Sensitive imaging composition, its preparation method and uses

An imaging composition and composition technology are applied in optomechanical equipment, removal of conductive materials by chemical/electrolytic methods, optics, etc., which can solve problems such as high cost, complicated circuit board manufacturing process, and environmental pollution, and achieve excellent The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

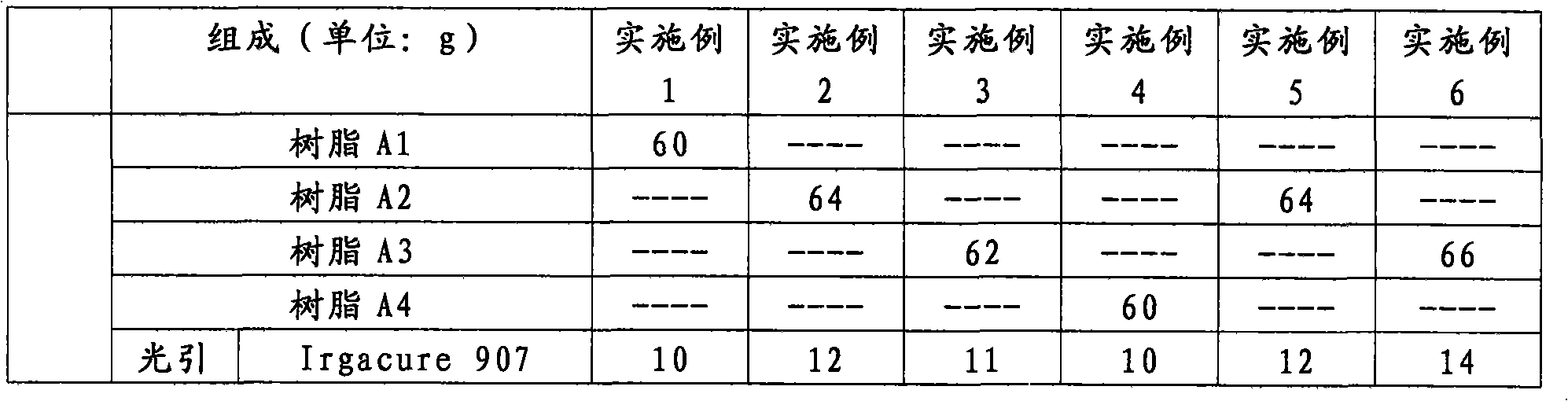

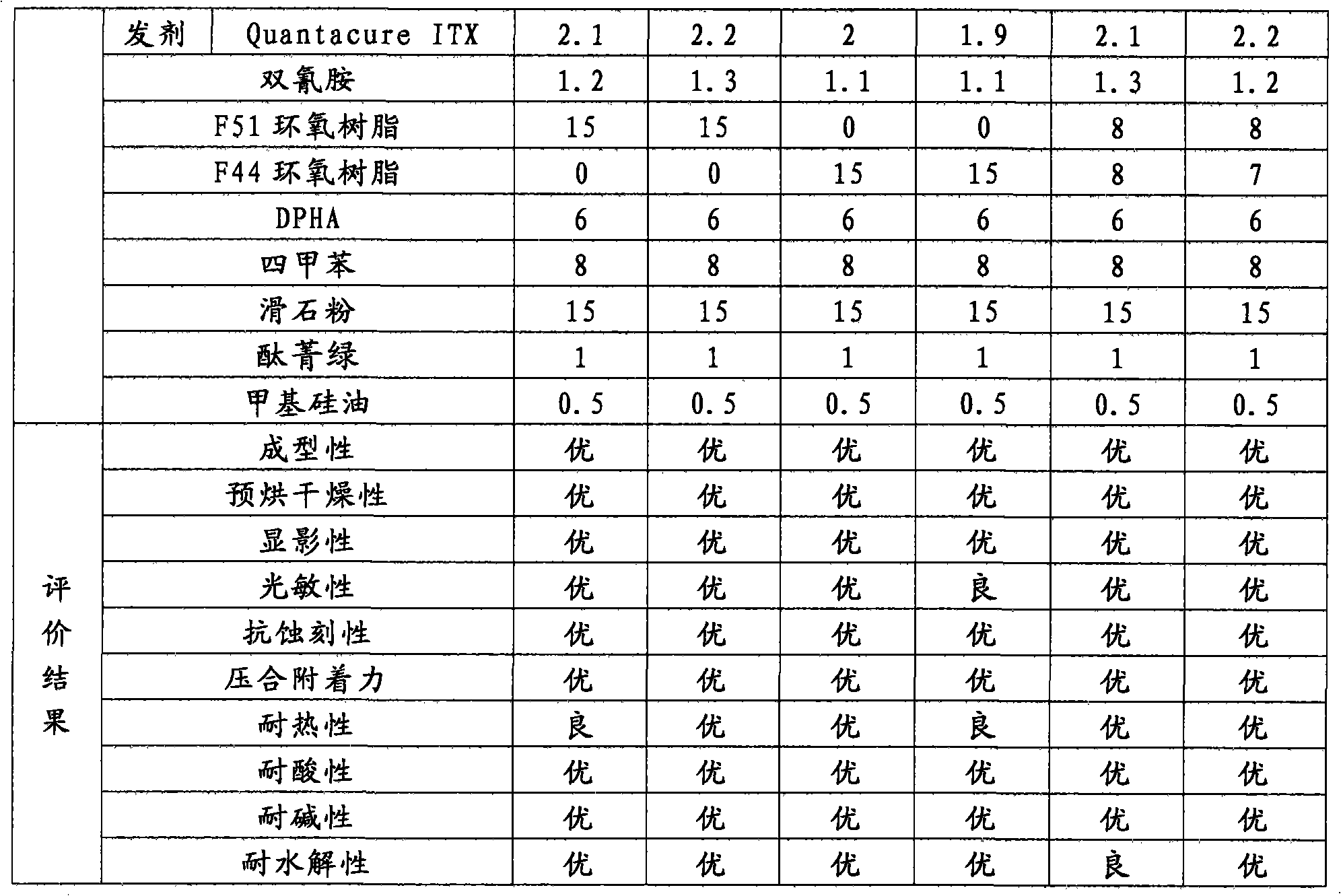

Examples

Embodiment

[0051] Synthesis Example 1

[0052] Add novolac epoxy resin CNE-202 (Taiwan Changchun Life Resin Factory, epoxy equivalent 210) 200g, propylene glycol methyl ether acetate (PMA) 250g, acrylic acid 69g in the reactor, heating and melting, add hydroquinone 0.5 g, 1.5g of triphenylphosphine, reacted at 110°C for 12 hours to obtain a product with an acid value of less than 5, then added 85g of tetrahydrophthalic anhydride, heated to 100°C, and reacted for 6 hours to obtain an acid value of 52mgKOH / g. Light yellow resin solution A1 with a solid content of 59%.

[0053] Synthesis Example 2

[0054] Add novolac epoxy resin CNE-202 (Taiwan Changchun Life Resin Factory, epoxy equivalent 210) 200g, propylene glycol methyl ether acetate (PMA) 250g, acrylic acid 69g in the reactor, heating and melting, add hydroquinone 0.5 g. Triphenylphosphine 1.5g, reacted at 110°C for 12 hours to obtain a product with an acid value of less than 5, then added 80g of tetrahydrophthalic anhydride, heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com