Patents

Literature

102results about How to "Excellent solvent solubility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

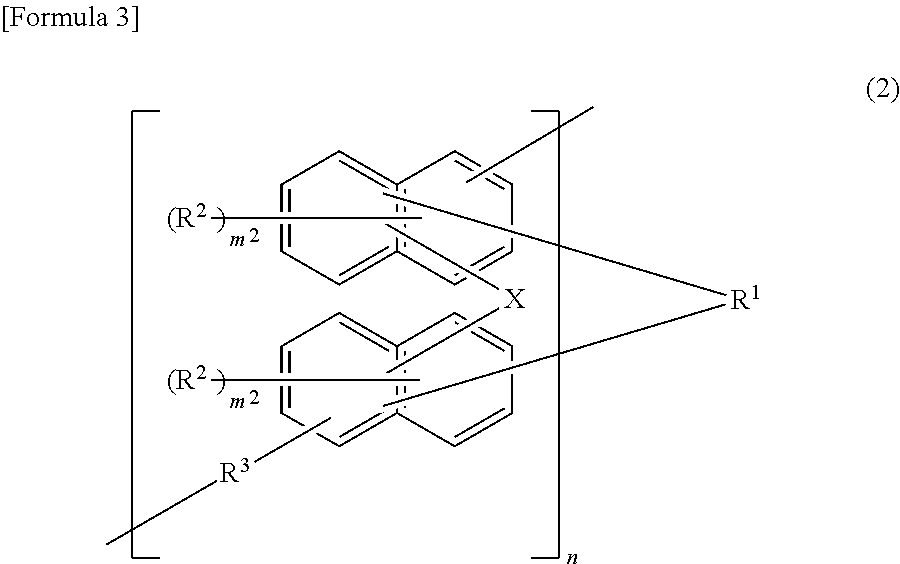

Polyimide resin composition and laminate including polyimide resin composition

InactiveUS20130288120A1Excellent solvent solubilityHigh viscoelasticityImpression capsElectrolytic capacitorsViscoelasticityHigh heat

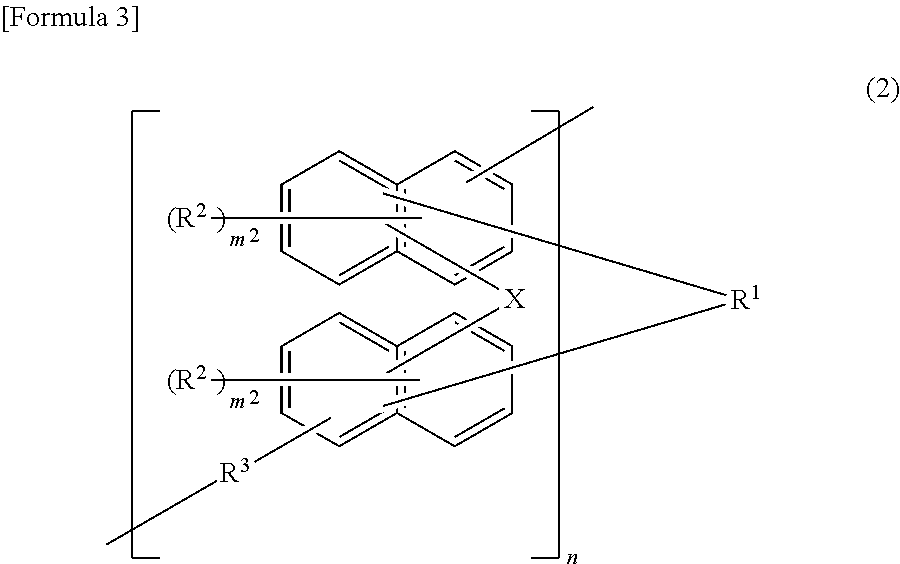

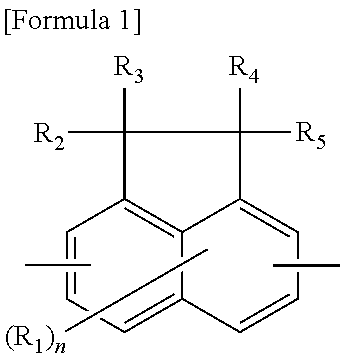

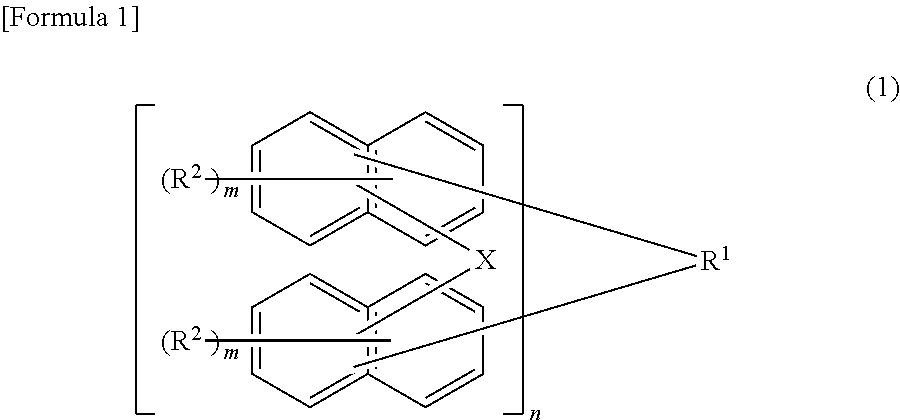

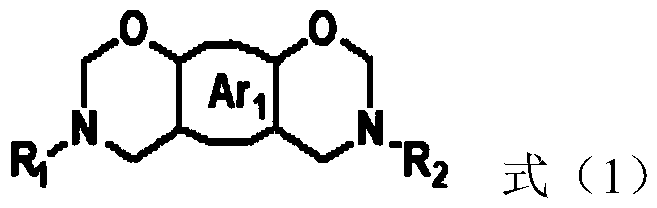

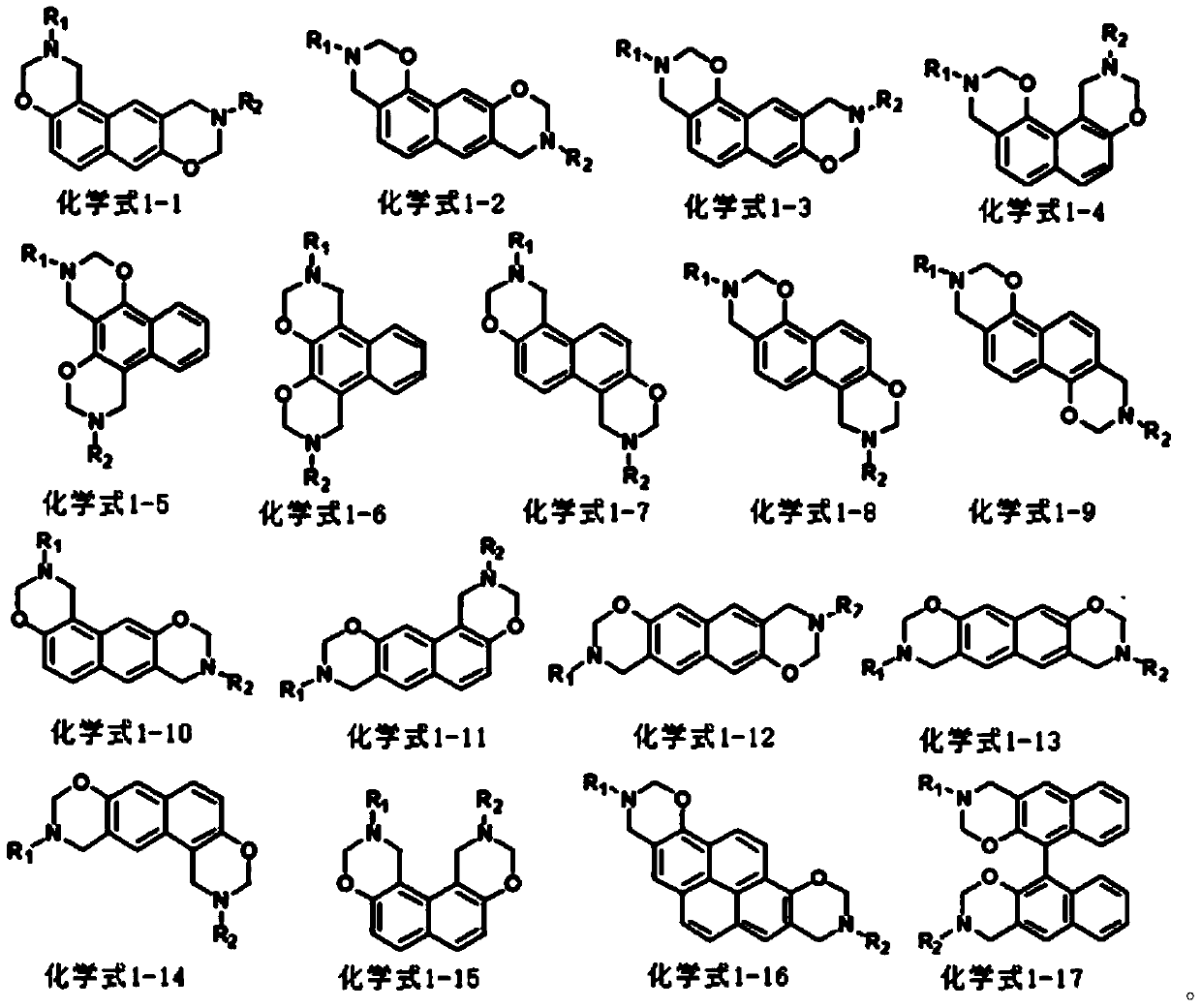

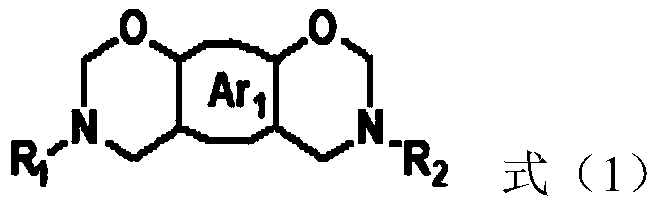

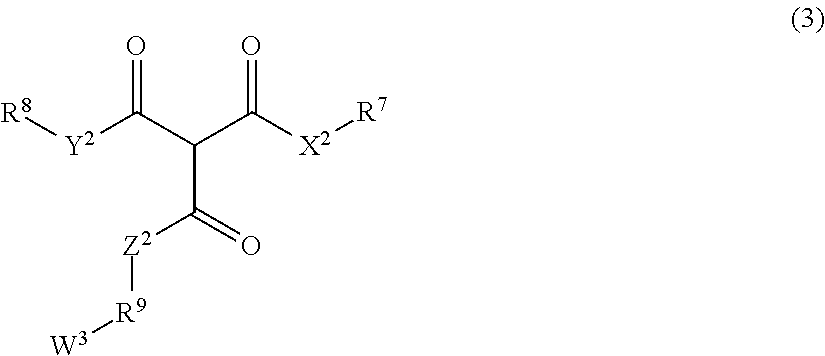

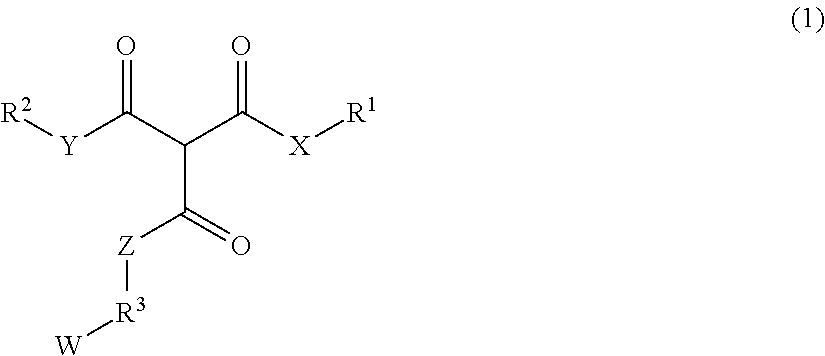

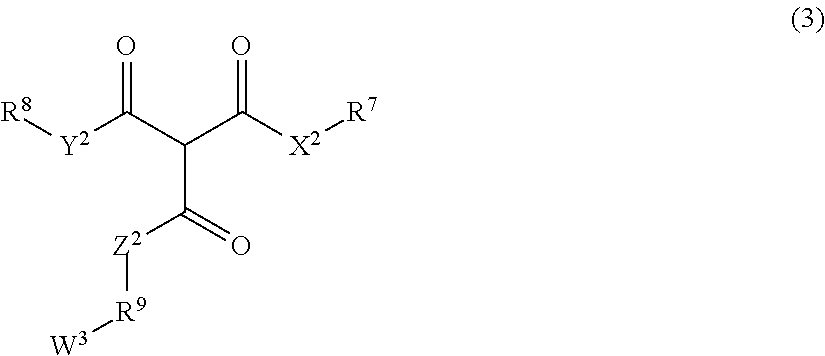

To provide a resin composition that contains a solvent-soluble polyimide and can provide a film exhibiting high viscoelasticity and flexibility at high temperatures. To attain this, a polyimide resin composition is provided that includes a polyimide having a polycondensation unit of a tetracarboxylic acid dianhydride and a diamine, wherein the tetracarboxylic acid dianhydride includes an (α1) tetracarboxylic acid dianhydride represented by general formula (1), or the diamine includes an (β1) aromatic diamine represented by general formula (2), the diamine includes an (β2) aliphatic diamine represented by general formula (3) or (4), a total amour of the (α1) tetracarboxylic acid dianhydride and the (β1) aromatic diamine is 5 to 49 mol % with respect to a total amount of the tetracarboxylic acid dianhydride and the diamine, and an amine equivalent of the polyimide is 4,000 to 20,000.

Owner:MITSUI CHEM INC

Method of forming a conductive metal region on a substrate

InactiveUS20060134318A1Less of definitionDelayPrinted circuit assemblingPrinted circuit aspectsMaterials scienceMetal

There is disclosed a method of forming a conductive metal region on a substrate, comprising depositing on the substrate a solution of a metal ion, and depositing on the substrate a solution of a reducing agent, such that the metal ion and the reducing agent react together in a reaction solution to form a conductive metal region on the substrate.

