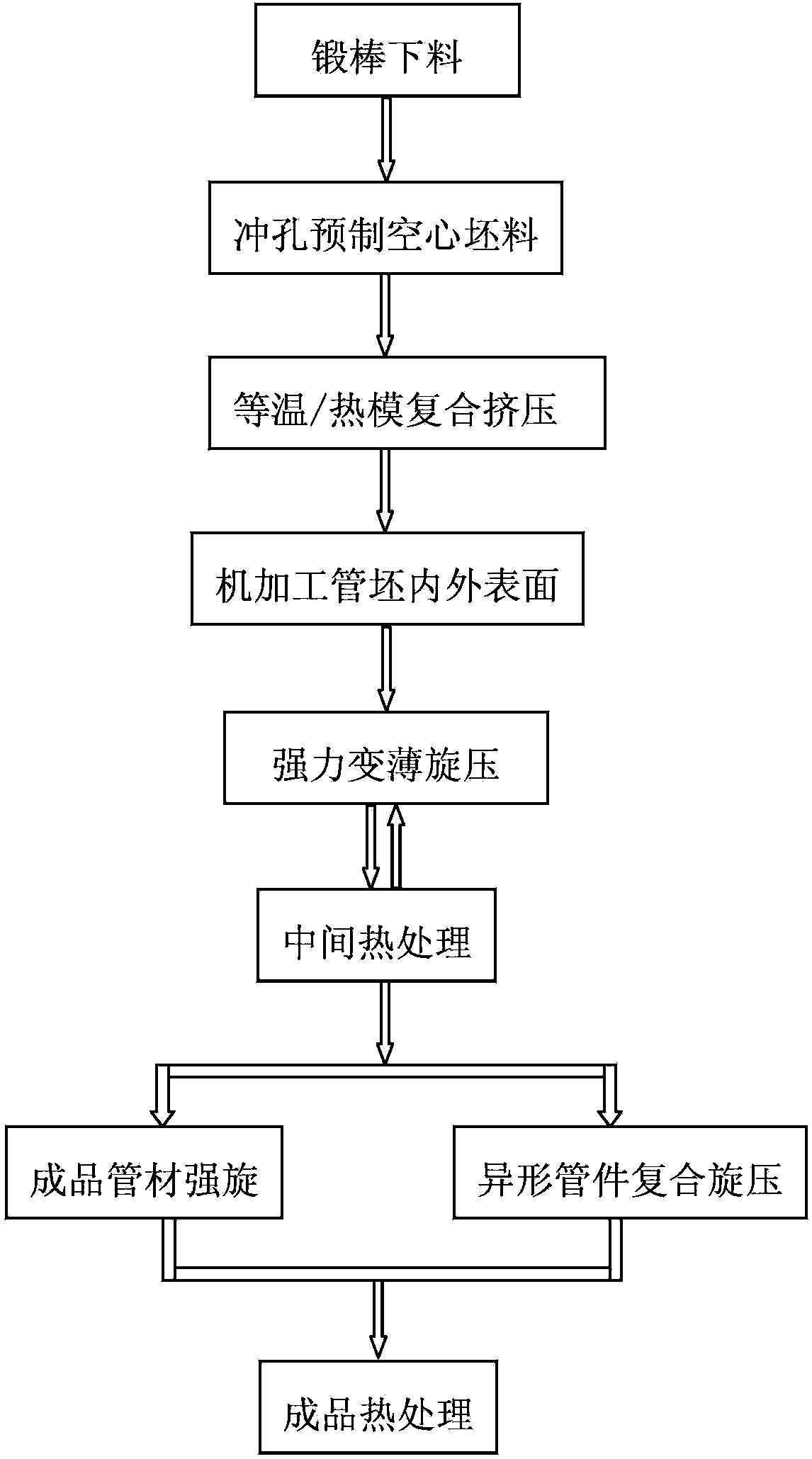

Preparation machining method of large-diameter pipe material and special-shaped pipe fitting

A technology for special-shaped pipe fittings and large-diameter pipes is applied in the field of preparation and processing of large-diameter pipes and special-shaped pipe fittings. Defects such as spinning cracks, good product structure uniformity, fine and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The processing object is Inconel718 alloy pipe. After the Inconel718 alloy forging rod is blanked, it is punched and machined to prefabricate a hollow billet with an outer diameter of Ф300 mm and an inner diameter of 120 mm, and then carries out isothermal composite extrusion. The extrusion ratio is 1 mm / s, the extrusion ratio is 3.4, and the extrusion temperature is 1050 °C. After machining, the outer diameter of the spinning tube blank is Ф295 mm, and the wall thickness is 12 mm. A three-wheel powerful spinning machine is used for thinning and spinning. The thinning rate of the first pass is 18%, and the thinning rate of subsequent passes is 25%. The feed ratio of the first two passes of the finished product is 0.7 mm / r. The feed ratio of other passes is 1.8 mm / r, the deformation of solution treatment is 70%, the solution temperature is 1065 ℃, and it is kept at this temperature for 2 h, and then water quenched. The finished pipe adopts the standard heat treatment sys...

