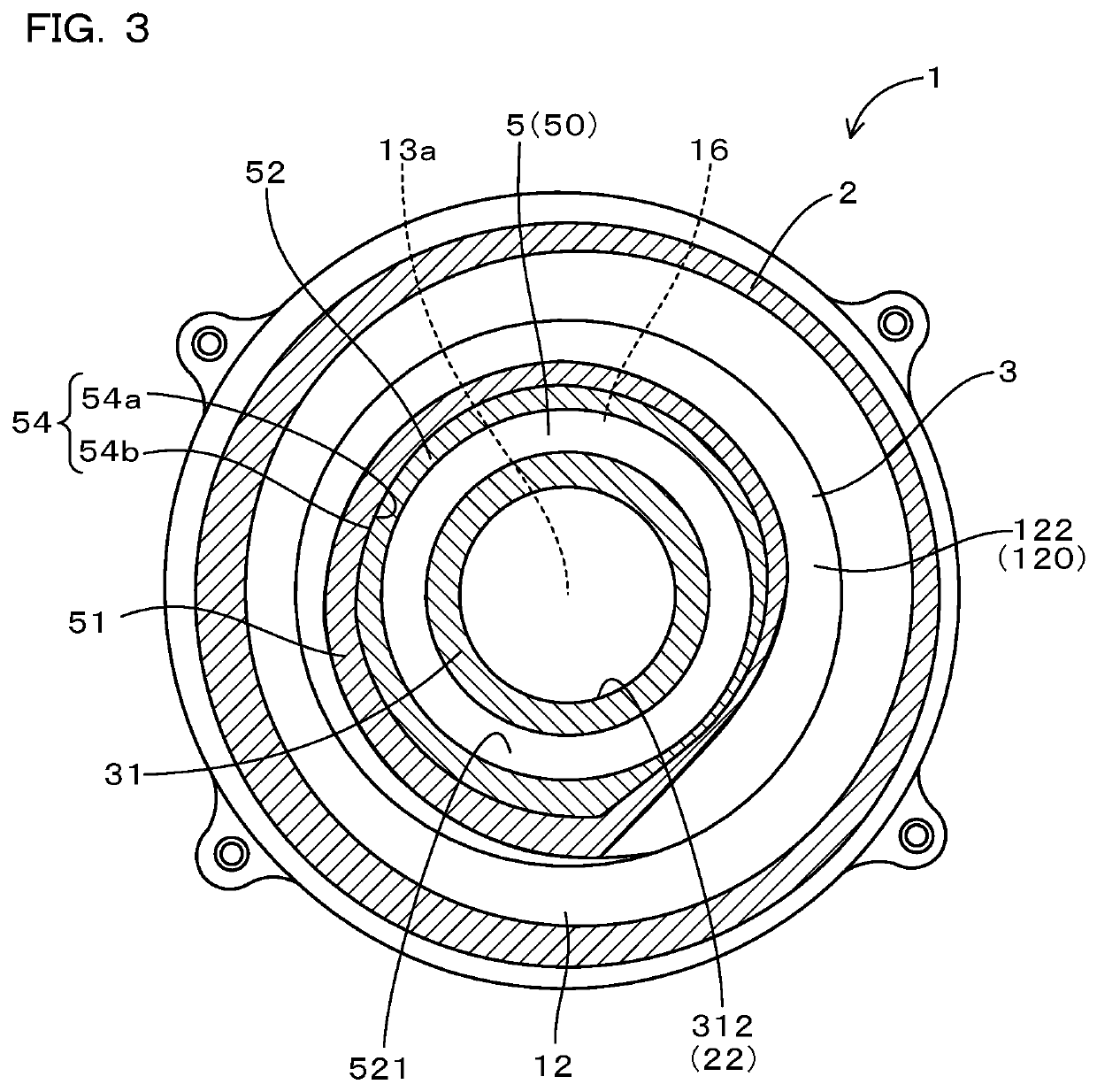

Housing for turbocharger and method for manufacturing the same

ActiveUS20180313361A1Reduce the number of partsSatisfactory assembly workabilityPump componentsEngine fuctionsTurbochargerDie casting

A housing for a turbocharger, which makes it possible to prevent sticking of deposit and attain satisfactory assembling workability and easy moldability by die casting. The housing is dividably composed of a scroll piece and a shroud piece, including an annular refrigerant flow path defined by a first flow path formation part of the scroll piece and a second flow path formation part of the shroud piece. The first and second flow path formation parts are fitted with each other at inner and outer circumferential seal parts for sealing the refrigerant flow path on inner and outer circumferential sides thereof. The inner circumferential seal part is formed by press-fitting a first press-fitting portion of the shroud piece into a first press-fitted portion of the scroll piece. The outer circumferential seal part is formed by press-fitting a second press-fitting portion of the shroud piece into a second press-fitted portion of the scroll piece.