Owner:CONDUCTIVE INKJET TECH

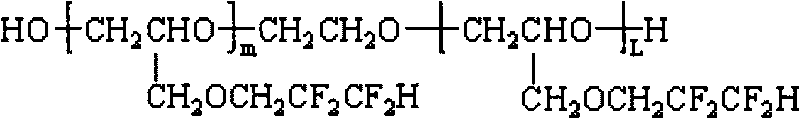

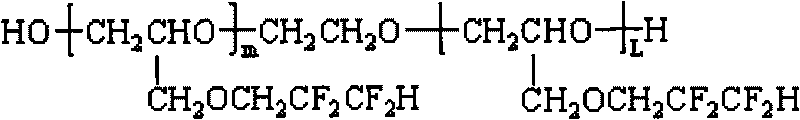

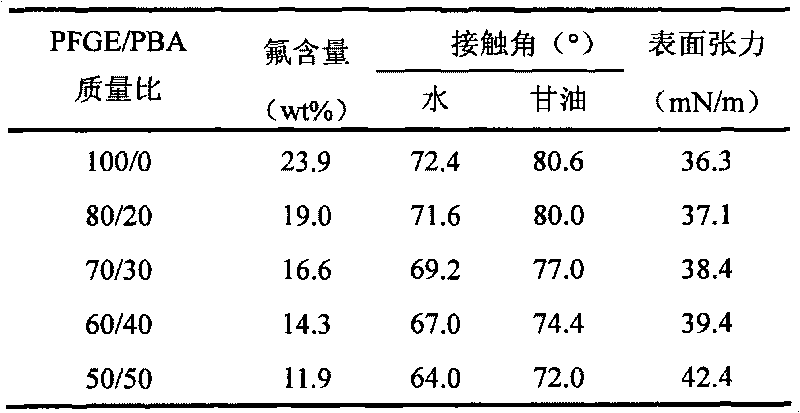

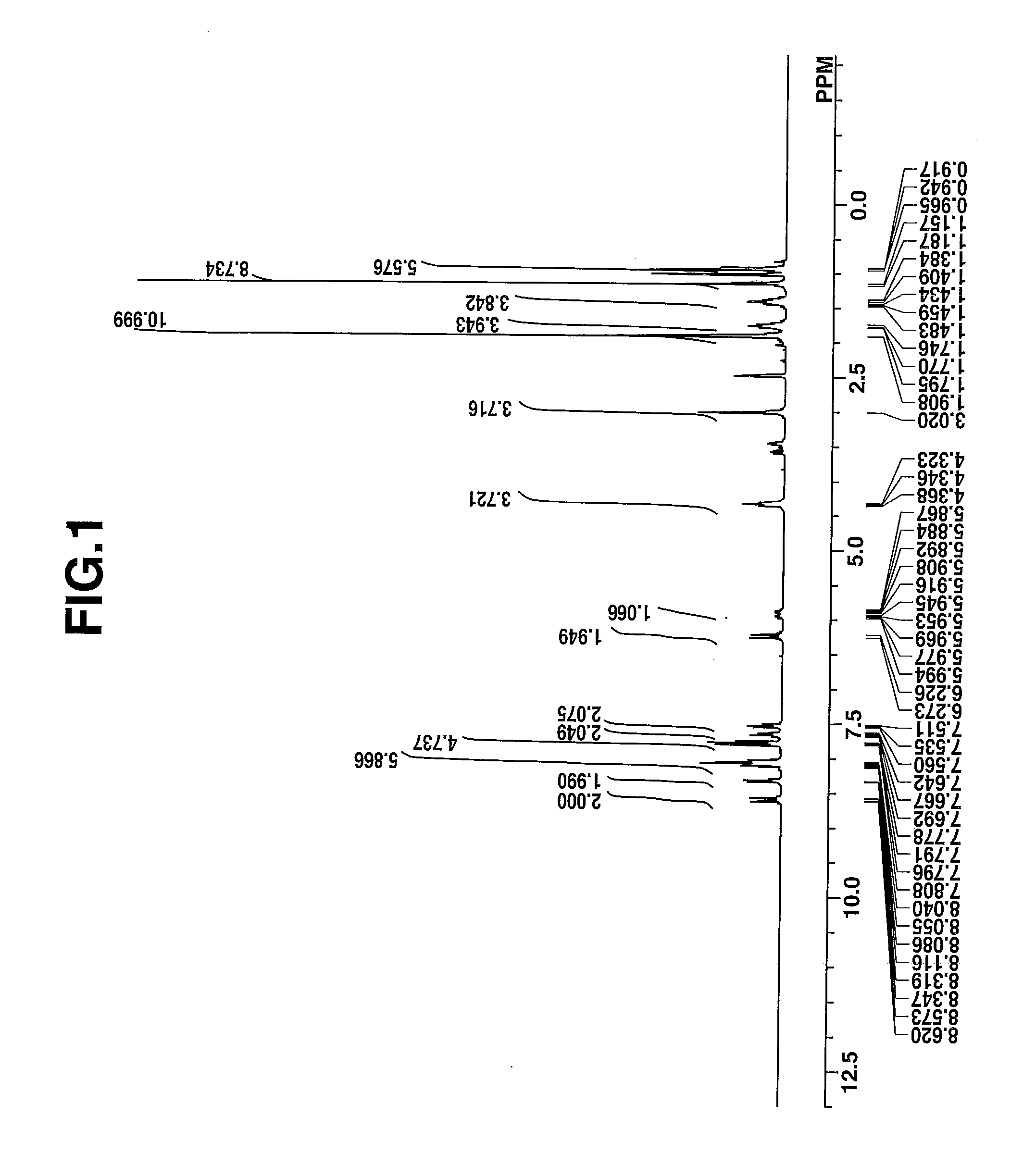

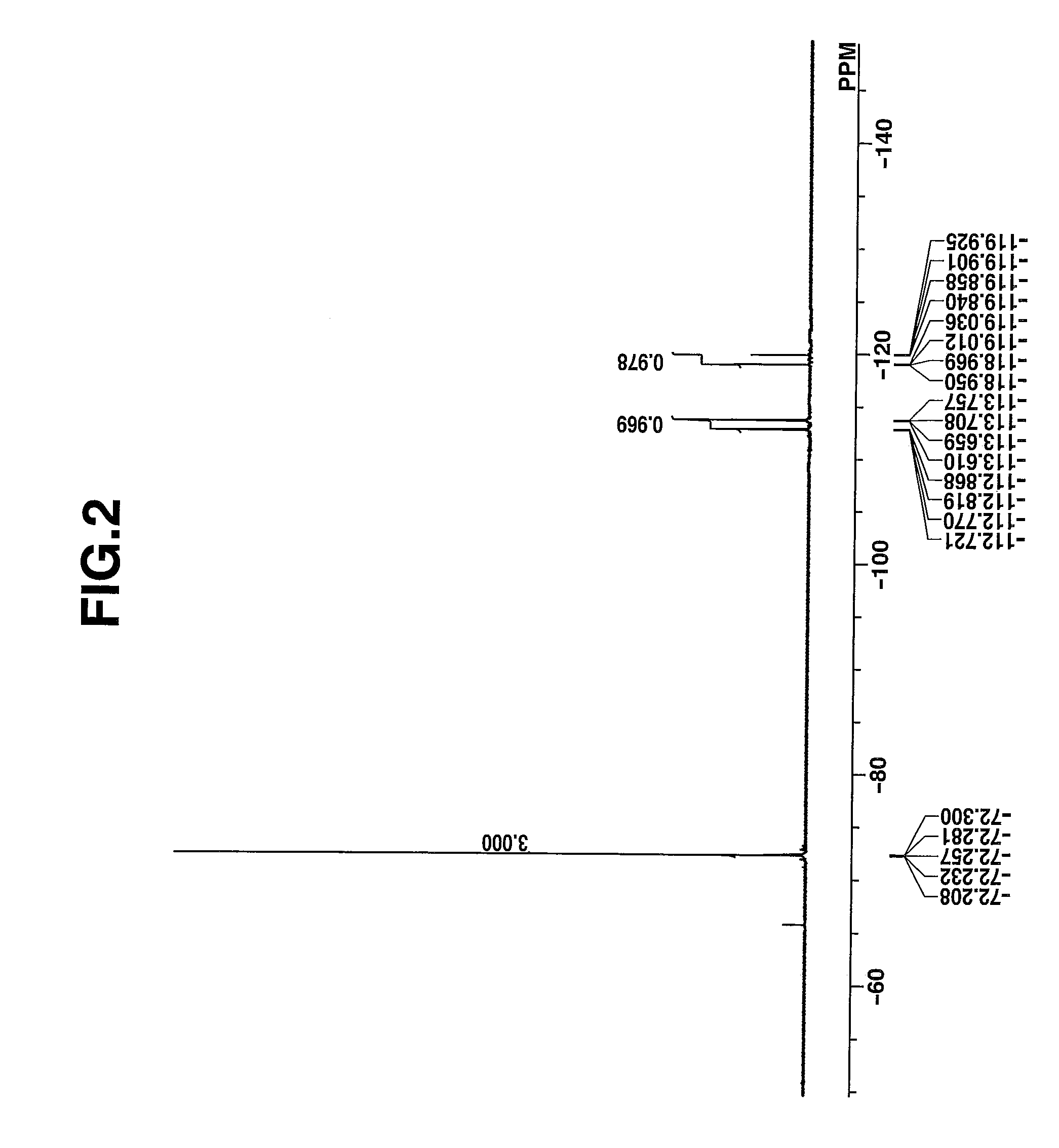

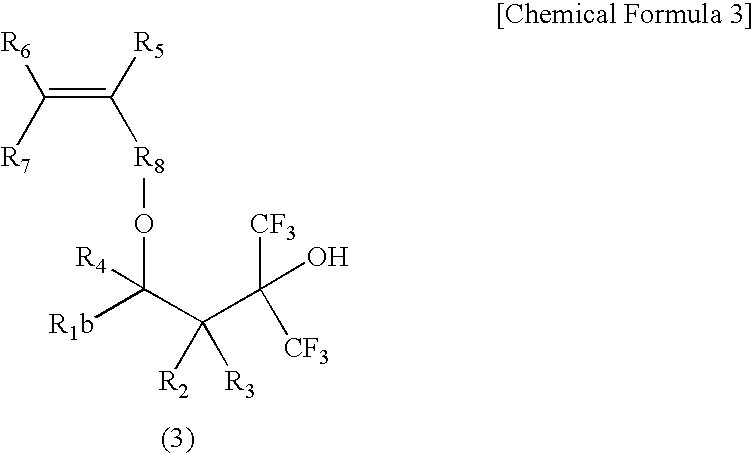

Method for preparing high-toughness thermoplastic fluorine-containing polyurethane elastomer

ActiveCN101717485AKeep the elastomer perfectly linearLower surface energyPolyurethane elastomerThermoplastic

The invention discloses a method for preparing a high-toughness thermoplastic fluorine-containing polyurethane elastomer, which is characterized in that a bulk polymerization two-step method is adopted to synthesize the fluorine-containing polyurethane elastomer, the isocyanate index is 0.98, and the hard segment content is between 20 and 40 weight percent. The method comprises the following steps of: weighing 6 to 40 parts of non-fluorine macromolecular polylol and / or 30 to 80 parts of fluorine-containing polyether diol in a reactor, performing vacuum dehydration on the mixture for 2h at thetemperature of 120 DEG C, cooling the mixture to be between 70 and 100 DEG C, adding 16 to 33 parts of polyisocyanate into the mixture, stirring the mixture to react for 3h, heating the mixture to bebetween 120 and 140 DEG C, adding 0.1 to 15 parts of low molecular (fluorine-containing) diol chain extender into the mixture, uniformly stirring the mixture, then dumping the mixture into a preheated container, and performing vacuum baking for 20 hours at the temperature of between 120 and 140 DEG C to obtain the high-toughness thermoplastic fluorine-containing polyurethane elastomer.

Owner:SICHUAN UNIV

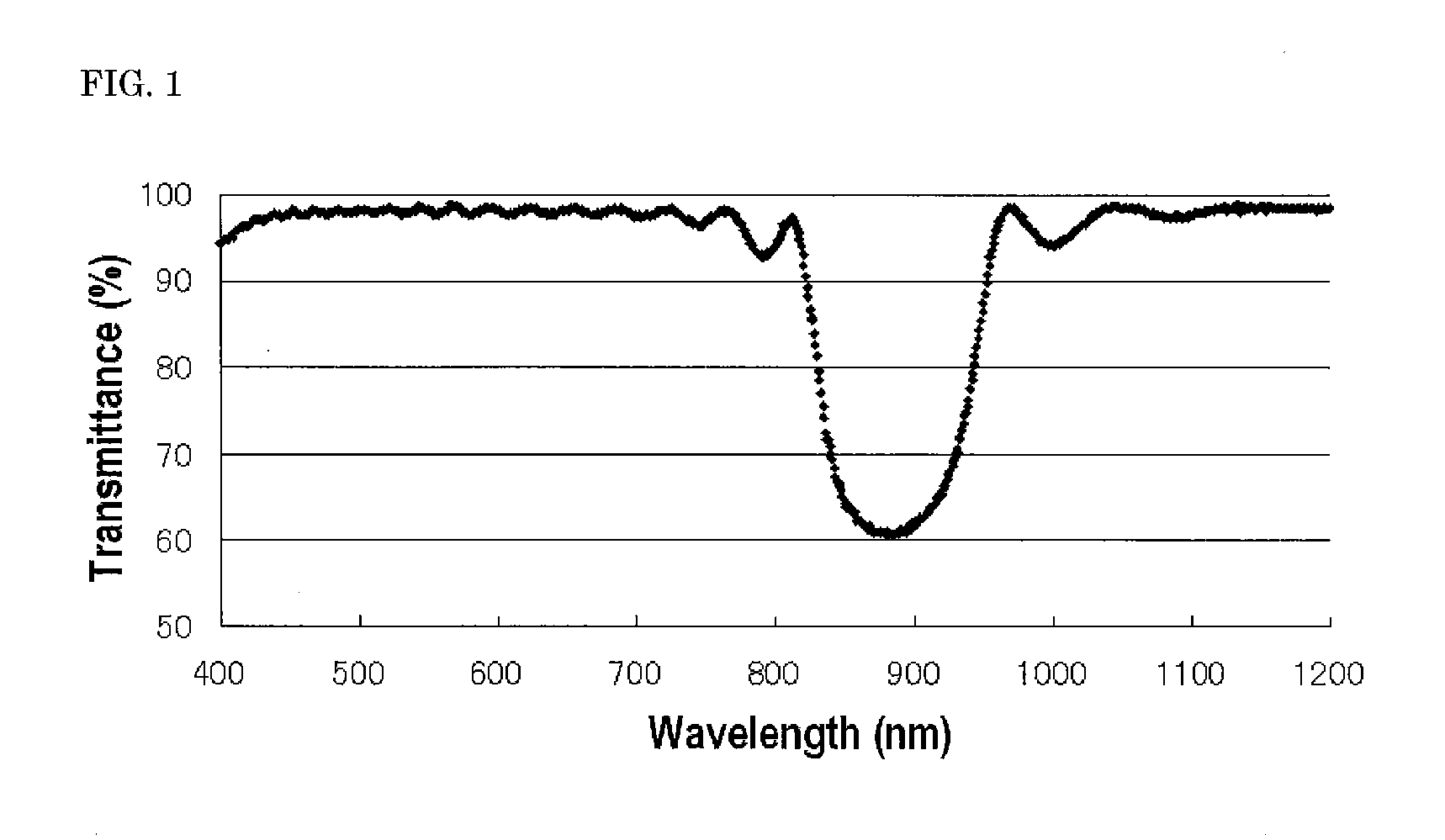

Near-infrared absorbing dye, near-infrared absorptive film-forming composition, and near-infrared absorptive film

ActiveUS20120119171A1Excellent solvent solubilityImprove the heating effectMethine/polymethine dyesOrganic chemistrySolubilityOptical property

A near-infrared absorbing dye has an anion of formula (1) wherein A1 is H or CF3, R0 is OH or —OC(═O)—R′, and R′ is a monovalent hydrocarbon group. The dye has excellent solvent solubility as well as good optical properties and heat resistance, offering the advantages of easy coating and effective working during film formation. The dye free of heavy metal in its structure is advantageously used in the process of fabricating semiconductor devices.

Owner:SHIN ETSU CHEM IND CO LTD

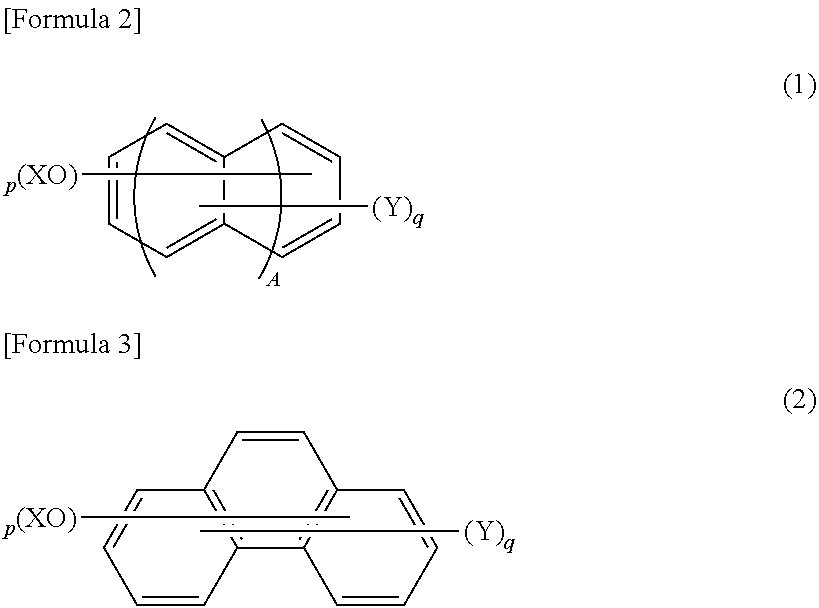

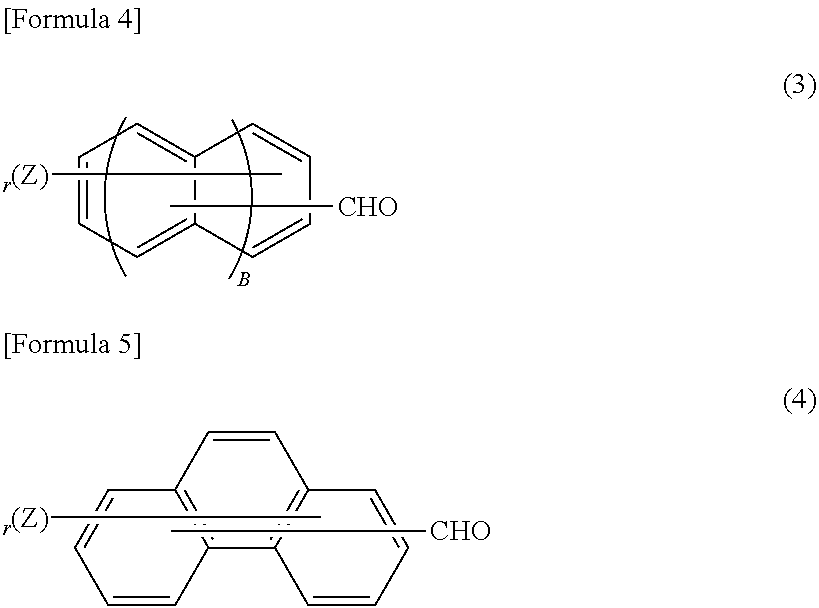

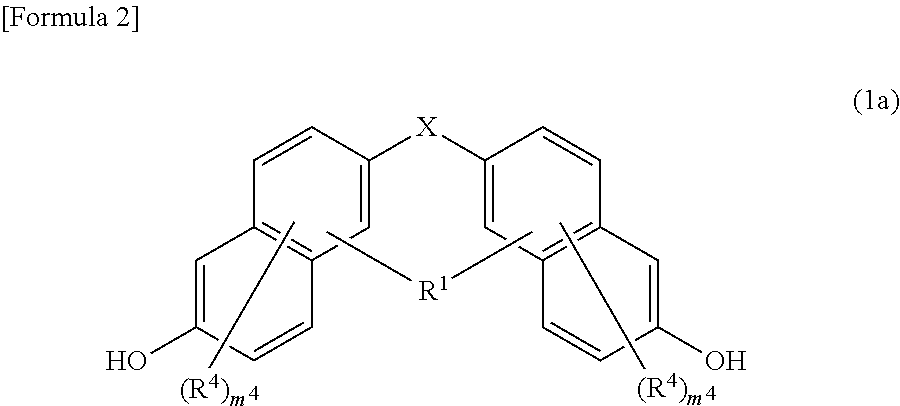

Material for forming underlayer film lithography, underlayer film for lithography and pattern forming method

ActiveUS20150090691A1Excellent in heat resistance and etching resistanceImprove the immunityOrganic chemistryOther chemical processesSolubilityHeat resistance

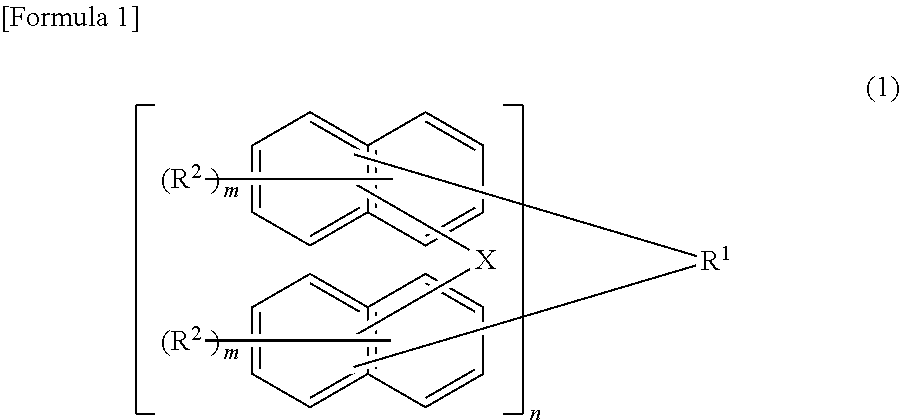

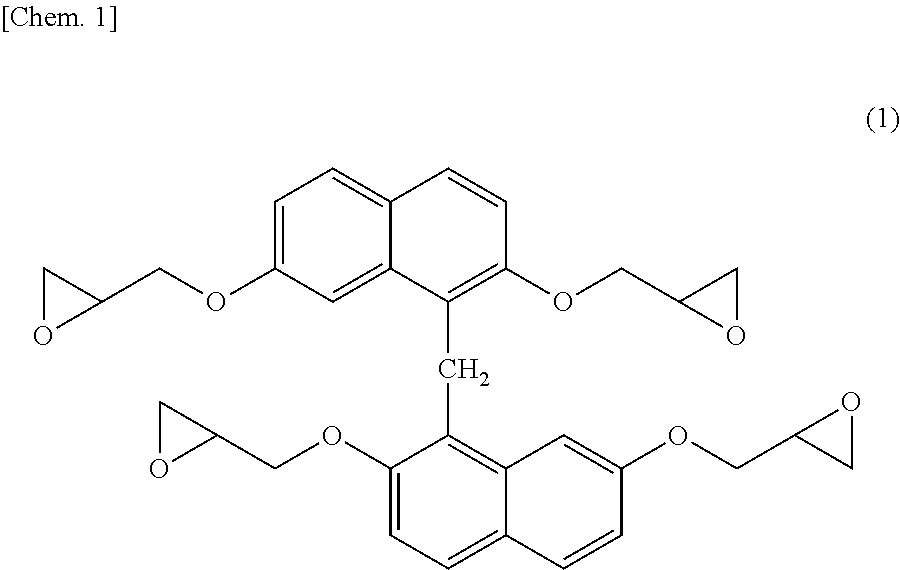

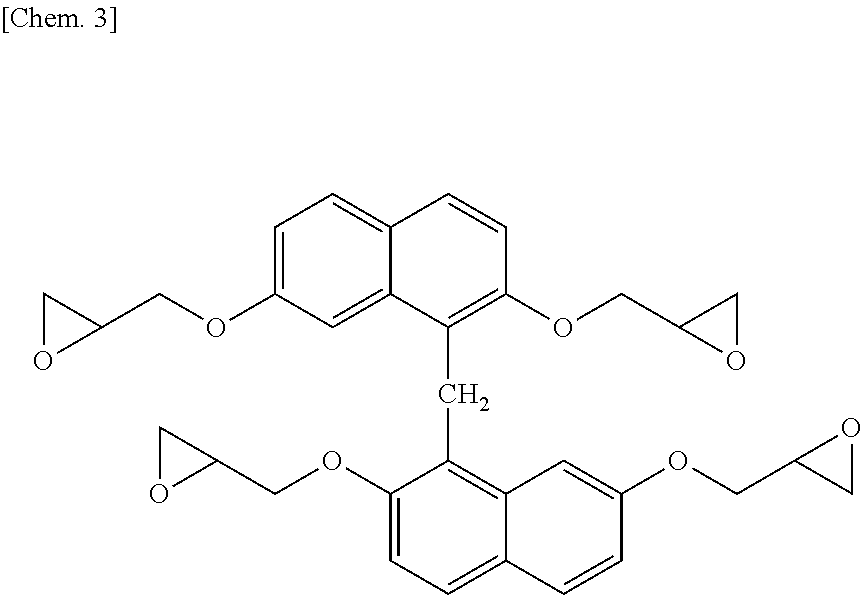

Material for forming an underlayer film for lithography, which has a high carbon concentration, a low oxygen concentration, a relatively high heat resistance and also a relatively high solvent solubility, and which can be applied to a wet process is disclosed. Material for forming an underlayer film for lithography contains a compound represented by general formula (1).