Embodiment 2

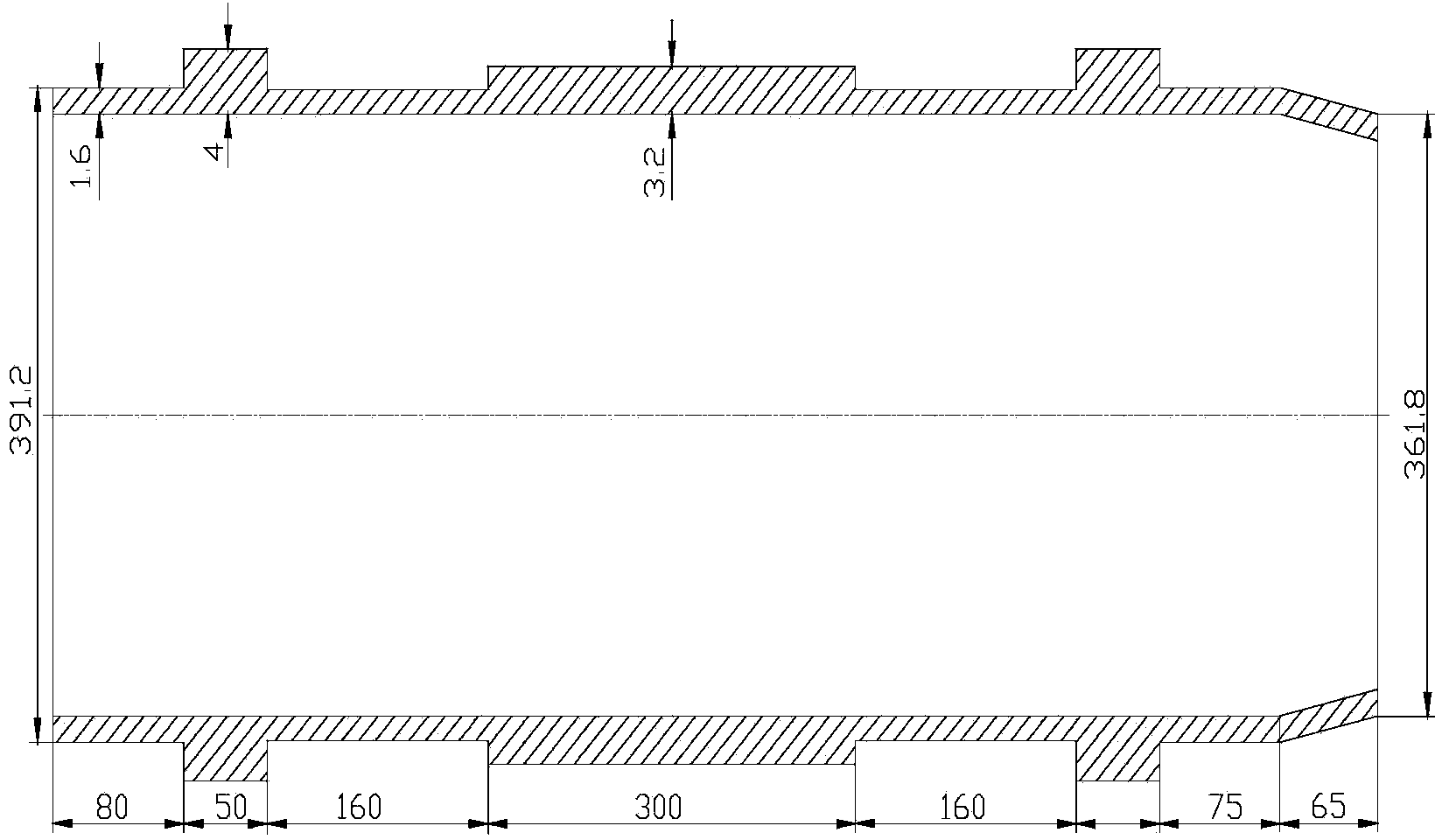

[0042] The processing object is GH4698 alloy special-shaped pipe fittings. After the GH4698 alloy forging rod is blanked, it is punched and machined to prefabricate a hollow blank with an outer diameter of Ф260 mm and an inner diameter of 120 mm. A hollow billet was prefabricated with a normal carbon steel ladle with a wall thickness of 10 mm, and then hot-die composite extrusion was carried out at an extrusion speed of 1.5 mm / s, an extrusion ratio of 2.7, an extrusion temperature of 1220 °C, and an extrusion die temperature of to 950°C. After machining, the outer diameter of the spinning tube blank is Ф256 mm and the wall thickness is 10 mm. Three-wheel powerful spinning machine is used for thinning and powerful spinning, the wall reduction rate of the first pass is 21%, the subsequent pass thinning rate is 27%, the feed ratio is 1.5 mm / r, and the deformation of solution heat treatment It is 65%, the solid solution temperature is 1100 ℃, it is kept at this temperature for 1 ...