Owner:OTICS CORP

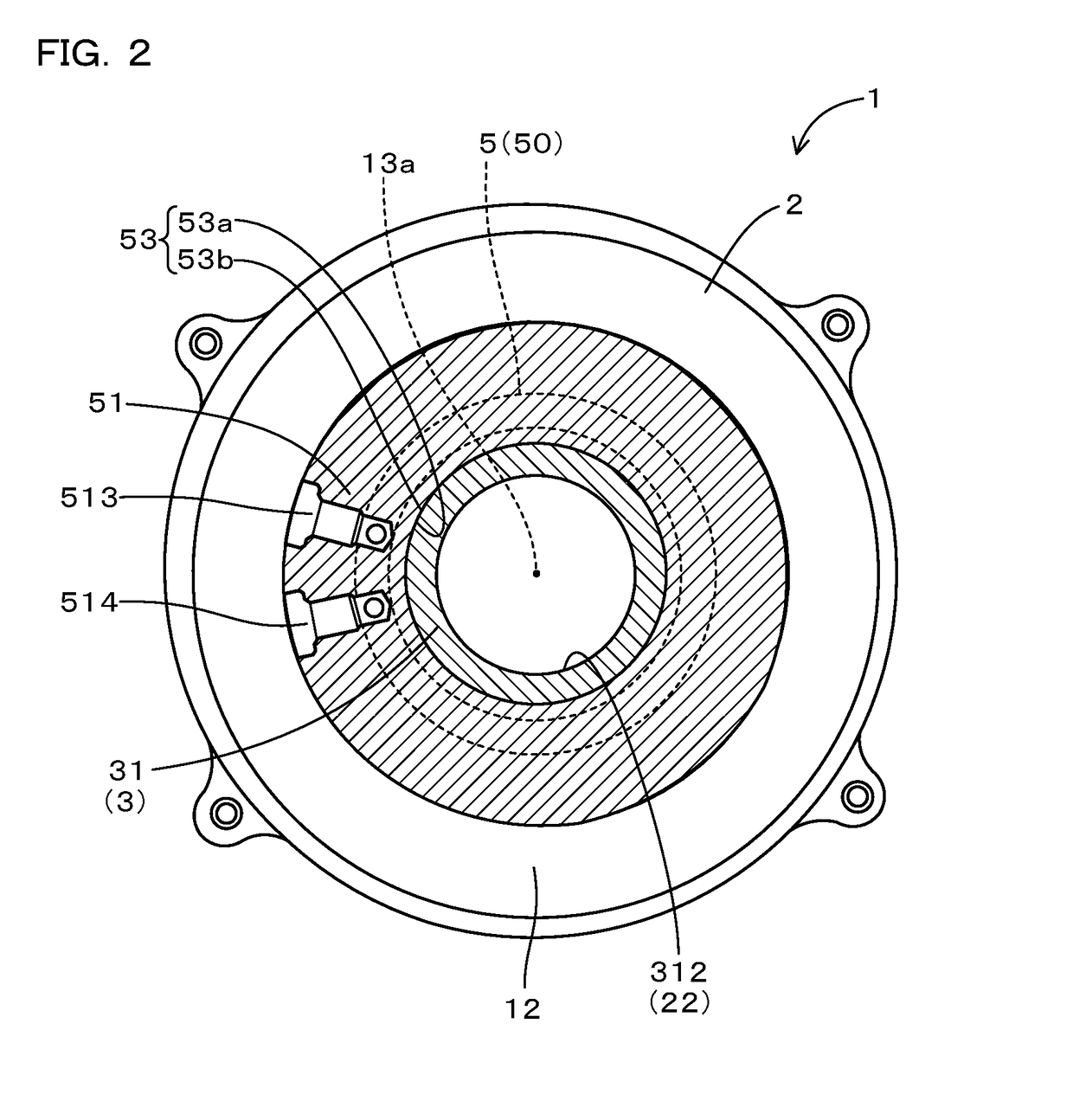

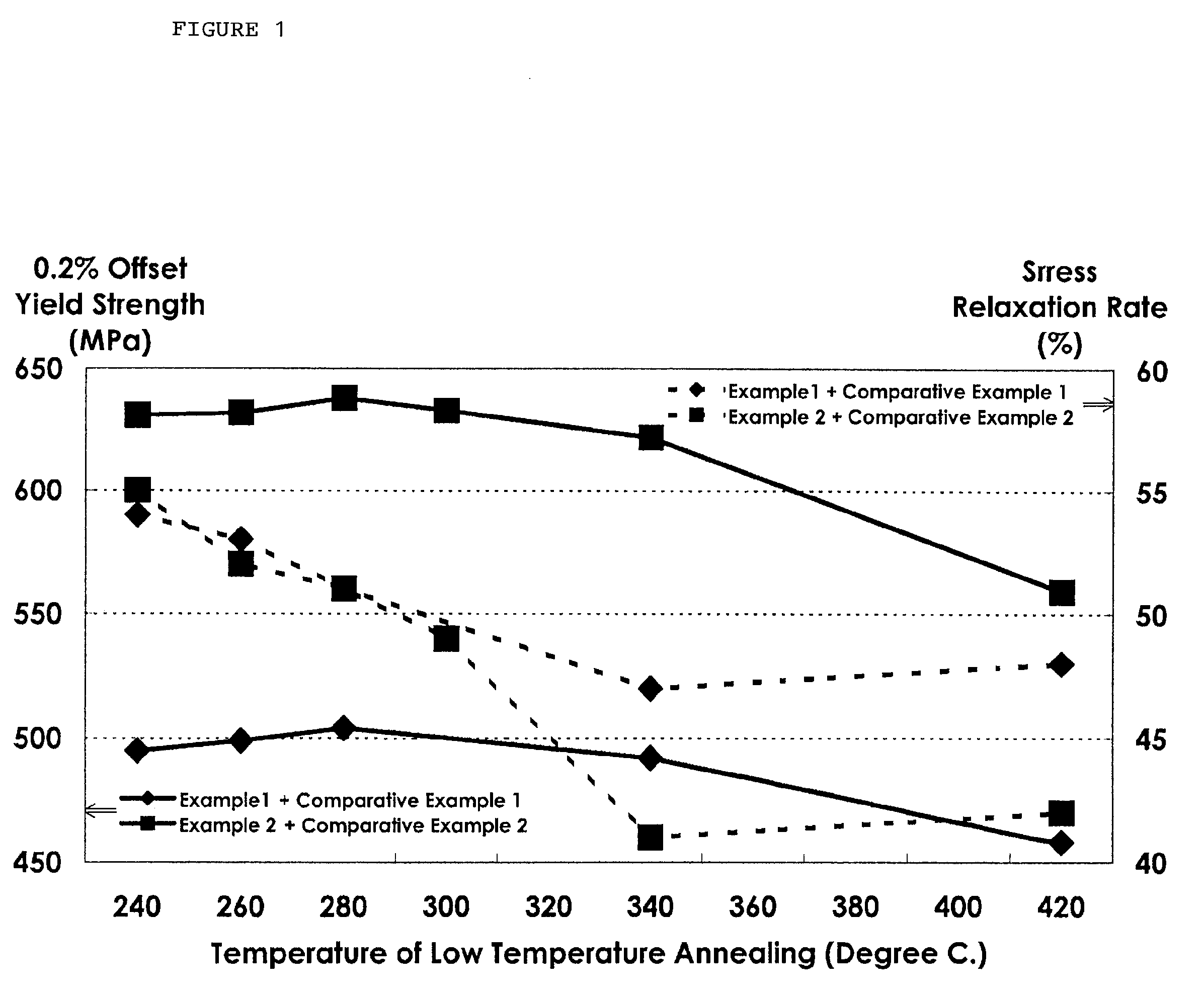

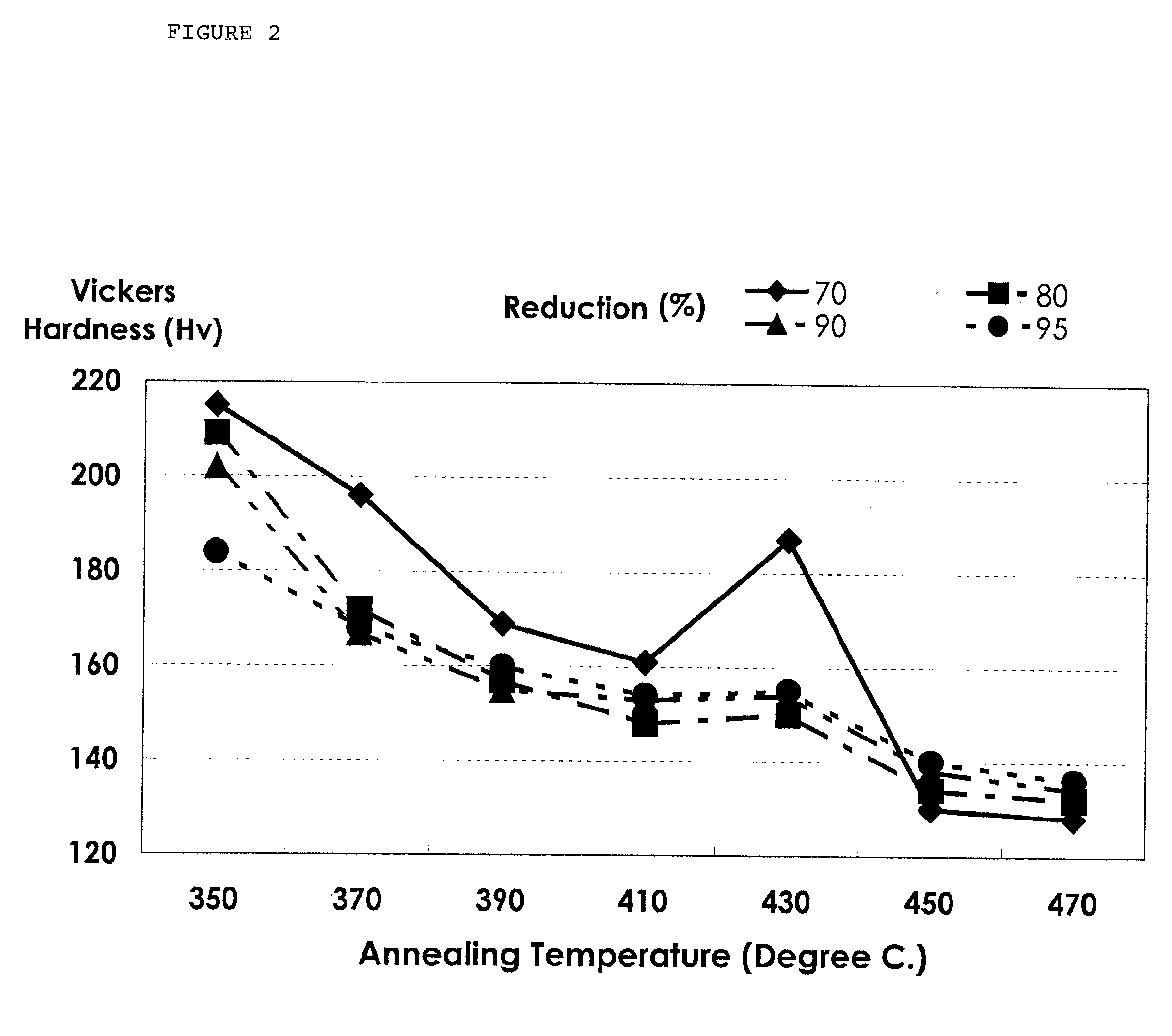

Strengthened Alpha Brass and Method for Manufacturing the Same

InactiveUS20090120544A1Less deviationEasy to applyMetal rolling arrangementsGranularityStress relaxation

An object of the present invention is to provide a strengthened alpha brass having a good balance between high offset yield strength and formability without deteriorated stress relaxation resistance in comparison with conventional brass and a manufacturing method of the strengthened alpha brass. In order to achieve this object, a strengthened alpha brass having a composition of 63 wt % to 75 wt % copper, incidental impurities and the balance zinc; the strengthened alpha brass which is obtained by using a starting plate material subjected to a re-crystallization annealing to have a grain size from 1-micron meter to 2-micron meter followed by cold rolling in 5% to 40% reduction, then the plate material is low temperature annealed at a temperature equal to or higher than the temperature at which a 0.2% offset yield strength exhibits a maximum value to