Owner:MITSUBISHI GAS CHEM CO INC

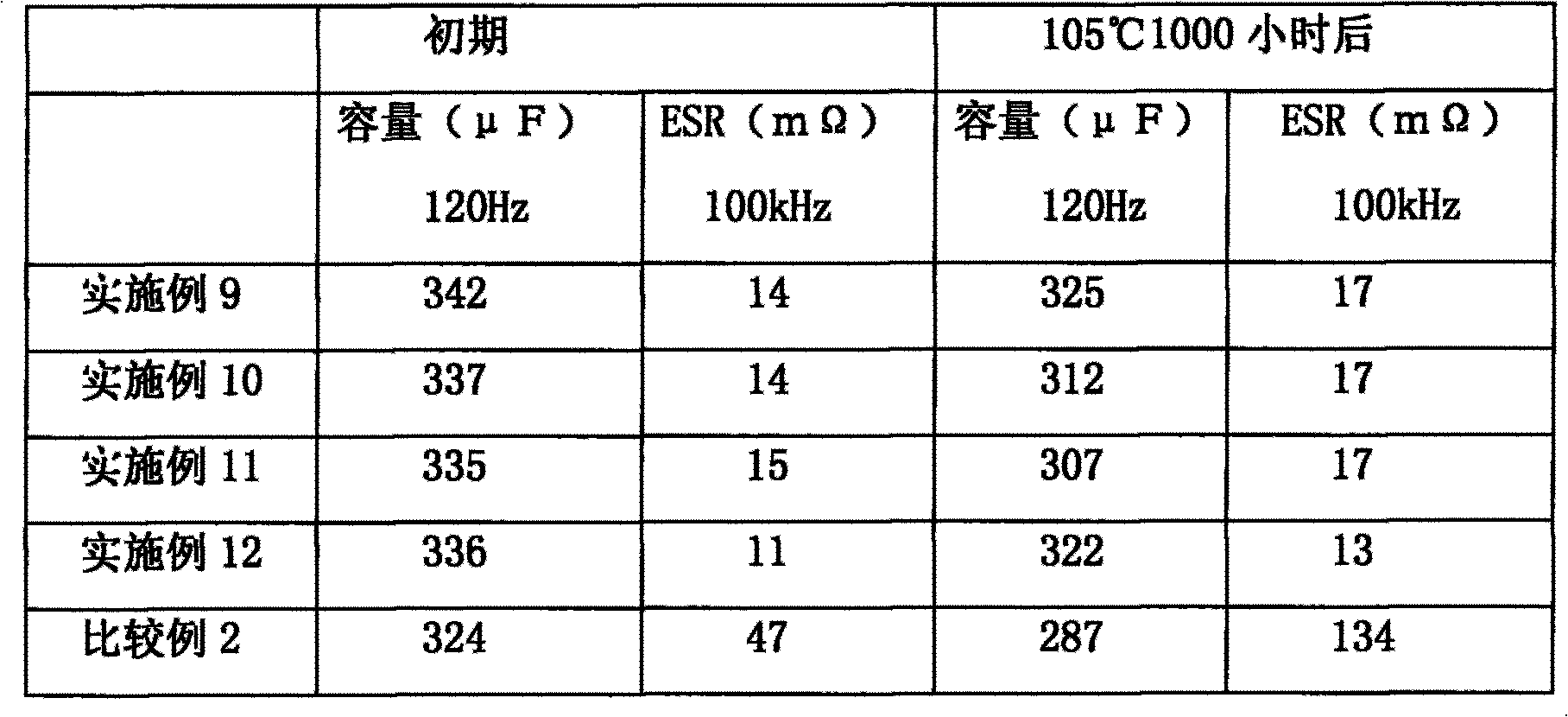

Conductive composite body, conductive polymer composition and electronic component using the conductive polymer composition

InactiveCN101302340AImprove long-term stabilityExcellent solvent solubilityOrganic conductorsConductive polymerDisplay device

The invention provides a conducting complex which is combined by a conducting polymer A and a compound B except for the conducting polymer, and also can comprise polyanion, wherein, the compound B is polyethylene and derivates thereof, polyvinyl ether and derivates thereof, polyacrylamide and derivates thereof, polyacrylic acid and derivates thereof, etc. The conducting complex improves clinging property and filming property for matrix, and can maintain low specific resistance in a high-temperature environment. A conducting polymer composition comprises the conducting complex, has reduced specific resistance, and can maintain low specific resistance in a high-temperature environment. The invention also provides an electronic element with excellent performance through using a coating of the conducting complex and the conducting polymer composition. The coating of the conducting complex or the conducting polymer composition can be used in a solid electrolytic capacitor, a solar cell, an organic light emitting diode, an electroluminance, a display, an electrostatic copying part, a transfer printing part, a battery, epaper, a touch panel, an organic thin-filmtransistor, a field emission display (FED) and so on.

Owner:ZHENGZHOU TAIDA ELECTRONICS MATERIAL TECH

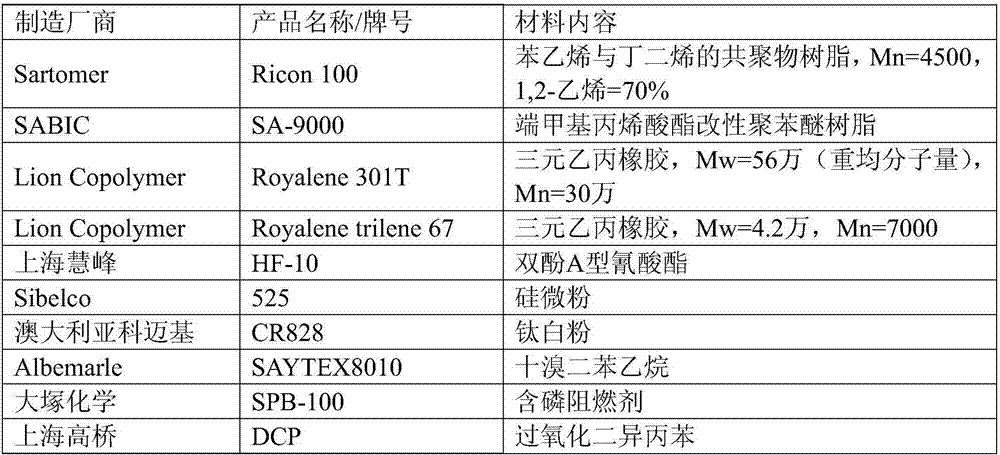

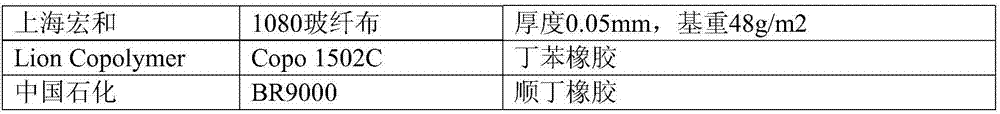

Composite material, high frequency circuit substrate prepared from composite material, and preparation of composite material

ActiveCN106867173AImproved long-term thermo-oxidative aging performanceExcellent solvent solubilityPrinted circuit aspectsHigh frequency circuit adaptationsSolubilityDielectric

The invention relates to a composite material, a high frequency circuit substrate prepared from the composite material, and a preparation of the composite material. The composite material comprises 20 to 70 parts of a thermosetting mixture, 10 to 60 parts of glass fibre cloth, 0 to 70 parts of a powder filling material, and 1 to 3 parts of a curing initiator; the thermosetting mixture is composed of a thermosetting resin and an ethylene propylene rubber; the thermosetting resin is a polybutadiene or a copolymer of the polybutadiene with styrene, wherein the molecular weight of the polybutadiene is lower than 11000Da, the polybutadiene is composed of C and H, and contains more than 60% vinyl; the weight average molecular weight of the ethylene propylene rubber is larger than 100kDa, and lower than 150kDa, the number-average molecular weight of the ethylene propylene rubber is larger than 60kDa, and lower than 100kDa, and the ethylene propylene rubber is a solid material at room temperature. The composite material possesses excellent solvent solubility, and is excellent in operability; the high frequency circuit substrate prepared from the composite material possesses excellent high frequency dielectric properties and better thermal-oxidative aging properties.

Owner:GUANGDONG SHENGYI SCI TECH

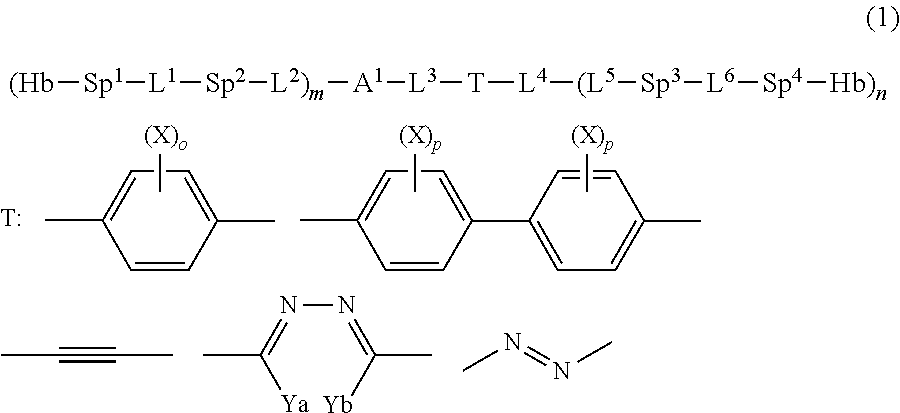

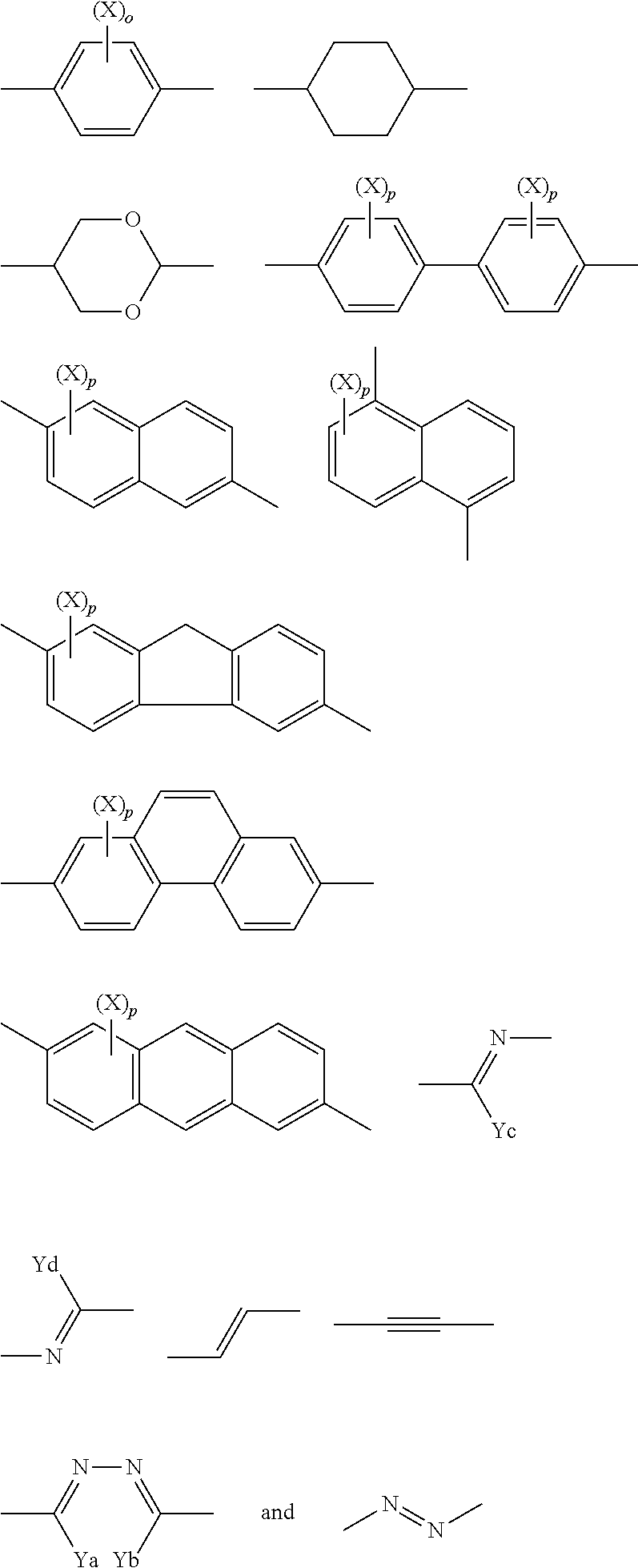

Compound, haze-lowering agent, liquid crystal composition, polymer material, and film

ActiveUS20140138580A1Wide usable concentration rangeExcellent solvent solubilityLiquid crystal compositionsOrganic chemistryCrystallographySolubility

A compound represented by the following formula (1) has sufficient solubility, a wide usable concentration range, and excellent haze-lowering performance. In the formula, L1 to L6 represent a single bond, —O—, —CO—, —COO—, etc; Sp1 to Sp4 represent a single bond or alkylene of 1 to 10 carbon atoms; A1 and A2 represent trivalent or tetravalent aromatic hydrocarbon or heterocyclic; T represents the following formulae, etc; Hb represent perfluoroalkyl of 2 to 30 carbon atoms; m and n are 2 or 3; and o and p are an integer of 0 or more.

Owner:FUJIFILM CORP

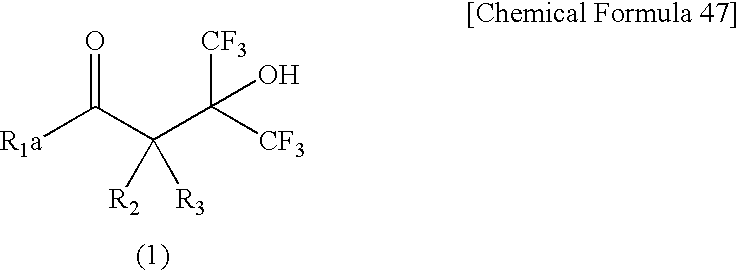

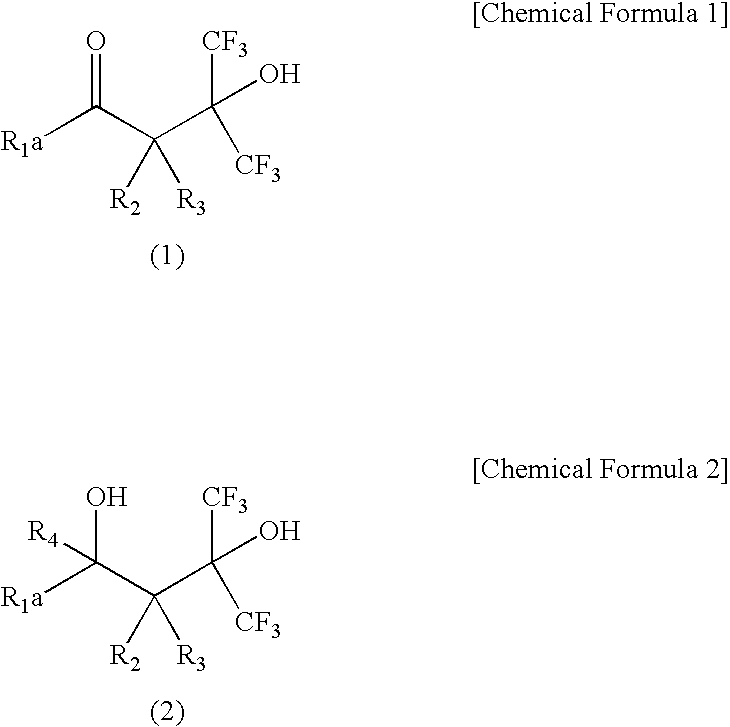

Fluorine-Containing Cyclic Compound, Fluorine-Containing Polymer Compound, Resist Material Using Same and Method for Forming Pattern

InactiveUS20080003517A1High transparencyImprove adhesionOrganic compound preparationPhotosensitive materialsResistHydrogen atom

The present invention relates to, for example, a fluorine-containing cyclic compound represented by the following general formula (1). In the general formula (1), R1a is a C1-C25 cyclic alkyl group, cyclic alkenyl group or cyclic alkynyl group; each of R2 and R3 is independently a hydrogen atom, a halogen atom, or a C1-C25 straight-chain, branched or cyclic alkyl group; and each of R1a, R2 and R3 may contain fluorine atom, oxygen atom, sulfur atom, nitrogen atom or an atomic group containing a carbon-carbon double bond.