Embodiment 3

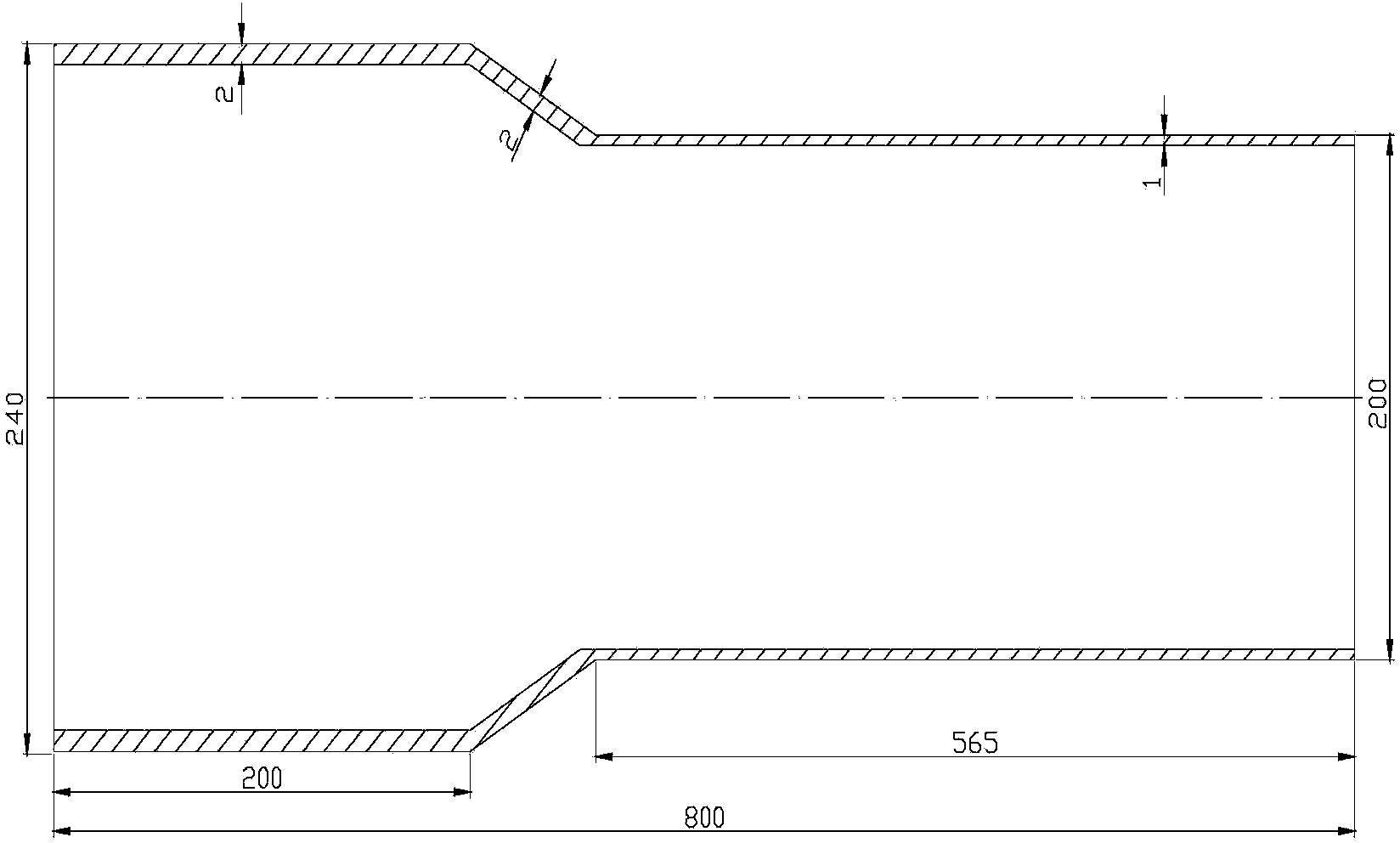

[0044] The processing object is Monel400 alloy special-shaped pipe fittings. After the Monel400 forging rod is blanked, it is punched and machined to prefabricate a hollow billet with an outer diameter of 420 mm and an inner diameter of 180 mm, and then isothermal composite extrusion. The extrusion ratio is 0.5 mm / s, the extrusion ratio is 4.5, and the extrusion temperature is 980 °C. After machining, the outer diameter of the spinning tube blank is Ф410 mm and the wall thickness is 12 mm. A three-wheel powerful spinning machine was used for thinning spinning, the thinning rate of the first pass was 20%, the subsequent pass was 25%, and the feed ratio was 2 mm / r. The annealing deformation is 70%, the annealing temperature is 900 ℃, and the temperature is kept at this temperature for 1.5 h. After heat treatment, the semi-finished pipe has an outer diameter of 396 mm and a wall thickness of 4 mm. The heat-treated pipe is subjected to three times of strong spinning to bring out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com