Strengthened Alpha Brass and Method for Manufacturing the Same

a technology of alpha brass and alpha, which is applied in the direction of metal rolling arrangements, etc., can solve the problems of increased thickness of material, increased weight of material, and cost drawback, and achieve excellent and stable properties, offset yield strength and formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0064]Hereinafter, the present invention is described further in detail with referring to Examples. The chemical compositions of brass ingots used for manufacturing and evaluation in Examples and Comparative Examples are shown in Table 1. Ingots 1 to 6 herein are samples obtained by semicontinuous casting in casting plant where manufacturing is conducted. Each of ingots 7, 8 and 9 are obtained by melting with a furnace in a laboratory and casting an ingot to have a size by 30 mm by 100 mm by 200 mm with a metal mold.

TABLE 1Component Composition (wt %)Ingot No.CuFePbSnSZn165.20.0020.0000.0030.001Balance269.90.0040.0000.0030.000Balance369.30.0020.0000.0030.000Balance465.40.0020.0020.0010.003Balance570.00.0030.0000.0020.000Balance669.90.0020.0020.0010.001Balance774.20.0060.0000.0020.000Balance868.90.0010.0000.0010.000Balance965.90.0010.0000.0010.000Balance

[0065]As is evident from Table 1, Ingots 1 to 9 satisfy the state of the present invention being a composition of wt % to 74.2 wt % ...

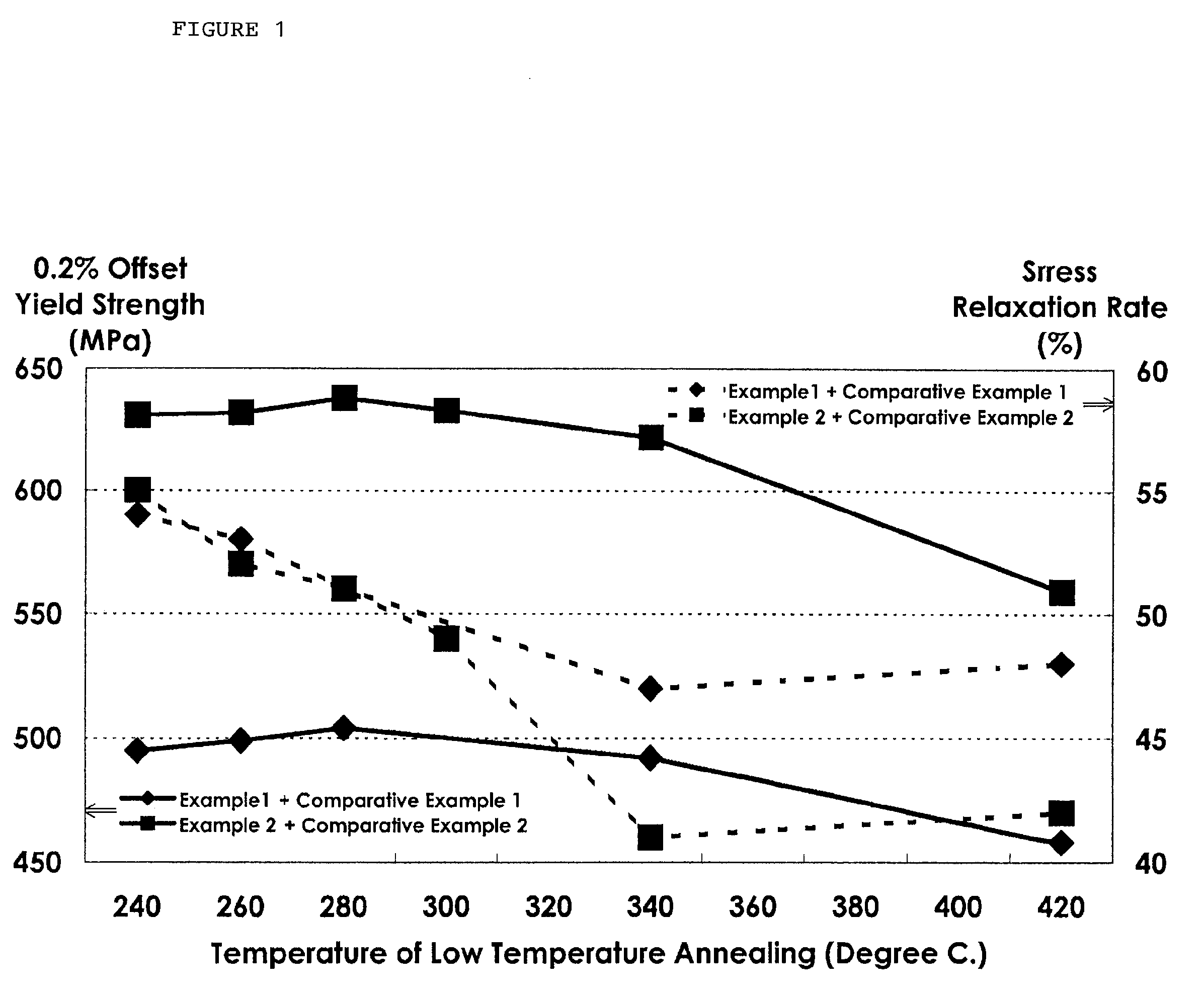

examples 1 and 2

[0071]The Ingot 1 obtained above was hot rolled, sculptured, cold rolled, and preliminary annealed to obtain a raw material with a thickness of 1.8 mm. Preparation of the raw material and a starting plate material 1 were conducted in a production line at the manufacturing site until the annealing (c) prior to the final cold rolling. Process conditions applied to Examples 1 and 2 are shown in Table 2 with Example 3 in comparison with Comparative Examples 1 and 2. In Table 2, the preliminary annealing (a: annealing prior to the re-crystallization annealing prior to the final cold rolling) and the annealing prior to the final process (c: annealing prior to the final cold rolling) are continuous annealings conducted in the production lines at the manufacturing site as mentioned above. The temperatures mentioned above are preset temperatures of furnaces. In this way, common starting plate material 1 was used for the process until the re-crystallization annealing prior to the final cold r...

examples 1

[0072]In these Examples, the starting plate materials 1 obtained above were subjected to cold rolling (d) with a reduction of 10% by using a laboratory cold rolling mill to prepare cold rolled brass plates, and further subjected to a low temperature annealing (e) in a salt bath. Annealing time in the salt bath was set to be short time of 2 seconds for the purpose of carrying out the annealing to be similar to a continuous annealing. Temperatures in the salt bath of Examples 1-1, 1-2, and 1-3 were 280-deg.C., 340-deg.C., and 420-deg.C. respectively. Physical properties of strengthened alpha brass obtained were evaluated. As a result, tensile strengths were 532 MPa to 556 MPa, 0.2% offset yield strength were 458 MPa to 504 MPa, Erichsen values (value calculated from 0.2% offset yield strength) were 8.6 mm (8.3 mm) to 8.8 mm (8.2 mm) and stress relaxation rates were 47% to 51%. Thus, the physical properties satisfied the target values. Details are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com