Owner:CENT GLASS CO LTD

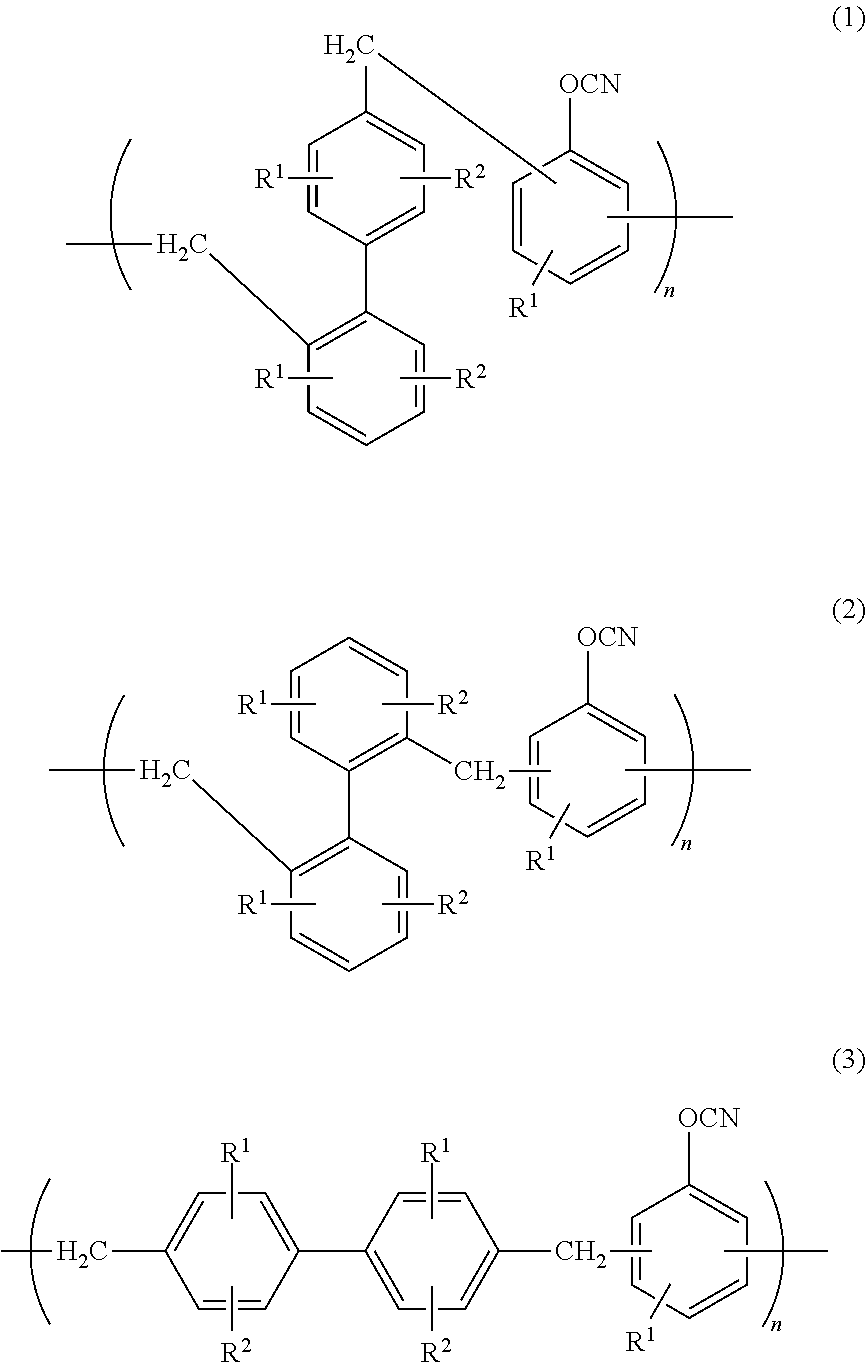

Phenolic resin and material for forming underlayer film for lithography

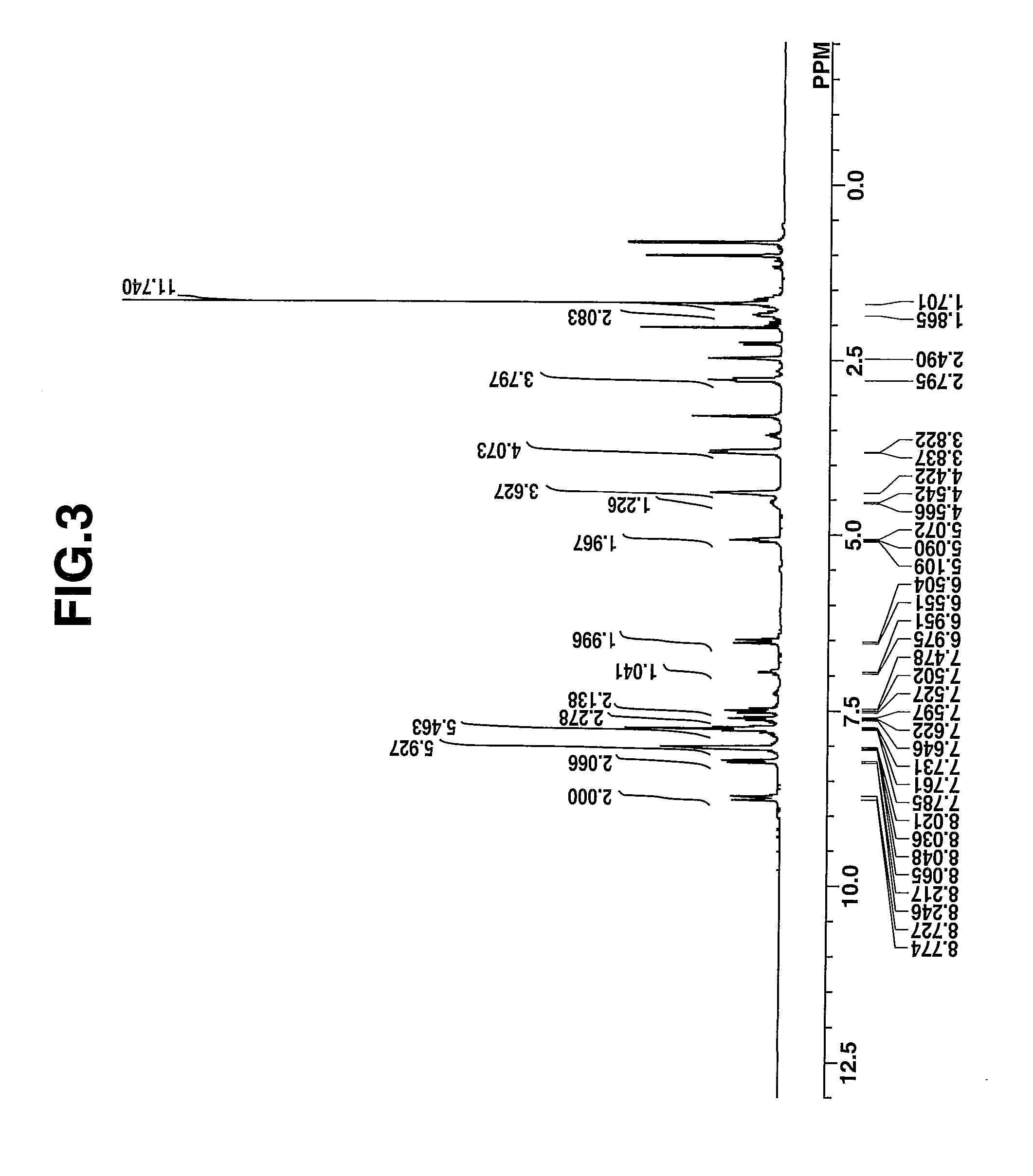

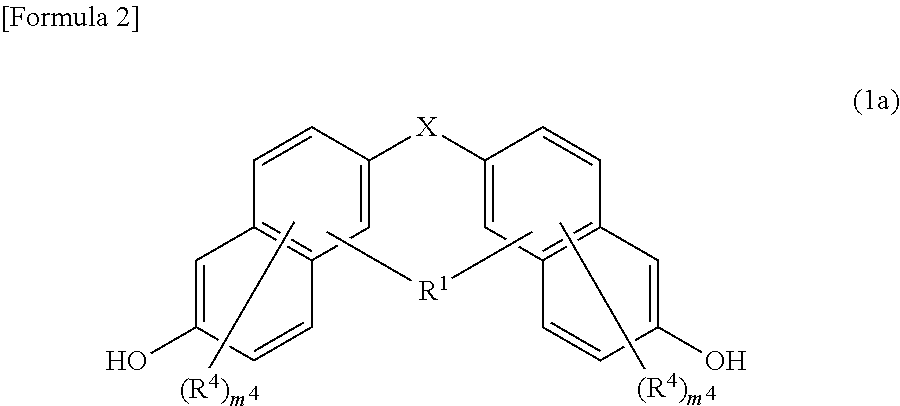

ActiveUS20140186776A1High carbon concentrationLow oxygen concentrationSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentSolventResist

There is provided a novel phenolic resin which can be used as a coating agent or a resist resin for a semiconductor, which has a high carbon concentration and a low oxygen concentration in the resin, which has a relatively high heat resistance and also a relatively high solvent solubility, and which can be applied to a wet process. There are also provided a material useful for forming a novel photoresist underlayer film which has a relatively high solvent solubility, which can be applied to a wet process, and which is excellent in etching resistance as an underlayer film for a multilayer resist, an underlayer film formed using the same, and a pattern forming method using the same. A resin of the present invention is obtained by reacting a compound having a specified structure and an aldehyde having a specified structure in the presence of an acidic catalyst. In addition, a material for forming an underlayer film for lithography of the present invention includes at least the resin and an organic solvent.

Owner:MITSUBISHI GAS CHEM CO INC

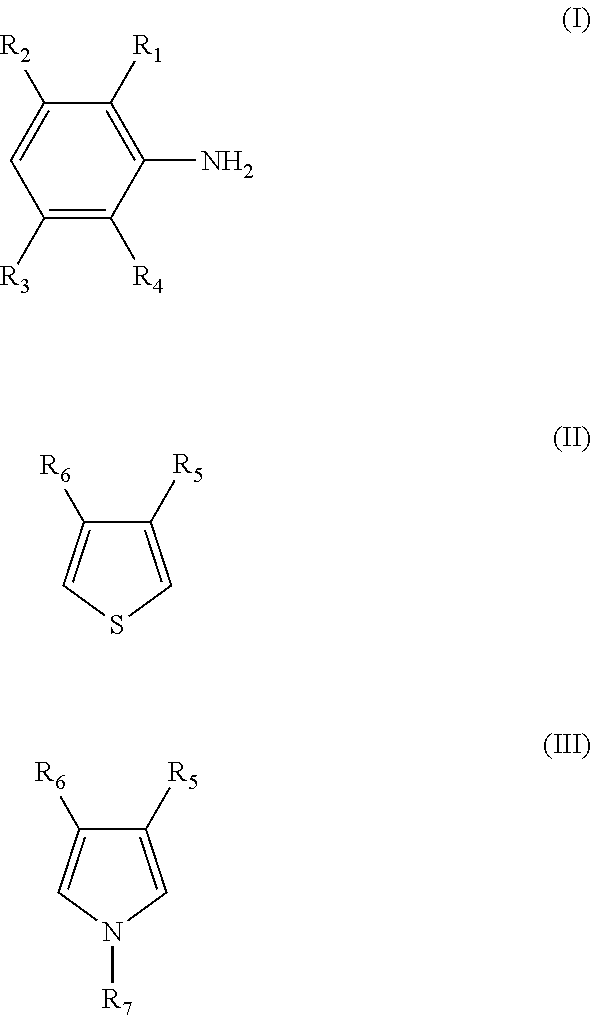

Composite conductive polymer composition, method of manufacturing the same, solution containing the composition, use of the composition

ActiveUS20110309308A1Easily formExcellent solvent solubilityHybrid capacitor electrodesCell electrodesChemistryKetone

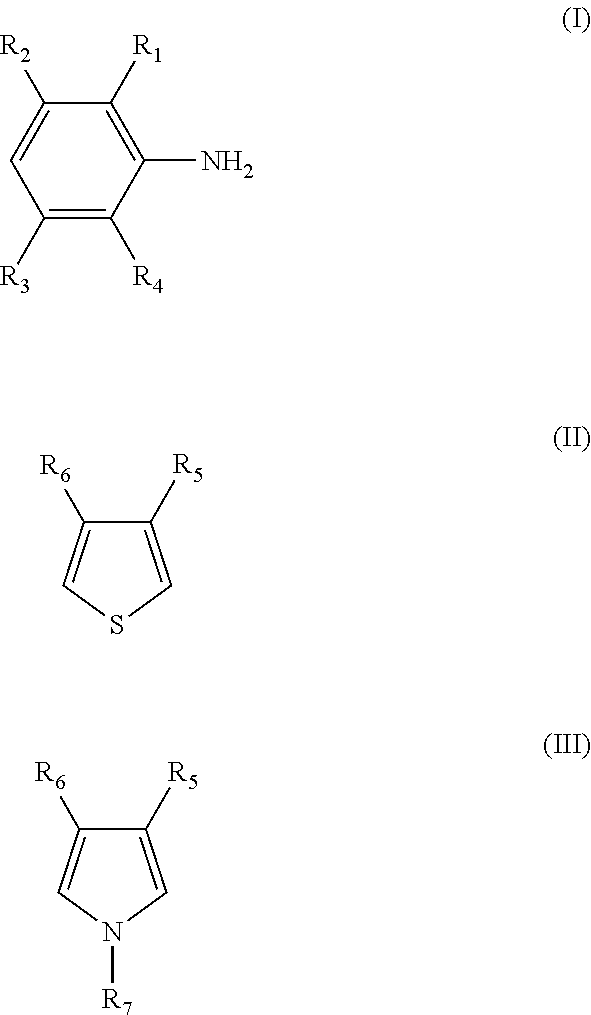

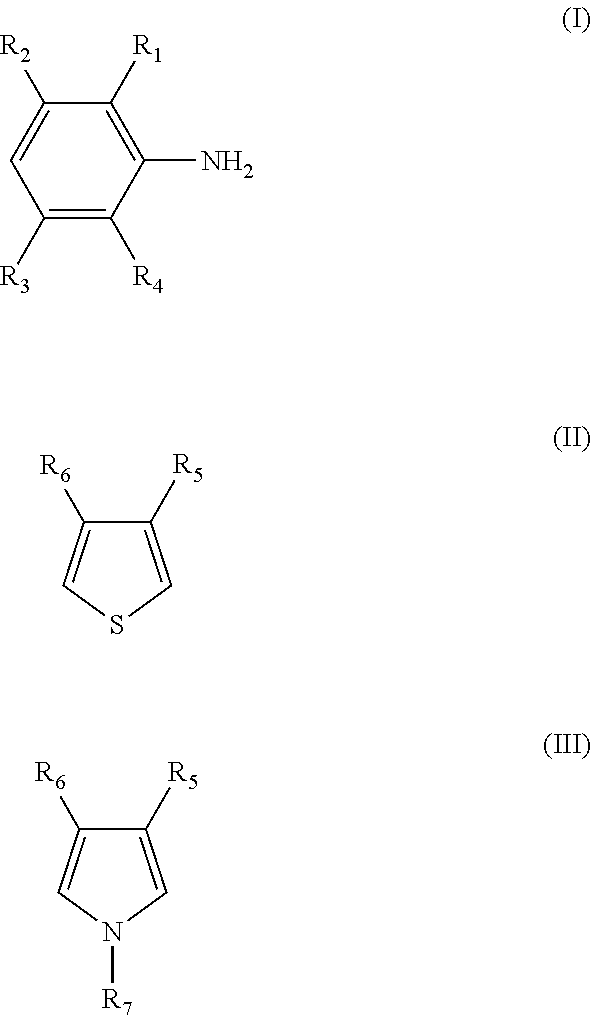

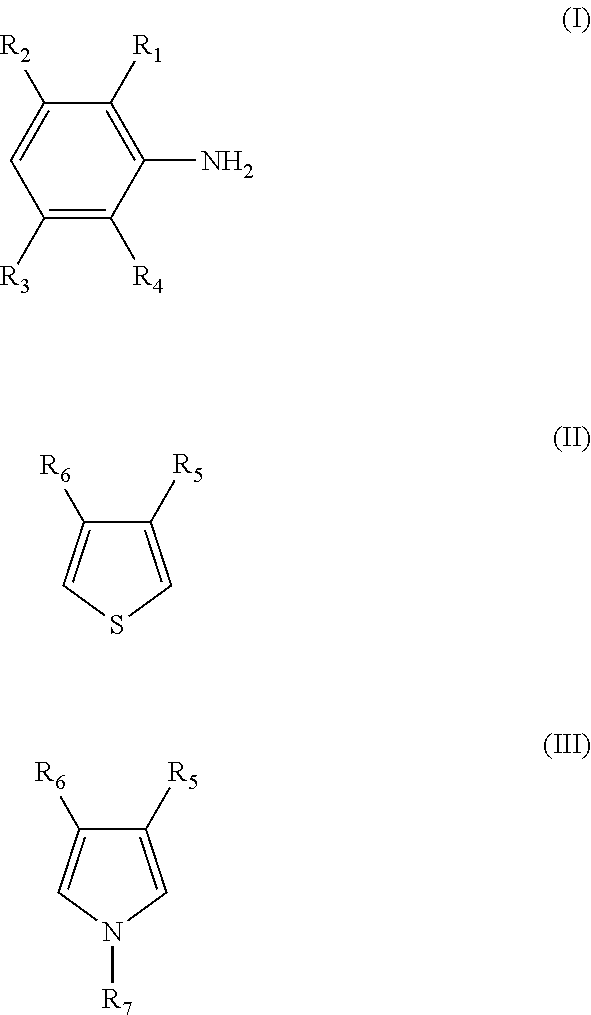

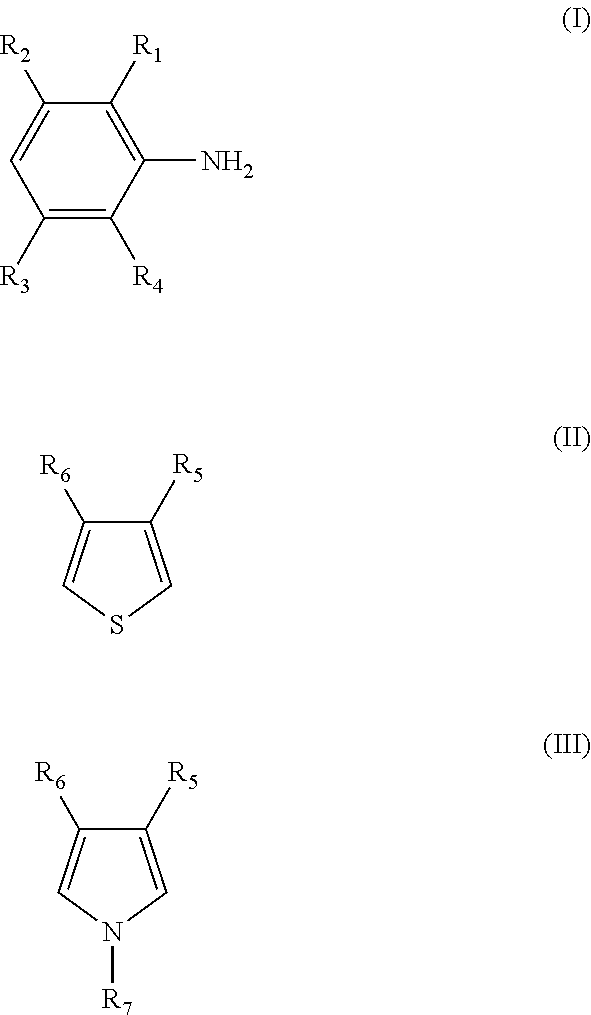

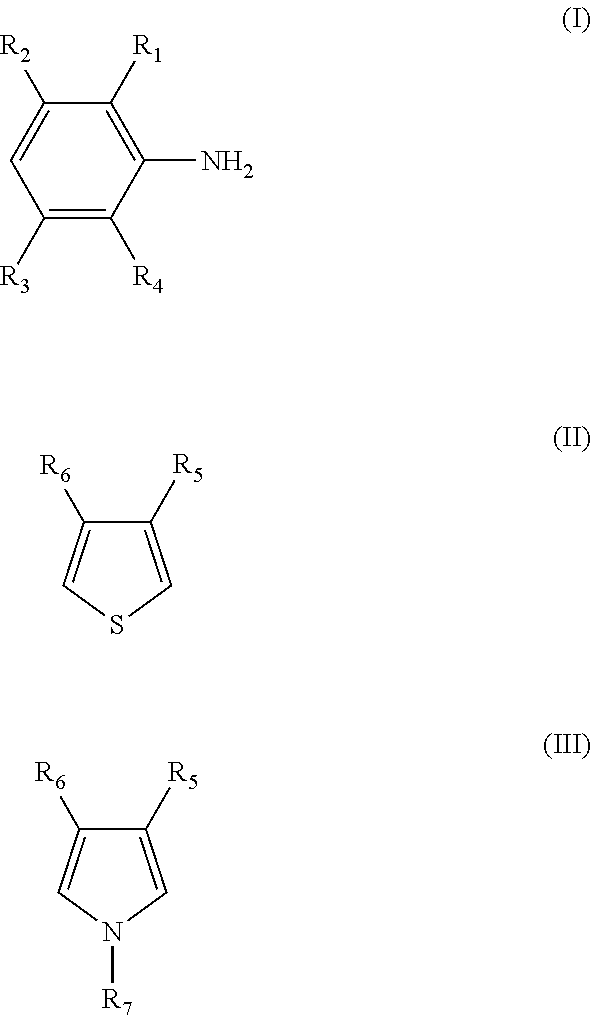

The purpose is to provide a technique which enables various kinds of conductive polymer composition to be dissolved in an organic solvent and to be used to form a conductive membrane on a target portion easily. Provided is a composite conductive polymer composition, a method of manufacturing the same, and a solution obtained by dissolving the composition in an aromatic solvent, ester-based solvent or ketone-based solvent. The composition is obtained by doping a π-conjugated polymer (β) with a polymer compound (A), wherein the polymer compound (A) is obtained from (a-1) a monomer having a sulfonic acid group and a polymerizable vinyl group in an amount of 20 to 60 mol %, (a-2) a polar monomer having a hydrophilic group and a polymerizable vinyl group in an amount of 20 to 60 mol %, and (a-3) another polymerizable monomer in an amount of 20 to 60 mol %, and the n-conjugated polymer (β) is obtained from a monomer compound selected from the formulas (I) to (III)in the formula (I) to (III), at least one of R1 to R4 represent an alkoxy group of C1 to C10, and the other groups represent H, an alkyl group of C1 to C10, or an alkoxy group of C1 to C10; at least one of R5 and R6 represent an alkoxy group of C1 to C10, and the other group represents H, an alkyl group or an alkoxy group of C1 to C10, or R5 and R6 jointly represent an alkylenedioxy group of C1 to C8; and R7 represents H, an alkyl group of C1 to C6, or an aromatic ring group.

Owner:SOKEN CHEM & ENG CO LTD

Underlayer film-forming material for lithography, underlayer film for lithography, and pattern formation method

ActiveUS9316913B2Excellent in heat resistance and etching resistanceImprove the immunityOrganic chemistrySemiconductor/solid-state device manufacturingSolubilityLithographic artist

Material for forming an underlayer film for lithography, which has a high carbon concentration, a low oxygen concentration, a relatively high heat resistance and also a relatively high solvent solubility, and which can be applied to a wet process is disclosed. Material for forming an underlayer film for lithography contains a compound represented by general formula (1).