adjust the 0.2% offset yield strength ([Sigma]0.2: MPa) to be equal to or higher than 90% of its maximum value is adopted. The strengthened alpha brass has a 0.2% offset yield strength of 450 MPa to 750 MPa and [minimum bend radius (MBR)] / [plate thickness (t)] and [0.2% offset yield strength] satisfy the following formulaMBR / t≦0.0125×σ0.2−6.7 (σ0.2: 0.2% offset yield strength), and [Erichsen value (Er: mm)] and [0.2% offset yield strength] preferably satisfy the following formula.Er≧−0.011×σ0.2+13.7 (σ0.2: 0.2% offset yield strength)

Owner:MITSUI MINING & SMELTING CO LTD

Functional cornstalk board and preparation method thereof

InactiveUS7838578B2FormabilityImprove mechanical propertiesSynthetic resin layered productsWood treatment detailsSilicateHeat press

Owner:HONG HOOK +1

Oil preparation agent in use for spinning in urethane elastic fiber

The invention discloses a polyurethane fibre spinning oil. Its composition includes (by wt%) 5-80% of mineral oil, 10-75% of silicone oil, 0.5%-30% of epoxyethane and epoxypropane copolyether, 0.5%-50% of polyether silicone oil, 0.5-15% of antistatic agent and 0.1-10% of anti-sticking property improving agent.

