Metal composite material bonding and rolling method for overcoming defects of bubbles and skin material deviation

A technology of metal composite materials and leather materials, applied in metal rolling, metal layered products, chemical instruments and methods, etc., can solve the problems of composite layer air bubbles, leather material deviation, etc., to improve the composite rate and reduce the pressure The effect of poor, high pass rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Prepare HF8061 aluminum alloy composite product, specifically according to the following steps:

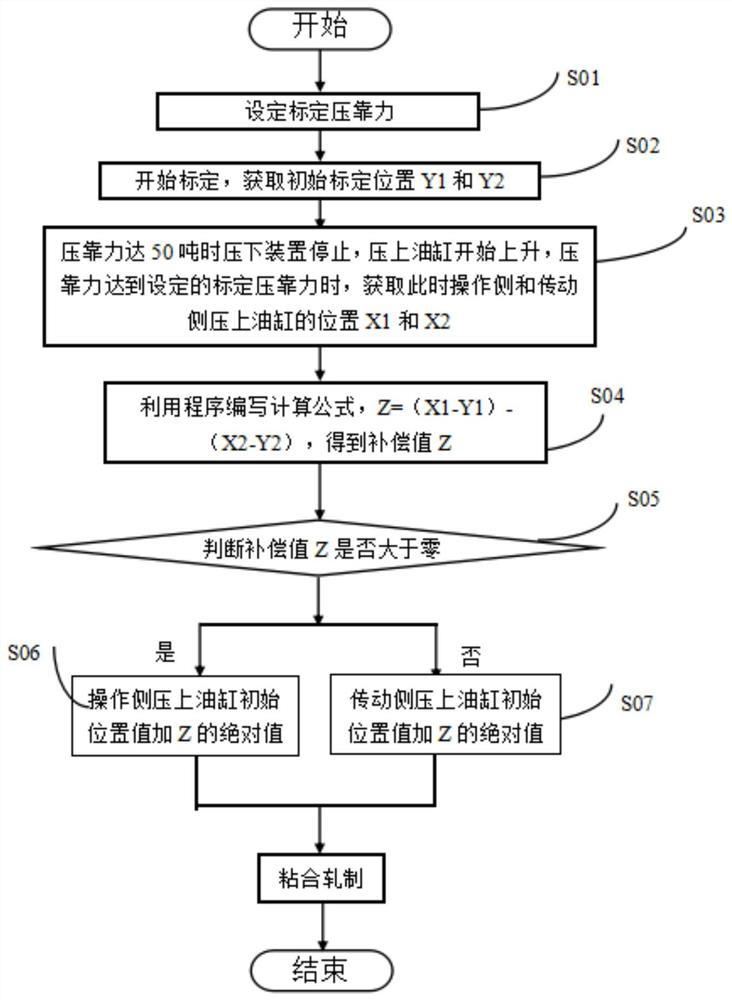

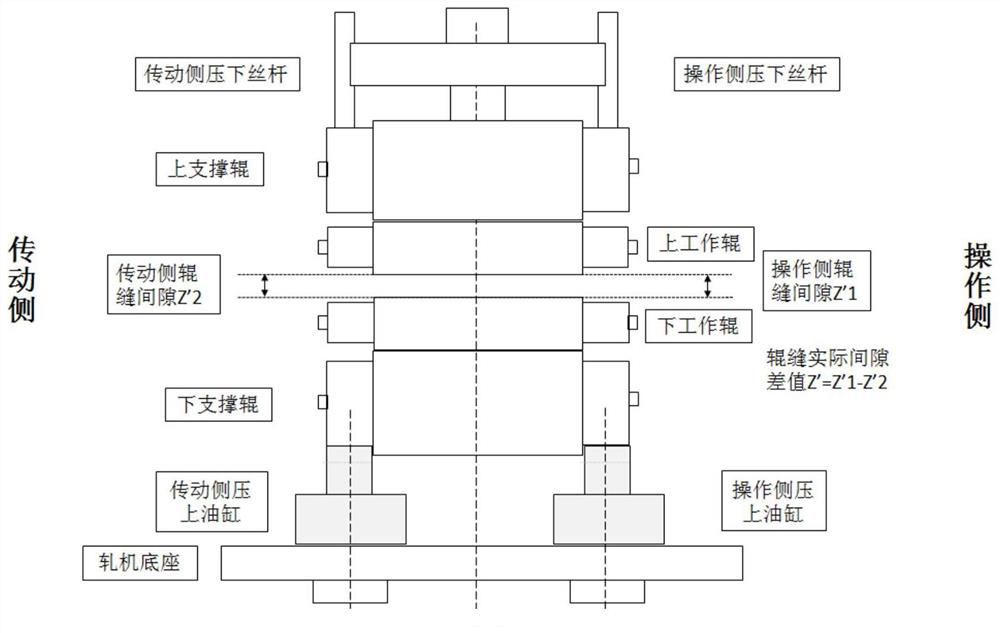

[0065] 1. Roll Gap Compensation

[0066] S01: Set the calibration pressing force;

[0067] In the step of bonding the HF8061 alloy, first set the calibration pressing force on the rolling mill, and the calibration pressing force is set to 100 tons;

[0068] S02: Position calibration;

[0069] The rolling mill starts calibration after receiving the calibration command, record the initial position of the upper oil cylinder on the operation side as Y1, and the initial position of the upper oil cylinder on the transmission side as Y2;

[0070] S03: Compensation calibration;

[0071] After performing the S02 step, the pressing device starts to run at a speed of 1.5mm / s under the drive of the motor. When the upper and lower work rolls just contact, the pressing force reaches 50 tons at this time, and the pressing device stops running; At this time, the upper cylinder starts t...

Embodiment 2

[0080] To prepare the HF8061 aluminum alloy composite product, the specific steps are the same as in Example 1, except that the calibration pressing force in step S01 is set to 170 tons.

Embodiment 3

[0082] To prepare the HF8061 aluminum alloy composite product, the specific steps are the same as in Example 1, except that the calibration pressing force in step S01 is set to 145 tons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com