Owner:MITSUBISHI GAS CHEM CO INC

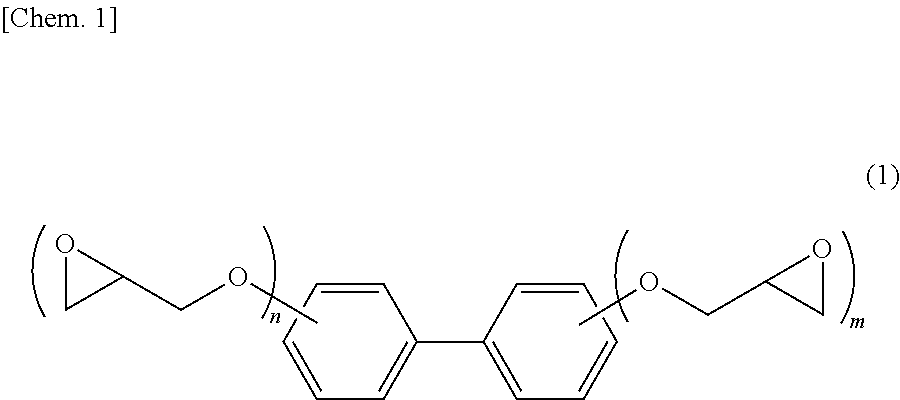

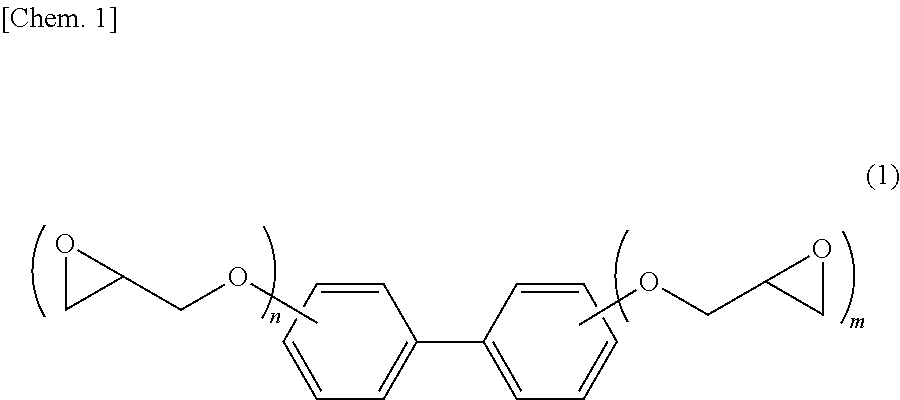

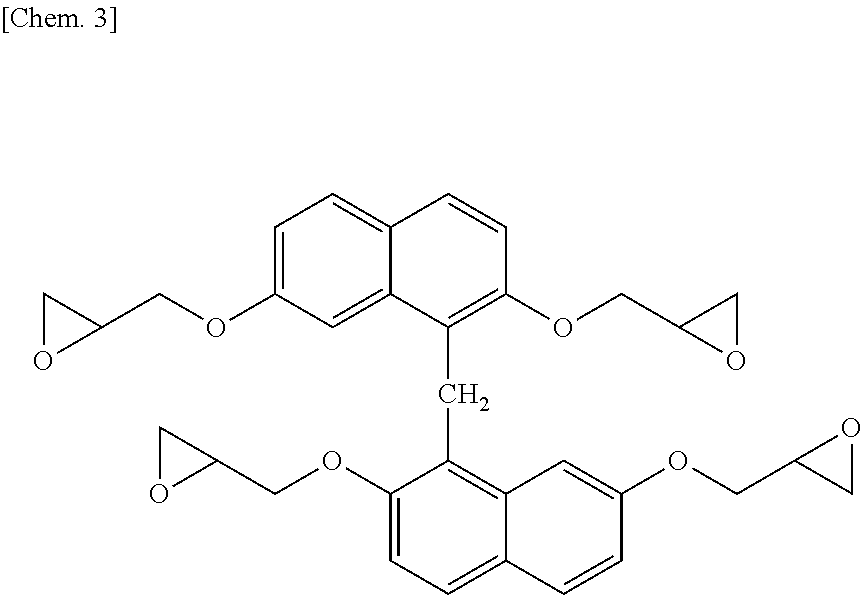

Epoxy resin composition for electronic material, cured product thereof and electronic member

InactiveUS20170158807A1Excellent solvent solubilityLow viscosityNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsEpoxyElectronic component

An epoxy resin composition for electronic material, containing a polyfunctional biphenyl type epoxy resin that is a triglycidyloxybiphenyl or a tetraglycidyloxybiphenyl and at least one of a curing agent and a curing accelerator is provided. Furthermore, the epoxy resin composition for electronic material, further containing a filler, in particular, a thermal conductive filler, is provided. Furthermore, a cured product obtained by curing the epoxy resin composition for electronic material, and an electronic component containing the cured product are provided.

Owner:DAINIPPON INK & CHEM INC

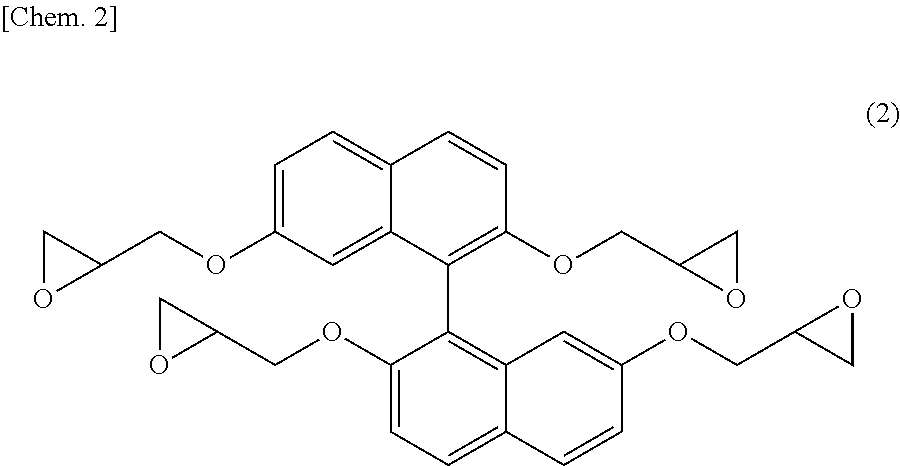

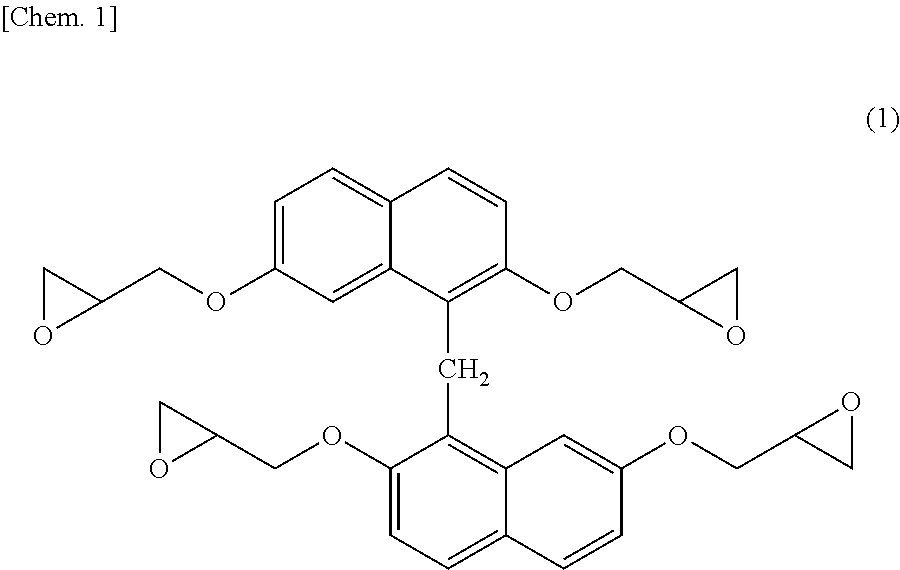

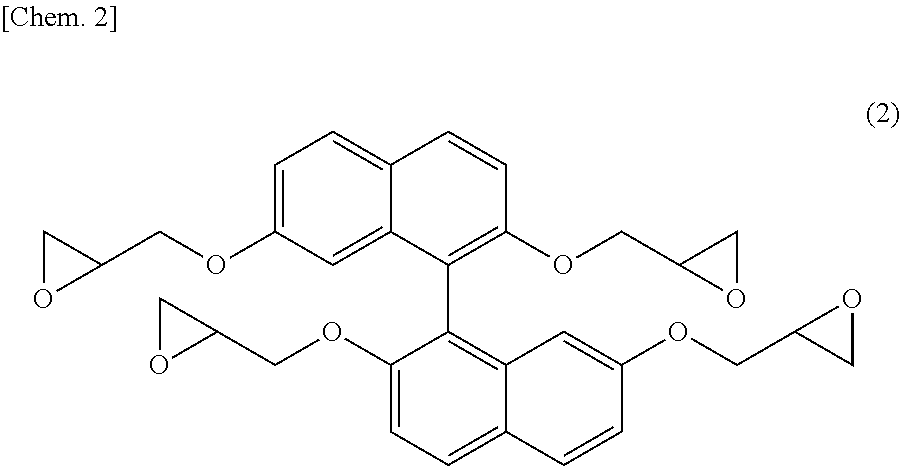

Epoxy resin composition, cured product, heat radiating material, and electronic member

ActiveUS20160122604A1Improve heat resistanceReduce absorptionNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsEpoxySilicon dioxide

The present invention provides an epoxy resin composition including 2,2′,7,7′-tetraglycidyloxy-1,1′-binaphthalene as an epoxy resin (A), and a filler (B). Further, the present invention provides an epoxy resin composition in which the filler (B) in the epoxy resin composition is a thermally conductive filler and an epoxy resin composition in which the filler (B) is silica. Further, the present invention provides a cured product produced by curing the epoxy resin composition of the present invention and a heat dissipation material and an electronic material each including the cured product.

Owner:DAINIPPON INK & CHEM INC

Binder resin compositions, production process and use thereof

InactiveUS7208552B2Delay transitionExcellent solvent solubilityOther chemical processesCoatingsSolubilityPolyolefin

The invention provides a novel binder resin composition with good adherence onto prime materials of polyolefin, poly (vinyl chloride), polycarbonate, PET, ABS and nylon, and also with excellent solvent solubility.A binder resin composition characterized by being chlorinated propylenic random copolymer with weight average molecular weight of 3000 to 250000, wherein propylenic random copolymer with melting point (Tm) measured by differential scanning calorimeter (DSC) of 115 to 165° C. obtained by copolymerizing propylene with other α-olefin in the coexistence of metallocene type catalyst is chlorinated to chlorine content of 10 to 40% by weight, after thermal degradation or directly without thermal degradation, and / or a binder resin composition characterized by containing carboxyl group-containing chlorinated propylenic random copolymer with weight average molecular weight of 30000 to 220000, wherein propylenic random copolymer with melting point (Tm) measured by differential scanning calorimeter (DSC) of 115 to 165° C. obtained by copolymerizing propylene with other α-olefin in the coexistence of metallocene type catalyst is grafted with α,β-unsaturated carboxylic acid or its anhydride in amounts of 0.1 to 20% by weight, after thermal degradation or directly without thermal degradation, and then chlorinated to chlorine content of 10 to 40% by weight, stabilizer and organic solvent.

Owner:NIPPON PAPER IND CO LTD

Composite conductive polymer composition, method of manufacturing the same, solution containing the composition, use of the composition

InactiveUS9058916B2Excellent solvent solubilityImprove solubilityHybrid capacitor electrodesCell electrodesPolymer scienceAromatic solvent

The purpose is to provide a technique which enables various kinds of conductive polymer composition to be dissolved in an organic solvent and to be used to form a conductive membrane on a target portion easily. Provided is a composite conductive polymer composition, a method of manufacturing the same, and a solution obtained by dissolving the composition in an aromatic solvent, ester-based solvent or ketone-based solvent. The composition is obtained by doping a π-conjugated polymer (β) with a polymer compound (A), wherein the polymer compound (A) is obtained from (a-1) a monomer having a sulfonic acid group and a polymerizable vinyl group in an amount of 20 to 60 mol %, (a-2) a polar monomer having a hydrophilic group and a polymerizable vinyl group in an amount of 20 to 60 mol %, and (a-3) another polymerizable monomer in an amount of 20 to 60 mol %, and the n-conjugated polymer (β) is obtained from a monomer compound selected from the formulas (I) to (III)in the formula (I) to (III), at least one of R1 to R4 represent an alkoxy group of C1 to C10, and the other groups represent H, an alkyl group of C1 to C10, or an alkoxy group of C1 to C10; at least one of R5 and R6 represent an alkoxy group of C1 to C10, and the other group represents H, an alkyl group or an alkoxy group of C1 to C10, or R5 and R6 jointly represent an alkylenedioxy group of C1 to C8; and R7 represents H, an alkyl group of C1 to C6, or an aromatic ring group.

Owner:SOKEN CHEM & ENG CO LTD

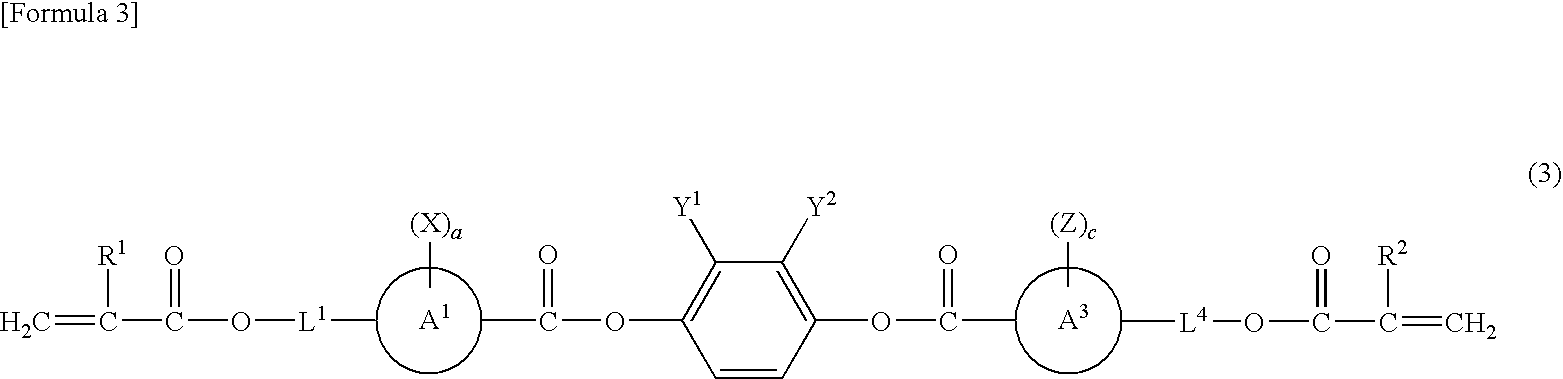

Polymerizable composition

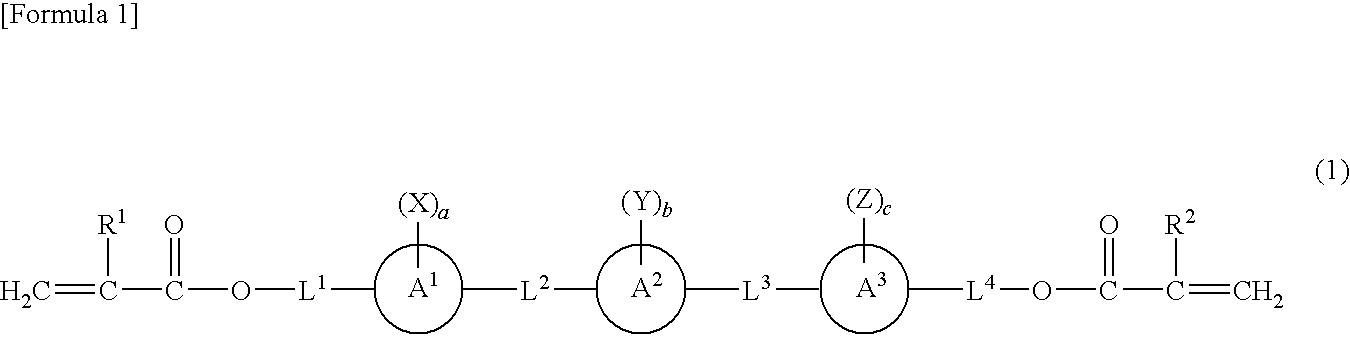

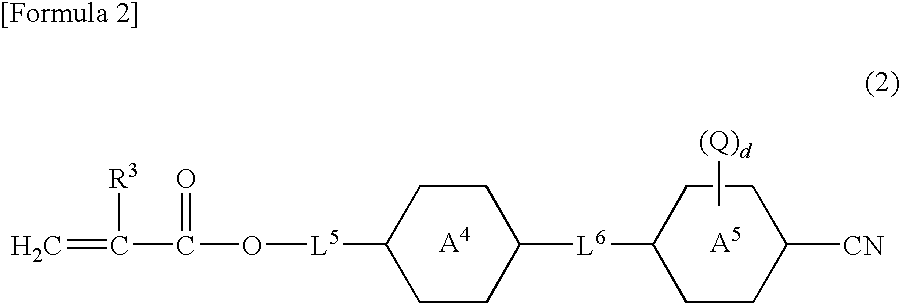

ActiveUS20100090163A1Excellent solvent solubilityExcellent optical propertiesLiquid crystal compositionsPolarising elementsMeth-Stereochemistry

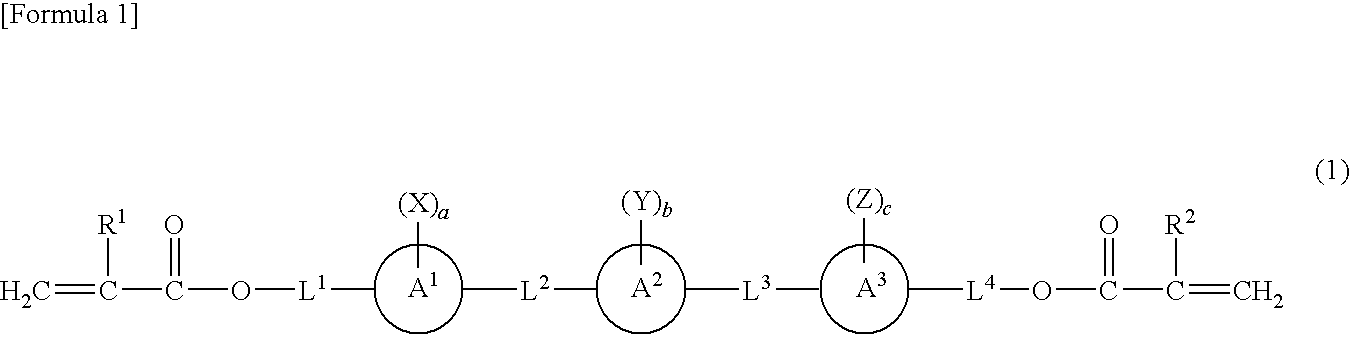

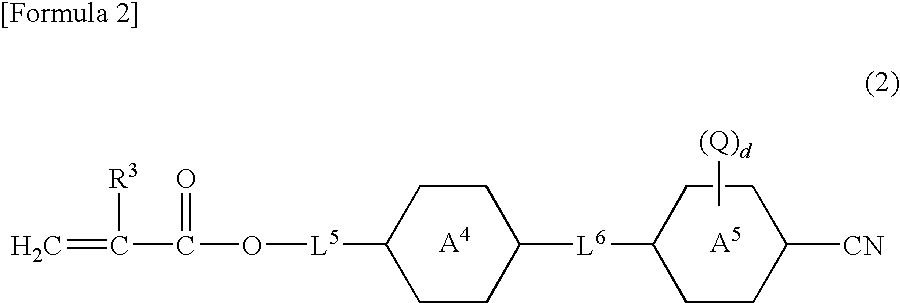

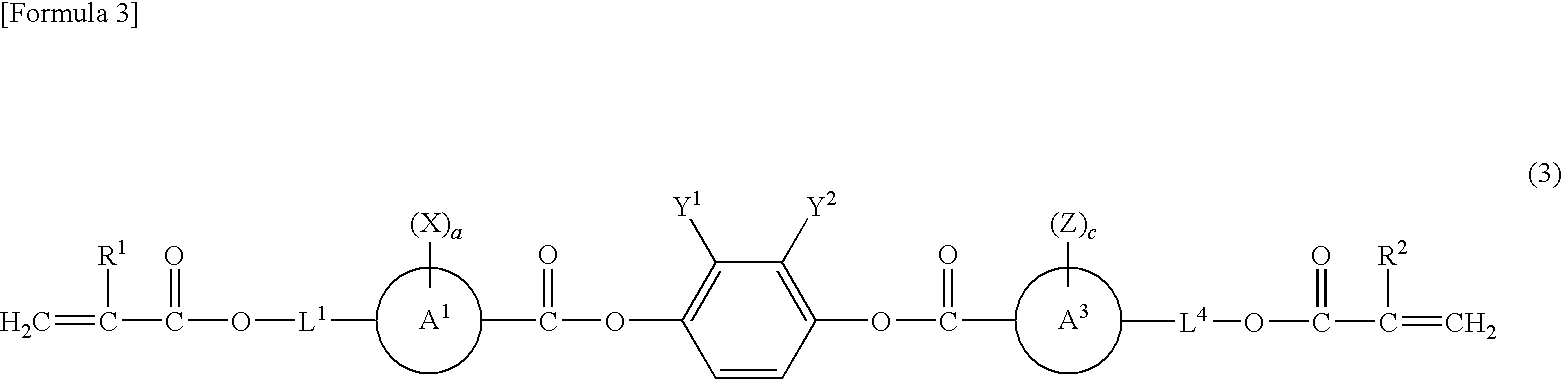

A polymerizable composition comprising a bifunctional (meth)acrylate compound represented by general formula (1) and a monofunctional (meth)acrylate compound having a nitrile group at the terminal thereof represented by general formula (2). The mass ratio of them (the former / the latter) is from 90 / 10 to 40 / 60.