Owner:CHINA PETROCHEMICAL CORP +1

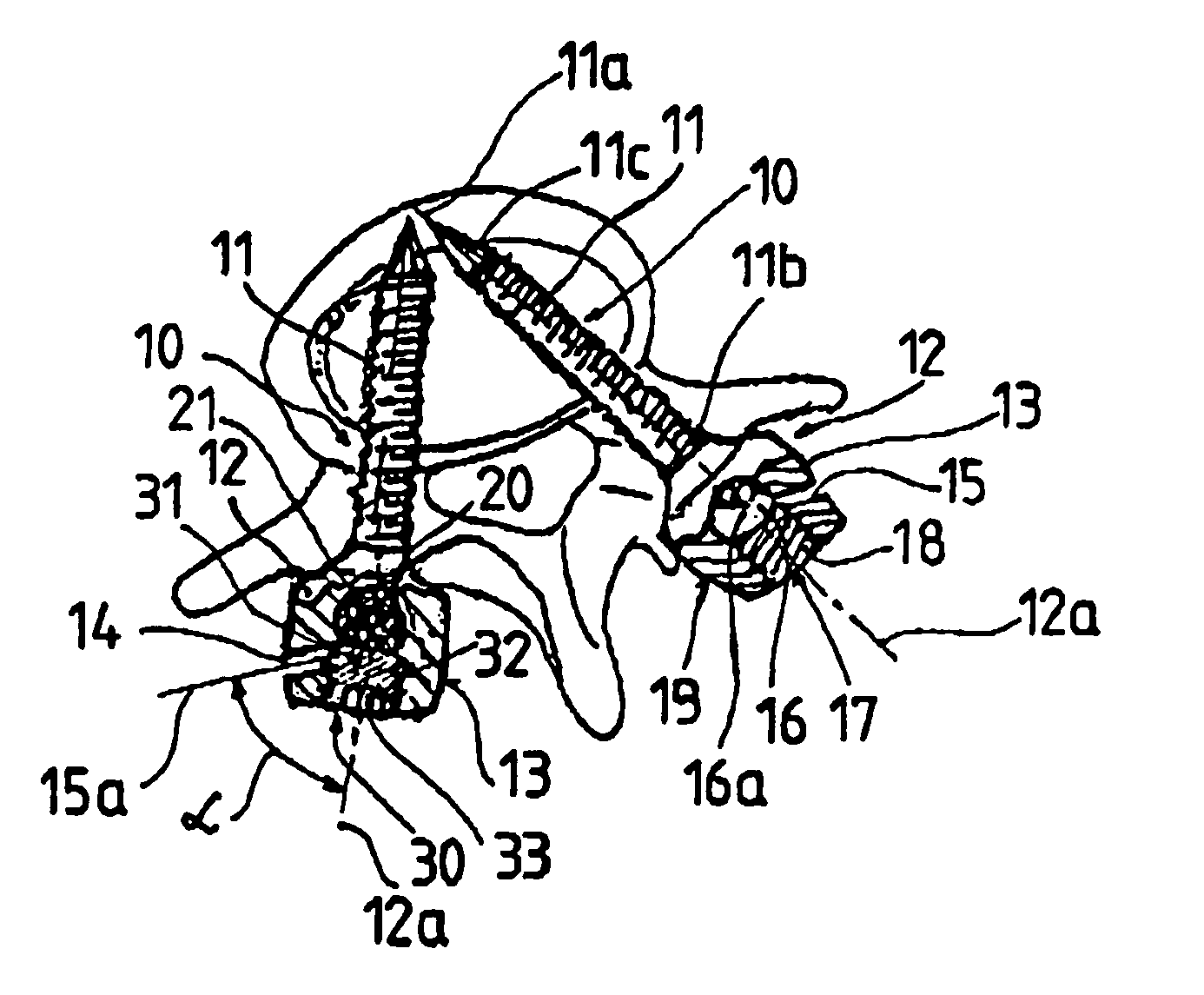

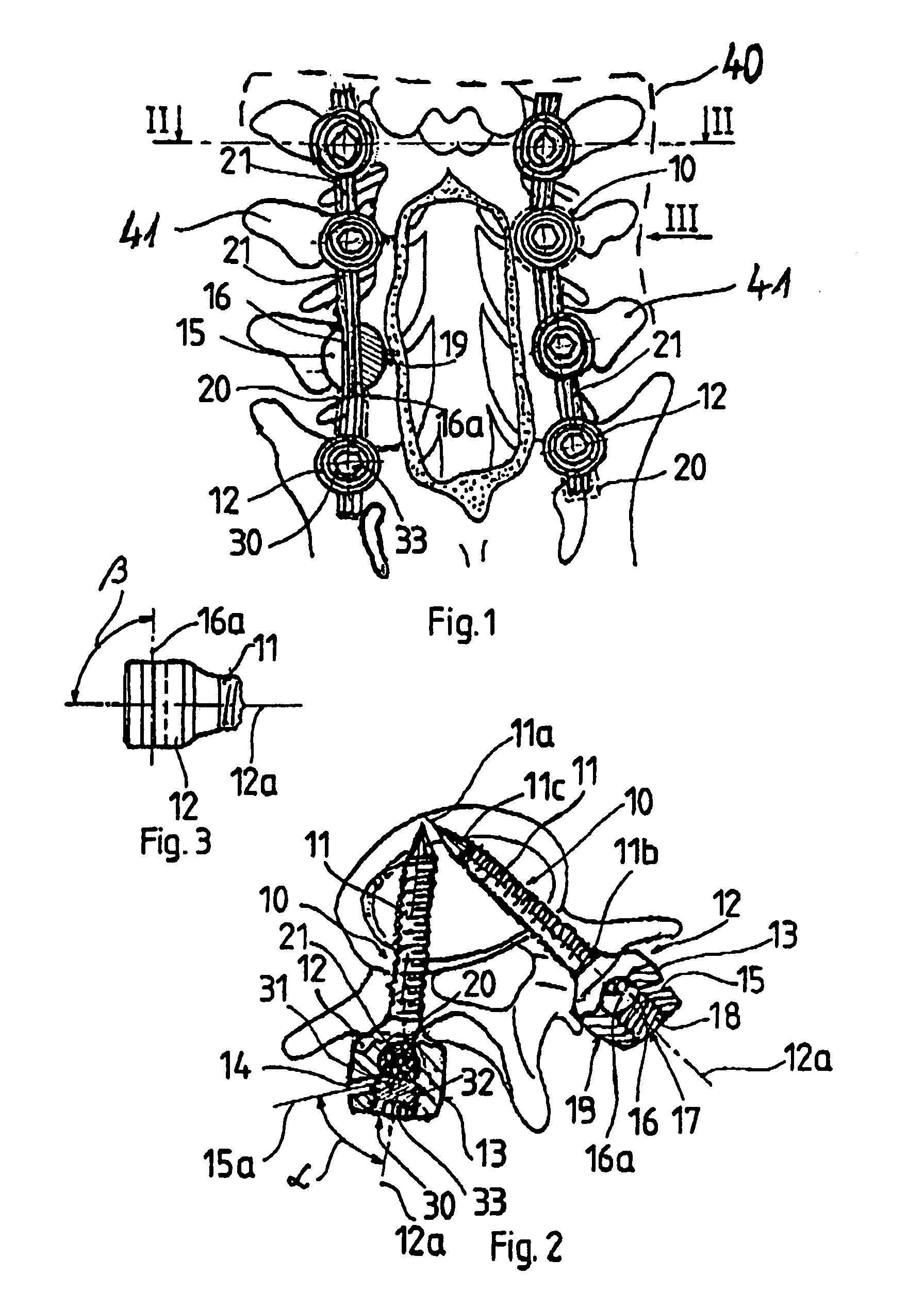

Set of surgical instruments for the fixation of vertebrae

InactiveUS7137983B2Reduce operational burdenPromote recoveryInternal osteosythesisJoint implantsEngineeringSurgical department

A set of surgical instruments for the fusion of vertebrae contains supporting elements that have a threaded stem that can be screwed into the vertebra and a head part positioned at the outer end of the threaded stem. A connection unit is fitted between the supporting elements and a fixating device serving to brace together the supporting elements and the connection unit, and the head part of the supporting element has an accepting opening suitable for joining the connecting unit. The accepting opening is formed by the unification of an introductory cleft running from the outer surface of the head part and penetrating into the head part, and a lead-through seat that forms the continuation of the introductory cleft, is worked into the head part and bells out from there. The head part has a fusion opening that has a first connection piece and ends in the lead-through seat, and the fixating device has a tightening body that is positioned in the fusion opening so that it may move. A second connecting piece operates in unison with the first connecting piece, and the connecting unit is assembled from the group of the elemental connection strands penetrating the introductory cleft of the head part.

