Etching and plating resist ink of hydrophobic printed circuit board

A printed circuit board, water-based technology, applied in the direction of ink, photosensitive materials for optical mechanical equipment, household appliances, etc., can solve the problems of large amount of water consumption, high consumption of water resources, etc., achieve water resource and electric energy saving, and easy board inspection , fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

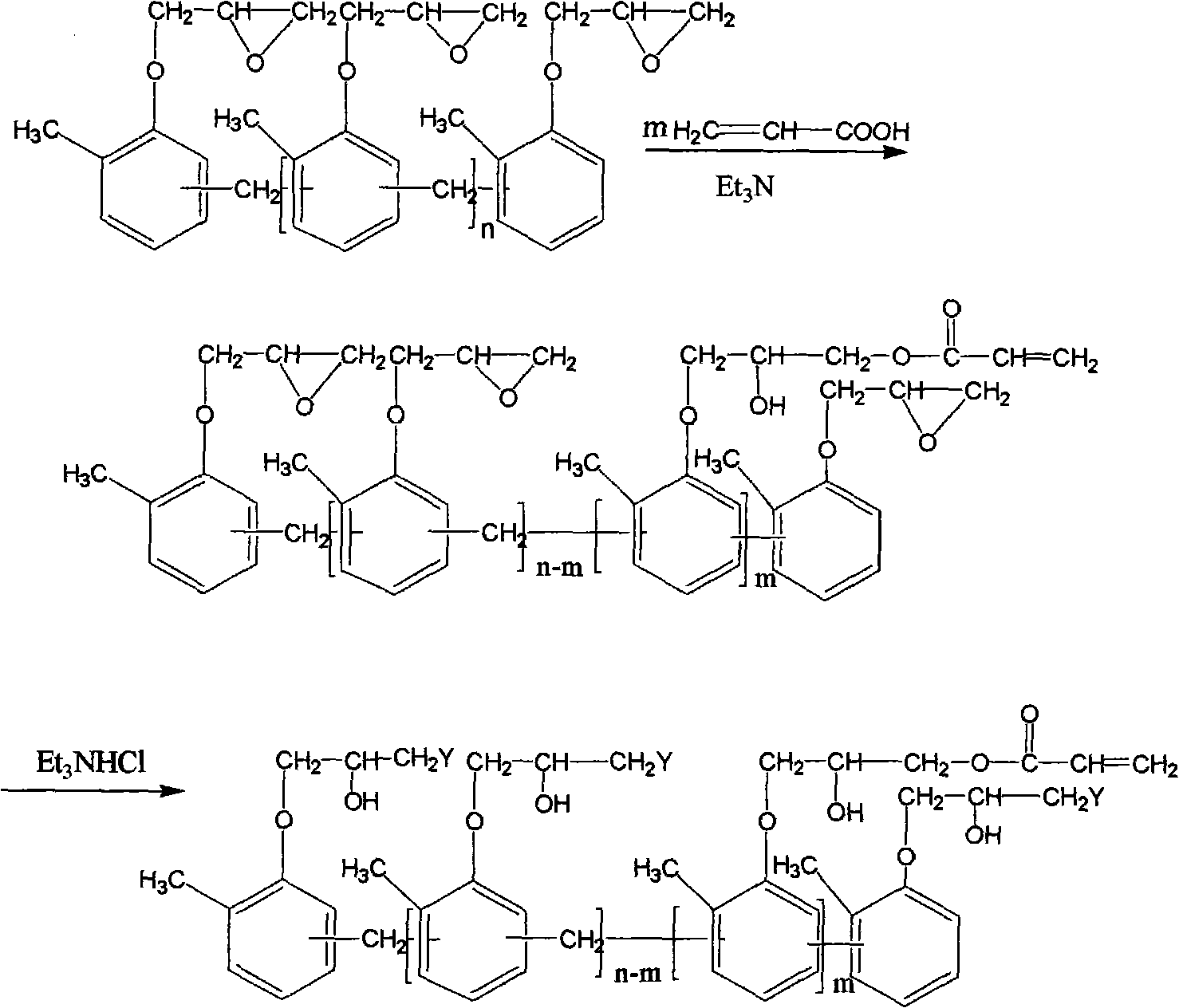

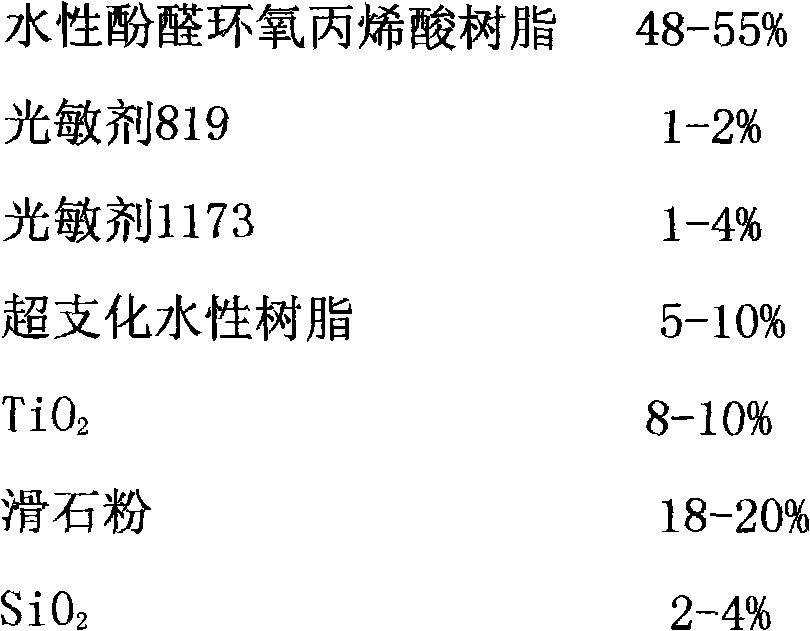

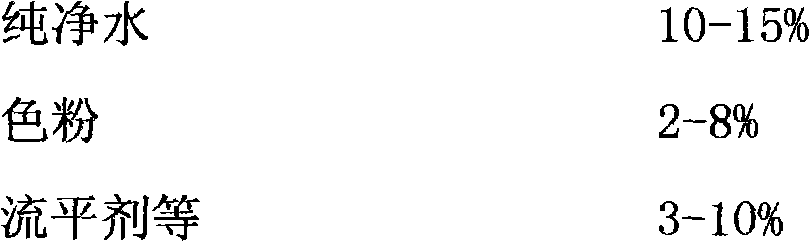

[0025] The application implementation of the product involved in the present invention is based on the current printed circuit board production equipment and process, that is, the product can be applied without adding, reducing and adjusting the equipment and changing the manufacturing process. The specific implementation process is further described. First, prepare the water-based reaction kettle, add o-cresol epoxy resin, acrylic acid and catalytic amount of triethylamine in a certain molar ratio, react at 90 to 110 ° C for 6 hours, and measure the acid value to the acid value. When it is zero, stop the reaction. Cool to room temperature (20~35℃), then add triethylamine hydrochloride dropwise, keep the temperature at 80~90℃ and react for 3 hours, until the solution is clear, the measured epoxy value is close to zero, stop the reaction, cool, That is, the synthesis of the water-based phenolic epoxy acrylic resin is completed.

[0026] Synthesis example of water-based phenoli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com