Owner:ADEKA CORP +1

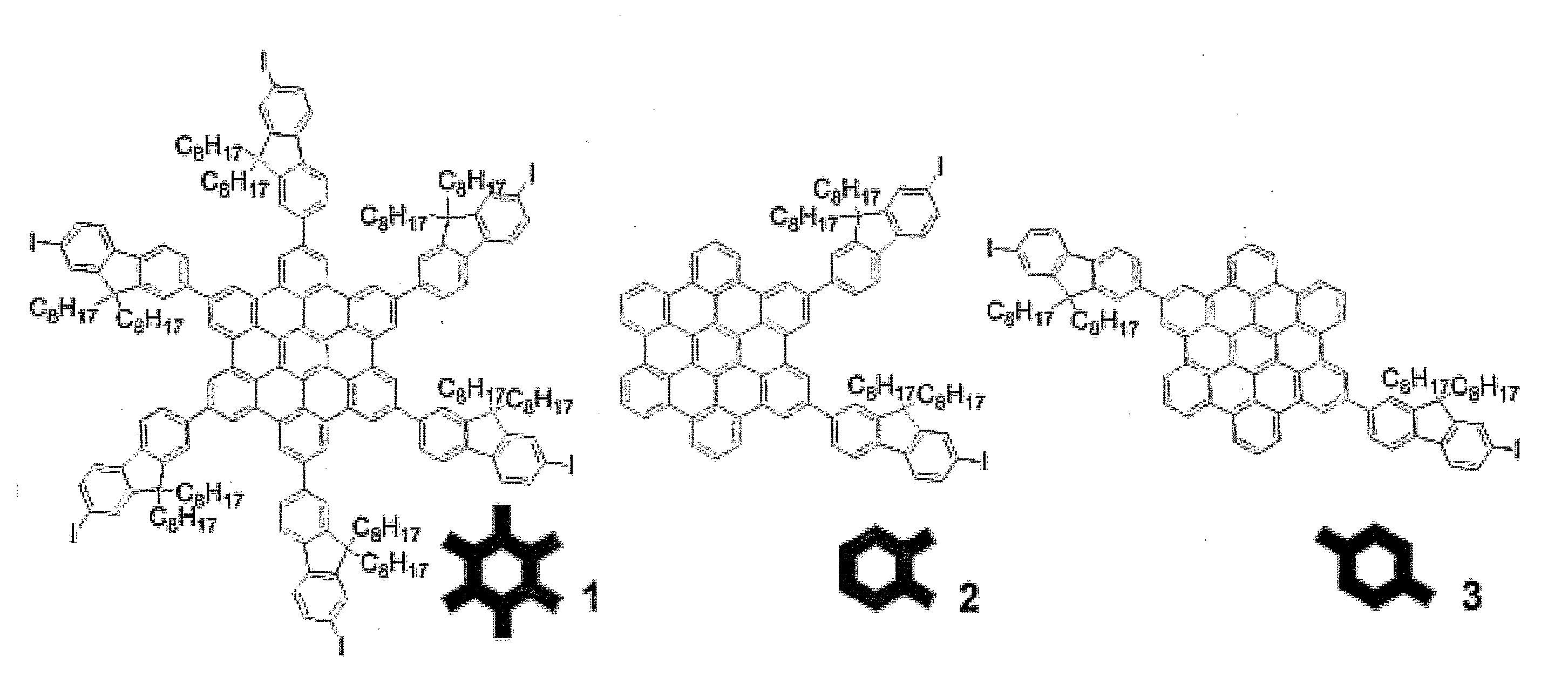

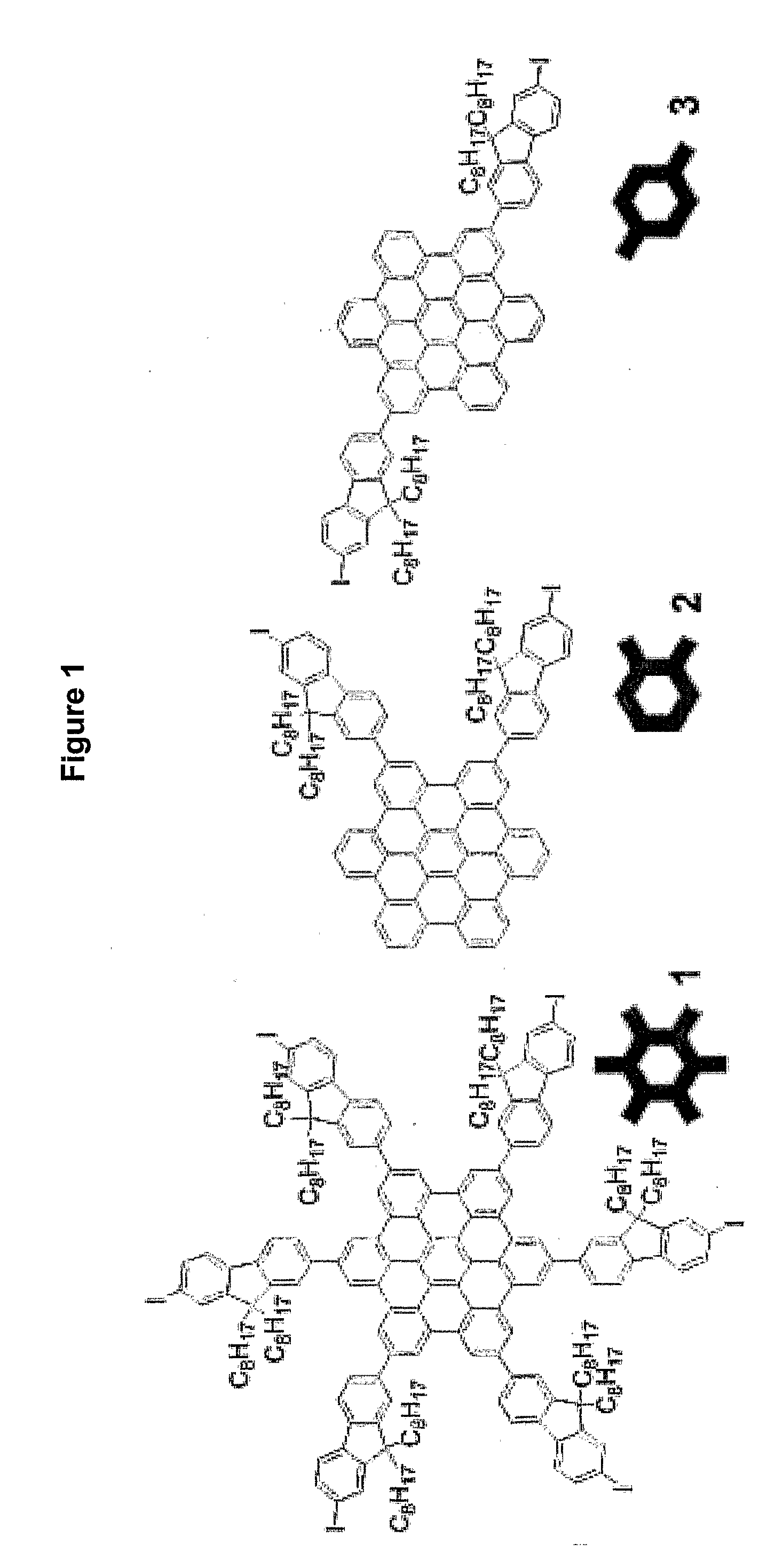

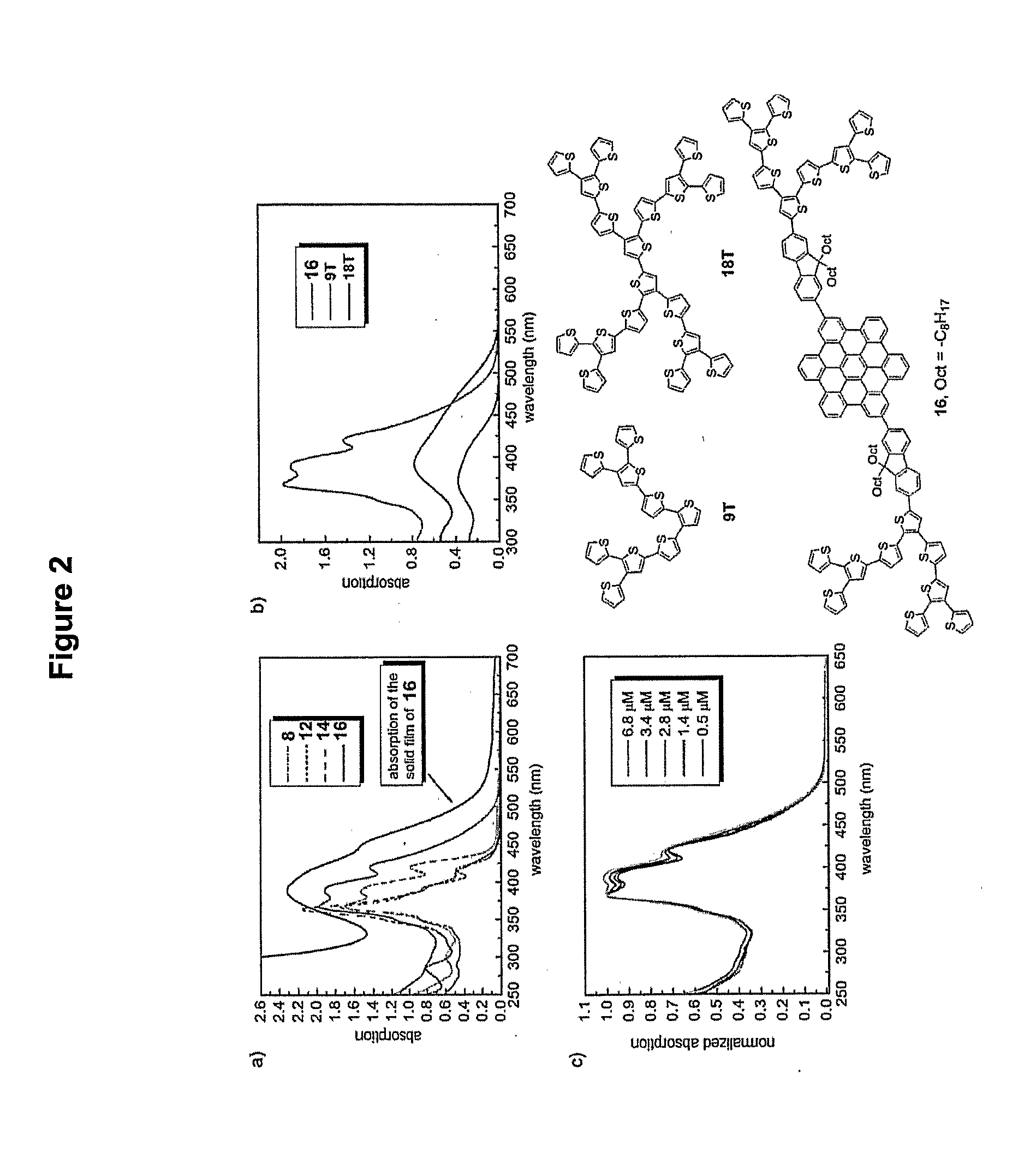

Novel compounds, derivatives thereof and their use in heterojunction devices

InactiveUS20120024382A1Avoid smallEasily-functionalised terminusSilicon organic compoundsCarbamic acid derivatives preparationOrganic filmHeterojunction

The invention relates to novel polyaromatic and polyheteroaromatic compounds and derivatives thereof. The compounds display high solubility in organic solvents. A further aspect of the invention relates to the use of the novel compounds in the fabrication of organic film based heterojunction devices. In one form the devices display high conversion efficiencies in solar cell applications.

Owner:UNIVERSITY OF MELBOURNE +1

Modified polyolefin resin and uses thereof

InactiveUS20100004383A1Maintain good propertiesExcellent solvent solubilitySpecial tyresGraft polymer adhesivesPolymer sciencePolyolefin

It is an object of the present invention to provide a modified polyolefin resin adhesive agent which is excellent in adhesiveness to a nonpolar substrate, particularly a poorly adhesive polyolefin substrate to which no surface treatment has been given and to a polar substrate, develops the excellent adhesiveness by drying or thermal compression bonding at relatively low temperature, and exhibits a low tack. That is, the present invention provides the modified polyolefin resin obtained by modifying a polyolefin resin with (A) a polarity imparting agent which is at least one selected from chlorine, unsaturated carboxylic acid, derivatives and anhydrides of unsaturated carboxylic acid and radical polymerizable monomers; and (B) an ethylene-α-olefin copolymer having an unsaturated bond at one end, and use of said modified polyolefin resin as an aqueous resin composition or an organic solvent resin composition.

Owner:NIPPON PAPER IND CO LTD

Slushing compound lower-layer membrane monomer and composition as well as patterning method

ActiveCN110041345AIncreased etch resistanceImprove heat resistanceOrganic chemistryOriginals for photomechanical treatmentSolubilityResist

The invention belongs to the field of photoetching, and particularly relates to a slushing compound lower-layer membrane monomer and composition as well as a patterning method. The slushing compound lower-layer membrane composition contains a slushing compound lower-layer membrane monomer shown in the formula (I), an aromatic polymer and a solvent, in the formula (I), Ar2 represents arylidene withthe carbon atomic number being 6-30, and R1 and R2 independently represent alkyl with the carbon atomic number being 1-6 or aryl with the carbon atomic number being 6-30. The slushing compound lower-layer membrane composition provided by the invention has the outstanding corrosion resistance, heat resistance, solvent solubility, gap filling feature and planarization feature. In addition, the slushing compound lower-layer membrane composition provided by the invention can have self cross-linking reaction through heating under the condition that no solidifying reaction additive is adopted, andgenerates no gas in the solidifying process, and accordingly can effectively prevent pollution problem of the slushing compound lower-layer membrane and equipment.