Owner:SANATMETAL

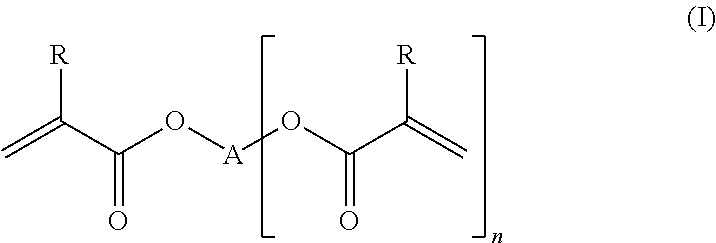

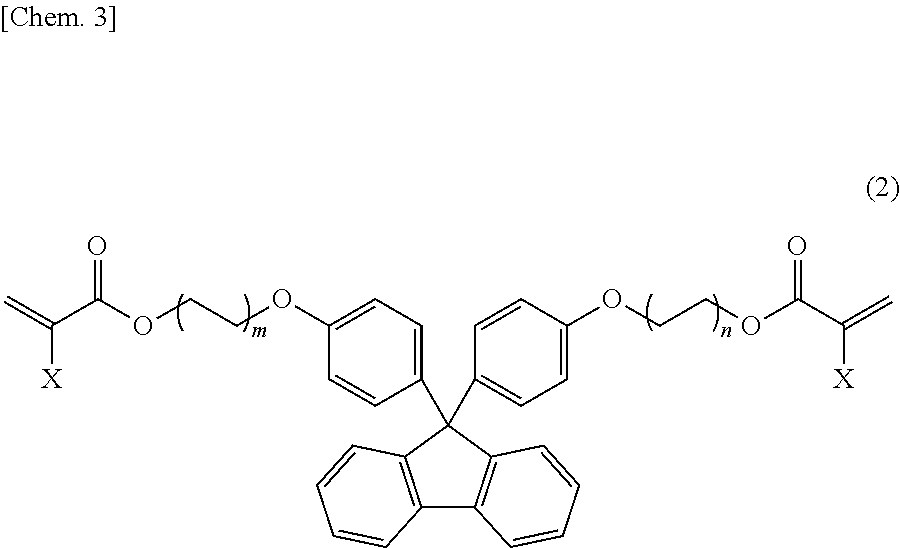

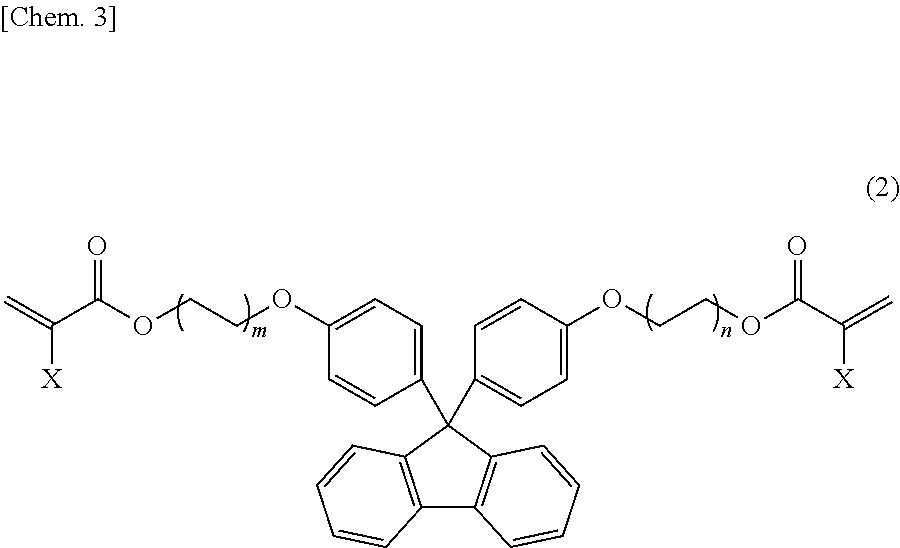

Urethane (METH)acrylate resin, curable resin composition, cured product thereof, and plastic lens

ActiveUS20180030198A1High refractive indexReduce resin viscosityPolyurea/polyurethane coatingsOptical elementsEthylene oxideRefractive index

A urethane (meth)acrylate resin wherein the viscosity of the resin is low, the formability into a sheet-formed product, in particular, an optical sheet provided with fine uneven shapes on the surface is excellent, and a high refractive index can be realized, a curable resin composition including the urethane (meth)acrylate resin as an indispensable component, a cured product thereof, and a plastic lens are provided. A urethane (meth)acrylate resin produced by reacting aromatic diisocyanate compound (a), bisphenol-ethylene oxide adduct diol (b) having at least three aromatic ring or alicyclic structures in the molecule, and hydroxy-containing (meth)acrylate compound (c), which are indispensable raw material components, a curable resin composition containing the urethane (meth)acrylate resin as a primary component, and a cured product thereof.

Owner:DAINIPPON INK & CHEM INC

Paper-based composite material

InactiveUS20120015137A1Good mouldabilityGood rigiditySurface covering paperLiquid surface applicatorsAdhesiveSurface layer

Owner:PAPER ART PROD

Polypropylene material with high strength and good moldability

The present invention relates to a polypropylene material with high strength and good moldability. The polypropylene material is characterized by comprising the following components in part by weight: 56.2-60 parts of polypropylene, 30-40 parts of talcum powder, 22-26 parts of glass fibers, 2-4 parts of a flexibilizer, 0.2-0.4 part of a coupling agent, 0.2-0.5 part of a lubricant, 0.1-1.0 part of a heat stabilizer DSTP, 0.1-1.0 part of a heat stabilizer 3114 and 0.1-0.5 part of a heat stabilizer 618. Compared with the prior art, the polypropylene material according to the present invention has higher mechanical strength and besides, is easy to mold, the size stability is substantially improved, and the combination property is excellent.

Owner:SUZHOU XISHIDA PLASTIC CO LTD

Production method of internally ribbed steel tube

ActiveUS8387251B2Low production costAvoid it happening againBoiler water tubesWater-tube boilersEngineeringHigh pressure

There is provided a production method of an internally ribbed steel tube, capable of forming spiral ribs stably so as to reduce troubles at the time of cold drawing for forming the spiral ribs of the steel tube. In this production method, the spiral ribs can be formed stably so as to reduce troubles at the time of cold drawing for forming the spiral ribs by straightening bends of a blank tube before the cold drawing for forming the spiral ribs, by optimizing the direction of the spiral rib formation after the bend straightening, and by correcting the drawing schedule depending on the blank tube. The obtained internally ribbed steel tube is well applicable to an increased capacity and a higher temperature / higher pressure operation of a boiler because the steel tube is provided with high formability and excellent quality as a boiler steel tube.

