Method for preparing high-toughness thermoplastic fluorine-containing polyurethane elastomer

A polyurethane elastomer and thermoplastic technology, used in the field of polymer synthesis, can solve the problems of low molecular weight of the final polymer, low activity of fluorine-containing monomers, and low mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

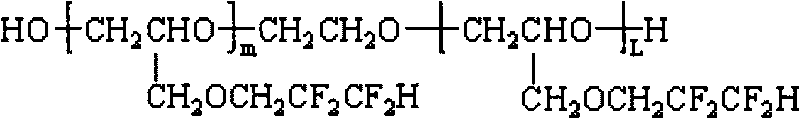

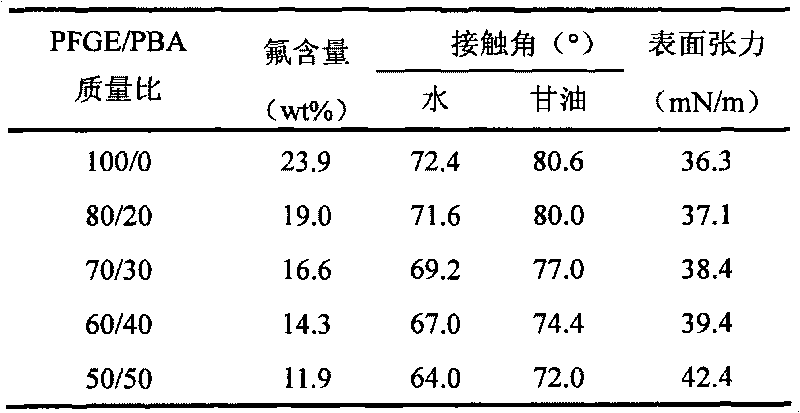

Method used

Image

Examples

Embodiment 1

[0028] Weigh 4 kg of hydroxyl-terminated polyethylene adipate (PEA, molecular weight 2000) and polyfluorinated glycidyl ether glycol (PFGE, molecular weight 2000) 4 kg in the reactor, with a mass ratio of 50 / 50, at 120 ° C Vacuum dehydration for 2 hours, lower the temperature to 80°C, add 1.726 kg of 4,4'-diphenylmethane diisocyanate (MDI), stir for 3 hours, raise the temperature to 140°C, add 1,4-butanediol (BDO) chain extender 0.274kg, stirred evenly, poured into a preheated container, and vacuum baked at 140°C for 20 hours to obtain the product.

Embodiment 2

[0030] Weigh 2.1 kg of hydroxyl-terminated polycaprolactone (PCL, molecular weight 2000) and 4.9 kg of polyfluorinated glycidyl ether glycol (PFGE, molecular weight 1000) in the reactor, with a mass ratio of 30 / 70, and vacuum dehydrate at 120 °C 2h, cool down to 70°C, add 2.498kg of 4,4'-diphenylmethane diisocyanate (MDI), stir for 3h, heat up to 140°C, add 0.502kg of 1,6-hexanediol (HG) chain extender , stirred evenly, poured into a preheated container, and vacuum baked at 140°C for 20 hours to obtain the product.

Embodiment 3

[0032] Weigh 6 kg of polytetramethylene ether glycol (PTHF, molecular weight 2000) in the reactor, vacuum dehydrate at 120 ° C for 2 h, cool down to 90 ° C, add 1.686 kg of toluene diisocyanate (TDI), stir for 3 h, and heat up to At 130°C, add 2.314 kg of hexafluorobisphenol A chain extender, stir evenly, pour it into a preheated container, and vacuum bake at 130°C for 20 hours to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com