Owner:福建泓光半导体材料有限公司

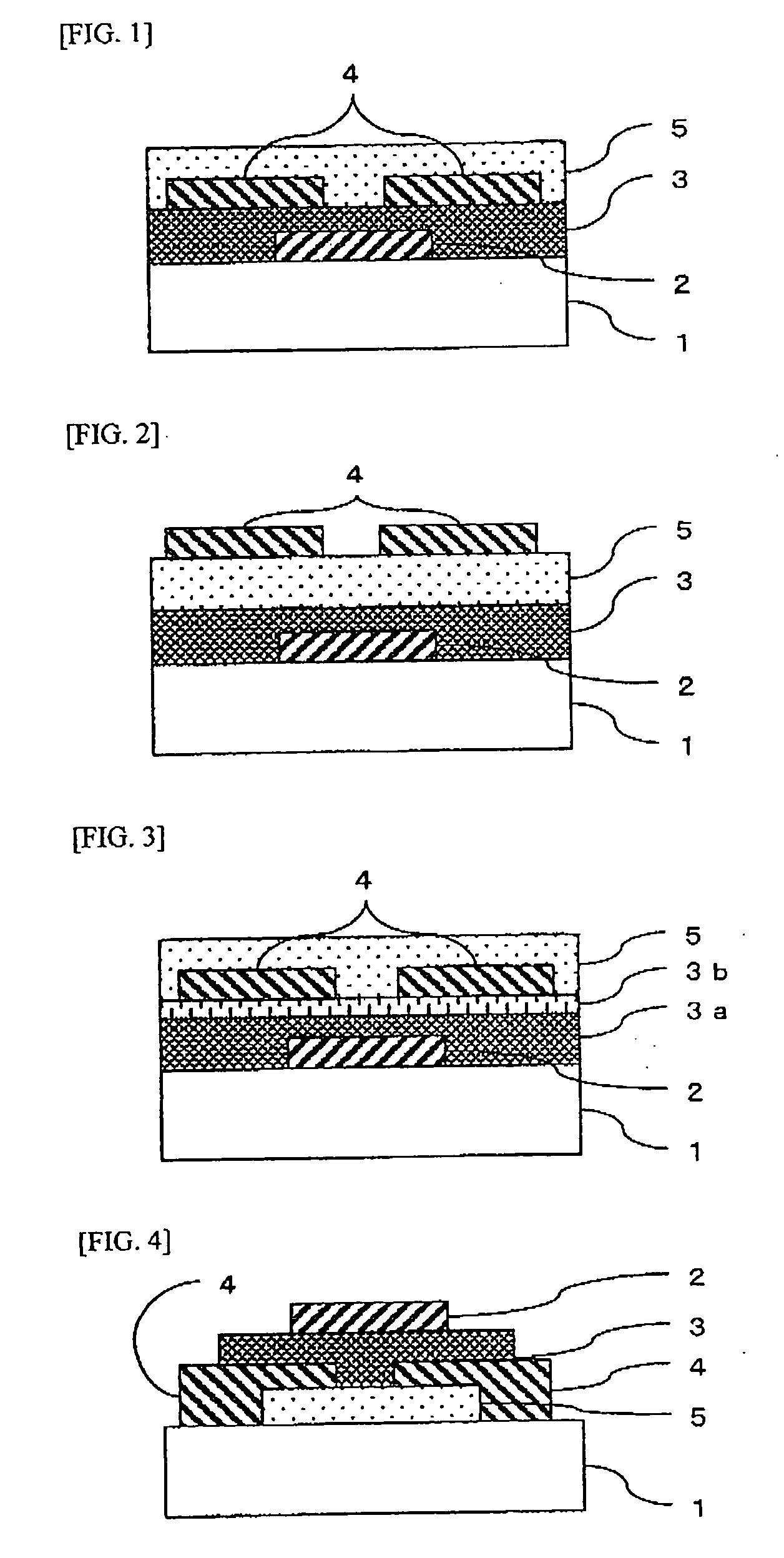

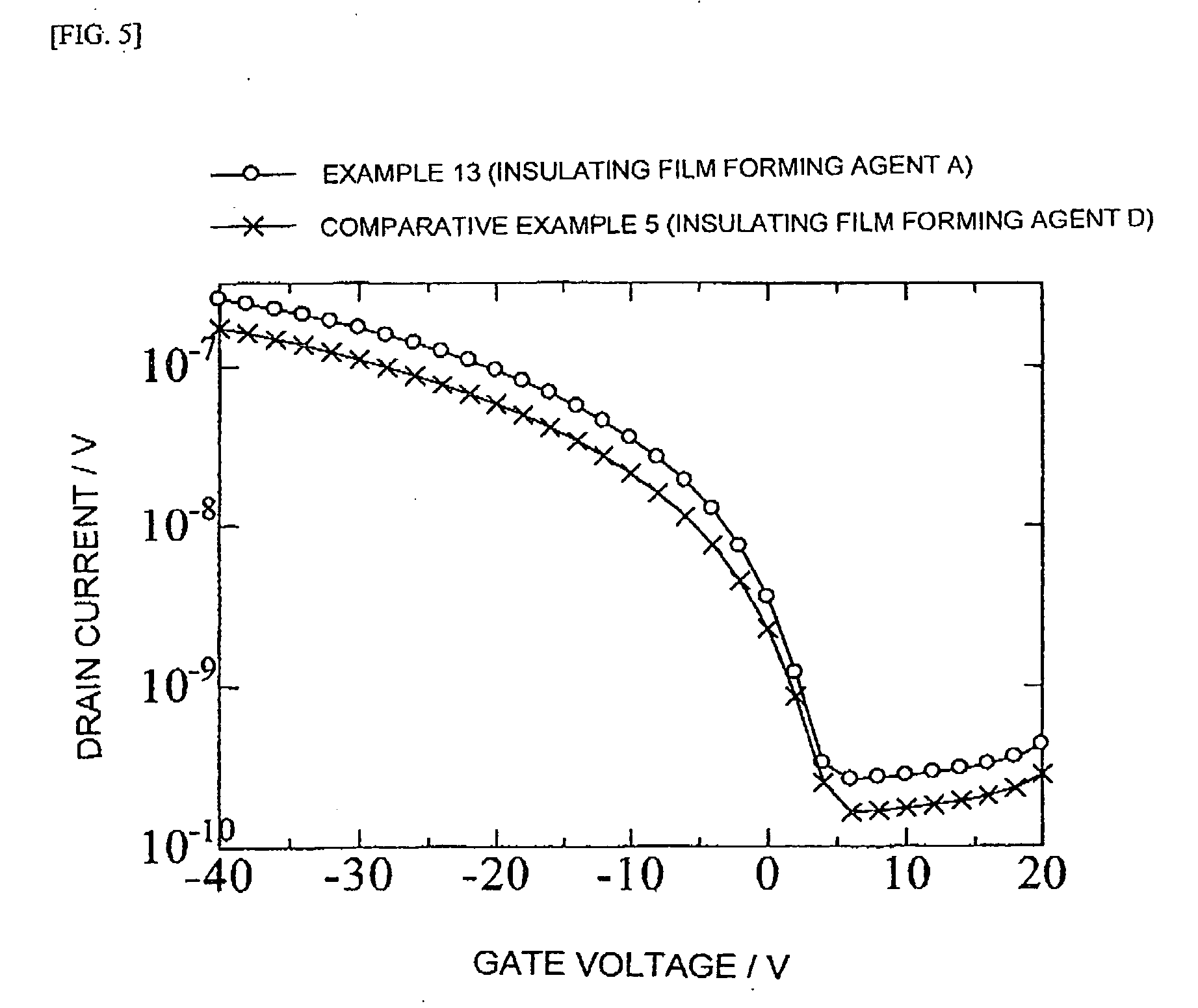

Gate insulating film forming agent for thin-film transistor

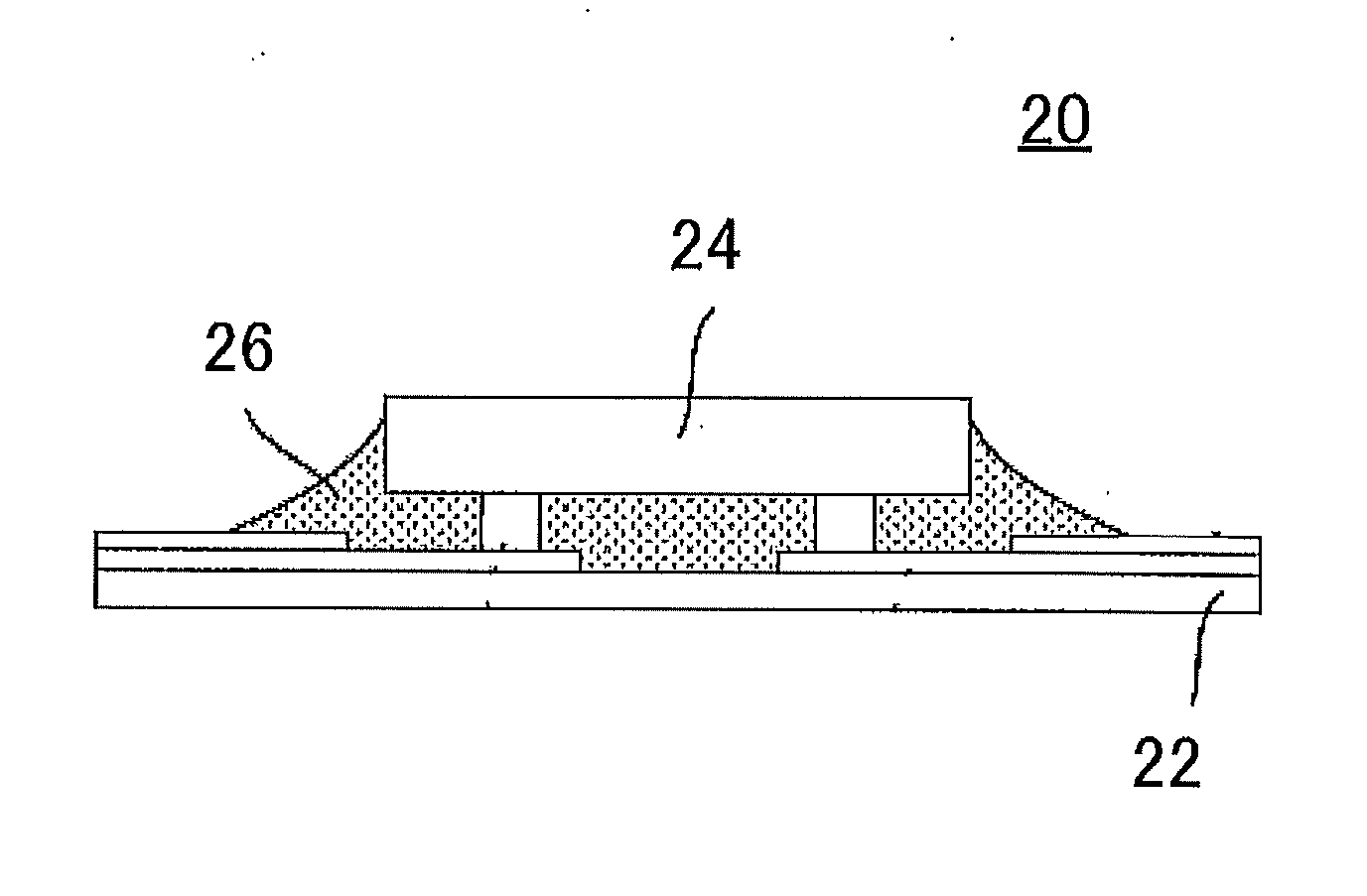

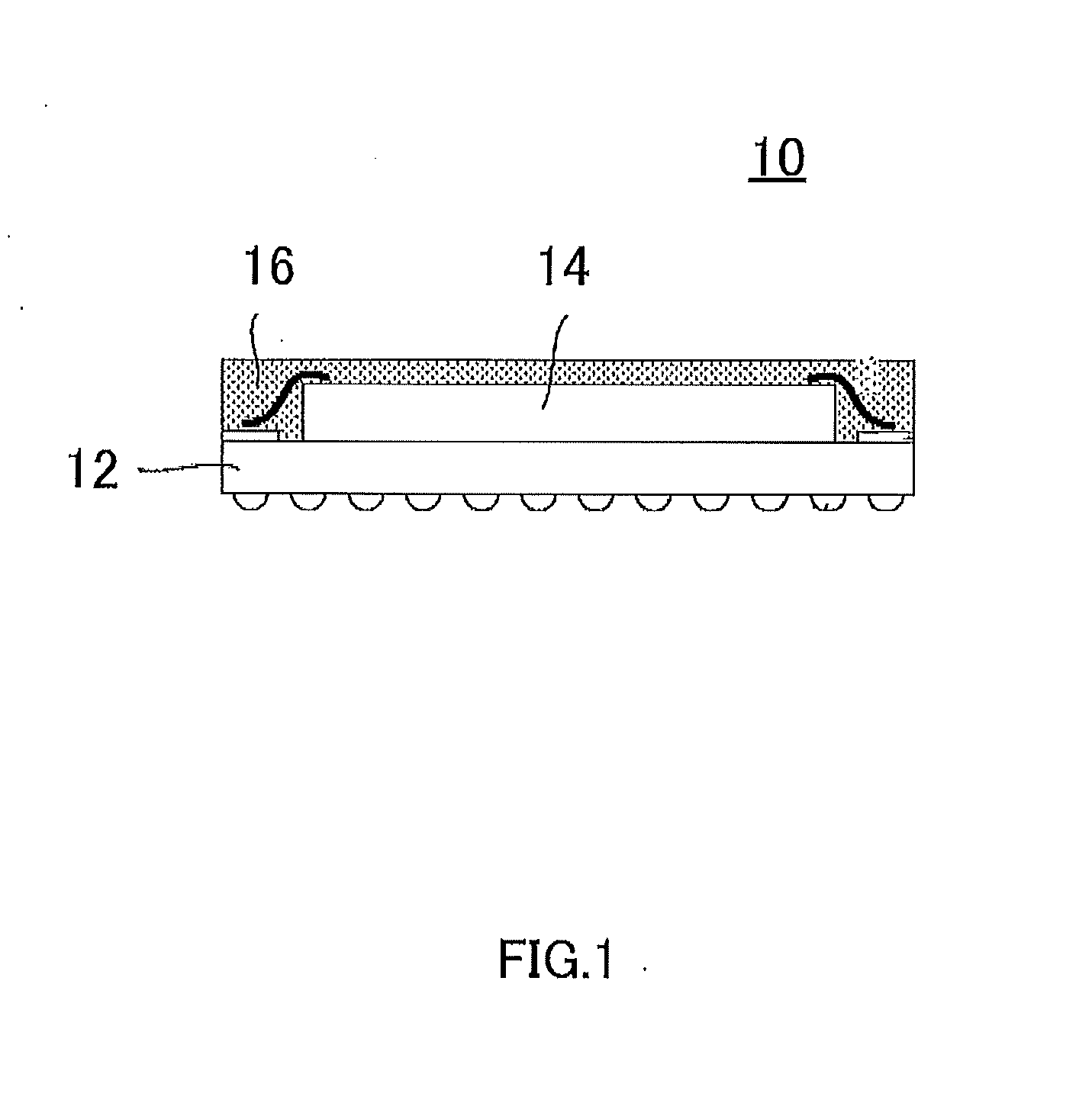

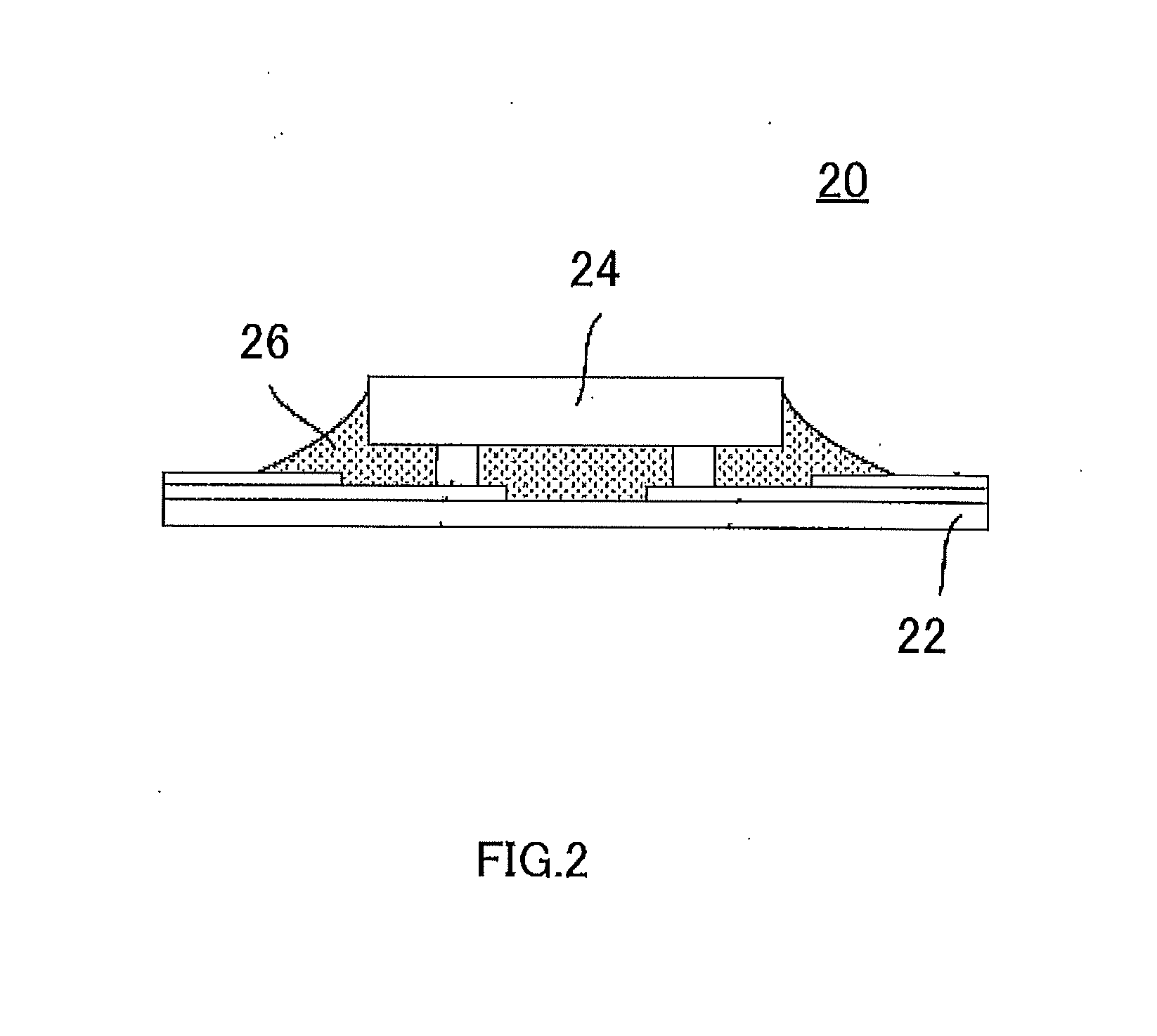

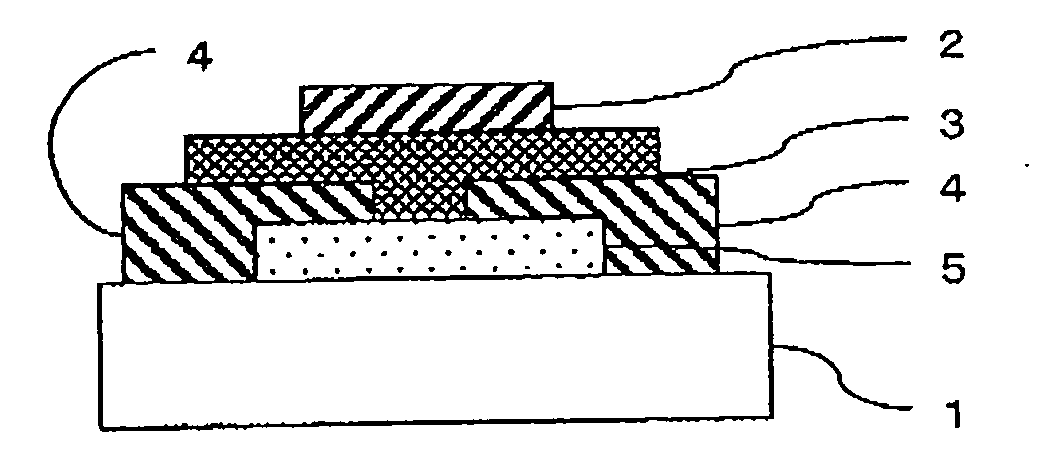

ActiveUS20100133518A1Readily solubleExcellent solvent solubilityFinal product manufactureSolid-state devicesEngineeringSolvent

There is provided a novel gate insulating film forming material in consideration of not only initial electric properties immediately after the production of a gate insulating film, but also electric properties after other steps are performed while producing a thin-film transistor using the gate insulating film, and even reliability in the electric properties of the produced element. A gate insulating film forming agent for a thin-film transistor comprising an oligomer compound or a polymer compound, both of which contain a repeating unit having a triazinetrione ring containing a hydroxyalkyl-containing group as a substituent on a nitrogen atom, and a solvent; a gate insulating film produced from the gate insulating film forming agent; a thin-film transistor having the gate insulating film; and a method for producing the gate insulating film or thin-film transistor.

Owner:NISSAN CHEM IND LTD

Graphene composite ultra-high molecular weight polyethylene fiber and preparation method thereof

InactiveUS20190211478A1Improve thermal stabilityAvoid influenceInorganic material artificial filamentsFilament/thread formingFiberGlass fiber

The present invention provides a composite ultra-high molecular weight polyethylene fiber and a preparation method thereof, wherein the method comprises mixing glass fiber, graphene slurry, UHMWPE powder and white oil, and then swelling to a molten state, then cooling into a gel-spun, and finally making the fiber from the gel-spun. The method of the present disclosure not only can solve the problem that the glass fiber has poor dispersibility in the case of high viscoelasticity of the ultra-high molecular weight polyethylene, but also can improve the cut resistance of the ultra-high molecular weight polyethylene fiber on the basis of ensuring the flexibility of the yarn.