Owner:NIPPON STEEL CORP

Multifibrous multilayer composite material for applications in the automotive sector

ActiveUS20190389175A1ElasticityFlexibilityLamination ancillary operationsSynthetic resin layered productsFiberAdhesive

The present invention concerns a process for preparing a microfibrous multilayer composite material comprising: 1) realizing a non-woven microfibrous semi-finished product made up of microfibres of one or more polymers dispersed in a polyurethane matrix (semi-finished product IE); 2) cutting the semi-finished product lengthwise into two layers; 3) buffing at least one layer on one side (side N) so as to extract the microfibres and form the nap, thereby obtaining a semi-finished raw product; 4) cutting at least one semi-finished raw product lengthwise parallel to the surfaces, producing an non-woven intermediate product, containing the buffed side (side N) and a waste layer (containing the side that has not been buffed—side S); 5) coupling the non-woven intermediate product (on the side opposite side N) to a fabric made of polyethylene terephthalate fibres by means of the application of a thermoplastic polyurethane adhesive that can be cross-linked between the non-woven intermediate product and the fabric; 6) submitting the multilayer composite material to a jet dyeing process. The invention also concerns a multilayer composite material that can be obtained by the process of the invention and the use thereof for covering the internal side of roofs or headliners of vehicles and for covering furnishing elements.

Owner:ALCANTARA

Resol-Type Para-Octylphenol-Formaldehyde Co-condensation Resin and Method for Producing the Same

A resol-type para-octylphenol-formaldehyde co-condensation resin and a method for producing the same are provided, the resol-type para-octylphenol-formaldehyde co-condensation resin having a content of a para-octylphenol monomer of 1 wt. % or less, having a total content of an aliphatic hydrocarbon, a halogenated aliphatic hydrocarbon, an aromatic hydrocarbon, a halogenated aromatic hydrocarbon, and an alcohol having 1 to 8 carbon atoms of 1 wt. % or less, the aliphatic hydrocarbon, the halogenated aliphatic hydrocarbon, the aromatic hydrocarbon, the halogenated aromatic hydrocarbon, and the alcohol having a boiling point of 60° C. or more, having a softening point of 70 to 105° C., and having an acid value of 20 to 28 KOHmg / g. The resol-type para-octylphenol-formaldehyde co-condensation resin can be used as a resin cross-linking agent for a rubber.

Owner:TAOKA CHEM COMPANY

Housing for turbocharger and method for manufacturing the same

ActiveUS10982687B2Degrades assembly workabilityHigh in shapePump componentsEngine fuctionsTurbochargerDie casting

A housing for a turbocharger that makes it possible to prevent sticking of deposit and attain satisfactory assembling workability and easy moldability by die casting. The housing dividably includes a scroll piece and a shroud piece, including an annular refrigerant flow path defined by a first flow-path formation part of the scroll piece and a second flow-path formation part of the shroud piece. The first and second flow path formation parts are fitted with each other at inner and outer circumferential seal parts for sealing the refrigerant flow path on inner and outer circumferential sides thereof. The inner circumferential seal part is formed by press-fitting a first press-fitting portion of the shroud piece into a first press-fitted portion of the scroll piece. The outer circumferential seal part is formed by press-fitting a second press-fitting portion of the shroud piece into a second press-fitted portion of the scroll piece.

Owner:OTICS CORP

Scratch-resistant-coated polycarbonates with high transparency, process for their production, and their use

ActiveUS9266998B2FormabilityReduce vehicle weightSynthetic resin layered productsPolyurea/polyurethane coatingsNanoparticleReactive diluent

The present invention relates to a process for the coating of polycarbonate substrates, in particular of transparent polycarbonate substrates, by applying a transparent coating composition encompassing at least one radiation-curing binder resin (A) and / or reactive diluent (C), nanoparticles (B), optionally solvent and at least one light stabilizer (L), to a polycarbonate substrate, wherein the coating composition comprises at least one light stabilizer (L) which comprises, per molecule, an average of at least one ethylenically unsaturated group bonded by way of a urethane group.The present invention also relates to the coating compositions used in said process, and to the coated polycarbonate substrates obtainable via the process, and to their use.

