Batch-type slag tapping control system for boiler capable of preventing dust raising and control method

A control system and intermittent technology, applied in lighting and heating equipment, etc., can solve problems such as air leakage at the bottom of the furnace, waste of resources, and boiler efficiency reduction, and achieve the effect of reducing equipment failure rate, prolonging service life, and improving boiler efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

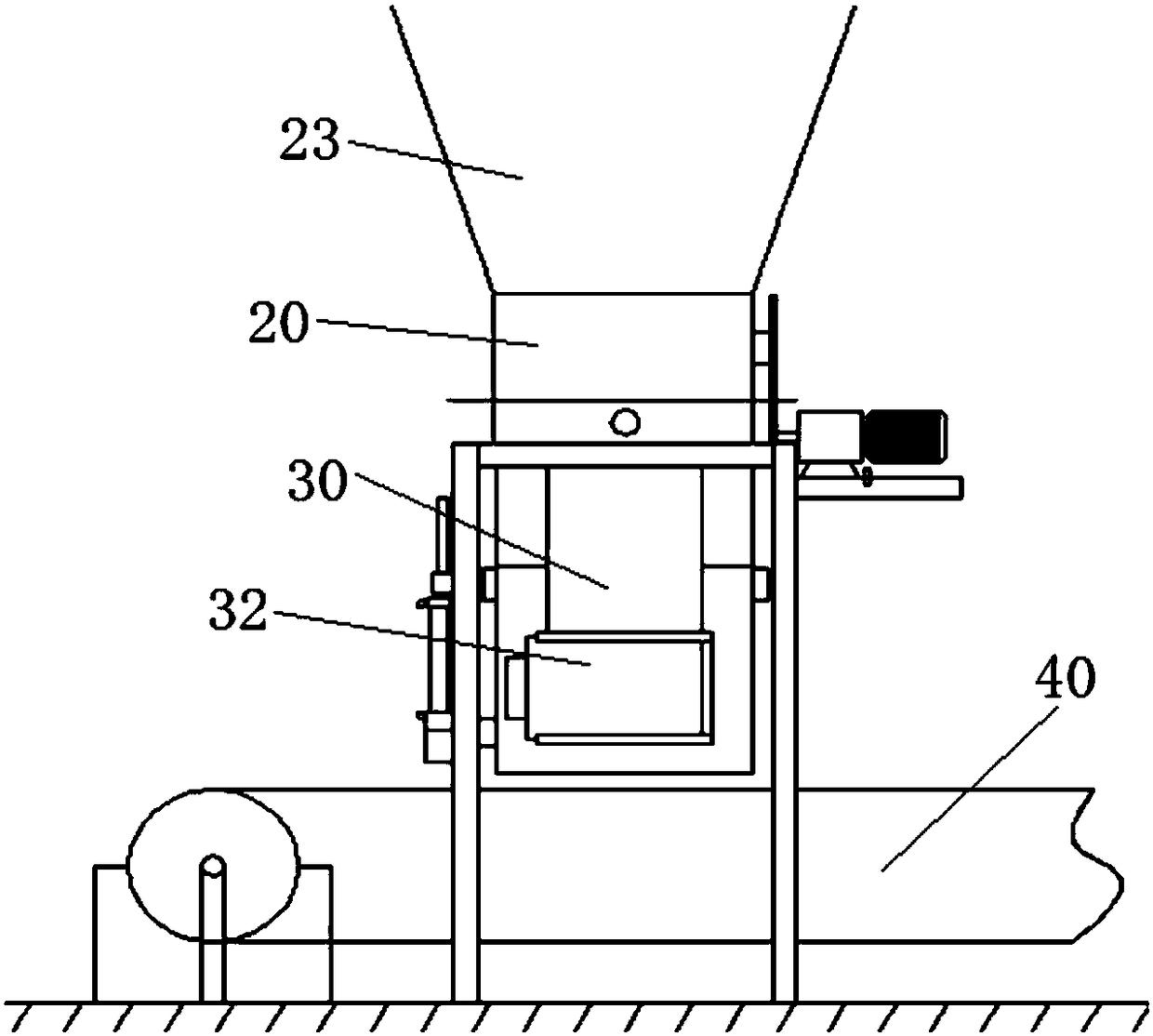

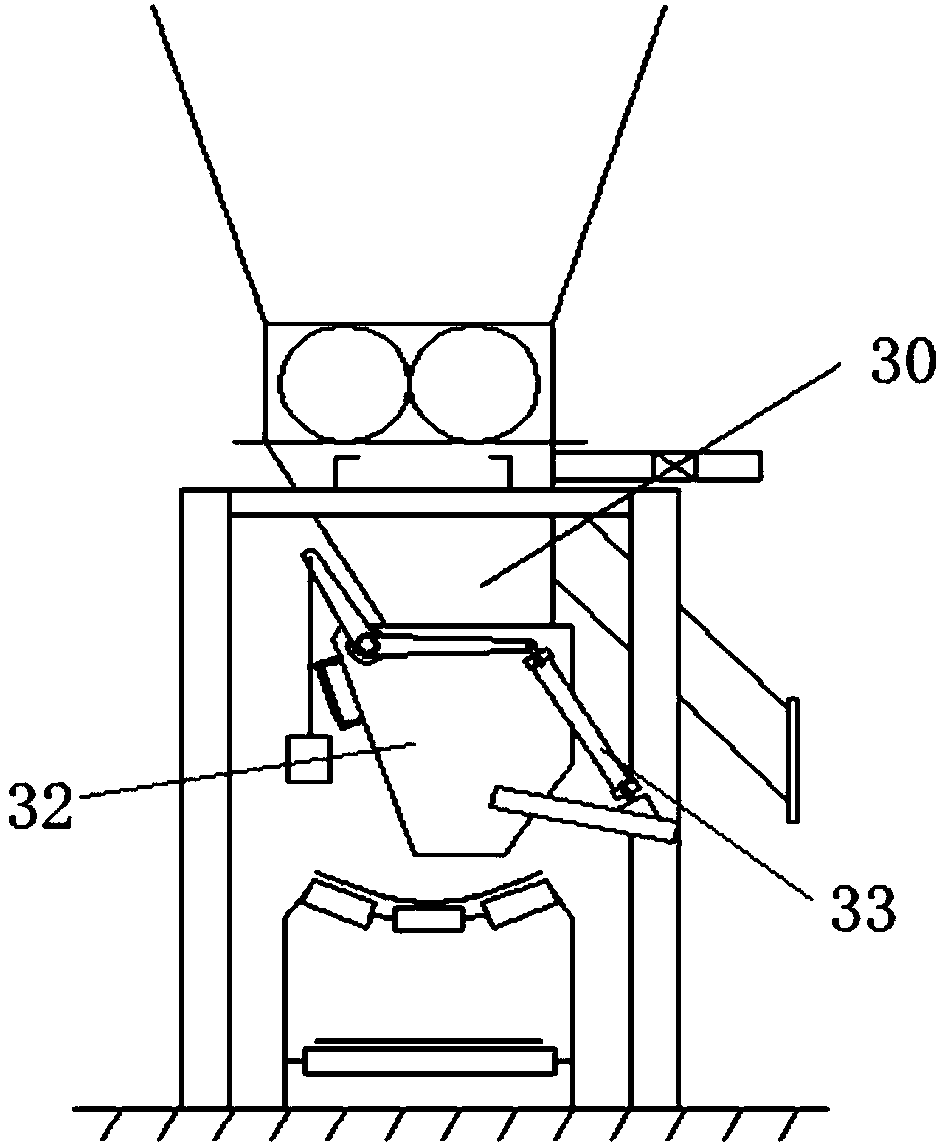

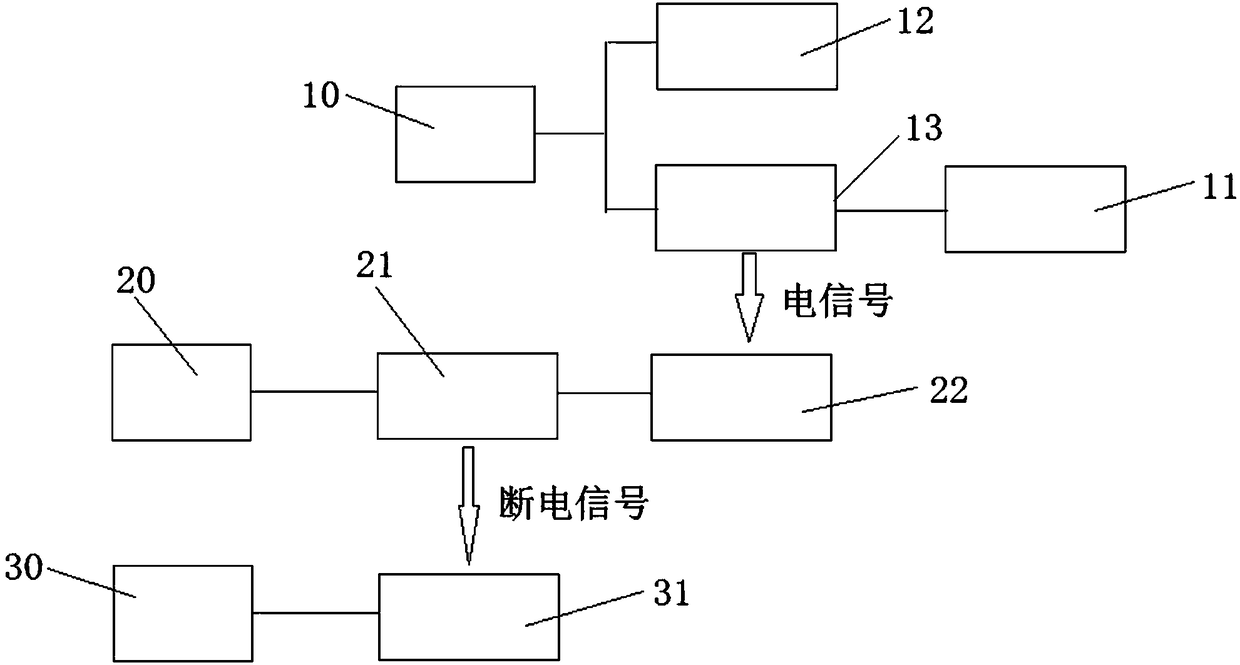

[0036] Such as figure 1 , figure 2 with image 3 As shown, an intermittent slagging control system for boilers capable of preventing dust, including a grate vibration switch 11, a slag crusher 20, an automatic switch 22 for interlocking the grate and slag crusher, a pneumatic buffer slag unloader 30, a Slag machine and pneumatic buffer slag unloader interlock automatic switch 31.

[0037] The fire grate vibration switch is connected with the fire grate vibration device 13, and is used to control the start and stop of the fire grate vibration device; the fire grate vibration device is used to control the vibration of the fire grate 10.

[0038] The grate vibration switch is preferably an analog switch, controlled by a computer, which is a prior art, and will not be described in detail herein.

[0039] When the grate vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com