Owner:JIANGSU HANVO SAFETY PROD CO LTD

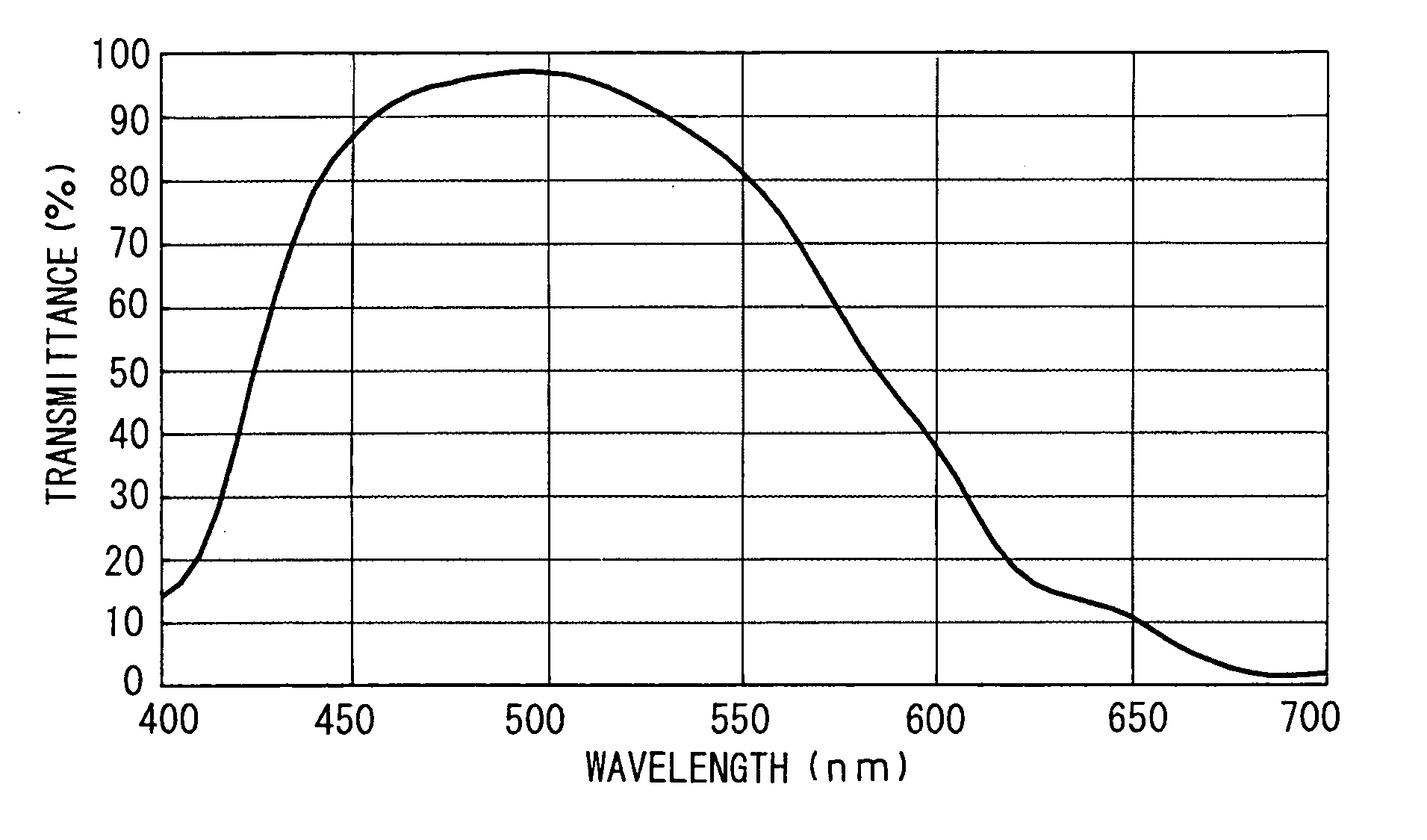

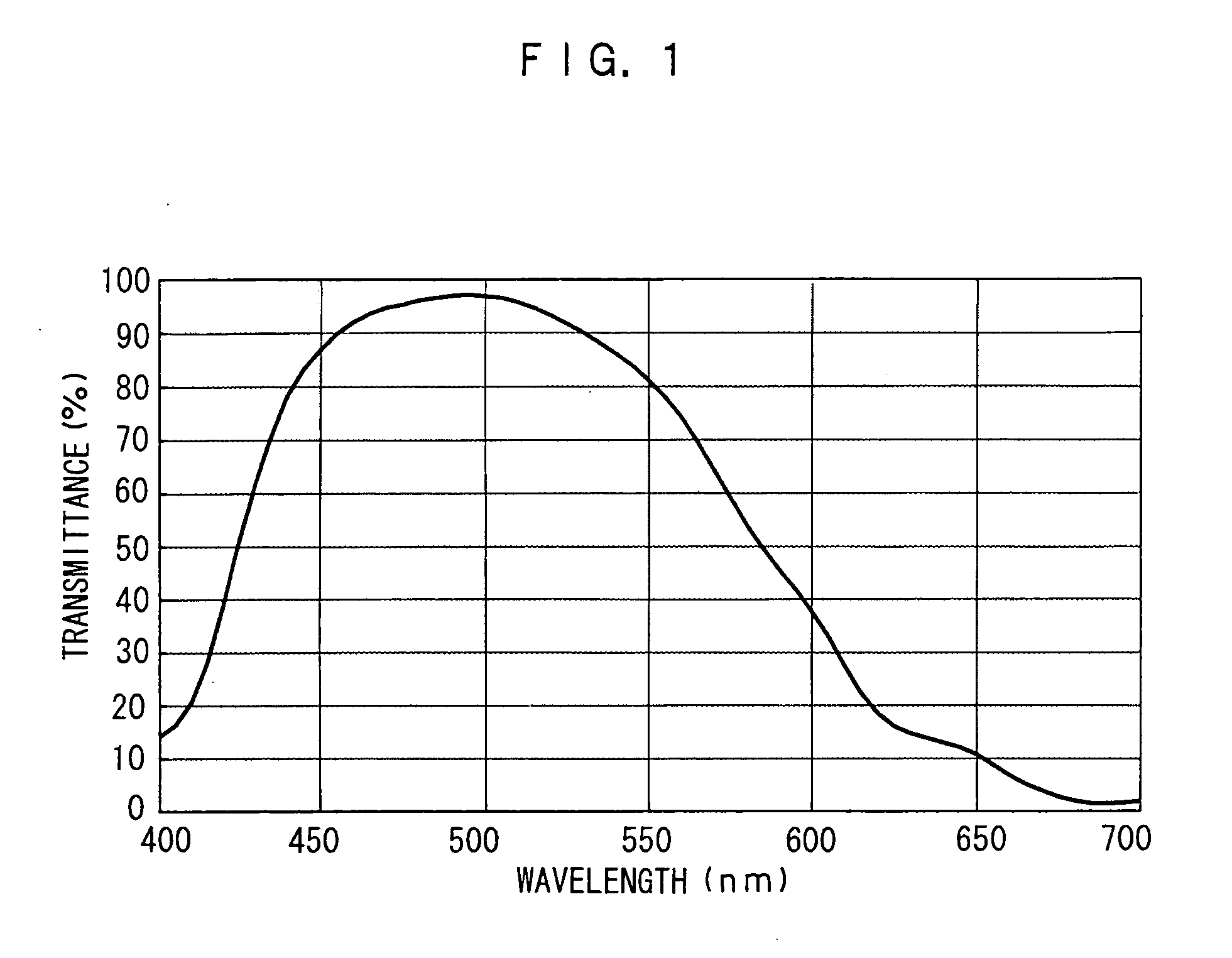

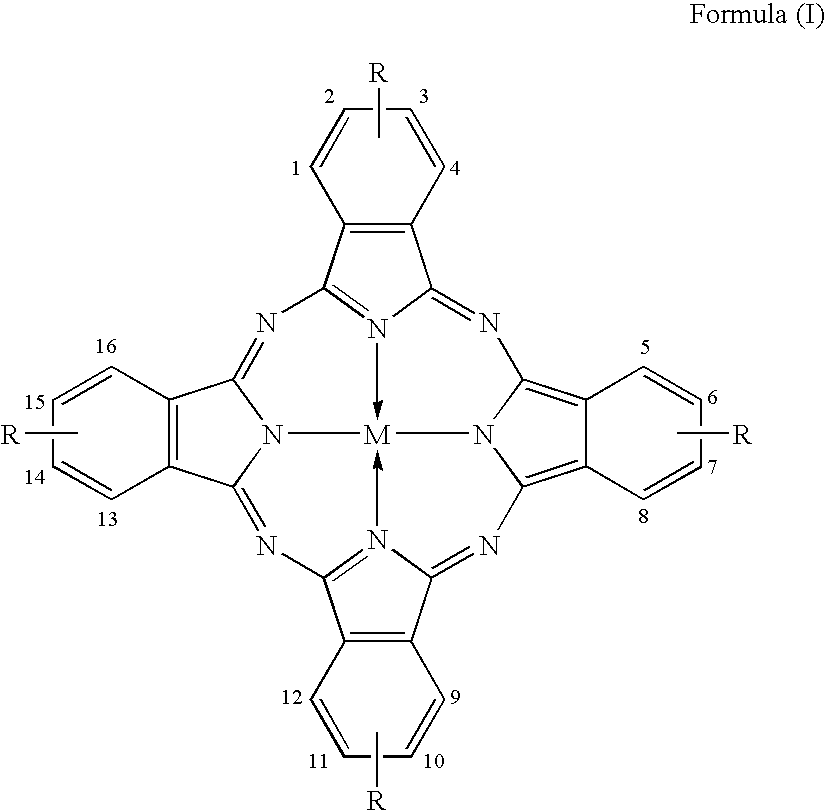

Dye-containing curable composition, color filter and method of producing the color filter

InactiveUS20050208394A1Improve featuresExcellent solvent solubilityWater/sewage treatment by irradiationSpecific water treatment objectivesMetal chlorideHydrogen atom

A dye-containing curable composition including at least (A) an alkali-soluble resin, (B) a dye, and (C) a photosensitive compound, the dye being a phthalocyanine compound represented by the following Formula (I): wherein M represents a metal atom, a metal oxide, a metal chloride, or a hydrogen atom, R represents a heterocyclic group containing, as heteroatoms, two or more nitrogen atoms or one or more of each of nitrogen and sulfur atoms, and the four R's are respectively bonded to a carbon atom at the α-positions (in Formula (I), 1 or 4, 5 or 8, 9 or 12, and 13 or 16) or at the β-positions (in Formula (I), 2 or 3, 6 or 7, 10 or 11, and 14 or 15) in a phthalocyanine nucleus at the same time.

Owner:FUJIFILM CORP +1

Resist base material, resist composition and method for forming resist pattern

ActiveUS20180107113A1Reduce resolutionHinder developabilityOrganic chemistryPhotomechanical coating apparatusResistMonomer

Owner:MITSUBISHI GAS CHEM CO INC

Polymerizable composition

ActiveUS7931825B2Excellent solvent solubilityExcellent optical propertiesLiquid crystal compositionsPolarising elementsStereochemistryAcrylate

A polymerizable composition comprising a bifunctional (meth)acrylate compound represented by general formula (1) and a monofunctional (meth)acrylate compound having a nitrile group at the terminal thereof represented by general formula (2). The mass ratio of them (the former / the latter) is from 90 / 10 to 40 / 60.

Owner:ADEKA CORP +1

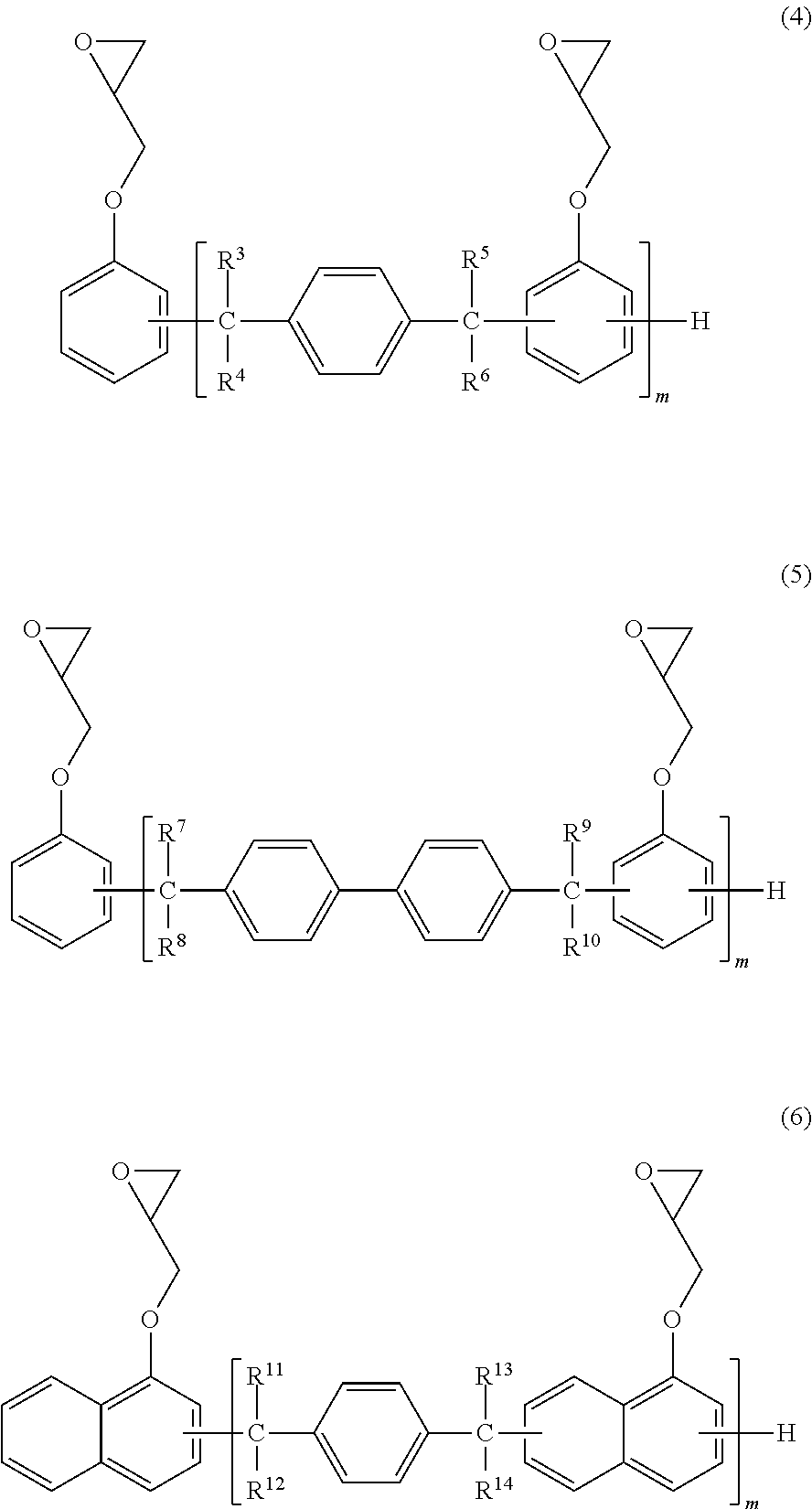

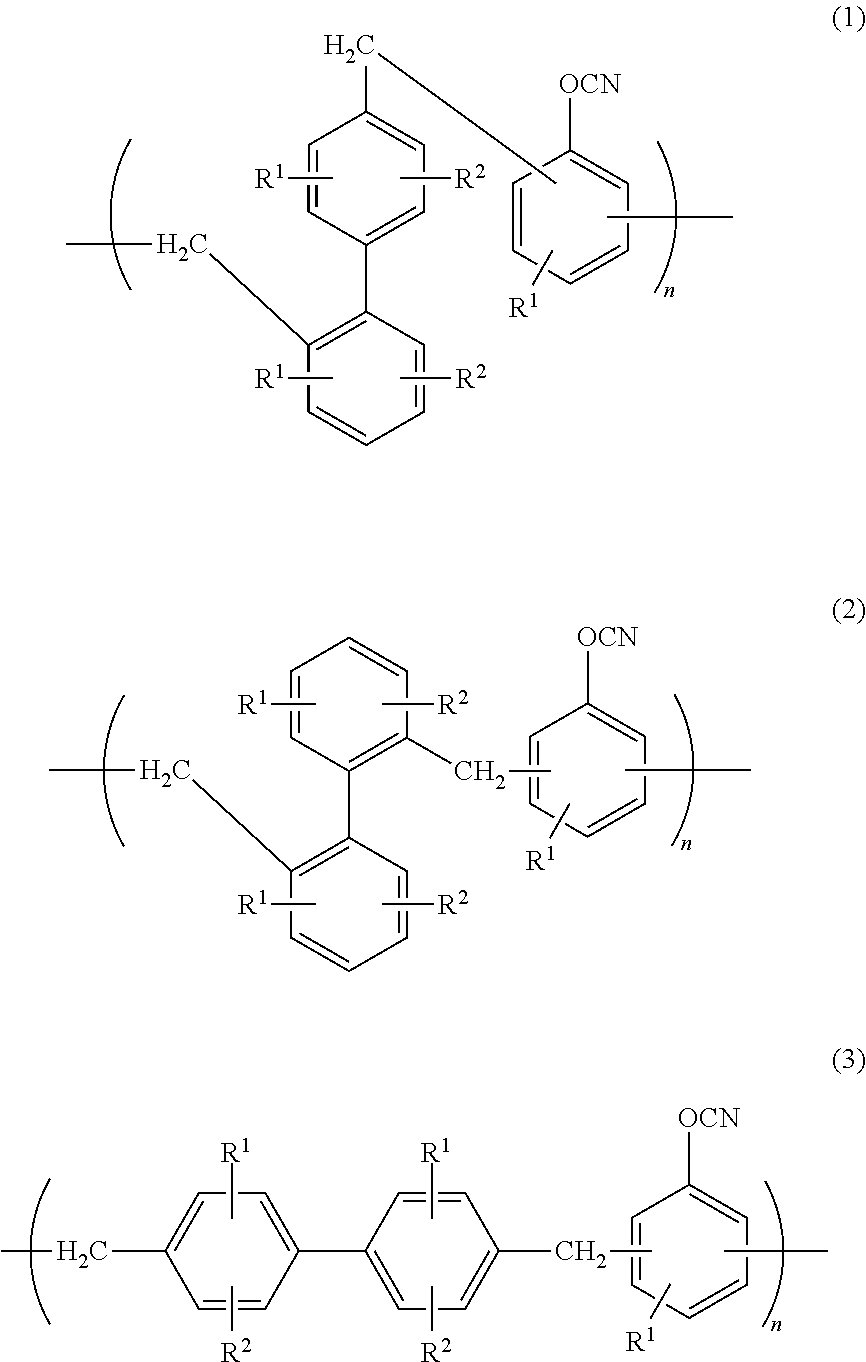

Resin composition, prepreg, and laminate

ActiveUS20140377565A1Excellent solvent solubilityEasy to operateSynthetic resin layered productsThin material handlingElectrical conductorMetal foil

A resin composition of the present invention contains a mixture (A) of at least two of cyanate ester compounds selected from the group consisting of cyanate ester compounds (A1) to (A3) having a specific structural unit, an epoxy resin (B), and an inorganic filler (C). A prepreg of the present invention is obtained by impregnating a base material with the resin composition or applying the resin composition to a base material. Furthermore, a metal foil-clad laminate of the present invention is the laminate comprising the prepreg. Furthermore, a printed wiring board of the present invention contains an insulating layer and a conductor layer formed on a surface of the insulating layer, in which the insulating layer contains the resin composition.

Owner:MITSUBISHI GAS CHEM CO INC

Carbodylated cellulose esters

InactiveCN1295581AHigh solid contentExcellent solvent solubilityCellulose coatingsInksSolubilityAcetic acid

A process for preparing a carboxylated cellulose ester from oxidized cellulose is described. The carboxylated cellulose esters have improved solvent solubility and coating resin compatibility when compared to cellulose esters made from regular grade cellulose. The process comprises activating the oxidized cellulose with water. The activated oxidized cellulose is then dehydrated by displacing the water with acetic acid and optionally displacing at least some of the acetic acid with butyric acid or propionic acid. After dehydration the activated cellulose is reacted with an esterifying reagent in the presence of a catalyst at about 0 DEG C. The temperature is gradually increased to a level sufficient to complete reaction and to obtain an intrinsic viscosity ranging from about 0.2 to about 1.6 dl / g. The reacted solution is then hydrolyzed to obtain a hydroxyl content ranging from about 0.05 to about 1.0. The catalyst is neutralized with a neutralizing agent and the solution is optionally filtered and the carboxylated cellulose ester is then precipitated with a precipitating agent. The invention also relates to carboxylated cellulose esters prepared by the process described above as well as high solids coating compositions containing carboxylated cellulose esters made by the above process.

Owner:EASTMAN CHEM CO

Epoxy resin composition, cured product, heat radiating material, and electronic member

ActiveUS10047256B2Improve heat resistanceReduce absorptionNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsEpoxyPolymer science

The present invention provides an epoxy resin composition including 2,2′,7,7′-tetraglycidyloxy-1,1′-binaphthalene as an epoxy resin (A), and a filler (B). Further, the present invention provides an epoxy resin composition in which the filler (B) in the epoxy resin composition is a thermally conductive filler and an epoxy resin composition in which the filler (B) is silica. Further, the present invention provides a cured product produced by curing the epoxy resin composition of the present invention and a heat dissipation material and an electronic material each including the cured product.

Owner:DIC CORPORATION

Compound, dispersant and toner

ActiveUS9505723B2Excellent solvent solubilityImprove suppression propertiesOrganic chemistryTransportation and packagingSolubilitySolvent

The present invention provides a dispersant excellent in the solubility to a solvent, the adsorption power to a coloring material, and the coloring material dispersibility, and reduced in the self-coloring property, a compound and a polymerizable compound for preparing the dispersant, and a toner using the dispersant.The dispersant has a structure in which a structure represented by the following specific formula (3) or a tautomer thereof is bonded with a polymer, and the toner contains the dispersant.

Owner:CANON KK

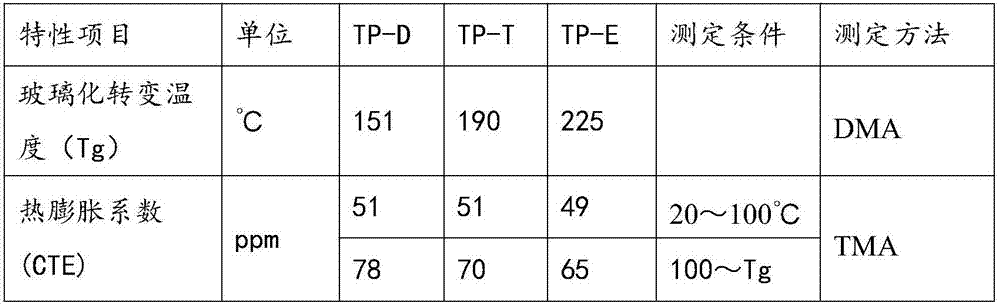

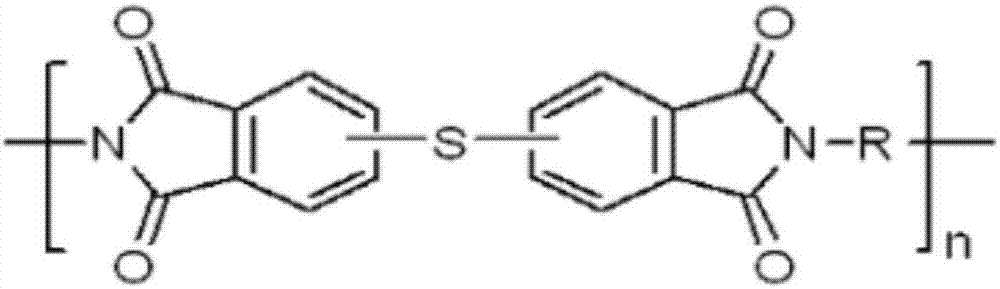

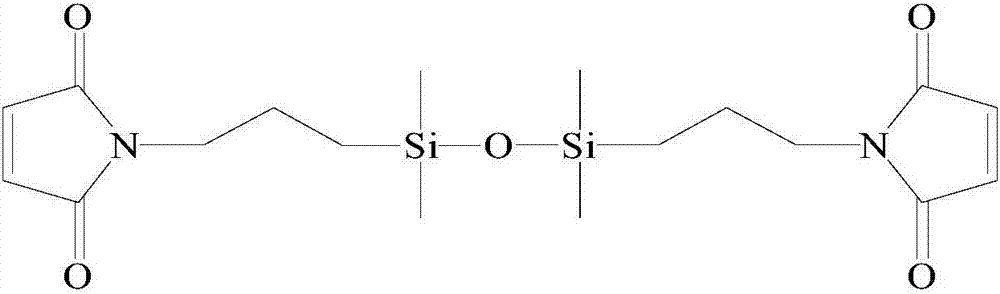

Semi-interpenetrating polymer network polyimide resin composition and film-like adhesive prepared from same

ActiveCN106905914AImprove performanceHigh affinityNon-macromolecular adhesive additivesFilm/foil adhesivesThermoplasticMoisture absorption

The invention relates to semi-interpenetrating polymer network polyimide resin composition and a film-like adhesive prepared from the same. The resin composition is a resin composition adhesive solution comprising polythioetherimide resin, a BMI (bismaleimide) prepolymer containing siloxane, filler and an adhesion promoter, and a semi-interpenetrating polymer network polyimide adhesive film is prepared with a tape casting method. A thermoplastic and thermosetting semi-interpenetrating polymer network structure is formed in the polyimide adhesive film, the advantageous properties of the thermoplastic and thermosetting adhesive films are combined, the CTE value and bonding strength of the adhesive film are controlled by adjusting the thermoplastic and thermosetting ratio, and the adhesive film with better comprehensive performance is obtained. The flexibility and moisture absorption performance of the adhesive film are optimized by using BMI resin containing the siloxane structure; the linear expansion coefficient is further decreased by using nano silica filler, and the stripping strength of the adhesive film with metal is further improved by using high-temperature-resistant 4-(trimethoxysilyl)aniline as the adhesion promoter; polythioetherimide is prepared from bis-nitrophthalimide and alkali metal hydrosulfide, and thus the cost of the adhesive film is reduced.

Owner:成都正威新材料研发有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com