Owner:BASF COATINGS GMBH

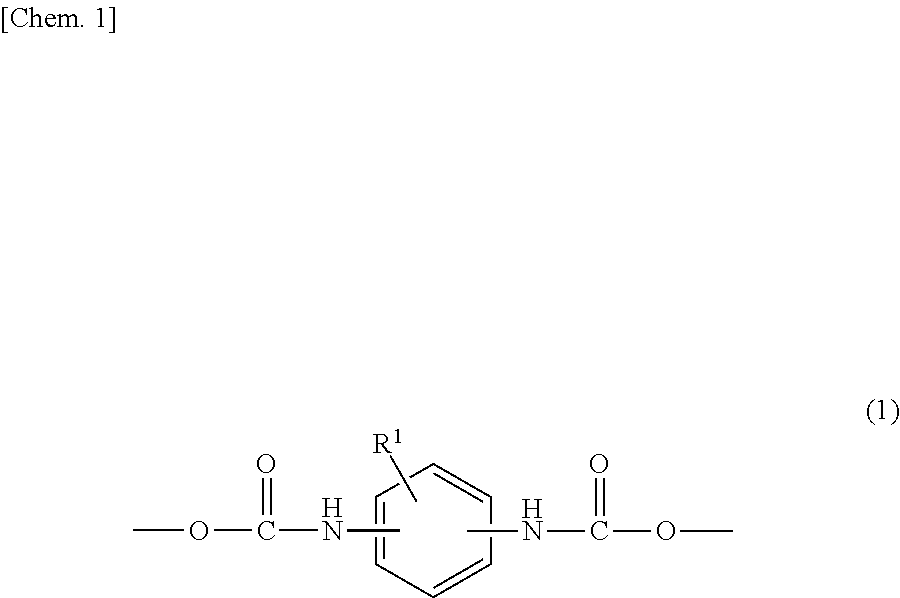

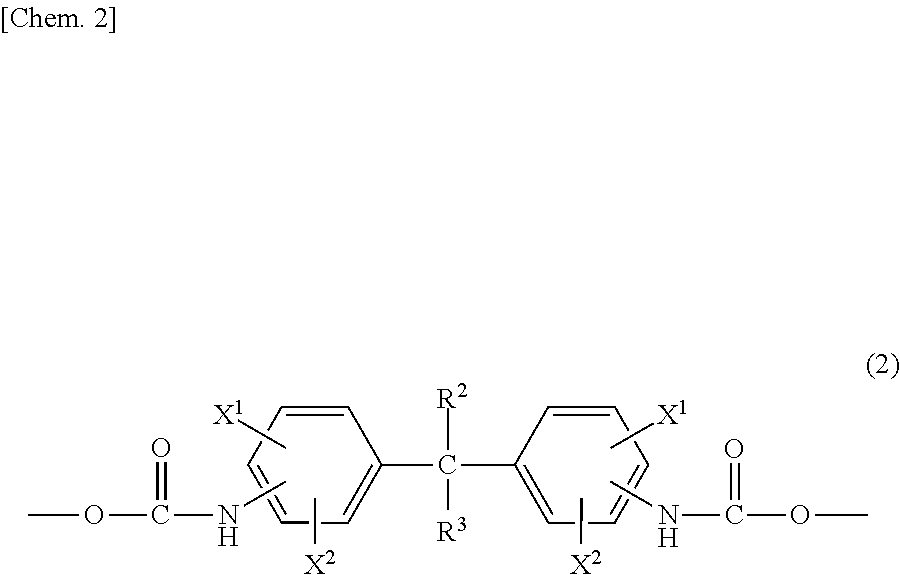

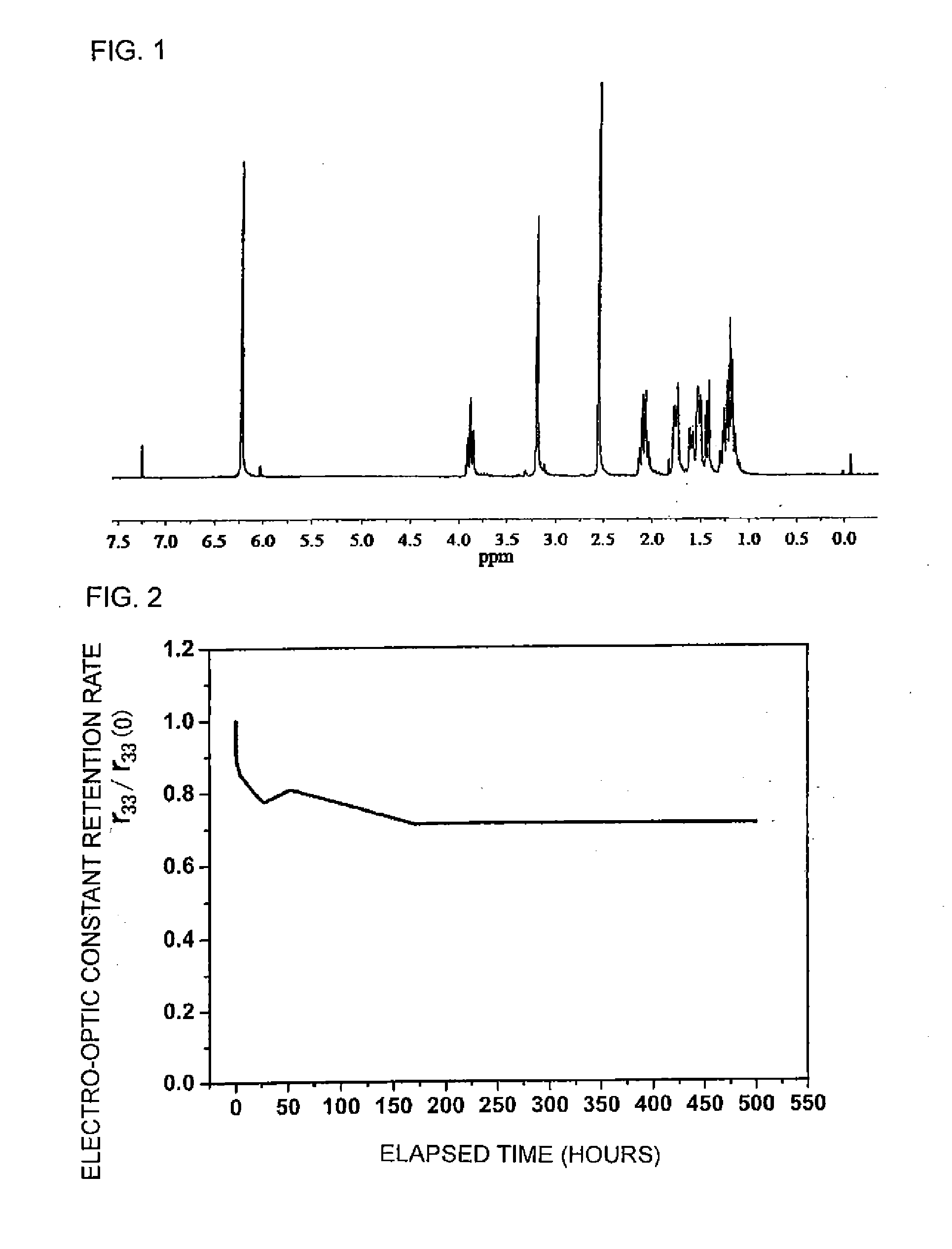

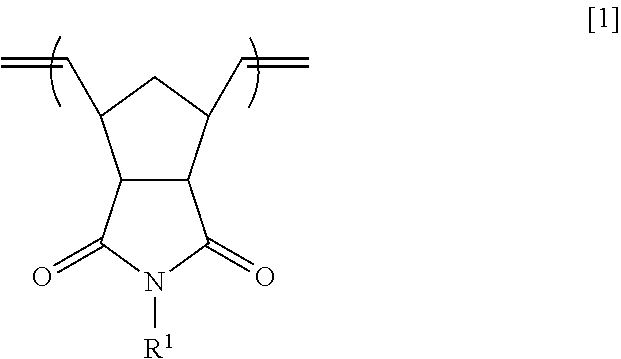

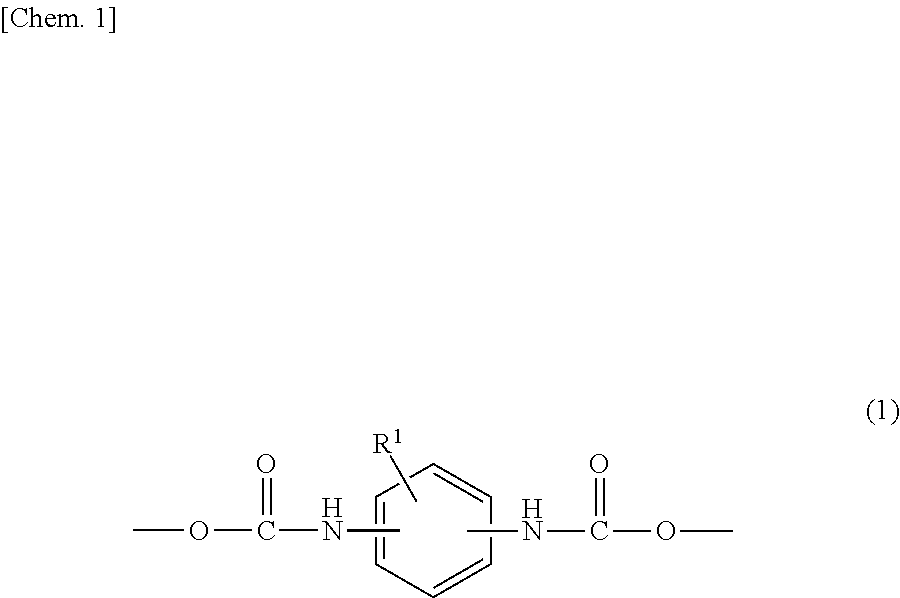

Polymer composition containing organic nonlinear optical compound

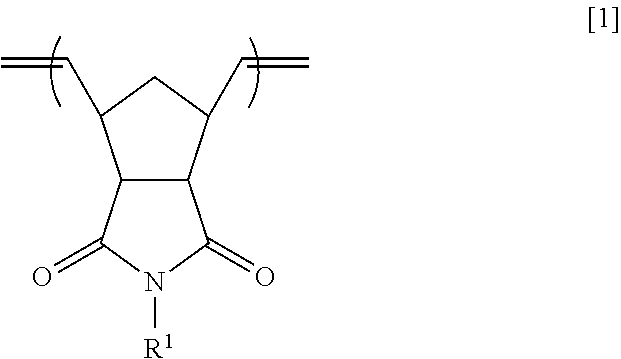

There is provided a polymer matrix that can suppress the orientational relaxation of an organic nonlinear optical compound, and a composition containing this polymer matrix and an organic nonlinear optical compound, and an optical material obtained by using the composition. A composition including: a norbornene imide polymer having a structural unit of Formula [1]; and an organic nonlinear optical compound:(where R1 is a C1-12 alkyl group optionally having a substituent or a C6-10 aryl group optionally having a substituent).

