Slushing compound lower-layer membrane monomer and composition as well as patterning method

A resist lower layer and composition technology, which is applied in the field of photolithography, can solve the problems of polluting the resist lower layer film and equipment, etc., and achieve the effect of excellent etching resistance and pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

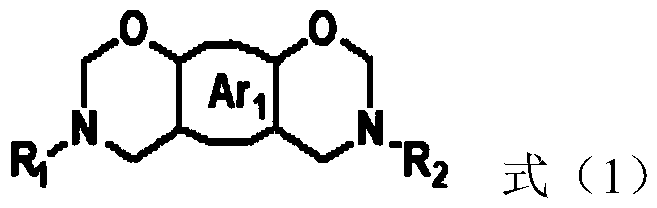

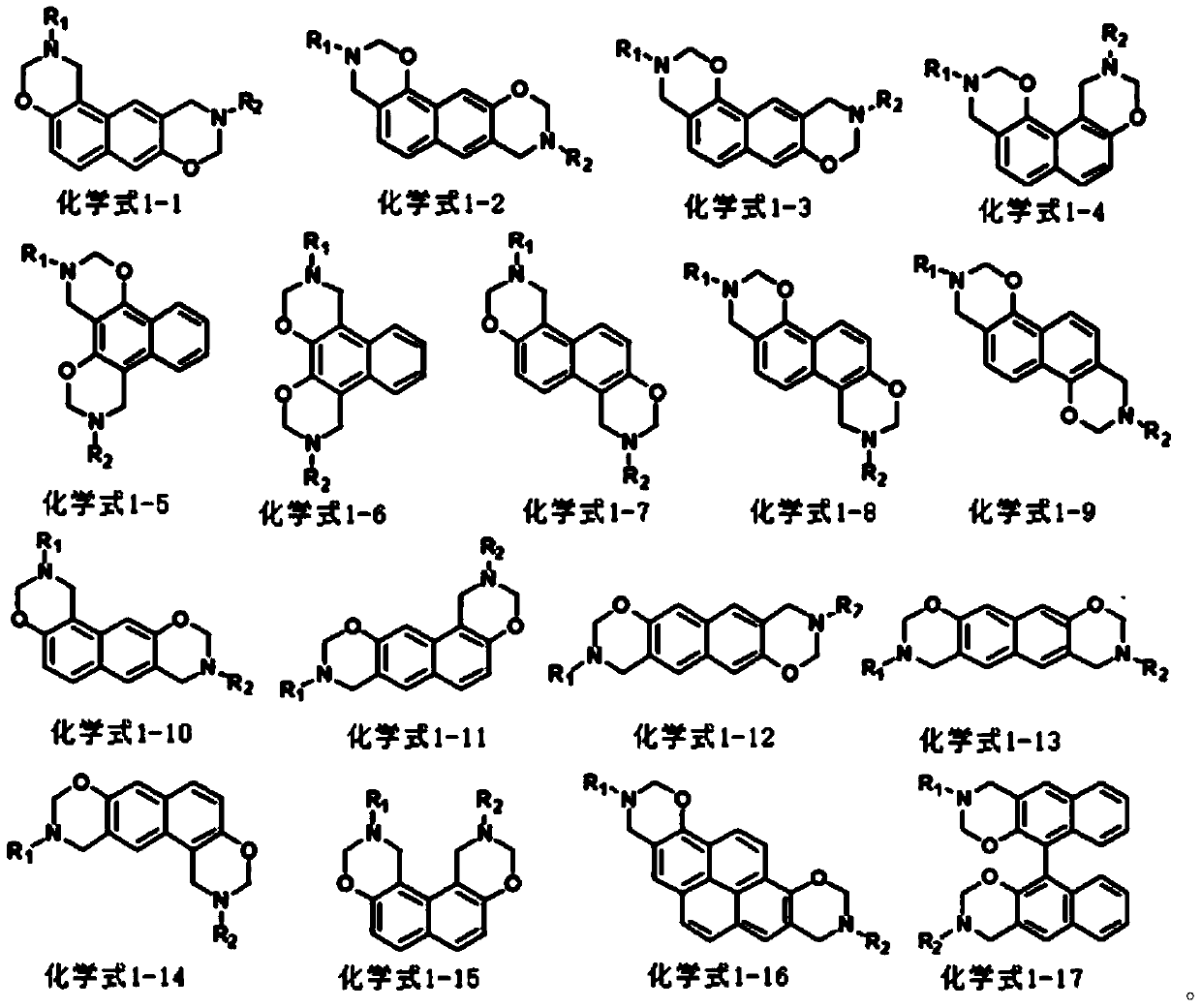

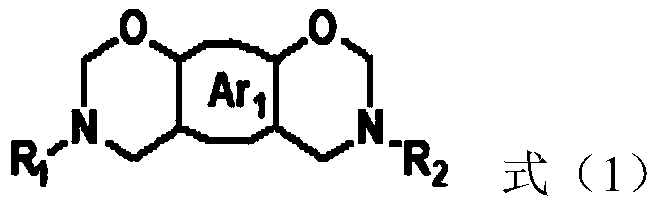

[0039] According to a preferred embodiment of the present invention, the resist underlayer film monomer is selected from at least one of the following chemical formulas 1-1 to 1-17:

[0040]

[0041] The resist underlayer film monomer provided by the present invention contains a benzoxazine structural unit. Under the action of heating, a ring-opening polymerization reaction such as reaction formula A will occur to form a nitrogen-containing network structure similar to phenolic resin. There is no release of small molecules during the process and the volume shrinkage rate is approximately zero, so there is no concern about polluting the underlying film of the resist and equipment.

[0042]

[0043]When the resist underlayer film monomer is used as the monomer component of the resist underlayer film composition, in the spin coating process of the resist underlayer film composition, due to the structure shown in formula (1) The monomer has low molecular weight and good solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com