Owner:KYUSHU UNIV +1

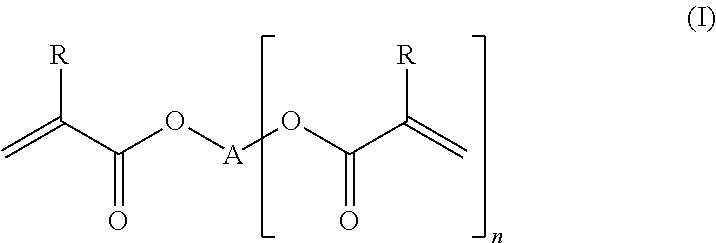

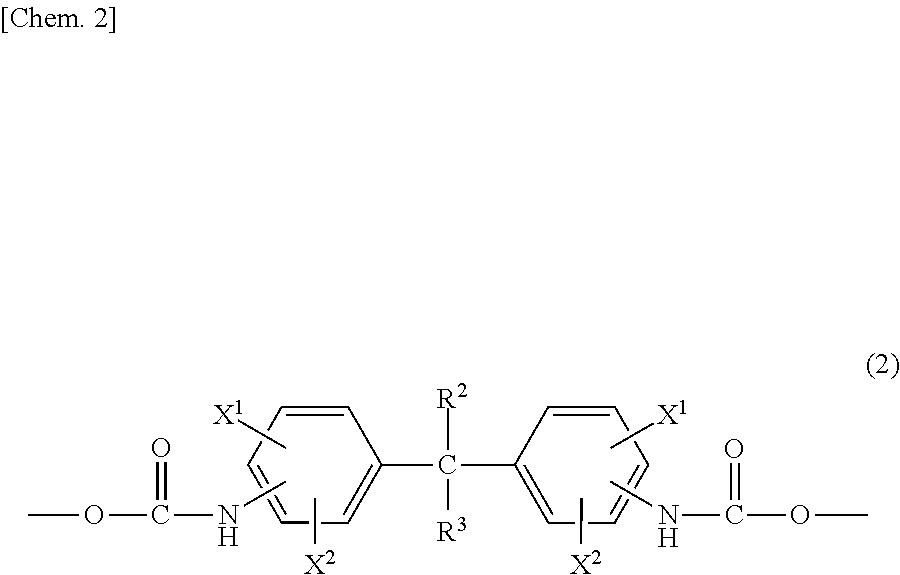

Curable compound

ActiveUS20200079726A1Excellent solvent solubilityExcellent dielectric propertiesOrganic chemistrySolubilityPolymer science

There is provided a curable compound having good solvent solubility and being capable of forming a cured material having super heat resistance. The curable compound according to the present invention is represented by the following formula (1). In the formula (1), R1 and R2 each represent a curable functional group; D1 and D2 each represent a single bond or a linking group; and L represents a divalent group having a repeating unit containing a structure represented by the following formula (I) and a structure represented by the following formula (II) (wherein Ar1 to Ar3 each represent a group made by eliminating two hydrogen atoms from a structural formula of an aromatic ring or a group made by eliminating two hydrogen atoms from a structural formula in which two or more aromatic rings are bound through a single bond or a linking group; X represents —CO—, —S— or —SO2—; each Y represents —S—, —SO2—, —O—, —CO—, —COO— or —CONH—; and n represents an integer of 0 or more):

Owner:DAICEL CHEM IND LTD

Dielectric material for polymeric actuator, and polymeric actuator using the same

InactiveUS8354774B2Improve production efficiencyLow Young 's modulusPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesPolymer scienceActuator

A dielectric material for a polymeric actuator having a moveable part of the polymeric actuator driven by an electric field, the dielectric material containing a block copolymer (A) having a microphase-separated structure including a polymer block (B1) and a polymer block (B2), both of which are immiscible with each other. A main compositional unit in both of the polymer block (B1) and the polymer block (B2) is a (meth)acrylic ester unit, the polymer block (B1) having an alpha-dispersion temperature of 70° C. or more, and the polymer block (B2) having an alpha-dispersion temperature of 25° C. or less. The polymeric actuator provides the dielectric material between electrodes.

Owner:KURARAY CO LTD +1

Urethane (meth)acrylate resin, curable resin composition, cured product thereof, and plastic lens

ActiveUS10640603B2FormabilityHigh refractive indexPolyurea/polyurethane coatingsOptical elementsMethacrylatePolymer science

A urethane (meth)acrylate resin wherein the viscosity of the resin is low, the formability into a sheet-formed product, in particular, an optical sheet provided with fine uneven shapes on the surface is excellent, and a high refractive index can be realized, a curable resin composition including the urethane (meth)acrylate resin as an indispensable component, a cured product thereof, and a plastic lens are provided. A urethane (meth)acrylate resin produced by reacting aromatic diisocyanate compound (a), bisphenol-ethylene oxide adduct diol (b) having at least three aromatic ring or alicyclic structures in the molecule, and hydroxy-containing (meth)acrylate compound (c), which are indispensable raw material components, a curable resin composition containing the urethane (meth)acrylate resin as a primary component, and a cured product thereof.

Owner:DAINIPPON INK & CHEM INC

Manufacturing method of refrigerator interior trim decorative strip

InactiveCN111761777AIncrease profitGood molding stabilityDomestic articlesCoatingsActivated carbonExtreme temperature

The invention discloses a manufacturing method of a refrigerator interior trim decorative strip. The method comprises the following steps of designing and manufacturing an aluminum mold, carrying outpretreatment inspection and flatness inspection on the surface of the aluminum mold, carrying out high-temperature melting on a plastic raw material, adding activated carbon as an additive, carrying out injection molding, cooling and demolding treatment, coating a nano coating film, and carrying out a deformation test in a cut-off treatment extreme temperature environment. The aluminum mold is adopted for injection molding to manufacture the decoration strip, the utilization rate of the mold can be increased, the molding stability is good, the production efficiency can be effectively improved,activated carbon ultrafine powder is added into the plastic raw material, the decoration effect is achieved, meanwhile, the problem that peculiar smells in the refrigerator are large can be solved, and by coating the surface of the decorative strip with the nano coating film, the problem that the decorative strip easily adsorbs oil stains and is difficult to clean can be effectively solved.

Owner:滁州市博爱金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com